Professional Documents

Culture Documents

Equilibrium in The Hydrogenation of Polycyclic Aromatics

Equilibrium in The Hydrogenation of Polycyclic Aromatics

Uploaded by

Paravastu VinuthaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Equilibrium in The Hydrogenation of Polycyclic Aromatics

Equilibrium in The Hydrogenation of Polycyclic Aromatics

Uploaded by

Paravastu VinuthaCopyright:

Available Formats

Equilibria in the Hydrogenation

of Polycylic Aromatics

C. G. FRYE

Research a n d Development Department, American Oil Co., Whiting, Ind.

AVAILABILITY of inexpensive hydrogen from naphtha was purified with sodium a t 200" C. and distilled. In all

reforming has markedly increased the interest in hydro- experiments the catalyst charge was 1 gram of 0.5 or 10%

genation equilibria. An important group of these equilibria platinum on gamma-alumina ground to pass a 100-mesh

are the hydrogenations of the polycyclic hydrocarbons. screen.

Published data on these equilibria are limited to the experi- After loading with feed and catalyst, the reactor was

mental determinations of Wilson (6) on the reaction of evacuated and pressured with hydrogen to a selected initial

naphthalene to tetralin and calculations from spectroscopic pressure. Then it was heated to and held a t the desired

data of Pitzer ( 5 ) on the reaction of naphthalene to decalin. temperature until pressure reached a constant value. The

Equilibria for the more complicated polycyclic systems can time a t constant temperature varied from about 30 minutes

be estimated only by such procedures as those suggested to about 70 hours depending upon temperature. Finally, the

by Bondi ( 3 ) .These calculated and estimated values have entire equilibrium product was rapidly withdrawn through

not been verified experimentally. heated pressure tubing and 10 inches of 12-mm. glass

One of the principal reasons for the absence of equilibrium tubing, packed with 3-mm. glass beads wet with benzene,

data on polycyclic systems has been the lack of suitable into a 600-ml. flask. The material held up in the pressure

analytical techniques. This situation has changed with the tubing; glass beads were washed into the flask with ether,

development of both the high, mass spectrometer and gas most of which was later distilled off. N o effort was made

chromatography. With these analytical techniques, investi- to determine the actual moles of hydrogen discharged from

gations have been performed in a batch system t o determine the reactor, nor was it found necessary to provide agitation

equilibrium constants for the hydrogenations of naphtha- inside the reactor to eliminate diffusional effects.

lene, diphenyl, and phenanthrene. In the study of the The product was analyzed by gas chromatography in an

naphthalene system, the results for the naphthalene-to- Aerograph instrument with helium as the carrier gas. A

tetralin reaction, when compared with those of Wilson, 20-foot Apiezon column was used for the naphthalene and

check on the techniques used. The results for the naphtha- phenanthrene systems; a 10-foot Carbowax column was

lene-to-decalin reaction directly test the equilibria calcu- used for the diphenyl system.

lated by Pitzer from spectroscopic data. The results for the Peaks were identified by comparison with chroma-

diphenyl and phenanthrene systems measure the validity of matographs of either nearly pure purchased compounds or

Bondi's empirical procedures. compounds prepared by hydrogenation and separated by

liquid chromatography or distillation or both. T h e prepared

compounds were identified in all cases by low-voltage mass

spectrometry, and the mass spectrometer results were

EXPERIMENTAL

confirmed by boiling temperature and refractive index when

All experiments were performed in a cylindrical stainless these data were available in the literature. The perhydro-

steel reactor 10 inches long and 1% inches in diameter phenanthrenes were recovered only as a mixture from low-

(300 cc. total volume). A longitudinal thermowell was temperature hydrogenation. Similarly, what were assumed

located along the inside wall of the reactor. Temperatures to have been the two asymetric octahydrophenanthrenes

determined a t one-inch intervals along the length of the were also recovered as a mixture.

reactor with a calibrated iron constantan thermocouple Compared with values for naphthalene, calibration

varied about.3.5" C. from the average. The position of the factors of area per unit weight of tetralin, trans-decalin, and

catalyst was not accurately known in the naphthalene and cis-decalin were all 1.00 & 0.04. Compared to values for

diphenyl experiments. I n the phenanthrene experiments, phenanthrene, a calibration factor of 1.00 i 0.04 was deter-

the catalyst position was known within % inch so that mined for the mixture of perhydrophenanthrenes; cali-

reaction temperature was determined within 2.0" C. bration factors of 1.00 were assumed to apply to all other

Pressure was measured with a conventional bourdon-tube components in the phenanthrene system. A calibration

gage. The gage was used in an inverted position and filled factor of 1.00 compared to diphenyl was assumed for all

with mercury to reduce gas volume outside the reactor. I t components of that system. Duplicate analyses of the major

was connected to the reactor with a 10-inch section of products were, in general, within the 4 5 variation observed

K-inch I.D. pressure tubing which was heated to near in the calibration factors. Duplicate analyses for minor

reactor temperature except close to the gage itself. The products showed variations of up to 1 0 5 a t about 5$

accuracy of the gage was determined while in position by concentration and 25 to occassionally 50% in the 1%

comparison with a standardized gage before and after each concentration range.

experiment. Equilibria were calculated by the procedure of Gilliland

For the naphthalene system, the feeds were commercially ( 4 ) for all three systems. I n all cases, hydrocarbon pressure

available naphthalene, tetralin, and trans-decalin purified was calculated with the perfect gas equation and was small

by distillation or liquid perc'olation over activated alumina, compared to either total pressure or the vapor pressure of

or both. For the diphenyl system the diphenyl feed (East- the equilibrium mixture. Hydrogen pressure was calculated

Man) was used without purication; the cyclohexylcyclo- by difference from the total pressure. Correction for the

hexane was prepared by hydrogenation of the diphenyl nonideality of hydrogen was made by assumption of an

followed by percolation over activated alumina and distil- activity coefficient of 1.000 + 3.30 X lo-' P H a t all tempera-

lation. For the phenanthrene system, a mixed perhydro- tures for all three systems. Thus, for example, calculated

phenanthrene feed was prepared by hydrogenation of equilibrium constants for the naphthalene to tetralin

phenanthrene followed by distillation; the phenanthrene reaction were:

592 JOURNAL OF CHEMICAL AND ENGINEERING DATA

(moles tetralin) DISCUSSION

K p =-

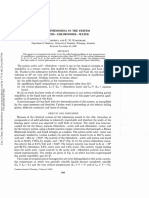

(moles naphthalene)(PH + 3.30 x PH:)* Data from the naphthalene hydrogenations are compared

with data from the literature in Figure 1. Results for the

where PH,was in atmospheres. naphthalene-to-tetralin reaction agree with those of Wilson

Experimental and calculated data for the naphthalene (6) and show that the batch technique is reliable as a means

system (No generally accepted technique for taking account of determining equilibrium distributions. Results for

of nonideality has been adopted. A technique such as that naphthalene to trans-decalin verify the equilibrium calcu-

used by Wilson (6) introduces a larger correction.) are lated from spectroscopic data by Pitzer ( 5 ) . The observed

presented in Table I . I n these experiments the temperature ratio of trans-to-cis decalin was slightly lower than that

given is the average of the highest and lowest measured calculated by Pitzer but higher than that reported by

temperature and may be inaccurate by about 3.5" C. Allinger ( I ) far the liquid system.

Similarly, data for the diphenyl system (Table 11) are Data from the diphenyl hydrogenation are plotted in

subject to the same error in temperature. Figure 2 . From these lines, the heats of hydrogenation and

Data for the phenanthrene system are presented in Table the relationships between absolute temperature and equilib-

111. The temperature uncertainty in these experiments is rium constant were calculated to be:

estimated to be 2.0"C. For the perhydro- and the

octahydro-phenanthrenes; the analyses are given in order of System -AH, Kcal. G. Mole H,

1 Log K;;

decreasing retention time in the chromatographic column;

with an Apiezon column this i s also the order of decreasing

c l , ~ I , , A ! , ~ : . 18

: -21.71 + 11,750 T

boiling point. For the six possible perhydrophenanthrenes,

CiiHi,+Ci?Hn 18 -22.37 + 11,750 T

only five gas-chromatography peaks appear that are large

C i2H iN,+C:?H?r 18 -44.08 + 23,500 T

enough to be measured, but slight broadening of the third Assuming the correction for nonideality is accurate, the

suggests the presence of two isomers of almost identical largest uncertainty in both the AH and log K , values results

retention time. The highest boiling perhydrophenanthrene from the 3.5' C. uncertainty in temperature. The AH value

was found only a t nonequilibrium under strongly hydro- of 18 (calculated value 17.9) kcal./gram mole H2 is probably

genating conditions. The concenhation of this isomer has uncertain by about 1 kcal.igram mole H2.This value is in

been omitted from Table I11 because at equilibrium its agreement with that for the tetralin to trans-decalin reaction

concentration was always zero. Lighter hydrocarbons were but is about 1 kcal. / gram mole H?larger than the value for

produced in significant amounts only in the run at 459" C.; alkyl substituted benzenes.

the feed hydrocarbon pressure would have been 1.8 atm. At a given temperature, the log K , terms for the first

had no cracking taken place, but the production of mainly two equilibria differ by 0.66, which differs slightly from the

methane through butane increased hydrocarbon pressure to 0.60 dictated by the symmetry factors ( 2 ) for this system.

P.2 atm. At all temperatures

Table I. Experimental Determinations of Ndphthalene-Hydrogenation Equilibria

Temp., C. 343 363 374 383 396 402 429

Feed A B B A C A B

Total Pressure, Atm. 14.5 22.3 23.9 24.9 39.8 41.8 75.6

Hydrocarbon Pres., Atm. 2.0 2.7 2.7 2.9 3.7 3.6 3.6

Hydrocarbon; Mole 7

trans- Decalin 43.9 51.7 36.1 41.0 51.3 40.2 44.9

C n

&Decalin 6.2 1.1 5.8 6.2 7.9 6.0 8.0

Tetralin 35.5 31.7 42.0 37.9 31.3 38.2 35.5

Naphthalene 14.4 8.9 16.1 11.9 9.5 15.6 11.6

-Log Equilibrium Constant

1.80 2.07 2.24 2.39 2.61 2.79 3.26

5.00 5.79 6.29 6.55 7.08 7.53 8.77

Equilibrium c onstant

C loH I,(cis)-Cl,~HI,(trans) 7.0 6.7 6.2 6.6 6.5 6.7 5.6

A = naphthalene B = tetralin C = trans-decalin

Table II. Experimental Determination of diphenyl-Hydrogenation Equilibria

Temp., C. 328 346 331 330 355 389 425 426

Feed A B B A B A B A

Total Pressure, Atm. 8.0 6.9 7.0 14.2 15.7 24.6 33.3 71.5

Hydrocarbon Pres,m Atm. 0.5 9.6 0.6 1.8 1.5 1.8 2.6 3.4

fiydrocarbon; Mole ' C

Diphenyl 18.3 33.5 28.0 15.9 18.3 34.6 62.0 14.0

Cyclohexyl benzene 51.5 50.8 50.1 49.0 50.2 49.9 33.6 48.8

C yclo hexylcyclohexane 30.2 15.7 21.9 35.1 31.5 15.5 4.4 37.2

-Log Equilibrium Constant

2.17 2.22 2.17 2.79 3.04 3.93 4.74 4.99

5.03 5.13 4.95 6.22 6.72 8.52 10.09 10.64

A = diphenyl B = cyclohexylcyclohexane

VOL. 7 , No. 4, OCTOBER 1962 593

~~

Table Ill. Experimental Determination of Phenanthrene-Hydrogenation Equilibria

Temp., C . 337 346 369 373 373 406 429 459

Feed A B A A B A B B

Total Pressure, Atm. 15.5 15.9 21.0 31.1 137.3 50.6 78.9 157.3

Hydrocarbon Pres., Atm. 0.5 0.9 0.9 0.9 1.1 0.9 1.1 8.2

Hydrocarbon; Mole 5

Phenanthrene 33.1 44.2 53.0 23.7 0.0 30.7 27.6 11.5

Dihydro- 7.3 8.3 8.7 6.2 0.0 8.0 7.9 5.2

Tetrahydro- 22.3 22.7 19.0 20.8 0.0 22.2 23.4 14.9

Sym. Octahydro- 13.9 12.1 6.5 14.5 0.0 13.8 16.3 14.9

Asym. Octahydro- 3.2 2.9 1.6 3.3 0.0 3.6 3.7 5.0

Asym. Octahydro- 1.9 2.0 0.9 2.2 0.0 2.4 2.3 2.8

Perhydro- 0.3 0.3 0.3 0.8 1.5 0.5 1.0 1.8

Perhydro- 3.3 1.1 I .8 3.7 11.6 2.8 2.9 8.7

Perhydro- 3.3 1.1 1.1 3.6 12.0 2.8 2.9 8.3

Perhydro- 12.4 5.3 7.1 21.2 74.9 13.2 12.0 26.9

-Log Equilibrium Constant

1.83 1.91 2.09 2.07 ... 2.28 2.45 2.53

2.52 2.64 3.06 3.03 ... 3.54 3.88 4.34

5.08 5.27 6.13 6.15 ... 7.15 7.84 8.60

8.65 9.16 10.01 10.44 ... 12.28 13.67 14.86

A = mixture of perhydrophenanthrenes B = phenanthrene c = calculated for most abundant isomer only

(diphenyl)(cyclohexylcyclohexane) Data for the more important reactions in the hydro-

= 0.22

(cyclohexylbenzenei‘ genation of phenanthrene are plotted in Figure 3. From

these lines, the heats of hvdroeenation and the relation

Experimentally, this ratio varied from 0.21 t o the 0.25 that between absolute temperature -and equilibrium constant

corresponds to the symmetry factor requirement. The first were calculated to be:

two of these reactions involve hydrogenation of isolated Svstem -AH,Kcal., G. Mole H2 Log KP

aromatic rings, but compared with t6e hydrogenation of C i H I ~ ,H

k 12 -6.11 + 2,6001 T

toluene, substitution of phenyl or cyclohexyl in place of a C14Hl-Cl,Hlr 15 -13.25+ 6,565 T

methyl group makes both equilibria significantly “more 15 -26.38 + 13,030 T

aromatic.” 15 -46.49 + 23,190 T

c

0 I I I 0 , I I I 0 , I

A TRANS-DEGALIN FEED CYCLOHEXYLCYCLOHEXANE FEED PERHYDROPHENANTHRENE FEED

- m NAPHTHALENE F E E D DIPHENYL FEED

PHENANTHRENE FEED

0 TETRALIN FEED

-2 - -e

-4

..( /

/ -

I

-4

-6 - - -6 -6 -

n n

Y

-8 - Y

c)

0

J

-10 -10 -10 -

-12 -12 -

-1B

1.3 1.4 1.5

IWO/T

1.6 1.7

-16

-I‘ L

1.3 1.4 1.5

lOOO/T

1.6 I.7 1.3 1.4 1.5

IOOO/T

1.6

-

1.7

Figure 1. Naphthalene-hydrogen equi- Figure 2. Diphenyl-hydrogen equi- Figule 3. Phenanthrene-hydrogen equi-

librium constants as a function brium constants as a function librium constants as a function

of temperature of temperature of temperature

5 94 JOURNAL OF CHEMICAL AND ENGINEERING DATA

Since temperature was more accurately known the uncer- low. For phenanthrene to sym. octahydrophenanthrene,

tainties in the AH and log IT,^ values resulting from for example, the calculated constant is less than a tenth of

uncertainties in temperature are smaller than with the the actual equilibrium constant.

diphenyl-hydrogen system. The AH values cannot be

directly compared with other data because accurate heat of CONCLUSION

combustion data are not available for the major components

of the phenanthrene-hydrogen system. I n general, the A H The experimentally determined equilibrium data for

values are in satisfactory agreement with those calculated selected polycyclic aromatic provide a firmer base for

using the empirical procedure of Bondi ( 3 ) . Because the interpreting hydrogenation data. They emphasize that

heats of hydrogenation are equal for the reactions of empirical correlations can be seriously in error and show the

phenanthrene .and tetrahydrophenanthrene and of tetra- need for similar experimental data for other polycyclic

hydro- to octahydrophenanthrene and both involve two systems. The techniques used in the present work should

moles of hydrogen, the ratio of their equilibrium constants serve in studying such systems.

is independent of hydrogen pressure and temperature.

Experimentally, this ratio LITERATURE CITED

(ohenanthrene)(svm. OctahvdroDhenanthrene)

" I

(1) Allinger, N.I., Coke, J.L., J . Am. Chem. SOC.81, 4080 (1959).

tetrahydrophenanthrene)' (2) Benson, S.W., Ibid.,80, 5151 (1958).

(3) Bondi, A,, Petrol. Refiner 38, No 2, 161 (1959).

varied from 0.78 to 1.03 and averaged 0.87. (4) Gilliland, "High Pressure Processes," p. 69, Mass. Inst.

Data on the minor components included in Table I11 Technol., Cambridge, Mass., 1949.

(5) Miyazawa, T., Pitzer, K.S., J . Am. Chem. SOC.80, 60 (1958).

show that the symmetrical compound accounts for about (6) Wilson, T.P., Caflisch, E.G., Hurley, G.F., J . Phys. Chem.

70'; of the total octahydrophenanthrenes, and the lowest 62. 1059 (1958).

boiling one accounts for 60 to 75'2 of the total perhydro-

phenanthrenes. I n neither case are the data sufficiently

accurate to determine heats of isomerization. RECEIVED tor review February 15, 1962. Accepted June 25. 1962.

T h e experimental data show that Bondi's empirically Division of Petroleum Chemistry, 140th Meeting, ACS. Chicago.

calculated equilibrium constants (3) are significantly too Ill., September 1961.

Specific Heat of Some High Temperature Materials

B. E. WALKER, JR., C. T. EWING, and R. R. MILLER

U. S. Naval Research Laboratory, Washington 25, D. C.

DEMAND FOR materials capable of withstanding then dropped into the calorimeter, which measures the heat

evolved in cooling the sample from the furance temperature

extreme temperatures has increased sharply in the past few

years. This has resulted from an increased emphasis on to the calorimeter operating temperature (30" C . ) . Heat

space and reactor programs, which require high temperature capacities are then derived from the heat content measure-

materials with specific properties. Selection, application, ments by the usual methods.

and evaluation of new materials require a through knowl- Type 304 stainless steel buckets, previously calibrated

edge of their physical and mechanical properties. for heat content in the calorimeter system from 30" to

This laboratory has performed precise specific heat 80OoC., were used to contain the samples. Samples were

determinations from room temperature t o 1000" C. on obtained from several companies as hot-pressed solids,

various materials such as synthetic sapphire and MoSiz machined to fit the sample containers. D a t a on the compo-

( 1 5 ) . TiB? ( 1 4 ) ,and several organic liquids ( 1 3 ) . sition of several samples are given in Table I . Those not

T h e present investigation involves similar specific heat listed are not known beyond the nominal compositions

determinations of 45 materials, which have potential high indicated in Table 11.

temperature applications. Heat capacities were derived

from heat content measurements, performed over the tem-

EXPERIMENTAL RESULTS

perature range 30" to 800" C., for BeO, Be, BeO-Be and

BeO-Be-Mo cermet mixtures: beryllides of T a , Zr, M o . Ti. Heat content measurements were obtained over the

and Cb; BeO-beryllide mixtures; S i c , Sic-graphite mix- temperature range from 30" t o 800' C . a t 100" to 150" C.

tures; and B N , BN-graphite mixtures. Smoothed specific intervals for approximately 25 samples, and a t 200°C.

heat results are presented for all samples, and the effeciive- intervals for the remainder of the samples, which were

ness of the additive law in predicting specific heats is duplicates or near-duplicates of eariler ones. Specific heats

demonstrated. were then derived from the enthalpy data.

Smoothed experimental results were obtained graphically

EQUIPMENT

from precise plots of specific heat-temperature and are

shown in Table 11. The probable absolute error in this

The apparatus has been previously described in some calorimetric system has been calculated to be less than

detail (1.3. Briefly, the calorimeter is a modified version &0.3'< for heat content measurements and less than ~ 3 ~ ;

of Southard's apparatus ( 1 2 ) , and the drop method is for specific heat. Measurements on synthetic sapphire, a

employed. Samples are heated to a known temperature and calorimetric standard, indicate that this calculated error

VOL. 7, No. 4, OCTOBER 1962 595

You might also like

- Kinetics of Catalytic Dehydrogenation of Ethylbenzene To StyreneDocument5 pagesKinetics of Catalytic Dehydrogenation of Ethylbenzene To Styreneibrahim3318No ratings yet

- Solid-Liquid Phase DiagramDocument4 pagesSolid-Liquid Phase DiagramMichael Go67% (9)

- 161 Exam II V1 Spring 2010 (1) ChemistryDocument9 pages161 Exam II V1 Spring 2010 (1) ChemistryMaheen MianNo ratings yet

- CH182 Chemistry For Engineers - EnergyDocument93 pagesCH182 Chemistry For Engineers - EnergyKaye Reies100% (1)

- 1 s2.0 0009250964850922 MainDocument12 pages1 s2.0 0009250964850922 MainPedro SiscatoNo ratings yet

- Ammonium Chloride-Reaction EquilibriumDocument6 pagesAmmonium Chloride-Reaction Equilibriumfatemeh afariNo ratings yet

- Measurements and Thermodynamic Modeling of Vapor-Liquid Equilibria For Binary SystemsDocument10 pagesMeasurements and Thermodynamic Modeling of Vapor-Liquid Equilibria For Binary SystemsJuan Fernando Cano LarrotaNo ratings yet

- Camacho Camacho2011Document7 pagesCamacho Camacho2011jasontodd22031995No ratings yet

- Isobarica NRTL, Wilson, UniquacDocument5 pagesIsobarica NRTL, Wilson, UniquacRicardo CortezNo ratings yet

- Pub Azeotropic Published PDFDocument4 pagesPub Azeotropic Published PDFQofiyyuNo ratings yet

- Esterase KineticsDocument6 pagesEsterase KineticskashyapNo ratings yet

- Dehydration of Hydrazine Azeotropic Distillation: R. Q. Wilson, W. H. Mink, H. P. Munger, J. W. CleggDocument5 pagesDehydration of Hydrazine Azeotropic Distillation: R. Q. Wilson, W. H. Mink, H. P. Munger, J. W. CleggGustavo Gabriel JimenezNo ratings yet

- Thermodynamics of H2-Bonding Mixtures. 5. GE, HE, and TSE and Zeotropy of Water + Acrylic Acid PDFDocument5 pagesThermodynamics of H2-Bonding Mixtures. 5. GE, HE, and TSE and Zeotropy of Water + Acrylic Acid PDFmurdanetap957No ratings yet

- Aic 690170119Document6 pagesAic 690170119Tiên PhạmNo ratings yet

- Artículo Científico Hept-ToluDocument4 pagesArtículo Científico Hept-ToluYli S'cNo ratings yet

- Equilibrio de Benceno, CiclohexanoDocument5 pagesEquilibrio de Benceno, CiclohexanoLuiz AzpilcuetaNo ratings yet

- Artdel28 PDFDocument6 pagesArtdel28 PDFFrancisco Rodriguez VazquezNo ratings yet

- General Research: L. Gil, S. Avila, P. Garcı A-Gime Nez, S. T. Blanco, C. Berro, S. Otin, and I. VelascoDocument7 pagesGeneral Research: L. Gil, S. Avila, P. Garcı A-Gime Nez, S. T. Blanco, C. Berro, S. Otin, and I. VelascopaulaNo ratings yet

- Data Experimental EVL Hexane - 1-Decene y Octane - 1-DeceneDocument5 pagesData Experimental EVL Hexane - 1-Decene y Octane - 1-DeceneJamesMorenoBustamanteNo ratings yet

- 25 Article-Iccbl-2015-Dhoni-25 - 1Document6 pages25 Article-Iccbl-2015-Dhoni-25 - 1Josemar Pereira da SilvaNo ratings yet

- Lab 7Document12 pagesLab 7api-25252422380% (5)

- Ternary Phase DiagramDocument9 pagesTernary Phase DiagramFabiha SheikhNo ratings yet

- Water + SulfolaneDocument5 pagesWater + SulfolaneGary Kiel Palacios EspinozaNo ratings yet

- Ethlyene Solubility PDFDocument4 pagesEthlyene Solubility PDFJijia BaiNo ratings yet

- 6 Phase Equilibria in Hydrocarbon Systems. Volumetric and Phase Behavior of The Methane-n-Heptane SystemDocument14 pages6 Phase Equilibria in Hydrocarbon Systems. Volumetric and Phase Behavior of The Methane-n-Heptane SystemRoy Royer Solorzano DuranNo ratings yet

- Chemical Engineering Science: Ardi Hartono, Muhammad Saeed, Arlinda F. Ciftja, Hallvard F. SvendsenDocument11 pagesChemical Engineering Science: Ardi Hartono, Muhammad Saeed, Arlinda F. Ciftja, Hallvard F. SvendsenrahulNo ratings yet

- Phase Equilibria in The Ternary System Hexane Q Ethyl 1,1-Dimethylethyl Ether Q HeptaneDocument10 pagesPhase Equilibria in The Ternary System Hexane Q Ethyl 1,1-Dimethylethyl Ether Q HeptaneKrause SpencerNo ratings yet

- 103-107 FragranceDocument5 pages103-107 FragranceРуслан ПетровичNo ratings yet

- Vapor Liquid Equilibrium Densities and Interfacial Tensions For The System Benzene Propan 1 OlDocument17 pagesVapor Liquid Equilibrium Densities and Interfacial Tensions For The System Benzene Propan 1 OlLorena AgudeloNo ratings yet

- FTPDocument5 pagesFTPSurendar Vejayan100% (1)

- Fluid Phase Equilibria Volume 95 Issue None 1994 (Doi 10.1016/0378-3812 (94) 80070-7) Monika Johannsen Gerd Brunner - Solubilities of The Xanthines Caffeine, Theophylline and Theobromine in SupeDocument12 pagesFluid Phase Equilibria Volume 95 Issue None 1994 (Doi 10.1016/0378-3812 (94) 80070-7) Monika Johannsen Gerd Brunner - Solubilities of The Xanthines Caffeine, Theophylline and Theobromine in Supenurul latifahNo ratings yet

- Log (Dim: Vapor-Liquid Equilibria For The System Water + Tert.-Pentanol at 4 TemperaturesDocument23 pagesLog (Dim: Vapor-Liquid Equilibria For The System Water + Tert.-Pentanol at 4 TemperaturesHarry Vara MarceloNo ratings yet

- Liquid Liquid EquilibriumDocument9 pagesLiquid Liquid EquilibriumLucas_ABNo ratings yet

- Solubility Measurement and Modeling For PropaneDocument8 pagesSolubility Measurement and Modeling For PropanerschirtNo ratings yet

- CHEM 111.1 Exercise 4Document13 pagesCHEM 111.1 Exercise 4paradoxcomplex100% (1)

- Baylon, Et. Al.-Solving Problems Regarding Vapor-Liquid EquilibriumDocument21 pagesBaylon, Et. Al.-Solving Problems Regarding Vapor-Liquid EquilibriumblessaNo ratings yet

- Integrating Computers Into The First-Year Chemistry Laboratory: Application of Raoult's Law To A Two-Component SystemDocument2 pagesIntegrating Computers Into The First-Year Chemistry Laboratory: Application of Raoult's Law To A Two-Component SystemjohnNo ratings yet

- The Rice InstituteDocument52 pagesThe Rice InstituteAyush SinghNo ratings yet

- Elison HR J Chem Educ 2005 82 1086Document3 pagesElison HR J Chem Educ 2005 82 1086Daniel ButlerNo ratings yet

- 1 Liquid-Liquid Equilibrium For The Ternary System Methanol + Acrylonitrile + WaterDocument10 pages1 Liquid-Liquid Equilibrium For The Ternary System Methanol + Acrylonitrile + WatersandraesiqNo ratings yet

- Vinyl AcetateDocument13 pagesVinyl AcetateRahmahPuspitaSariNo ratings yet

- Analytical Chemistry Volume 49 Issue 11 1977 [Doi 10.1021%2Fac50019a033] Brown, Alan P.; Anson, Fred C. -- Cyclic and Differential Pulse Voltammetric Behavior of Reactants Confined to the Electrode SurfaceDocument7 pagesAnalytical Chemistry Volume 49 Issue 11 1977 [Doi 10.1021%2Fac50019a033] Brown, Alan P.; Anson, Fred C. -- Cyclic and Differential Pulse Voltammetric Behavior of Reactants Confined to the Electrode SurfaceMagdalena ArdeleanNo ratings yet

- Density of Liquefied Natural Gas: U. of Krmsas SPE-AIME, U. of KansasDocument9 pagesDensity of Liquefied Natural Gas: U. of Krmsas SPE-AIME, U. of KansasAnonymous Kr13NEBNo ratings yet

- Alkaline PhosphatasesDocument6 pagesAlkaline PhosphatasesMohammed AlMujainiNo ratings yet

- статья №2Document189 pagesстатья №2Jessica WilliamsNo ratings yet

- Dorn 2007Document7 pagesDorn 2007PelagiusNo ratings yet

- Further Studies On Enzyme, Tyrosinase: (1) Keilin and T. MannDocument6 pagesFurther Studies On Enzyme, Tyrosinase: (1) Keilin and T. MannHà ThiNo ratings yet

- Can J Chem Eng - April 1969 - Sheel - Simulation and Optimization of An Existing Ethylbenzene Dehydrogenation ReactorDocument5 pagesCan J Chem Eng - April 1969 - Sheel - Simulation and Optimization of An Existing Ethylbenzene Dehydrogenation ReactorSangHao NgNo ratings yet

- A Cautionary Note On The Use of The Evans Method For Magnetic MeasurementsDocument1 pageA Cautionary Note On The Use of The Evans Method For Magnetic MeasurementskawtherahmedNo ratings yet

- Feick 1954Document3 pagesFeick 1954magdy salehNo ratings yet

- Vapor-Liquid Equilibria Under Elevated Pressures: Diamine-WaterDocument7 pagesVapor-Liquid Equilibria Under Elevated Pressures: Diamine-WaterCsaba AndrásNo ratings yet

- Jcpsa6 9 12 859 1Document5 pagesJcpsa6 9 12 859 1Abiyyi SufyanNo ratings yet

- 5.-Galicia-J. Chem. Eng. Data 2012, 57, 2896 2901 - 5Document6 pages5.-Galicia-J. Chem. Eng. Data 2012, 57, 2896 2901 - 5Moltimer Folchart CrawNo ratings yet

- Can the π−facial selectivity of solvation be predicted by atomistic simulation?Document20 pagesCan the π−facial selectivity of solvation be predicted by atomistic simulation?argoniodideNo ratings yet

- United States Department of The InteriorDocument10 pagesUnited States Department of The InteriorKashilal IndraNo ratings yet

- Solvent E Ffects On Vapor Liquid Equilibria of The Binary System 1 Hexene + N HexaneDocument9 pagesSolvent E Ffects On Vapor Liquid Equilibria of The Binary System 1 Hexene + N HexaneGrinder Hernan Rojas UrcohuarangaNo ratings yet

- Laboratory Report 1: Form and FunctionDocument11 pagesLaboratory Report 1: Form and FunctionJade DesireNo ratings yet

- Artículos para Introducción y DemásDocument6 pagesArtículos para Introducción y DemásCarlos Mario Ortiz MuñozNo ratings yet

- Solving Problems Regarding Vapor-Liquid EquilibriumDocument19 pagesSolving Problems Regarding Vapor-Liquid EquilibriumblessaNo ratings yet

- Fdocuments - Us Stabilization of Methylacetylene and Propadiene MixturesDocument7 pagesFdocuments - Us Stabilization of Methylacetylene and Propadiene MixturesPedro BrandãoNo ratings yet

- Camacho Camacho2007Document6 pagesCamacho Camacho2007Moltimer Folchart CrawNo ratings yet

- Chemesthesis: Chemical Touch in Food and EatingFrom EverandChemesthesis: Chemical Touch in Food and EatingShane T. McDonaldNo ratings yet

- Catalytic Hyrogenation On PD Al2o3Document9 pagesCatalytic Hyrogenation On PD Al2o3Paravastu VinuthaNo ratings yet

- Us 4088569Document7 pagesUs 4088569Paravastu VinuthaNo ratings yet

- Effect of Small Amounts of Nitrogen Compounds in FeedstockDocument9 pagesEffect of Small Amounts of Nitrogen Compounds in FeedstockParavastu VinuthaNo ratings yet

- 2nd Stage Deep Desulphurization of Gas OilsDocument15 pages2nd Stage Deep Desulphurization of Gas OilsParavastu VinuthaNo ratings yet

- Enthalpy and Reaction Rates NotesDocument33 pagesEnthalpy and Reaction Rates NotestausmanNo ratings yet

- Nist SP-1021Document489 pagesNist SP-1021Ada DarmonNo ratings yet

- Iso Astm 51631-13Document9 pagesIso Astm 51631-13Dmitry_ucpNo ratings yet

- CalorimetryDocument54 pagesCalorimetryTrixsha TapsirulNo ratings yet

- Example Kimia Fizik PDFDocument32 pagesExample Kimia Fizik PDFMiaHusnaNo ratings yet

- Bomb CalorimeterDocument5 pagesBomb CalorimeterAbhishek SinghNo ratings yet

- Part II Heat Capacity and CalorimetryDocument47 pagesPart II Heat Capacity and CalorimetryRalph CimanesNo ratings yet

- 3dd028-N05-Fire Test For Quarter-Turn Valves and Valves Equipped With Nonmetallic SeatsDocument16 pages3dd028-N05-Fire Test For Quarter-Turn Valves and Valves Equipped With Nonmetallic SeatsPrathik Yeresh ReddyNo ratings yet

- Detect High Building SP - Report - 2003 - 33Document120 pagesDetect High Building SP - Report - 2003 - 33Böðvar TómassonNo ratings yet

- Energetics Question DatabaseDocument23 pagesEnergetics Question DatabaseKamrul Alam MasumNo ratings yet

- FRITZLER, 2014. Acetic Anhydryde Hydrolysis at High Acetic Anhydride To Water RatiosDocument10 pagesFRITZLER, 2014. Acetic Anhydryde Hydrolysis at High Acetic Anhydride To Water RatiosAnonymous DMjWxgNo ratings yet

- Experiment 12Document9 pagesExperiment 12Sy TamNo ratings yet

- Specific Heat of A Metal Using The Mixture Method ExperimentDocument5 pagesSpecific Heat of A Metal Using The Mixture Method ExperimentAwny HabibNo ratings yet

- Calorimeter Brochure IWS EN PDFDocument19 pagesCalorimeter Brochure IWS EN PDFAhmed IsmailNo ratings yet

- Jespersen 8e Lecture ch06-1Document172 pagesJespersen 8e Lecture ch06-1Lee KaysiaNo ratings yet

- Spesifikasi Dan Gambar Alat Pengadaan Alat Laboratorium Di Gedung I-Cell FtuiDocument14 pagesSpesifikasi Dan Gambar Alat Pengadaan Alat Laboratorium Di Gedung I-Cell Ftuiefendi susantoNo ratings yet

- 10 5923 J Jlce 20170502 01Document6 pages10 5923 J Jlce 20170502 01SanjeevMishraNo ratings yet

- Energetics - CN - STDT3Document2 pagesEnergetics - CN - STDT3NkemziNo ratings yet

- Experiment No.: TITLE HERE: Department of Chemical EngineeringDocument10 pagesExperiment No.: TITLE HERE: Department of Chemical EngineeringCARLO CASTILLONo ratings yet

- TMPC 632 - Mechanical Engineering Lab 1 Lab Report: Lab Experiment #: Lab Activity 2 Submitted By: TMEC 3-2Document6 pagesTMPC 632 - Mechanical Engineering Lab 1 Lab Report: Lab Experiment #: Lab Activity 2 Submitted By: TMEC 3-2Axel Jeremiah ManaloNo ratings yet

- SPH 2173 and SPH 2174 Phyc For Eng 1 and 2 Phyc TIE PDFDocument22 pagesSPH 2173 and SPH 2174 Phyc For Eng 1 and 2 Phyc TIE PDFKenson MutaiNo ratings yet

- The Heat Formation: OF OF DioxideDocument24 pagesThe Heat Formation: OF OF Dioxidevela vanNo ratings yet

- Internal Combustion Engine Lab/heat Engine Lab ExperimentsDocument19 pagesInternal Combustion Engine Lab/heat Engine Lab ExperimentsMathew John0% (2)

- Final Report Exp 3Document11 pagesFinal Report Exp 3Daryl T. CaballeroNo ratings yet

- Ch05 - Lecture PPT-Part 2Document31 pagesCh05 - Lecture PPT-Part 2William AndreasNo ratings yet

- Chm271 - Chapter 2 Thermochemistry - UpdatedDocument68 pagesChm271 - Chapter 2 Thermochemistry - UpdatedNurfarhanah AsyknNo ratings yet

- Calorimetry in Pharmaceutical Research PDFDocument13 pagesCalorimetry in Pharmaceutical Research PDFAndré Luís Della VolpeNo ratings yet

![Analytical Chemistry Volume 49 Issue 11 1977 [Doi 10.1021%2Fac50019a033] Brown, Alan P.; Anson, Fred C. -- Cyclic and Differential Pulse Voltammetric Behavior of Reactants Confined to the Electrode Surface](https://imgv2-1-f.scribdassets.com/img/document/187125064/149x198/1d5b47c140/1385436295?v=1)