Professional Documents

Culture Documents

6 - 2022 - Digital Assessment of The Accuracy of Implant Impression Technique

6 - 2022 - Digital Assessment of The Accuracy of Implant Impression Technique

Uploaded by

VõHoàngThủyTiênOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6 - 2022 - Digital Assessment of The Accuracy of Implant Impression Technique

6 - 2022 - Digital Assessment of The Accuracy of Implant Impression Technique

Uploaded by

VõHoàngThủyTiênCopyright:

Available Formats

Dohiem et al.

BMC Oral Health (2022) 22:486 BMC Oral Health

https://doi.org/10.1186/s12903-022-02505-7

RESEARCH Open Access

Digital assessment of the accuracy of implant

impression techniques in free end saddle

partially edentulous patients. A controlled

clinical trial

Mohamed M. Dohiem1, Medhat Sameh Abdelaziz5*, Mohamed Farouk Abdalla2,3 and Aya Mohamed Fawzy4

Abstract

Objectives This in vivo study aims to assess the accuracy of the digital intraoral implant impression technique, the

conventional closed-tray impression technique, and open-tray impression techniques in a standardized method of

data segmentation along with the best-fit algorithm to overcome the inconsistency of results of previous studies

regarding implant impression techniques.

Materials and methods Sixteen implants were placed in eight patients. Each patient has undergone four impression

techniques: direct intraoral scanning of the stock abutment, intraoral scanning using a scan body, conventional closed

tray impression technique, and the conventional open tray impression technique. The conventional impressions

were poured into stone casts with analogues and stock abutments and scanned using a desktop scanner. In intraoral

scanning of the scan body, computer-aided design software was used for the replacement of the scan body with

a custom-made abutment that is identical to the stock abutment, allowing comparison with the other impression

techniques. The deviation in implant position between the groups was measured using special 3D inspection and

metrology software. Statistical comparisons were carried out between the studied groups using a one-way analysis of

variance (ANOVA) test.

Results The total deviation between groups was compared to the reference group represented by the intraoral

scanning of the abutment. The total deviation was statistically significantly different (P = 0.000) among the different

studied groups. The mean deviation was recorded as 21.45 ± 3.3 μm, 40.04 ± 4.1 μm, and 47.79 ± 4.6 μm for the

intraoral scanning of the scan body, the conventional closed, and open tray, respectively.

Conclusion For implant impressions in partially edentulous patients, intraoral oral scanning using a scan body

significantly improves scanning and overall accuracy. Regarding conventional impressions, the closed-tray impression

techniques showed more accuracy than conventional open-tray impressions.

*Correspondence:

Medhat Sameh Abdelaziz

medhat.abdelaziz@fue.edu.eg; dr.medhatsameh@gmail.com

Full list of author information is available at the end of the article

© The Author(s) 2022. Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use,

sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and

the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this

article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included

in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will

need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The

Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available

in this article, unless otherwise stated in a credit line to the data.

Content courtesy of Springer Nature, terms of use apply. Rights reserved.

Dohiem et al. BMC Oral Health (2022) 22:486 Page 2 of 9

Clinical relevance Intraoral digital implant impression using scan body offers more accuracy than conventional

implant impression techniques for recording posterior implant position in free-end saddle partially edentulous

patients.

Keywords Accuracy, Implants, Digital impression, Partially edentulous, Scan body, Custom abutment

Introduction Conventional implant impressions can be classi-

The most important step in the fabrication of an implant- fied as closed or open-tray impression techniques. The

supported prosthesis with long-term success is to accu- open-tray impression technique utilizes a tray with an

rately transfer the 3D implant position from the patient’s open window for unscrewing the impression copings to

mouth to the master cast or prosthesis design software be removed as one unit with the impression, while the

[1, 2]. Inaccurate transfer of the implant position results closed-tray impression technique utilizes an impression

in a poor fit of the prosthesis with biomechanical com- transfer that remains on the implants while the tray is

plications such as bone loss and screw loosening [3, 4]. removed from the mouth. This transfer is later removed

Many factors affect the implant position on the master from the implant and repositioned into the impression [5,

cast, such as the impression technique, impression mate- 16]. The closed tray impression technique is indicated in

rial, tray type, and dental stone manipulation during cast limited inter-arch space situations or where inaccessible

pouring, which are unavoidable human and materials- posterior implants are present. The conventional impres-

related factors [3, 5]. sions could be digitized using desktop optical scanners

With the advancement of computer-aided design and [5].

computer-aided manufacturing (CAD-CAM) technol- To date, different articles have investigated the accu-

ogy, there are direct and indirect approaches for implant racy of digital implant impression techniques. Tomita et

prosthetics digital workflow [6]. The indirect work- al. [17] reported that the use of an intraoral digital scan

flow involves making a conventional implant impres- for a complete arch impression was more accurate than

sion which is then digitized by using an optical desktop a conventional impression, in agreement with Arcuri et

scanner, while the direct workflow creates a digital scan al. and Alikhasi et al. [18, 19]. On the other hand, Seo and

directly from the patient’s mouth using an intraoral scan- Kim [3] highlighted how the accuracy of digital implant

ner, and scan bodies [6, 7]. impression decreases in the case of full arch scanning

Direct digital implant impression has several advan- in comparison with conventional impression. How-

tages over conventional impression techniques, including ever, even if different in vitro studies showed promising

reduced chairside time and increased patient acceptance. results, in vivo studies are currently scarce. etc.

[8] It reduces the possible distortion of an impression It was reported that clinical data regarding digital and

during impression making and cast pouring [1]. It also conventional impressions are sparse, and there is a need

eliminates some procedures related to conventional for valid clinical data on the accuracy of implant impres-

impressions, such as tray selection, pouring of the cast, sions as most of the previous studies are in-vitro stud-

transportation to the laboratory, and cast storage, as all ies, particularly for partially edentulous arches [2, 4].

the data is stored virtually [8–10]. The intraoral scanning Therefore, the primary purpose of this in vivo study was

procedure is very suitable for patients having problems to compare the accuracy between the digital intraoral

with conventional impression techniques, such as gag implant impression technique, the conventional closed-

reflex or allergy to the impression material [11–13]. tray impression technique, and the open-tray impression

For making a direct digital implant impression, a scan technique. The null hypothesis was that conventional

body is screwed onto the implant, then an optical intra- closed-tray and open-tray implant impression techniques

oral scanner (IOS) is used to capture the scan body’s 3D have similar accuracy to digital intraoral scans using a

position [10, 14, 15]. A specific digital library compatible scan body for partially edentulous arches.

with each scan body and implant commercial brand is

used for virtually determining the exact implant position Materials and methods

using superimposition, and a best-fit algorithm [8, 14]. The present study followed the Declaration of Helsinki

The conventional implant transfers the implant posi- for the ethical principles of medical research involving

tion to the master cast using a rigid tray, an impression human subjects and was approved by the research eth-

coping, and elastomeric material [3]. Several conven- ics committee of Future University (FUE-REC (7)/2-

tional implant impression techniques were proposed for 2021). The study was registered on clinicaltrials.gov with

enhancing the accuracy of implant impressions, by splint- registration number NCT04908618. first registered on

ing impression copings and modifying tray design [3]. 1/6/2021. Eight male patients with free-end saddle par-

tially edentulous mandibles, with ages ranging from 30

Content courtesy of Springer Nature, terms of use apply. Rights reserved.

Dohiem et al. BMC Oral Health (2022) 22:486 Page 3 of 9

to 50, were selected from the outpatient clinic of the

Department of Prosthodontics at Future University

Faculty of Oral and Dental Medicine (FUE). The inclu-

sion criteria were patients with missing first and second

mandibular molars and a full set of maxillary dentitions

with appropriate inter-arch space. All patients have ade-

quate bone width and length for implant placement. All

patients were free from any debilitating diseases such as

bone diseases, diabetes mellitus, or any other diseases

that affect dental implant osteointegration.

Implant placement

A prosthetically driven implant placement was imple-

mented using a computer-guided flapless surgical pro-

tocol. Each patient was scanned using a Cone-Beam

Computed Tomography x-ray machine (PaX-i3D Green;

VATECH) to obtain a Digital Imaging and Communica-

tion in Medicine (DICOM) file. Intraoral scanning of

the working arch, the opposing arch, and bite registra-

tion was performed using (MEDIT i700; MEDIT Corp)

to create a standard tessellation language (STL) file of the

patient arches.

After the virtual setting of missing teeth using (Exo-

cad, Dental CAD software), and superimposition of the

patient’s DICOM & STL files using (Real guide 5.0 soft-

ware 3DIEMME), the surgical guides were created.

Two dental implants, 4 mm in diameter and 10 mm in

length (Internal hex, conical connection tapered dental

implant, IS-II active, Neo Biotech.) were placed in the

posterior area of the first and second mandibular molars

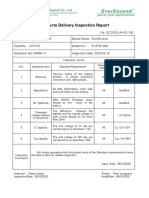

Fig. 1 Conventional implant impression techniques. (a) closed tray im-

in each patient according to prosthetically driven implant

pression technique. (b) open tray impression technique

placement using the surgical guide with copious irriga-

tion. After 6 months, loading of the healing abutments

was carried out over the implants for 2 weeks. All the a low-expansion type IV dental stone (Zhermack Elite)

surgical procedures for implant placement were per- with an appropriate water/powder ratio according to the

formed by one experienced implantologist. manufacturer’s instructions (Fig. 1a).

Impression techniques Open-tray impression technique

Each patient has undergone four impression techniques, Open tray impression copings were screwed over the

including: implants with a tightening torque of 20 Ncm as recom-

mended by the manufacturer. A bitewing radiograph of

Closed tray impression technique the implant is used to confirm that the impression cop-

The healing abutments were removed and the closed tray ings are correctly seated. The impression copings were

short impression copings were screwed over the implants splinted using dental floss and Dura-lay.

with a tightening torque of 20 Ncm as recommended by A custom hard tray with open holes over the copings

the manufacturer. A bitewing radiograph of the implant was used to make a one-step impression using Putty

is used to eliminate the possibility of a gap between the and a light body rubber base after applying tray adhe-

coping and the implant. sive 10 min before the impression making. After setting

A one-step impression technique using hard, stock tray, the impression material, the impression copings were

and putty and light body rubber base (polyvinyl silox- unscrewed and the tray was removed from the mouth.

ane, Zhermack Elite HD+) was made. The implant ana- The implant analogues were screwed into the impres-

logues were screwed into the impression coping, then sion coping, and the impression was poured into a low-

the impression coping-analog assembly was positioned expansion type IV dental stone (Fig. 1b).

into the impression. The impression was poured using

Content courtesy of Springer Nature, terms of use apply. Rights reserved.

Dohiem et al. BMC Oral Health (2022) 22:486 Page 4 of 9

of the scan bodies and surrounding structures on the

software.

A dental computer-aided design (CAD) software (Exo-

cad Dental CAD) was used to fabricate the digital model.

Using the best-fit algorithm and a scan body from the

digital software library, the exact implant position was

determined [20–22], and custom abutments identical

to the abutments used in all the other impression tech-

niques were loaded onto the implant (Fig. 2a–b).

For all four studied groups, the scanning protocol was

performed in a continuous pattern, starting from the

posterior teeth on one side, passing through the anterior

teeth, and ending at the stock abutments/scan bodies on

the other side. The scan was done over the occlusal sur-

face first, followed by the lingual surface, and ended with

the labial and vestibular sides of the teeth. For any miss-

ing data, a smooth vertical rotation of the scanner head

was made over the defective part of the scanning [23, 24].

The scans were done by one experienced operator

in around 5 min for each scan, and then the scans were

exported as an STL file.

The digital comparison of accuracy between implant

impression techniques

Using special 3D inspection and metrology soft-

ware (Geomagic Control X; 3D systems), the intraoral

scanning of the stock abutments tightened over the

implants was set as a reference model for all upcoming

comparisons.

3D segmentation of the model was carried out to split

Fig. 2 Intraoral scanning of scan body. (a) implant position determination

the model into 2 parts: teeth and abutments. The teeth

using the superimposition of the scan body from the digital library. (b)

digital designing of custom abutments over the implants part is used for superimposition between the models

using the best-fit algorithm, while the abutments part

To digitize the conventional impressions I and II, the is used for 3D comparison of accuracy and deviation in

stock abutments were screwed with a tightening torque micrometers (Fig. 3a–b).

of 20 Ncm as recommended by the manufacturer on the The 3D comparison was carried out between the stud-

analogs, followed by digital scanning using an intraoral ied groups, and the root mean square (RMS) values

scanner (MEDIT i700; MEDIT Corp) after being pow- representing the total deviation were collected for each

dered with a homogenous layer of spray (3 M high-reso- group (Fig. 4a–c) (video 1). The RMS value represents

lution scanning spray). the deviation between the data by squaring the distance

between the compared data points, divided by the num-

Intraoral scanning of stock abutments ber of data points, which is automatically calculated by

Stock abutments identical to those used in conventional the software [10, 25].

impressions were torqued in place intraorally at 20 Ncm, Horizontal split sections are made in all the models at

followed by the application of a homogenous layer of the same Z plane for measuring the distance between the

optical scanning powder, and scanned with the MEDIT abutments of the superimposed models using the desk

I700 intraoral scanner, producing a digital representation contact method (software tool) (Fig. 5a–c) (video 1).

of the abutments directly on the software.

Statistical methodology

Intraoral scanning using scan bodies Data were collected and entered into the computer using

Nonmetallic, cylindrical with flattened side scan bodies SPSS (Statistical Package for Social Science) statistical

of 17.1 mm in length (Neo Biotech IS scan body) were analysis program (ver. 25). Kolmogorov-Smirnov test of

screwed onto the implants intraorally with a tightening normality revealed no significance in the distribution of

torque of 20 Ncm, producing a digital representation the variables, so the parametric statistics were adopted.

Content courtesy of Springer Nature, terms of use apply. Rights reserved.

Dohiem et al. BMC Oral Health (2022) 22:486 Page 5 of 9

Fig. 3 Segmentation of the scanned model into teeth and abutments. (a) Fig. 4 3D deviation of different implant impression techniques. (a) 3D de-

the scanned model is composed of multiple segments. (b) segmenting viation of intraoral scanning with scan body. (b) 3D deviation of closed tray

the model into teeth to be used for best-fit superimposition and abut- impression technique. (c) 3D deviation of open tray impression technique

ments used for 3D comparison

deviation between each of the studied groups. Intraoral

The mean and standard deviation were used to describe scanning of the scan body group showed the best accu-

the data. Comparisons were carried out between more racy when compared to the control group, while the con-

than two independent, normally distributed subgroups ventional open tray impression group showed the lowest

using a one-way Analysis of Variance (ANOVA) test. level of accuracy. Tables 1 and 2.

Post-hoc multiple comparisons were done using the Bon- The distances measured between the superimposed

ferroni method. An alpha level was set at 5% with a sig- abutments at the horizontal cross-section revealed sta-

nificance level of 95%. tistically significant (p = 0.006) differences between the

groups investigated. The post-hoc comparison showed

Results a statistically insignificant difference between intraoral

The trueness of the different implant impression tech- scanning of the scan body and the closed tray impres-

niques was shown by the mean and standard deviation sion technique. (p = 0.629). The conventional open tray

of the root mean square values. Intraoral scanning of the impression group showed the lowest level of accuracy

scan body and conventional closed and open tray impres- at the horizontal cross-section measurements recording

sions were compared to intraoral scanning of the stock (267.5 ± 21.213 μm) (Tables 1 and 2).

abutment. The mean values of total deviation for the

studied groups were 21.45 ± 3.3 μm, 40.04 ± 4.1 μm, and Discussion

47.79 ± 4.6 μm respectively (Fig. 6). Passive fit is a very important factor for the success of

The total deviation was statistically significantly dif- any implant-supported prosthesis. For this reason, an

ferent among the three studied groups (p = 0.000). The accurate impression free from distortion is very criti-

post-hoc comparison showed a statistically significant cal [8, 26]. In a systematic review, Ting-Shu S and Jian

Content courtesy of Springer Nature, terms of use apply. Rights reserved.

Dohiem et al. BMC Oral Health (2022) 22:486 Page 6 of 9

abutments’ positional relationship with the elimination

of the errors related to different impression materials

and techniques [28, 29]. In a study by Natsubori R, it was

concluded that Scan powder improves the accuracy in

stock abutment scanning, especially in cases of multiple

implants [29]. For this reason, the intraoral scanning of

implant abutments was set as a reference for all the com-

parisons in the present study.

IOS scanning of movable tissues such as the tongue

and frenum leads to inaccurate results. On the contrary,

a better scan is achieved of soft tissue with little or no

movement, such as the attached gingiva [11]. For this

reason, movable tissues such as the frenum cannot be

used as a landmark for superimposition and compari-

son between different impression techniques; otherwise,

false results in evaluating accuracy will occur [11]. The

segmentation method used in this study along with the

best-fit algorithm guarantee standardization of research

results by neglecting any irrelevant data in the compari-

son, such as soft tissue, which may affect the results of

the previous studies.

Accuracy is defined by two factors: trueness and pre-

cision. Trueness refers to how close the test scan data is

to the reference scan [8, 10, 30]. The best fit alignment

method is used to evaluate the accuracy of different digi-

tal impressions by scanning either closed or open tray

stone cast using a desktop scanner to fabricate a digital

model, which was the best fit aligned over the digital

models obtained from scanning intraorally using IOS. It

was reported that the best-fit alignment method is suit-

Fig. 5 Horizontal split sections in the compared abutments. (a, b) Hori-

able for the evaluation of accuracy in one quadrant [3,

zontal split sections are made in all the models at the same Z plane. (c)

measuring the distance between the abutments of the superimposed 31, 32]. This algorithm minimizes the global distances

models using the disk contact method between the test and reference data, and the deviation

between the data is measured using the root-mean-

S concluded that digital scans are clinically satisfactory square error [6]. The further the test data was from the

when compared to conventional impression techniques reference, the greater the root mean square and the devi-

in the fabrication of tooth or implant-supported fixed ation [30].

partial dentures [27]. Introducing intraoral optical scan- In our study, a one-step polyvinyl siloxane impression

ners (IOSs) into implant prosthodontics has many ben- technique using putty and light rubber base was used for

efits, such as the elimination of tray selection, impression recording closed-tray and open-tray impression tech-

disinfection, and delivery to the dental laboratory. It niques. Polyvinyl Siloxane impression material is more

also decreases impression distortion during making or accurate compared with polyether impressions in record-

on removal from a patient’s mouth, as well as improves ing implants in a partially edentulous arch [33].

patient comfort and acceptance. Moreover, digital scans In a study by Ajioka H et al., it was reported that an

can be stored electronically as digital information [15, optical impression has a smaller error concerning the

27]. angulation between implants compared to a conventional

Kim JE et al. evaluated the accuracy of intraoral scan- impression [13]. The results of our study emphasize these

ning of stock abutments and reported that intraoral findings as the least mean deviations were in the intraoral

scanning of stock abutments is an accurate method to scanning of the scan body group (21.45 ± 3.3) µm com-

fabricate implant-supported prostheses as the stock pared with the conventional open tray and closed tray

abutment doesn’t require repeated removal as most groups.

impression copings and scan body which could affect The findings of the present study showed that the

the impression accuracy [25]. It was also reported that closed tray impression technique was more accurate

the intraoral scanners can precisely record the stock compared to the open tray impression technique, which

Content courtesy of Springer Nature, terms of use apply. Rights reserved.

Dohiem et al. BMC Oral Health (2022) 22:486 Page 7 of 9

Fig. 6 Bar chart comparing the accuracy of the intraoral scanner with scan body Vs. conventional closed and open tray implant impression techniques

Table 1 One-way ANOVA test comparisons between the three Table 2 Post hoc multiple comparisons between the three

different implant impression techniques different implant impression techniques

Different Digital im- Conven- Conventional P Different impression techniques P value P value

impression pression with tional open-tray value Total Distance between

techniques intraoral scan closed-tray impression deviation abutments in the

body impression (R.M.S.) horizontal plane

Mean ± SD 21.45 ± 3.3 40.04 ± 4.1 47.79 ± 4.6 0.000* Digital impression Convention- 0.000* 0.629 NS

Total deviation with intraoral scan al closed-tray

in micro-meter body impression

represented by Digital impression Convention- 0.000* 0.006*

Root Mean with intraoral scan al open-tray

Square (RMS) body impression

Mean ± SD 225 ± 0.27.774 236 ± 23.261 267.5 ± 21.213 0.006* Conventional closed- Convention- 0.003* 0.044*

The distance tray impression al open-tray

in micro-meter impression

between the *: Statistically significant (p < 0.05)

abutments at NS: Statistically not significant (p>0.05)

the horizontal

plane

*: Statistically significant (p < 0.05)

The less deviation in the closed tray impression tech-

NS: Statistically not significant (p>0.05)

nique coincides with Parameshwari G’s findings, which

carried out an in-vitro study comparing different implant

can be attributed to its simplicity, and the closed tray impression techniques for partially edentulous patients

impression copings ideal for single and multiple implants [33]. It also coincides with Balouch et al., who carried

impression in patients with inadequate mouth open- out an in-vitro study comparing the accuracy between

ing for access to the screws retaining the pick- up type the closed tray and open tray impression techniques

impression copings with the impression in place, also in in 15° angled implants and concluded that the closed

patients with limited inter arch space, the tendency to tray is more accurate than the open tray technique [35].

gag, and implants placed in the inaccessible posterior Another in-vitro study by Sabouhi M et al. examined the

region of the mouth [34]. The greater accuracy of the effect of impression techniques and impression coping

closed tray impression technique could also be due to the on the accuracy of impressions and reported that closed-

fact that the path of removal of the impression along with tray impression coping provides a more accurate impres-

the impression copings in the open tray impression tech- sion compared to the other coping designs [26].

nique which cause deformation of the impression mate- On the contrary, after an in-vitro study, Izadi A et

rial which will not be fully recovered [14]. al. reported that the open tray impression technique

Content courtesy of Springer Nature, terms of use apply. Rights reserved.

Dohiem et al. BMC Oral Health (2022) 22:486 Page 8 of 9

Authors contributions

provides more accurate impressions compared to other 1. M. M. Dohiem (article approval, operator in all the practical work,

impression techniques [36]. In an in-vitro study com- manuscript Writing-concept).

paring the accuracy of different impression techniques 2. M. S. Abd El Aziz (corresponding Author, operator in all the practical work,

writing of the manuscript-design- interpretation -statistics-data collection-

in partially edentulous patients by Marghalani A et al., it software- article approval).

was reported that there was no difference between open- 3. M. Farouk: concept- design-interpretation.

tray and closed-tray techniques [15]. Concerning the 4. A. M. Fawzy: manuscript Writing- interpretation- article approval)

inconsistent results on the accuracy of either the open Funding

tray or closed tray method, it appears that the measure- This research did not receive any specific grant from funding agencies in the

ment method and superimposition have a great effect on public, commercial, or not-for-profit sectors.

Open access funding provided by The Science, Technology & Innovation

the result [8], there for the segmentation method used in Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank

the present study can overcome this problem. (EKB).

Even though the total deviation between the three

Data availability

implant impression techniques was statistically signifi- All data generated or analyzed during the current study are included in this

cant, these deviations were clinically insignificant as they published article and its additional files.

were below the reported deviation for clinically accept-

able fit (below 200 μm) [2, 15, 37, 38]. Declarations

The limitations of this study include in vivo compari-

Ethics approval and consent to participants

son of different implant impression techniques in full The present study followed the Declaration of Helsinki for the ethical

arch cases and completely edentulous patients, which can principles of medical research involving human subjects and was approved by

represent a challenge in the intraoral scanning impres- the research ethics committee of Future University (FUE-REC (7)/2-2021).

sion technique. The comparison between implant level Informed consent

and abutment level impression techniques is also consid- Informed consent was obtained from all subjects and/or their legal guardians.

ered a limitation of this study. This study compares dif-

Consent for publication

ferent implant impression techniques in free-end saddle Not Applicable.

partially edentulous cases. The different implant impres-

sion techniques in bonded posterior or anterior partially Conflict of interest

The authors declare that they have no conflict of interest.

edentulous patients are also considered a limitation

of this study. It is recommended to utilize the adopted Clinical trial registration

methodology in this study in a large sample size, compar- study was registered on clinicaltrials.gov with registration number

NCT04908618.

ing the mandibular and maxillary partially edentulous

patients’ different implant impression techniques for dif- Author details

1

ferent implant placement positions. Faculty of Oral and Dental Medicine, Zagazig University, El-Zagazig

University, Sharqia, Egypt

2

Faculty of Oral and Dental Medicine, Prosthodontics Department, Cairo

Conclusion University, Cairo, Egypt

3

1. Intraoral oral scanning and scan body significantly Faculty of Dentistry, Galala University, Suez, Egypt

4

Faculty of Oral and Dental Medicine, Future University in Egypt, Cairo,

improve implant impression accuracy. Egypt

2. Closed-tray implant impression technique is more 5

Faculty of Oral and Dental Medicine, Future University in Egypt, Fifth

accurate than the open-tray impression technique in Settlement, End of 90 street, New Cairo, Cairo, Egypt

partially edentulous patients.

Received: 3 June 2022 / Accepted: 11 October 2022

3. The introduced method in this research of data

segmentation along with the best-fit algorithm

has the ability to standardize the measurements

regarding implant impression accuracy. References

1. Kim KR, Seo K, young, Kim S. Conventional open-tray impression versus

Supplementary information intraoral digital scan for implant-level complete-arch impression. J Prosthet

The online version contains supplementary material available at https://doi. Dent. 2019;122:543–9.

org/10.1186/s12903-022-02505-7. 2. Alsharbaty MHM, Alikhasi M, Zarrati S, Shamshiri AR. A Clinical Comparative

Study of 3-Dimensional Accuracy between Digital and Conventional Implant

Impression Techniques. J Prosthodont. 2019;28:e902–8.

Supplementary Material 1 3. Seo K, Kim S. A new method to evaluate trueness and precision of digital

Supplementary Material 2 and conventional impression techniques for complete dental arch. Appl Sci.

2021;11:1–13.

4. Schmidt A, Rein PE, Wöstmann B, Schlenz MA. A comparative clinical study

Acknowledgements on the transfer accuracy of conventional and digital implant impres-

The authors thank professor Hussien El Charkawi (head of the prosthodontics sions using a new reference key-based method. Clin Oral Implants Res.

department) for his valuable advice throughout conducting this research. 2021;32:460–9.

Content courtesy of Springer Nature, terms of use apply. Rights reserved.

Dohiem et al. BMC Oral Health (2022) 22:486 Page 9 of 9

5. Moura RV, Kojima AN, Saraceni CHC, Bassolli L, Balducci I, Özcan M, et al. 24. Dohiem MM, Emam NS, Abdallah MF, Abdelaziz MS. Accuracy of digital

Evaluation of the Accuracy of Conventional and Digital Impression Tech- auricular impression using intraoral scanner versus conventional impression

niques for Implant Restorations. J Prosthodont. 2019;28:e530–5. technique for ear rehabilitation: A controlled clinical trial. J Plast Reconstr

6. Mizumoto RM, Yilmaz B. Intraoral scan bodies in implant dentistry: A system- Aesthetic Surg. 2022. https://doi.org/10.1016/j.bjps.2022.08.002.

atic review. J Prosthet Dent. 2018;120:343–52. 25. Kim JE, Hong YS, Kang YJ, Kim JH, Shim JS. Accuracy of Scanned Stock Abut-

7. Lee H, Son K, Lee WS, Lee KB. Displacement of Customized Abutments ments Using Different Intraoral Scanners: An In Vitro Study. J Prosthodont.

Designed on a Working Cast and in the Oral Cavity: A Comparative In Vivo 2019;28:797–803.

Study. J Prosthodont. 2020;29:12–8. 26. Sabouhi M, Bajoghli F, Dakhilalian M, Beygi A, Abolhasani M. Effects of impres-

8. Huang R, Liu Y, Huang B, Zhang C, Chen Z, Li Z. Improved scanning accuracy sion coping design, impression technique, and dental undercuts on the

with newly designed scan bodies: An in vitro study comparing digital versus accuracy of implant impressions assessed by 3-dimensional optical scanning:

conventional impression techniques for complete-arch implant rehabilita- An in vitro study. Implant Dent. 2016;25:238–46.

tion. Clin Oral Implants Res. 2020;31:625–33. 27. Ting-shu S, Jian S. Intraoral Digital Impression Technique: A Review. J Prostho-

9. Li J, Chen Z, Wang M, Wang HL, Yu H. Dynamic changes of peri-implant dont. 2015;24:313–21.

soft tissue after interim restoration removal during a digital intraoral scan. J 28. Fukazawa S, Odaira C, Kondo H. Investigation of accuracy and reproducibility

Prosthet Dent. 2019;122:288–94. of abutment position by intraoral scanners. J Prosthodont Res. 2017;61:450–9.

10. Tohme H, Lawand G, Chmielewska M, Makhzoume J. Comparison between 29. Natsubori R, Fukazawa S, Chiba T, Tanabe N, Kihara H, Kondo H. In vitro com-

stereophotogrammetric, digital, and conventional impression techniques parative analysis of scanning accuracy of intraoral and laboratory scanners

in implant-supported fixed complete arch prostheses: An in vitro study. J in measuring the distance between multiple implants. Int J Implant Dent.

Prosthet Dent. 2021;:1–9. 2022;8:1–9.

11. Kim JE, Amelya A, Shin Y, Shim JS. Accuracy of intraoral digital impressions 30. Kim RJY, Benic GI, Park JM. Trueness of ten intraoral scanners in determining

using an artificial landmark. J Prosthet Dent. 2017;117:755–61. the positions of simulated implant scan bodies. Sci Rep. 2021;11:1–9.

12. Cho WT, Bae E, Bin, Ahn JJ, Huh JB. Cordless digital workflow for scanning 31. Schmidt A, Wöstmann B, Amelie M. Accuracy of digital implant impressions

implant-supported prostheses at the abutment level: A dental technique. J in clinical studies: A systematic review. Clin Oral Impl Res. 2022;00 May:1–13.

Prosthet Dent. 2020;124:428–30. 32. Albanchez-González MI, Brinkmann JCB, Peláez-Rico J, López-Suárez C,

13. Ajioka H, Kihara H, Odaira C, Kobayashi T, Kondo H. Examination of the posi- Rodríguez-Alonso V, Suárez-García MJ. Accuracy of Digital Dental Implants

tion accuracy of implant abutments reproduced by intra-oral optical impres- Impression Taking with Intraoral Scanners Compared with Conventional

sion. PLoS One. 2016;11:1–12. Impression Techniques: A Systematic Review of In Vitro Studies. Int J Environ

14. Abduo J, Palamara JEA. Accuracy of digital impressions versus conventional Res Public Health. 2022;19.

impressions for 2 implants: an in vitro study evaluating the effect of implant 33. Parameshwari G, Chittaranjan B, Sudhir Chary N, Anulekha Avinash CK, Taruna

angulation. Int J Implant Dent. 2021;7:1–13. M, Ramureddy M. Evaluation of accuracy of various impression techniques

15. Marghalani A, Weber HP, Finkelman M, Kudara Y, El Rafie K, Papaspyridakos and impression materials in recording multiple implants placed unilater-

P. Digital versus conventional implant impressions for partially edentulous ally in a partially edentulous mandible- An in vitro study. J Clin Exp Dent.

arches: An evaluation of accuracy. J Prosthet Dent. 2018;119:574–9. 2018;10:e388–95.

16. Albayrak B, Sukotjo C, Wee AG, Korkmaz İH, Bayındır F. Three-Dimensional 34. Imen D. Open Tray Impression Technique Using the Direct Pick-Up Coping: A

Accuracy of Conventional Versus Digital Complete Arch Implant Impressions. Case Report. Mod Approaches Dent Oral Heal Care. 2018;3:233–6.

J Prosthodont. 2021;30:163–70. 35. Balouch F, Jalalian E, Nikkheslat M, Ghavamian R, Toopchi S, Jallalian F,

17. Tomita Y, Uechi J, Konno M, Sasamoto S, Iijima M, Mizoguchi I. Accuracy of et al. Comparison of Dimensional Accuracy between Open-Tray and

digital models generated by conventional impression/plaster-model meth- Closed-Tray Implant Impression Technique in 15° Angled Implants. J Dent.

ods and intraoral scanning. Dent Mater J. 2018;37:628–33. 2013;14:96–102.

18. Arcuri L, Pozzi A, Lio F, Rompen E, Zechner W, Nardi A. Influence of implant 36. Izadi A, Heidari B, Roshanaei G, Allahbakhshi HFF. Comparative Study of

scanbody material, position and operator on the accuracy of digital impres- Dimensional Accuracy in Three Dental Implant Impression Techniques: Open

sion for complete-arch: A randomized in vitro trial. J Prosthodont Res. Tray, Closed Tray with Impression Coping, and Snap Cap. J Contemp Dent

2020;64. Pract. 2018;19:974–81.

19. Alikhasi M, Siadat H, Nasirpour A, Hasanzade M. Three-Dimensional Accuracy 37. Papaspyridakos P, Hirayama H, Chen CJ, Ho CHCV, Weber HP. Full-arch

of Digital Impression versus Conventional Method: Effect of Implant Angula- implant fixed prostheses: a comparative study on the effect of connection

tion and Connection Type. Int J Dent. 2018;2018:1–9. type and impression technique on accuracy of fit. Clin Oral Implant Res.

20. Revilla-León M, Att W, Özcan M, Rubenstein J. Comparison of conventional, 2016;27:1099–105.

photogrammetry, and intraoral scanning accuracy of complete-arch implant 38. Jung HT, Kim HY, Song SY, Park JH, Lee JY. Accuracy of implant impression

impression procedures evaluated with a coordinate measuring machine. J techniques with a scannable healing abutment. J Prosthet Dent. 2021;:1–6.

Prosthet Dent. 2021;125:470–8.

21. Knechtle N, Wiedemeier D, Mehl A, Ender A. Accuracy of digital complete-

arch, multi-implant scans made in the edentulous jaw with gingival move- Publisher’s note

ment simulation: An in vitro study. J Prosthet Dent. 2021;:1–11. Springer Nature remains neutral with regard to jurisdictional claims in

22. Lee SJ, Jamjoom FZ, Le T, Radics A, Gallucci GO. A clinical study comparing published maps and institutional affiliations.

digital scanning and conventional impression making for implant-supported

prostheses: A crossover clinical trial. J Prosthet Dent. 2021;:1–7.

23. Oh KC, Park JM, Moon HS. Effects of Scanning Strategy and Scanner Type on

the Accuracy of Intraoral Scans: A New Approach for Assessing the Accuracy

of Scanned Data. J Prosthodont. 2020;29.

Content courtesy of Springer Nature, terms of use apply. Rights reserved.

Terms and Conditions

Springer Nature journal content, brought to you courtesy of Springer Nature Customer Service Center GmbH (“Springer Nature”).

Springer Nature supports a reasonable amount of sharing of research papers by authors, subscribers and authorised users (“Users”), for small-

scale personal, non-commercial use provided that all copyright, trade and service marks and other proprietary notices are maintained. By

accessing, sharing, receiving or otherwise using the Springer Nature journal content you agree to these terms of use (“Terms”). For these

purposes, Springer Nature considers academic use (by researchers and students) to be non-commercial.

These Terms are supplementary and will apply in addition to any applicable website terms and conditions, a relevant site licence or a personal

subscription. These Terms will prevail over any conflict or ambiguity with regards to the relevant terms, a site licence or a personal subscription

(to the extent of the conflict or ambiguity only). For Creative Commons-licensed articles, the terms of the Creative Commons license used will

apply.

We collect and use personal data to provide access to the Springer Nature journal content. We may also use these personal data internally within

ResearchGate and Springer Nature and as agreed share it, in an anonymised way, for purposes of tracking, analysis and reporting. We will not

otherwise disclose your personal data outside the ResearchGate or the Springer Nature group of companies unless we have your permission as

detailed in the Privacy Policy.

While Users may use the Springer Nature journal content for small scale, personal non-commercial use, it is important to note that Users may

not:

1. use such content for the purpose of providing other users with access on a regular or large scale basis or as a means to circumvent access

control;

2. use such content where to do so would be considered a criminal or statutory offence in any jurisdiction, or gives rise to civil liability, or is

otherwise unlawful;

3. falsely or misleadingly imply or suggest endorsement, approval , sponsorship, or association unless explicitly agreed to by Springer Nature in

writing;

4. use bots or other automated methods to access the content or redirect messages

5. override any security feature or exclusionary protocol; or

6. share the content in order to create substitute for Springer Nature products or services or a systematic database of Springer Nature journal

content.

In line with the restriction against commercial use, Springer Nature does not permit the creation of a product or service that creates revenue,

royalties, rent or income from our content or its inclusion as part of a paid for service or for other commercial gain. Springer Nature journal

content cannot be used for inter-library loans and librarians may not upload Springer Nature journal content on a large scale into their, or any

other, institutional repository.

These terms of use are reviewed regularly and may be amended at any time. Springer Nature is not obligated to publish any information or

content on this website and may remove it or features or functionality at our sole discretion, at any time with or without notice. Springer Nature

may revoke this licence to you at any time and remove access to any copies of the Springer Nature journal content which have been saved.

To the fullest extent permitted by law, Springer Nature makes no warranties, representations or guarantees to Users, either express or implied

with respect to the Springer nature journal content and all parties disclaim and waive any implied warranties or warranties imposed by law,

including merchantability or fitness for any particular purpose.

Please note that these rights do not automatically extend to content, data or other material published by Springer Nature that may be licensed

from third parties.

If you would like to use or distribute our Springer Nature journal content to a wider audience or on a regular basis or in any other manner not

expressly permitted by these Terms, please contact Springer Nature at

onlineservice@springernature.com

You might also like

- Case Study Goshe CorporationDocument5 pagesCase Study Goshe Corporationmanisha_jha_110% (1)

- Penetration Testing Step-By-Step GuideDocument417 pagesPenetration Testing Step-By-Step GuideДенис Пискайкин100% (3)

- Accuracy of Half Guided Implant Placement With Machine DrivenDocument9 pagesAccuracy of Half Guided Implant Placement With Machine DrivenGustavo IsmaelNo ratings yet

- Imburgia-2017-Accuracy of Four Intraoral Scann PDFDocument13 pagesImburgia-2017-Accuracy of Four Intraoral Scann PDFAdinaBicaNo ratings yet

- Jced 13 E487Document6 pagesJced 13 E487Rafaela VillamaguaNo ratings yet

- Computer-Assisted, Template-Guided Immediate Implant Placement and Loading in The Mandible: A Case ReportDocument9 pagesComputer-Assisted, Template-Guided Immediate Implant Placement and Loading in The Mandible: A Case Reportnesrine boubakriNo ratings yet

- Guided Surgery in Dental ImplantologyDocument5 pagesGuided Surgery in Dental Implantologynarendra singhNo ratings yet

- Accuracy of Computer-Aided Template-Guided Oral Implant Placement A Prospective Clinical StudyDocument10 pagesAccuracy of Computer-Aided Template-Guided Oral Implant Placement A Prospective Clinical StudyMário LúcioNo ratings yet

- Learning Curve of Digital Intraoral Scanning - An in Vivo StudyDocument7 pagesLearning Curve of Digital Intraoral Scanning - An in Vivo StudyodontoensenadaNo ratings yet

- CJDR 2019 01 s0021Document8 pagesCJDR 2019 01 s0021Faisal hayatNo ratings yet

- Scanning Accuracy of An Intraoral Scanner According To Different Inlay Preparation DesignsDocument7 pagesScanning Accuracy of An Intraoral Scanner According To Different Inlay Preparation DesignsGt SolarcNo ratings yet

- IA e OrtodontiaDocument9 pagesIA e OrtodontiaCarolina DezanNo ratings yet

- Leido PDFDocument15 pagesLeido PDFAlejandro MejiaNo ratings yet

- Marlière Et Al. 2018 ProsthodonticsDocument8 pagesMarlière Et Al. 2018 ProsthodonticsApril FloresNo ratings yet

- Clinical Applications of Intraoral Scanning in Removable Prosthodontics: A Literature ReviewDocument16 pagesClinical Applications of Intraoral Scanning in Removable Prosthodontics: A Literature ReviewSantiago ParedesNo ratings yet

- A Systematic Review of The Accuracy of Digital Surgical Guides For Dental ImplantationDocument23 pagesA Systematic Review of The Accuracy of Digital Surgical Guides For Dental ImplantationehabidentNo ratings yet

- Uso de Sistemas de Impresion Digital Con Scaners Intraorales para Fabricacion de Protesis FijaDocument7 pagesUso de Sistemas de Impresion Digital Con Scaners Intraorales para Fabricacion de Protesis FijaPaola Alexandra LaguadoNo ratings yet

- SICATDocument40 pagesSICATBenjaporn AuttagangNo ratings yet

- 2018 Article 523Document16 pages2018 Article 523pyrockerNo ratings yet

- C.E. Credit. Effect of Steam Sterilization On Accuracy of 3D Printed Implant Surgical Guides A Pilot StudyDocument7 pagesC.E. Credit. Effect of Steam Sterilization On Accuracy of 3D Printed Implant Surgical Guides A Pilot Studymarcela fajardoNo ratings yet

- Intraoral Scanning To Fabricate Complete Dentures With Functional Borders: A Proof-Of-Concept Case ReportDocument7 pagesIntraoral Scanning To Fabricate Complete Dentures With Functional Borders: A Proof-Of-Concept Case ReportVeronica Regina RosselleNo ratings yet

- Journal of Prosthodontics - 2023 - Papaspyridakos - Reverse Scan Body The Scan Pattern Affects The Fit of Complete ArchDocument6 pagesJournal of Prosthodontics - 2023 - Papaspyridakos - Reverse Scan Body The Scan Pattern Affects The Fit of Complete Archjoaquin.reyes04No ratings yet

- Artigo 06Document8 pagesArtigo 06Julia PimentelNo ratings yet

- Buap 6Document11 pagesBuap 6WawawaNo ratings yet

- CBCT Ch.7 DCNADocument30 pagesCBCT Ch.7 DCNAgibsonNo ratings yet

- Voxel-Based Superimposition of Cone Beam CT Scans For Orthodontic and Craniofacial Follow-Up Overview and Clinical ImplementationDocument21 pagesVoxel-Based Superimposition of Cone Beam CT Scans For Orthodontic and Craniofacial Follow-Up Overview and Clinical ImplementationPhachara SiripraphonrojNo ratings yet

- Essay "Is The Surgeon Redundant in The Age of Dental Planning and Workflow"Document24 pagesEssay "Is The Surgeon Redundant in The Age of Dental Planning and Workflow"Gabriel RodriguezNo ratings yet

- The Accuracy of Different Dental Impression Techniques For Implant-Supported Dental Prostheses: A Systematic Review and Meta - AnalysisDocument19 pagesThe Accuracy of Different Dental Impression Techniques For Implant-Supported Dental Prostheses: A Systematic Review and Meta - AnalysisAnonymous AyxIccS4aXNo ratings yet

- Comparison of Different Impression Techniques ForDocument8 pagesComparison of Different Impression Techniques ForQabas MustafaNo ratings yet

- 2024 - Digital Design of A Hybrid Bone and Tooth Supported GuideDocument9 pages2024 - Digital Design of A Hybrid Bone and Tooth Supported GuideLenny GrauNo ratings yet

- Digital Workflows in Contemporary OrthodonticsDocument7 pagesDigital Workflows in Contemporary OrthodonticsAndreaVanoyMartinNo ratings yet

- Joda 2016Document6 pagesJoda 2016Juan MusanNo ratings yet

- Using A Clinical Protocol For Orthognathic Surgery and Assessing A 3-Dimensional Virtual ApproachDocument15 pagesUsing A Clinical Protocol For Orthognathic Surgery and Assessing A 3-Dimensional Virtual ApproachKorkmaz SayınsuNo ratings yet

- Minimal Invasiveness at Dental Implant Placement A Systematic Review With Meta-Analyses On Flapless Fully Guided SurgeryDocument24 pagesMinimal Invasiveness at Dental Implant Placement A Systematic Review With Meta-Analyses On Flapless Fully Guided Surgerymahesh kumarNo ratings yet

- Van Der Meer-2012-Application of Intra-Oral de PDFDocument8 pagesVan Der Meer-2012-Application of Intra-Oral de PDFAdinaBicaNo ratings yet

- 3D Workflows in Orthodontics Maxillofacial Surgery and ProsthodonticsDocument182 pages3D Workflows in Orthodontics Maxillofacial Surgery and ProsthodonticsA ANo ratings yet

- Bai 2014Document7 pagesBai 2014Bruna LannesNo ratings yet

- Sanda-2021-Trueness and Precision of Digital IDocument25 pagesSanda-2021-Trueness and Precision of Digital IJudit SchmalzlNo ratings yet

- DR Meni Implanto 1Document7 pagesDR Meni Implanto 1Itzel MarquezNo ratings yet

- Joda 2016Document15 pagesJoda 2016shraddhaNo ratings yet

- 3D Technology ChapterDocument42 pages3D Technology ChapterKrupal MehtaNo ratings yet

- Digital IMPLANT Impression TechniquesDocument25 pagesDigital IMPLANT Impression Techniquesjuanandresro93No ratings yet

- Reducing Errors in Guided Implant Surgery To Optimize Treatment OutcomesDocument10 pagesReducing Errors in Guided Implant Surgery To Optimize Treatment OutcomesDenisa CorneaNo ratings yet

- Implant Placement Accuracy Using Dynamic NavigationDocument9 pagesImplant Placement Accuracy Using Dynamic NavigationMrinmayee ThakurNo ratings yet

- 2023JP - Papaspyridakos - Reverse Scan Body A Complete Digital Workflow For Prosthesis PrototypeDocument6 pages2023JP - Papaspyridakos - Reverse Scan Body A Complete Digital Workflow For Prosthesis PrototypedrjonduNo ratings yet

- Dentistry 11 00015 With CoverDocument10 pagesDentistry 11 00015 With Coverjqffnykg4nNo ratings yet

- Three-Dimensional Assessment of Virtual Bracket Removal For Orthodontic Retainers: A Prospective Clinical StudyDocument10 pagesThree-Dimensional Assessment of Virtual Bracket Removal For Orthodontic Retainers: A Prospective Clinical StudyAndré DrumondNo ratings yet

- Assessment of The Accuracy of Imaging Software For 3D Rendering of The Upper Airway, Usable in Orthodontic and Craniofacial Clinical SettingsDocument14 pagesAssessment of The Accuracy of Imaging Software For 3D Rendering of The Upper Airway, Usable in Orthodontic and Craniofacial Clinical SettingsPhachara SiripraphonrojNo ratings yet

- Periodontology 2000 - 2022 - Chackartchi - Reducing Errors in Guided Implant Surgery To Optimize Treatment OutcomesDocument9 pagesPeriodontology 2000 - 2022 - Chackartchi - Reducing Errors in Guided Implant Surgery To Optimize Treatment OutcomesDr.CdiazNo ratings yet

- Running Title: Digital Vs Conventional Implant Impressions: DDS, MS, PHDDocument41 pagesRunning Title: Digital Vs Conventional Implant Impressions: DDS, MS, PHDÁł ÃăNo ratings yet

- Artificial Intelligence in Fixed Implant Prosthodontics: A Retrospective Study of 106 Implant-Supported Monolithic Zirconia Crowns Inserted in The Posterior Jaws of 90 PatientsDocument16 pagesArtificial Intelligence in Fixed Implant Prosthodontics: A Retrospective Study of 106 Implant-Supported Monolithic Zirconia Crowns Inserted in The Posterior Jaws of 90 Patientsanantha narayananNo ratings yet

- JCM 10 00704 v2Document18 pagesJCM 10 00704 v2Mrinmayee ThakurNo ratings yet

- Precision and Accuracy of A Digital Impression Scanner in Full-Arch Implant RehabilitationDocument5 pagesPrecision and Accuracy of A Digital Impression Scanner in Full-Arch Implant Rehabilitationgeorgios031No ratings yet

- The Accuracy of Implant Placement With Computer-GuidedDocument11 pagesThe Accuracy of Implant Placement With Computer-GuidedRyan Ardi PradanaNo ratings yet

- Comparison of The Occlusal Contact Area of Virtual Models and Actual Models: A Comparative in Vitro Study On Class I and Class II Malocclusion ModelsDocument15 pagesComparison of The Occlusal Contact Area of Virtual Models and Actual Models: A Comparative in Vitro Study On Class I and Class II Malocclusion ModelsVirgil ZvoristeanuNo ratings yet

- Accuracy of The Digital Workflow For Guided Insertion of Orthodontic Palatal Tads: A Step-By-Step 3D AnalysisDocument8 pagesAccuracy of The Digital Workflow For Guided Insertion of Orthodontic Palatal Tads: A Step-By-Step 3D AnalysisThibaut BossuytNo ratings yet

- Conventional Impression TechniqueDocument8 pagesConventional Impression Techniquejassi pwarkNo ratings yet

- Fabrication of Low Cost Soft Tissue Prostheses With The Desktop 3D PrinterDocument7 pagesFabrication of Low Cost Soft Tissue Prostheses With The Desktop 3D PrinterReem ShakirNo ratings yet

- Ijerph 19 02026 v2Document18 pagesIjerph 19 02026 v2Cihan ÖzdemirNo ratings yet

- Computer Technology Applications in Surgical Implant Dentistry: A Systematic ReviewDocument18 pagesComputer Technology Applications in Surgical Implant Dentistry: A Systematic ReviewsujeetNo ratings yet

- Digital Dental Implantology: From Treatment Planning to Guided SurgeryFrom EverandDigital Dental Implantology: From Treatment Planning to Guided SurgeryJorge M. GalanteNo ratings yet

- The Immediacy Concept: Treatment Planning from Analog to DigitalFrom EverandThe Immediacy Concept: Treatment Planning from Analog to DigitalNo ratings yet

- 2022 - Effect of Guiding Sleeve Design On Intraosseous Heat Generation During Implant Site PreparationDocument8 pages2022 - Effect of Guiding Sleeve Design On Intraosseous Heat Generation During Implant Site PreparationVõHoàngThủyTiênNo ratings yet

- 1 s2.0 S0022391323003761 MainDocument3 pages1 s2.0 S0022391323003761 MainVõHoàngThủyTiênNo ratings yet

- 2 - 2023 - Novel Technique For Placement of Immediate Implant in Mandibular RegionDocument5 pages2 - 2023 - Novel Technique For Placement of Immediate Implant in Mandibular RegionVõHoàngThủyTiênNo ratings yet

- 2019 - in Vitro Comparison Between Metal Sleeve-Free and Metal SleeveDocument10 pages2019 - in Vitro Comparison Between Metal Sleeve-Free and Metal SleeveVõHoàngThủyTiênNo ratings yet

- S - 2022 - Open-Sleeve Templates For Computer-Assisted Implant Surgery at Healed or Extraction SocketsDocument11 pagesS - 2022 - Open-Sleeve Templates For Computer-Assisted Implant Surgery at Healed or Extraction SocketsVõHoàngThủyTiênNo ratings yet

- 2020 - Stereolithographic Surgical Guide With A Combination of Tooth and Bone SupportDocument13 pages2020 - Stereolithographic Surgical Guide With A Combination of Tooth and Bone SupportVõHoàngThủyTiênNo ratings yet

- S - 2019 - Influence of Implant Macrodesign and Insertion Connection Technology On The Accuracy of Static Computer-Assisted Implant SurgeryDocument7 pagesS - 2019 - Influence of Implant Macrodesign and Insertion Connection Technology On The Accuracy of Static Computer-Assisted Implant SurgeryVõHoàngThủyTiênNo ratings yet

- S - 2022 - Precision and Trueness of Computer Assisted Implant Placement Using Static Surgical Guides With Open and Closed SleevesDocument10 pagesS - 2022 - Precision and Trueness of Computer Assisted Implant Placement Using Static Surgical Guides With Open and Closed SleevesVõHoàngThủyTiênNo ratings yet

- 2018 - The Influence of Guided Sleeve Height, Drilling Distance and Drilling Key Length On The Accuracy of Static ComputerAssisted Implant SurgeryDocument7 pages2018 - The Influence of Guided Sleeve Height, Drilling Distance and Drilling Key Length On The Accuracy of Static ComputerAssisted Implant SurgeryVõHoàngThủyTiênNo ratings yet

- 2011 - Key Principles That Enhance Success When Restoring Endodontically Treated TeethDocument7 pages2011 - Key Principles That Enhance Success When Restoring Endodontically Treated TeethVõHoàngThủyTiênNo ratings yet

- Clinical Tips & Tricks Anterior Restorations. FiltekTM. Supreme Plus. Universal RestorativeDocument40 pagesClinical Tips & Tricks Anterior Restorations. FiltekTM. Supreme Plus. Universal RestorativeVõHoàngThủyTiênNo ratings yet

- APolycromaticCompositeLayeringApproachforSolvingaComplexClassIV DirectVenner DiastemaCombination Part1Document7 pagesAPolycromaticCompositeLayeringApproachforSolvingaComplexClassIV DirectVenner DiastemaCombination Part1VõHoàngThủyTiênNo ratings yet

- Design: Dung d ịch bù nước qua đường uốngDocument2 pagesDesign: Dung d ịch bù nước qua đường uốngVõHoàngThủyTiênNo ratings yet

- Empire State Wind StressesDocument176 pagesEmpire State Wind StressesIngeniero 12No ratings yet

- Firefly-RK3399 V10 SCH (2017-2-8)Document30 pagesFirefly-RK3399 V10 SCH (2017-2-8)Satvik HardatNo ratings yet

- Crystal Report 2016 Unit 1Document10 pagesCrystal Report 2016 Unit 1Ann JeeNo ratings yet

- IT Disaster Recovery Plan Template: ContentsDocument7 pagesIT Disaster Recovery Plan Template: ContentsUriel TijerinoNo ratings yet

- Aggregate PlanningDocument44 pagesAggregate PlanningJoli SmithNo ratings yet

- Product Name Description AH-1613 Datasheet of AH-1613 Host-Based GPS Module 1.0Document13 pagesProduct Name Description AH-1613 Datasheet of AH-1613 Host-Based GPS Module 1.0Felis FlammeusNo ratings yet

- DAR Stair Case PressurizationDocument16 pagesDAR Stair Case PressurizationfebousNo ratings yet

- UntitledDocument154 pagesUntitledJuanca100% (1)

- BTM 200 NotesDocument70 pagesBTM 200 NotesJoshua RemirezNo ratings yet

- WCDMA BTS3900 Hardware Structure-20100208-B-V1.0Document64 pagesWCDMA BTS3900 Hardware Structure-20100208-B-V1.0MohamedNasser Gad El MawlaNo ratings yet

- Tooway Presentation PDFDocument5 pagesTooway Presentation PDFPRESS-NEW-BALKANNo ratings yet

- Input Module, Input/output Module: Sinteso™/ Cerberus™ PRODocument8 pagesInput Module, Input/output Module: Sinteso™/ Cerberus™ PROEmmanuel ToretaNo ratings yet

- DS Series IndicatorDocument2 pagesDS Series IndicatorShreyasi SinhaNo ratings yet

- Risk Management TerminologyDocument8 pagesRisk Management TerminologyTata OdoyNo ratings yet

- Factory Test Report For OPzS 800 EED-20041724 2VDocument3 pagesFactory Test Report For OPzS 800 EED-20041724 2VmaherNo ratings yet

- Data Analytics For Decision MakingDocument8 pagesData Analytics For Decision MakingMartin MugambiNo ratings yet

- DuckDuckGo - Cheat Sheet FULLDocument3 pagesDuckDuckGo - Cheat Sheet FULLleon_galNo ratings yet

- Accounting Information System QuestionsDocument7 pagesAccounting Information System QuestionsMohsin ShaikhNo ratings yet

- Geeetech A30M 3D Printer User Manual: Shenzhen Getech Technology Co.,LtdDocument62 pagesGeeetech A30M 3D Printer User Manual: Shenzhen Getech Technology Co.,LtdAngel RojasNo ratings yet

- Polar Fire FPGADatasheetDocument86 pagesPolar Fire FPGADatasheetMarsupjoNo ratings yet

- Tiket PesawatDocument2 pagesTiket PesawatDwiki RahmatNo ratings yet

- Main Project HMTDocument34 pagesMain Project HMTVenkatAdityaNo ratings yet

- Cicind: Model Code Steel ChimneysDocument3 pagesCicind: Model Code Steel ChimneysSugumar N Shanmugam100% (1)

- AWS Solutions Architect Associate Master Cheat SheetDocument124 pagesAWS Solutions Architect Associate Master Cheat SheetSapna Popat SitarNo ratings yet

- 02 Architecture Audit Ternoa Bridge RelayerDocument23 pages02 Architecture Audit Ternoa Bridge RelayeratmxNo ratings yet

- Devulapalli Sneha: Career ObjectiveDocument3 pagesDevulapalli Sneha: Career ObjectiveDeekshithaNo ratings yet

- Instructor Guide Wooden Spoon v1.0 12 Nov 15Document14 pagesInstructor Guide Wooden Spoon v1.0 12 Nov 15Joy UyNo ratings yet

- ICS Worksheet1Document5 pagesICS Worksheet1agergizat girmaNo ratings yet