Professional Documents

Culture Documents

Material Balance in Froth Flotation Using Microsoft Excel Solver 14

Material Balance in Froth Flotation Using Microsoft Excel Solver 14

Uploaded by

aktivrudarpf1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material Balance in Froth Flotation Using Microsoft Excel Solver 14

Material Balance in Froth Flotation Using Microsoft Excel Solver 14

Uploaded by

aktivrudarpf1Copyright:

Available Formats

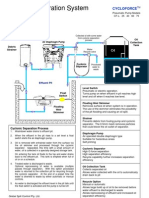

15.

– water

16. – Hydrocyclone feed

17. – Hydrocyclone underflow

18. – Hydrocyclone overflow

19. – Re-cleaner tailing

20.– Cleaner concentrate

21.– Cleaner concentrate launder water addition

22.– Cleaner concentrate pulp

23.– Cleaner tailings

24.– Re-cleaner concentrate

3.2. Operating plant data

Sampling campaign has been done and Table 3 gives data of the operating plant for each flow.

Table 3: Sampling data of the operating plant

Designation SGp Solid mass Pulp volume Water Cu grade

Kg/m3 t/m3 m3/h m3/h %

Feed 1,239 1,243.01 1.93

Scavenger cleaner tailing 1,104 0.88

Rougher concentrate 1,234 14.57

Rougher concentrate launder water addition 2

Rougher tailing 1,256 0.84

Scavenger concentrate 1,152 4.28

Scavenger concentrate launder water addition 4

Scavenger tailing 1,264 0.67

Outlet regrind ball mill

Scavenger cleaner concentrate 1,070 9.49

Scavenger cleaner concentrate launder water addition 5

water

Hydrocyclone feed 1,301 1,275

Hydroclyclone underflow 1,740 7.44

Hydrocyclone overflow 1,123 11.29

Re-cleaner tailing 1,072 1.18

Cleaner concentrate 1,203 19.15

Cleaner concentrate launder water addition 4

Cleaner tailing 1,095 2.57

Re-cleaner concentrate 1,275 23.78

The hydrocyclone feed data come from the control room. In this case, mathematical expression (32)

gives the relationship between solid specific gravity and copper grade. In general for complex ore, solid specific

gravity must be found for each flow by using method explained in chapter 2.

SGs (t/m3) = 0.0005 x (%Cu)2 +0.0259 x (%Cu) + 2.6728 (32)

Joseph Kafumbila

Page 13

You might also like

- Client Name: XXX: Standard Operating ProcedureDocument6 pagesClient Name: XXX: Standard Operating ProcedureEra Enviro Solitions100% (2)

- Case Study of Bhandup Water Treatment Plant: - Project Guide: Satishchandra OzarkarDocument27 pagesCase Study of Bhandup Water Treatment Plant: - Project Guide: Satishchandra OzarkarMAYURESH PATIL100% (1)

- Carbon Dioxide Scrubber RPDocument5 pagesCarbon Dioxide Scrubber RPpassionNo ratings yet

- Industrial Manufacturing of Caustic Soda Flakes at Tamilnadu Petroproducts Ltd.Document59 pagesIndustrial Manufacturing of Caustic Soda Flakes at Tamilnadu Petroproducts Ltd.Hemant Gaule88% (17)

- Equipment ListDocument16 pagesEquipment ListFebri Noval TNo ratings yet

- Process Streams Around Reactor System Stream Names: Liquid Benzene Chlorine Vapour Product Liquid Product MCB DCB Chlorine HCI Water Benzene TotalDocument6 pagesProcess Streams Around Reactor System Stream Names: Liquid Benzene Chlorine Vapour Product Liquid Product MCB DCB Chlorine HCI Water Benzene Totalcarleston thurgoodNo ratings yet

- Accelator: InfilcoDocument4 pagesAccelator: InfilcoVanessa Cervantes CampoNo ratings yet

- Evaluation Statement For Zero PDDocument2 pagesEvaluation Statement For Zero PDAnonymous i3lI9MNo ratings yet

- Chlorosulphonatlon Main Reaction: "Chemical Reactions For Vinyl S Ulph ON EE Ster of Aniline"Document22 pagesChlorosulphonatlon Main Reaction: "Chemical Reactions For Vinyl S Ulph ON EE Ster of Aniline"Ankit PatelNo ratings yet

- Exchanger Cleaning Contest: Chemicals Vs JettingDocument3 pagesExchanger Cleaning Contest: Chemicals Vs JettingDavid Diaz PadillaNo ratings yet

- Machine Load - KCLDocument3 pagesMachine Load - KCLMd HossainNo ratings yet

- Material Stream: 1: ConditionsDocument75 pagesMaterial Stream: 1: Conditionskelvinlauwk99No ratings yet

- 1.03 MLD Sbr-EquipmentDocument3 pages1.03 MLD Sbr-EquipmentHemant KaleNo ratings yet

- Kelani Right Bank Water Treatment Plant Sri LankaDocument11 pagesKelani Right Bank Water Treatment Plant Sri LankaSudeepa SumanasekaraNo ratings yet

- Design of SEPTIC TANK: Water Supply DemandDocument2 pagesDesign of SEPTIC TANK: Water Supply DemandaberraNo ratings yet

- Water Softener Cycles of Operation: Regeneration: BackwashDocument4 pagesWater Softener Cycles of Operation: Regeneration: BackwashJacob LumbNo ratings yet

- Evaporator PDFDocument27 pagesEvaporator PDFMelvin YapwhNo ratings yet

- Mecanica de Fluidos - MOTTDocument16 pagesMecanica de Fluidos - MOTTMarvinJosephDeLaCruzAntaurcoNo ratings yet

- Basic Design of Bna PlantDocument11 pagesBasic Design of Bna Plantmasprie2010100% (1)

- Databank - Centrifugal PumpDocument27 pagesDatabank - Centrifugal PumpnayanNo ratings yet

- NHT Amine Degrease Procedure Rev2Document29 pagesNHT Amine Degrease Procedure Rev2raj kumarNo ratings yet

- 10 1 1 552 4533 PDFDocument17 pages10 1 1 552 4533 PDFmebrahtomNo ratings yet

- Manual of Practice - Sludge Production, Preliminary Treatment and DigestionDocument99 pagesManual of Practice - Sludge Production, Preliminary Treatment and Digestioneva.dewsburyNo ratings yet

- Al Khaleej Water Efficient Refinery 2000Document12 pagesAl Khaleej Water Efficient Refinery 2000roy@daesNo ratings yet

- Pressure Decreases Increase The Amount of Power That A Pump Must Deliver To The FluidDocument40 pagesPressure Decreases Increase The Amount of Power That A Pump Must Deliver To The FluidRiaz JokanNo ratings yet

- Biological Wastewater Treatment Process: Group Members: TutorDocument113 pagesBiological Wastewater Treatment Process: Group Members: TutorkkgbkjNo ratings yet

- AQC FosterDocument2 pagesAQC FosterJuan Carlos GNo ratings yet

- Basic CWT Training For NPP - NPSDocument39 pagesBasic CWT Training For NPP - NPSKookkai NuttimaNo ratings yet

- Mid Evaluation Amine Gas Treating Unit PresentationDocument39 pagesMid Evaluation Amine Gas Treating Unit PresentationAsad PatelNo ratings yet

- HMTDocument16 pagesHMTfreakameNo ratings yet

- Moh Optimisation of Small Drinking Water Treatment Systems 2007 PDFDocument49 pagesMoh Optimisation of Small Drinking Water Treatment Systems 2007 PDFSami Al-aminNo ratings yet

- 200kld STP Proposal FOR Bhumi AssociatesDocument6 pages200kld STP Proposal FOR Bhumi AssociatesTech MongerNo ratings yet

- Pipe Size CalcDocument8 pagesPipe Size CalcNitin KumarNo ratings yet

- Demineralization ADocument30 pagesDemineralization Arahul ranaNo ratings yet

- Fluid Mech ManualDocument75 pagesFluid Mech ManualGANESH KUMARNo ratings yet

- FDP Reservoir DeptDocument11 pagesFDP Reservoir DeptMuhammad Khairul HaziqNo ratings yet

- Material and Energy BalanceDocument18 pagesMaterial and Energy BalanceAADILNo ratings yet

- Amal Jyothi College of Engineering Koovapally P.O., Kanjirapally Department of Chemical EngineeringDocument69 pagesAmal Jyothi College of Engineering Koovapally P.O., Kanjirapally Department of Chemical EngineeringElsyNo ratings yet

- Absorber CH2 Updated IIDocument21 pagesAbsorber CH2 Updated IIAimanNo ratings yet

- 8.23 Evaporator Controls: T. J. Myron B. G. LiptákDocument18 pages8.23 Evaporator Controls: T. J. Myron B. G. LiptákInnerXNo ratings yet

- Mechanical Part - Lesotho ProjectDocument2 pagesMechanical Part - Lesotho ProjectYogesh SonawaneNo ratings yet

- Trickling Filters: Trickling Filter at Al Awir WWTPDocument12 pagesTrickling Filters: Trickling Filter at Al Awir WWTPMostafaNo ratings yet

- Utilities Batch 3Document25 pagesUtilities Batch 3SowmyaNo ratings yet

- HC Flow DiaDocument1 pageHC Flow Diaapi-3703371No ratings yet

- P 00194 Wastewater Plant Design PDFDocument2 pagesP 00194 Wastewater Plant Design PDFabrehamNo ratings yet

- Recovery Plant Summary ReportDocument2 pagesRecovery Plant Summary ReportKGS. MALIK ATA' AL-RAHMANNo ratings yet

- Internship Report For A Water Treatment PlantDocument23 pagesInternship Report For A Water Treatment PlantJanet Bello50% (2)

- Comparison Between MSF and Med TVC ConfigurationsDocument75 pagesComparison Between MSF and Med TVC ConfigurationsmurtadaNo ratings yet

- Baffle and Unbaffled Tanks PDFDocument47 pagesBaffle and Unbaffled Tanks PDFPriyank Raj0% (1)

- Kupper-2018b Methane and Ammonia Emissions From WWTPs Literature ReviewDocument18 pagesKupper-2018b Methane and Ammonia Emissions From WWTPs Literature ReviewljimenaruedaNo ratings yet

- Advantage Mud ManualDocument413 pagesAdvantage Mud ManualSaravana100% (1)

- Cold Water Booster Pump Sizing (Without Flushing) : Loading Units Per ApartmentDocument2 pagesCold Water Booster Pump Sizing (Without Flushing) : Loading Units Per ApartmentMaxmore KarumamupiyoNo ratings yet

- Actiflo Process For Drinking Water TreatmentDocument6 pagesActiflo Process For Drinking Water TreatmentworkingNo ratings yet

- Python ProjectDocument24 pagesPython ProjectSRIMANTH BATTULANo ratings yet

- APTI413 PP Ch8Document65 pagesAPTI413 PP Ch8Stefanos DiamantisNo ratings yet

- Urea-1 PlantDocument34 pagesUrea-1 PlantAjeet SinghNo ratings yet

- Waste WaterDocument9 pagesWaste WaterSanzida IslamNo ratings yet

- WO Hole Cleaning GuidelinesDocument22 pagesWO Hole Cleaning GuidelinespitosadaNo ratings yet

- Cytec Solutions 2013 10Document1 pageCytec Solutions 2013 10aktivrudarpf1No ratings yet

- Material Balance in Froth Flotation Using Microsoft Excel Solver 22Document1 pageMaterial Balance in Froth Flotation Using Microsoft Excel Solver 22aktivrudarpf1No ratings yet

- Material Balance in Froth Flotation Using Microsoft Excel Solver 16Document1 pageMaterial Balance in Froth Flotation Using Microsoft Excel Solver 16aktivrudarpf1No ratings yet

- Material Balance in Froth Flotation Using Microsoft Excel Solver 17Document1 pageMaterial Balance in Froth Flotation Using Microsoft Excel Solver 17aktivrudarpf1No ratings yet

- Material Balance in Froth Flotation Using Microsoft Excel Solver 9Document1 pageMaterial Balance in Froth Flotation Using Microsoft Excel Solver 9aktivrudarpf1No ratings yet

- Material Balance in Froth Flotation Using Microsoft Excel Solver 31Document1 pageMaterial Balance in Froth Flotation Using Microsoft Excel Solver 31aktivrudarpf1No ratings yet

- Material Balance in Froth Flotation Using Microsoft Excel Solver 11Document1 pageMaterial Balance in Froth Flotation Using Microsoft Excel Solver 11aktivrudarpf1No ratings yet

- Material Balance in Froth Flotation Using Microsoft Excel Solver 36Document1 pageMaterial Balance in Froth Flotation Using Microsoft Excel Solver 36aktivrudarpf1No ratings yet

- Material Balance in Froth Flotation Using Microsoft Excel Solver 32Document1 pageMaterial Balance in Froth Flotation Using Microsoft Excel Solver 32aktivrudarpf1No ratings yet

- Material Balance in Froth Flotation Using Microsoft Excel Solver 34Document1 pageMaterial Balance in Froth Flotation Using Microsoft Excel Solver 34aktivrudarpf1No ratings yet

- Material Balance in Froth Flotation Using Microsoft Excel Solver 28Document1 pageMaterial Balance in Froth Flotation Using Microsoft Excel Solver 28aktivrudarpf1No ratings yet

- Material Balance in Froth Flotation Using Microsoft Excel Solver 29Document1 pageMaterial Balance in Froth Flotation Using Microsoft Excel Solver 29aktivrudarpf1No ratings yet

- Material Balance in Froth Flotation Using Microsoft Excel Solver 25Document1 pageMaterial Balance in Froth Flotation Using Microsoft Excel Solver 25aktivrudarpf1No ratings yet

- Material Balance in Froth Flotation Using Microsoft Excel Solver 26Document1 pageMaterial Balance in Froth Flotation Using Microsoft Excel Solver 26aktivrudarpf1No ratings yet

- Aceptance SamplingDocument22 pagesAceptance Samplingjamie04No ratings yet

- Effects of Different Air Pressure On Investment MaterialDocument4 pagesEffects of Different Air Pressure On Investment Materialvarsha ammuNo ratings yet

- Cambridge IGCSE: Additional Mathematics 0606/12Document16 pagesCambridge IGCSE: Additional Mathematics 0606/12Ann Jee TanNo ratings yet

- 7.0 Overview of Vibrational Structural Health Monitoring With Representative Case StudiesDocument9 pages7.0 Overview of Vibrational Structural Health Monitoring With Representative Case Studiesankurshah1986No ratings yet

- LED Light - Datasheet (Philips LED Panel 600x600) PDFDocument2 pagesLED Light - Datasheet (Philips LED Panel 600x600) PDFLit Phen TuNo ratings yet

- S2 CHE2203 Introduction To Fluid TransportDocument10 pagesS2 CHE2203 Introduction To Fluid TransportKing Antonio AbellaNo ratings yet

- Lab Exp. No. 5 FormatDocument10 pagesLab Exp. No. 5 FormatRenielle Mae Marquez VerdeNo ratings yet

- OENG1205 - Creative Engineering CAD: Section 3 Designing A Counter Weight TrebuchetDocument4 pagesOENG1205 - Creative Engineering CAD: Section 3 Designing A Counter Weight TrebuchetAnh PhanNo ratings yet

- Proper and Improper FractionsDocument6 pagesProper and Improper Fractionsellen mae GonatoNo ratings yet

- ReSumo GravitationDocument100 pagesReSumo GravitationwavennNo ratings yet

- String EfficiencyDocument5 pagesString EfficiencyManish KumawatNo ratings yet

- 14Document5 pages14bertinNo ratings yet

- Ray Optics Med EasyDocument12 pagesRay Optics Med Easyakhfar291No ratings yet

- Ancient Philosophy-I-SyllabusDocument2 pagesAncient Philosophy-I-SyllabusFaruk KanlıNo ratings yet

- Pascal'S Principle: Chapter 11 Section 3Document9 pagesPascal'S Principle: Chapter 11 Section 3Niekey JohnNo ratings yet

- Picket Fence LabDocument3 pagesPicket Fence Labapi-236349398No ratings yet

- A Theory of EverythingDocument16 pagesA Theory of EverythinggamahucherNo ratings yet

- Astm D4970 D4970M 22Document3 pagesAstm D4970 D4970M 22Buvanesh WaranNo ratings yet

- 402-Wiring DetailDocument1 page402-Wiring DetailRuchit PavasiyaNo ratings yet

- Feed-Through Terminal Block - SSK 116 KER-EX - 0503057: Key Commercial DataDocument9 pagesFeed-Through Terminal Block - SSK 116 KER-EX - 0503057: Key Commercial DataBinhvvNo ratings yet

- 09 Worksheet 1Document1 page09 Worksheet 1Jr YansonNo ratings yet

- CBSE Class 9 Maths Paper 5Document4 pagesCBSE Class 9 Maths Paper 5Shweta MishraNo ratings yet

- BSEE CurriculumDocument5 pagesBSEE Curriculumkayem14No ratings yet

- TDS en LP27022 - Uf3070Document2 pagesTDS en LP27022 - Uf3070Radovan KovacevicNo ratings yet

- Phys516 2021 Lec 031121Document8 pagesPhys516 2021 Lec 031121LokeshNo ratings yet

- Faceting Made Easy Trevor HannamDocument58 pagesFaceting Made Easy Trevor Hannamابراهيم حمودNo ratings yet

- Q3 Lesson 44 Effects of Force On The Shape of An Object BEVSDocument21 pagesQ3 Lesson 44 Effects of Force On The Shape of An Object BEVSmarieljane IgnaligNo ratings yet

- Failure Analysis Industrial Composite Materials PDFDocument2 pagesFailure Analysis Industrial Composite Materials PDFJenniferNo ratings yet

- Question Bank On Unit ViDocument2 pagesQuestion Bank On Unit ViAayushNo ratings yet

- Reflection of LighttDocument19 pagesReflection of LighttPatrick Jerome SilvanoNo ratings yet