Professional Documents

Culture Documents

Permit Number P240-00-6761810 State Waiting For Verification Lifetime Expires On

Permit Number P240-00-6761810 State Waiting For Verification Lifetime Expires On

Uploaded by

Sagar SharmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Permit Number P240-00-6761810 State Waiting For Verification Lifetime Expires On

Permit Number P240-00-6761810 State Waiting For Verification Lifetime Expires On

Uploaded by

Sagar SharmaCopyright:

Available Formats

Permit number : P240-00-6761810

State : Waiting for verification

Lifetime expires on

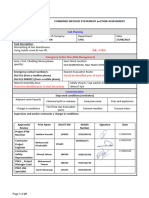

Industrial Cleaning - High

Title Grit blasting of Roof Plates of SP-23 Tank.

Description of work: • Mobilization of Material & Manpower to site

• Site Preparation – Installation of green net with roof reeling for enclosed space

• Grit blasting of Roof plate of SP-23

• Barricade & Removal of green net after grit blasting.

• Housekeeping & Demobilisation

Emergency Information

Muster point Assembly Point

Communication VHF Channel 1, Ext 224

Other Emergency Information Arrange TBM before start of work

Follow the manual handling protocol

Follow the ERP protocol

Details

Planned Start Date: 25 Mar 2024

Planned End Date: 01 Apr 2024

Site: DS T&S East Keamari

Area Authorization DS T&S East Keamari

Work locations: P240 - B - Upper Tank Farm

Equipment description: Storage Tank Terminal B (P240-TANKS_B)

Tank, SP-23 SUPLL (P240-SP23)

Hazardous Substance and Hazardous Area Grit

classification

Work order number:

Work Performer: Naseem and Son

Vehicles, Equipment and Tools to be used Scaffolding Material,, green net, grit , compressor, hopper and other general hand tools

Expected Number of People 15

ICC Requirement Full P240-00-6385660

Is Start Work Check required? No

Selected Checklists: Energy Isolation, Hot Work, Working At Height

Lead Discipline: Maintenance

Initial Gas test by Authorised Person: Yes

Continuous gas monitoring required? No

Influence of nearby activities:

Hazardous Area Classification Zone 1

General comments

Any information entered should not affect the Ensure Gas testing before starting work

assigned risk level, identified hazard/controls Ensure Proper Housekeeping

or permit type:

Initial signatures

P240-00-6761810 25/03/2024 09:25 Page 1 of 47

Type Name: Date: Dep./Company:

Request by Permit Requester Mohammed Arshad 25 Mar 2024 09:24 Naseem & Sons

Signature History

Type Name: Date: Dep./Company: Remarks:

Request by Permit Requester Mohammed Arshad 25 Mar 2024 09:24 Naseem & Sons

P240-00-6761810 25/03/2024 09:25 Page 2 of 47

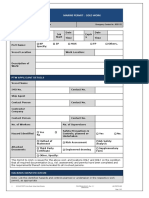

Industrial Cleaning Workpermit

P240-00-6761810

Substances to be measured Carbon Monoxide [CO <35ppm]

Hydrocarbon [LEL <1perc]

Hydrogen Sulphide [H2S <10ppm]

Oxygen [O2 20perc - 21.5perc]

Note - The printed measurement are the last measurement for each substance, entered into Permit Vision

Date Time Substance Value Signer Remarks

P240-00-6761810 25/03/2024 09:25 Page 3 of 47

Keep this record with the PTW paper copy, & display these at the worksite

All members of the work party have participated in the LMRA and are Name of holder

familiar with the Jobscope and Hazard&Controls.

Company

Name Initials Name Initials

Permit number P240-00-6761810

......................... ......................... ......................... .........................

Date

......................... ......................... ......................... .........................

......................... ......................... ......................... ......................... What kind of work are you going to do?

......................... ......................... ......................... ......................... Grit blasting of Roof Plates of SP-23 Tank.

......................... ......................... ......................... .........................

Has the Permit Issuer discussed the hazards & Does the work party know the emergency alarm

controls with the Permit Holder? Yes n/a and action required in event of an alarm or Yes n/a

accident?

Has the Permit Holder warned others that may be

affected by your work? Yes n/a Does the work party know the most effective Yes n/a

escape route and the location of the nearest

muster point?

Is there conflicting work that may affect you? Yes n/a Yes n/a

Does the work party know the location of the

If yes describe hazards and controls below.

nearest eyewash station, emergency shower, first

aid kit and AED device?

Are there additional hazards that need to be controlled? If newly identified hazards are material changes to the permit, contact Permit Issuer!

Hazards Controls / Recovery Measures

.............................................................................................................. ..............................................................................................................

.............................................................................................................. ..............................................................................................................

.............................................................................................................. ..............................................................................................................

Pictograms for key hazards Indicate which Life Saving Rules are applicable.

Bypassing Safety Confined Space Driving

Controls

Obtain authorization Obtain authorization before Follow safe driving rules

FIRE AND MOTION PEOPLE

before overriding or entering a confined space

EXPLOSION

disabling safety controls

Energy Isolation Hot Work Line of Fire

Verify isolation and zero Control flammables and Keep yourself and others out

PRESSURE TOXICS energy before work ignition sources of the line of fire

begins

Safe Mechanical Work Authorisation Working At Height

Lifting

Plan lifting operations and Work with a valid permit Protect yourself against a fall

control the area when required when working at height

P240-00-6761810 25/03/2024 09:25 Page 4 of 47

Start-Work Checks | Energy Isolation

Start Work Authority: Confirm below are in place and verified prior to starting work

Save Your Life Actions Person(s)

Start-Work

All exposed person(s) performing work must confirm each of the action Performing

Verifier

items below Work

(initial)

(initial)

Checklist

I have confirmed:

1 The circuit, system, and/or equipment to be worked on, is identified

in the isolation plan or drawing.

2 All hazardous energy sources have been identified.

3 Isolation points are identified per the isolation plan and/or drawing.

4 Isolation devices are set in the identified position per isolation plan

or drawing.

5 The locks and tags are installed on the equipment/devices per the

isolation plan.

6 Zero energy state has been verified, proven and demonstrated.

Stop and seek help if any of the above controls/safeguards are not in place

Role Printed Name Date

Start -Work Verifier

P240-00-6761810 25/03/2024 09:25 Page 5 of 47

Save Your Life Actions | Energy Isolation

Start Work Authority: I will not start work until I confirm...

Actions How to (examples)

Checklist

1 The circuit, system, and/or equipment to be worked on, is identified in • Tags or markings identify the circuit, system and/or equipment indicated by the isolation plan or drawing.

the isolation plan or drawing.

2 All hazardous energy sources have been identified. • Complete a task risk assessment specific to the scope of work

• Discuss hazards with the work team prior to starting work

• Inspect equipment for potential energy sources (e.g., electrical, pressure, hydraulic, mechanical, etc.)

• Identify and mitigate hazards on any nearby energized circuit/systems/equipment

3 Isolation points are identified per the isolation plan and/or drawing. • All isolations points are in place and tagged or marked (i.e., use isolation diagram, Equipment Isolation Procedure, P&IDs, or Process Flow Diagrams).

4 Isolation devices are set in the identified position per isolation plan or • Valves are open or closed per the diagram and/or plan.

drawing. • Blinds, spades and skillets are:

• stamped or certified for the pressure rating of the equipment.

• installed per the diagram and/or plan

• Electrical isolation points are open/switched off or disconnected from power source

5 The locks and tags are installed on the equipment/devices per the • All isolations are in place and tagged or marked (i.e., use isolation diagram, Equipment Isolation Procedure, P&'IDs, or Process Flow Diagrams).

isolation plan. • Lock out tagout devices are on isolation points

• Keys are in a designated secure location

Note: If a lock is unable to be placed, confirm hazardous energy source(s) points are isolated and secured per isolation plan.

6 Zero energy state has been verified, proven and demonstrated. • Demonstrate powered equipment cannot be started.

• Systems (lines, gauges, etc.) have been tested for residual or stored energy by:

• Check bleed and vent points are open to release stored energy

• Check gauges, measurements & volt meters

Note: If zero energy is not possible, STOP and

• Confirm controls/safeguards are in place, functioning, operated and maintained to manage the risk from residual energy

P240-00-6761810 25/03/2024 09:25 Page 6 of 47

Start-Work Checks | Hot Work

Start Work Authority: Confirm below are in place and verified prior to starting work

Save Your Life Actions Person(s)

Start-Work

All exposed person(s) performing work must confirm each of the action Performing

Verifier

items below Work

(initial)

(initial)

Energy Isolation

I have confirmed:

1 The Hot Work has been evaluated for Energy Isolation requirements.

Does Hot Work require Energy Isolation? If Yes: Complete Energy

Isolation Start-Work Check. If No: Continue to the next step2.

Hot Work

I have confirmed:

2 The hazards have been identified, controlled and it is safe to start.

3 Is the Hot Work in a Hazardous area? If Yes: Confirm the initial gas

test has been completed. If No: Move to Step 5

4 The Hot Work atmosphere will be continually monitored.

5 Ignition sources are identified and controlled.

6 Flammable/combustible materials have been removed or isolated.

Stop and seek help if any of the above controls/safeguards are not in place

Role Printed Name Date

Start -Work Verifier

P240-00-6761810 25/03/2024 09:25 Page 7 of 47

Save Your Life Actions | Hot Work

Start Work Authority: I will not start work until I confirm...

Actions How to (examples)

Energy Isolation

1 The Hot Work has been evaluated for Energy Isolation requirements. • All potential energy sources have been identified, isolated and locked and tagged per isolation plan.

Does Hot Work require Energy Isolation? If Yes: Complete Energy • The system has been drained, flushed, or purged to remove flammable/explosive materials or gases.

Isolation Start-Work Check. If No: Continue to the next step2.

Hot Work

2 The hazards have been identified, controlled and it is safe to start. • Complete a task risk assessment specific to the scope of work

• Discuss hazards with the work team prior to the start of work

• Check for simultaneous operations that may introduce an additional hazards

3 Is the Hot Work in a Hazardous area? If Yes: Confirm the initial gas test • The initial gas test has been completed by a Qualified Gas Tester.

has been completed. If No: Move to Step 5 • At all openings below and above the hot work area

• At a minimum distance around the hot work area

• Gas readings are within the required range

Note: Confirm gas testing outside of defined hazardous area if required for other reasons. Gas testing should be in compliance with company

requirements and applicable regulations.

4 The Hot Work atmosphere will be continually monitored. • Follow-up test frequency is documented (e.g., permit) before starting work.

Note: 'Continually' monitored means periodic monitoring of the atmosphere with a defined frequency or continuous monitoring throughout the duration

of work activities.

5 Ignition sources are identified and controlled. • Barriers are in place to prevent ignition in the hot work area:

•Drains, gaps, openings in tanks or piping have been covered/sealed

•Vents are isolated/routed away from the area

• A trained Fire Watch has been designated and is at the work location.

• Firefighting equipment is inspected, on site and fully functional.

6 Flammable/combustible materials have been removed or isolated. • All flammable/combustible materials have been removed or, if not removed, measures (e.g., fire blankets) are in place to shield them from ignition

sources

P240-00-6761810 25/03/2024 09:25 Page 8 of 47

Start-Work Checks | Working At Height

Start Work Authority: Confirm below are in place and verified prior to starting work

Save Your Life Actions Person(s)

Start-Work

All exposed person(s) performing work must confirm each of the action Performing

Verifier

items below Work

(initial)

(initial)

Checklist

I have confirmed:

1 The hazards are identified, controlled and it is safe to start.

2 My fall protection equipment is: •certified •inspected •rated •fit for

the task

3 The fall protection harness is adjusted to fit.

4 The approved anchor point(s) are in place for 100% tie off.

5 If a fall occurs, the fall path is clear.

6 The tools/materials being used at height are secured.

7 Barriers and drop/exclusion zones are in place.

8 The rescue plan is in place and is ready to be used.

Stop and seek help if any of the above controls/safeguards are not in place

Role Printed Name Date

Start -Work Verifier

P240-00-6761810 25/03/2024 09:25 Page 9 of 47

Save Your Life Actions | Working At Height

Start Work Authority: I will not start work until I confirm...

Actions How to (examples)

Checklist

1 The hazards are identified, controlled and it is safe to start. • Complete a task risk assessment specific to the scope of work

• Discuss hazards with the work team prior to the start of work

• Check for simultaneous operations that may introduce additional hazards

2 My fall protection equipment is: •certified •inspected •rated •fit for the • Fall Protection equipment includes fall arrest and/or fall restraint

task • Full body harness is load rated to support the weight of the worker

• Check every strap, buckle, fitting and/or grommet for signs of wear on fall protection harness.

• Fall arrest system contains a self-retracting lifeline or shock absorbing lanyard

• Fall restraint contains a fixed lifeline configured to prevent the worker from reaching the edge and falling

• Fall arrest is shorter than the potential fall distance

Note: Stop and notify supervisor if the fall protection equipment has excessive wear/damage/mechanical malfunction or is not fit for the task.

3 The fall protection harness is adjusted to fit. • Only full body harnesses are used

• Harness straps are not twisted

• Harness body straps are adjusted for close body fit (i.e., no slack)

Note: Use of body belts is not allowed.

4 The approved anchor point(s) are in place for 100% tie off. • 100% tie off can occur outside of protected areas (such as an elevated work area not enclosed by handrails)

• The anchor point meets regulatory/company requirements

• The position(s) of anchor points allow for 100% tie off

• The number of anchor-points available allow for 100% tie off

• Pull on the connecting device to test if attachment is secure.

Note: Confirm anyone working at height is 100% tied off at all times (e.g., at least one hook must be anchored at all times).

5 If a fall occurs, the fall path is clear. • Fall protection is fit for purpose to protect the worker if they fall

• Fall arrest distance is shorter than fall distance to first obstruction

• If the worker is likely to swing, check that the path is free of obstructions

• Mobile obstructions have been removed from fall path

6 The tools/materials being used at height are secured. • Tools used at heights have securing wire/lanyards/tethers

• Materials used at height are secured in storage boxes, pouches, bags etc.

• Cover openings to lower levels (e.g., grating, gaps etc.) or use debris nets

Note: Follow the site/company dropped object prevention program (e.g., Work at Height tool register)

7 Barriers and drop/exclusion zones are in place. • Identify drop/exclusion zones

• Control access to drop/exclusion zones during work at height (e.g., attendant or physical barriers)

8 The rescue plan is in place and is ready to be used. • The rescue plan has been discussed, including:

• how to start the rescue response for person(s) in the water

• location of rescue equipment (i.e. fast rescue craft, pole hooks, life rings)

• The rescue crew:

• is available

• is aware of specific hazards related to this rescue

• can execute the rescue plan for the environment (e.g. stationary vs moving vessels, fixed dock / jetty, water flow/current, sea state)

• Escape routes are unobstructed

P240-00-6761810 25/03/2024 09:25 Page 10 of 47

RA/JHA P240-00-6761813

Attached to: Permit P240-00-6761810

Title: Grit blasting of Roof Plates of SP-23 Tank.

Team: Mohammed Arshad, Shaikh Ayyaz Rehman, Shariq Ahmed Approval:

Task steps Hazards Control measures Action party

Mobilization of Material & [.PE.05] Fatigue (PEOPLE) [.PE.05.02] Prior to start of work request work party to self S Permit Holder

Manpower to site report if they are suffering from fatigue

[.PE.05.04] Monitor for signs of fatigue and intervene/stop work S Permit Holder

if necessary.

Ensure proper rest breaks S Permit Holder

[.PE.07] Hazardous Weather (PEOPLE) [.PE.07.02] Set weather limitations (lightning, rain, wind speed) S Permit Holder

and stop work when limit is exceeded.

[DS T&S - East PE.02] COVID-19 virus (PEOPLE) [DS T&S - East PE.02.01] No worker on site with symptom/s of S Permit Holder

COVID-19 (cough, colds, fever, shortness of breath, diarrhea,

sore throat)

[DS T&S - East PE.02.05] Thoroughly wash hands for at least S Permit Holder

20 sec before entering the terminal, before and after

break/lunch, after going to restroom, and leaving the site.

[DS T&S - East PE.02.06] Cover your mouth and nose with your S Permit Holder

covered wrist or tissue when you cough or sneeze

[DS T&S - East PE.02.07] Avoid touching your eyes, nose, or S Permit Holder

mouth

[.MO.12] Slips & Trips (MOTION) [.MO.12.01] Remove any trip hazards in the area, clean up any S Permit Holder

spills, wear anti-slip safety shoes

Ensure proper housekeeping S Permit Holder

Site Preparation – [.PE.01] Communication (PEOPLE) [.PE.01.01] During permit issuance and toolbox talk/Last Minute S Permit Holder

Installation of green net Risk Assessment discuss and agree the methods of

with roof reeling for communication within the work party, with Operations (if

enclosed space necessary) and with Emergency Responders (if necessary)

[.PE.07] Hazardous Weather (PEOPLE) [.PE.07.02] Set weather limitations (lightning, rain, wind speed) S Permit Holder

and stop work when limit is exceeded.

[.MO.05] Hand Tools - ALL (MOTION) [.MO.05.01] Flogging spanners are prohibited from use S Permit Holder

[.MO.05.02] The use of knives is prohibited S Permit Holder

[.MO.05.03] Wear appropriate hand protection suitable for task S Permit Holder

P240-00-6761810 25/03/2024 09:25 Page 11 of 47

RA/JHA P240-00-6761813

Attached to: Permit P240-00-6761810

Don't use damage tools and equipment S Permit Holder

[.MO.12] Slips & Trips (MOTION) [.MO.12.01] Remove any trip hazards in the area, clean up any S Permit Holder

spills, wear anti-slip safety shoes

Ensure proper housekeeping S Permit Holder

Grit blasting of complete [.PE.08] Noise (PEOPLE) Ensure ear plugs during grit blasting work S Permit Holder

Roof of SP-23

[.PE.01] Communication (PEOPLE) [.PE.01.01] During permit issuance and toolbox talk/Last Minute S Permit Holder

Risk Assessment discuss and agree the methods of

communication within the work party, with Operations (if

necessary) and with Emergency Responders (if necessary)

[.MO.12] Slips & Trips (MOTION) [.MO.12.01] Remove any trip hazards in the area, clean up any S Permit Holder

spills, wear anti-slip safety shoes

Ensure proper housekeeping on daily basis S Permit Holder

[.MO.05] Hand Tools - ALL (MOTION) [.MO.05.03] Wear appropriate hand protection suitable for task S Permit Holder

Ensure proper PPEs suitable with the task S Permit Holder

[.TO.06] Dust, fume and Contaminants (TOXICS) [.TO.06.09] Ensure general ventilaton sufficient S Permit Holder

Ensure Proper dust mask S Permit Holder

Ensure KN-95 mask during painting work S Permit Holder

[.PR.01] Abrasive blasting (PRESSURE) [.PR.01.03] Erect a temporary enclosure around the open air S Permit Holder

blasting operation

Ensure Blasting hood during blasting activity S Permit Holder

● Ensure Ear Muffs during grit blasting for noise hazard

● Ensure Proper Dust Masks during grit blasting activity

● Ensure Area barricading & Safety Signage’s on site

● Ensure Housekeeping on site on daily basis

● Ensure Blasting unit is third party certified

[.PE.03] Emergency Response (PEOPLE) [.PE.03.01] A job specific emergency response plan must be S Permit Holder

available. The plan must be reviewed and understood by the

work party. The plan should include: Notifications, Roles and

Responsibilities, Initial Actions, Equipment and General Tactics

[.PE.05] Fatigue (PEOPLE) [.PE.05.02] Prior to start of work request work party to self S Permit Holder

report if they are suffering from fatigue

[.PE.05.04] Monitor for signs of fatigue and intervene/stop work S Permit Holder

if necessary.

Ensure proper rest breaks S Permit Holder

P240-00-6761810 25/03/2024 09:25 Page 12 of 47

RA/JHA P240-00-6761813

Attached to: Permit P240-00-6761810

[.PE.07] Hazardous Weather (PEOPLE) [.PE.07.02] Set weather limitations (lightning, rain, wind speed) S Permit Holder

and stop work when limit is exceeded.

[.MO.11] Sharp, abrasive objects (MOTION) Use cut resistant gloves S Permit Holder

[.FL.01] Flammable Materials - All (FIRE AND EXPLOSION) [.FL.01.01] A Fire Extinguisher shall be located at the work site. S Permit Holder

[.FL.01.06] Flammable and combustible material shall be S Permit Holder

removed and verified as hazard free from work area (including

void spaces and pockets of potential trapped material) and

surrounding area

Maintain a competent fire watch throughout the hot work. The S Permit Holder

fire Watch shall wear a High Visibility Vest

Removal of Barrications [.MO.12] Slips & Trips (MOTION) [.MO.12.01] Remove any trip hazards in the area, clean up any S Permit Holder

& green net after grit spills, wear anti-slip safety shoes

blasting.

[.PE.05] Fatigue (PEOPLE) [.PE.05.02] Prior to start of work request work party to self S Permit Holder

report if they are suffering from fatigue

[.PE.05.04] Monitor for signs of fatigue and intervene/stop work S Permit Holder

if necessary.

Ensure proper rest breaks S Permit Holder

[.PE.01] Communication (PEOPLE) [.PE.01.01] During permit issuance and toolbox talk/Last Minute S Permit Holder

Risk Assessment discuss and agree the methods of

communication within the work party, with Operations (if

necessary) and with Emergency Responders (if necessary)

[.MO.05] Hand Tools - ALL (MOTION) [.MO.05.01] Flogging spanners are prohibited from use S Permit Holder

[.MO.05.02] The use of knives is prohibited S Permit Holder

[.MO.05.03] Wear appropriate hand protection suitable for task S Permit Holder

Never use damage tools and equipment S Permit Holder

Housekeeping & [.PE.07] Hazardous Weather (PEOPLE) [.PE.07.02] Set weather limitations (lightning, rain, wind speed) S Permit Holder

Demobilization and stop work when limit is exceeded.

[.MO.12] Slips & Trips (MOTION) [.MO.12.01] Remove any trip hazards in the area, clean up any S Permit Holder

spills, wear anti-slip safety shoes

[.MO.11] Sharp, abrasive objects (MOTION) Use cut resistant gloves S Permit Holder

P240-00-6761810 25/03/2024 09:25 Page 13 of 47

Isolation Certificate

ICC Number : P240-00-6385660

State : Isolation in place (Live)

Isolation Confirmation Certificate

Title Internal cleaning of NDP Tank SP-23

Reason for isolation 1. Mobilization of material and manpower to site Manually

2. Verify isolation & Gas testing

3. Installation of exhaust fan for forced ventilation & gas free

4. Internal Cleaning of Tank SP-23 Manually & Moping

5. After cleaning inspection will be done

6. Housekeeping

Details

Site DS T&S East Keamari

Working location P240 - B - Upper Tank Farm

Equipment description Keamari Terminal (P240)

Minimum Isolation Method required

Signature History

Type Name: Date: Remarks

Verify Isolation in place by Isolation Verifier Mirza Zeeshan Baig 26 Dec 2023 11:08

Isolate electrical low voltage isolation points by Isolation Owner (Electrical Low Voltage) Mirza Zeeshan Baig 26 Dec 2023 11:08

Isolate electrical low voltage isolation points by Isolation Owner (Electrical Low Voltage) Mirza Zeeshan Baig 26 Dec 2023 11:08

Isolate electrical low voltage isolation points by Isolation Owner (Electrical Low Voltage) Mirza Zeeshan Baig 26 Dec 2023 11:08

Isolate electrical low voltage isolation points by Isolation Owner (Electrical Low Voltage) Mirza Zeeshan Baig 26 Dec 2023 11:08

Isolate mechanical isolation points by Isolation Owner (Mech) Mirza Zeeshan Baig 26 Dec 2023 11:08

Isolate mechanical isolation points by Isolation Owner (Mech) Mirza Zeeshan Baig 26 Dec 2023 11:08

Isolate mechanical isolation points by Isolation Owner (Mech) Mirza Zeeshan Baig 26 Dec 2023 11:08

Isolate mechanical isolation points by Isolation Owner (Mech) Mirza Zeeshan Baig 26 Dec 2023 11:08

P240-00-6761810 25/03/2024 09:25 Page 14 of 47

Isolate mechanical isolation points by Isolation Owner (Mech) Mirza Zeeshan Baig 26 Dec 2023 11:08

Isolate mechanical isolation points by Isolation Owner (Mech) Mirza Zeeshan Baig 26 Dec 2023 11:08

Isolate mechanical isolation points by Isolation Owner (Mech) Mirza Zeeshan Baig 26 Dec 2023 11:08

Isolate mechanical isolation points by Isolation Owner (Mech) Mirza Zeeshan Baig 26 Dec 2023 11:08

Authorise by Isolation Authoriser Mirza Zeeshan Baig 26 Dec 2023 11:05

Verify by Isolation Verifier Mirza Zeeshan Baig 26 Dec 2023 11:05

Electrical low voltage isolation request by Isolation Owner (Electrical Low Voltage) Mohammad Anis 26 Dec 2023 11:05

Mechanical isolation request by Isolation Owner (Mech) Mohammad Anis 26 Dec 2023 11:05

Verify by Isolation Verifier Shahnawaz Khan 26 Dec 2023 10:40

(reverted)

Electrical low voltage isolation request by Isolation Owner (Electrical Low Voltage) Mohammad Anis 26 Dec 2023 09:58

(reverted)

Mechanical isolation request by Isolation Owner (Mech) Mohammad Anis 26 Dec 2023 09:57

(reverted)

P240-00-6761810 25/03/2024 09:25 Page 15 of 47

Isolation Scheme

Nr. PT ID Isolation Point Comments Type Method(s) Current State De-isolated Isolated lockout box Lockout UTI

state state no Key

1 1 250-p08-178B-11011 dispatch line Blind installed Mechanical Spade/Blind (Installed / Installed Removed Installed 23-11

Removed)

2 2 Vg-901B receipt line Blind intalled Mechanical Spade/Blind (Installed / Installed Removed Installed 23-12

Removed)

3 3 VG-334B Drain line valve Mechanical Spade/Blind (Installed / Installed Removed Installed 23-13

Removed)

4 4 Iso Valve, VG-320B 08-TRV-011B Mechanical Spade/Blind (Installed / Installed Removed Installed 23-14

(+300000341371) Removed)

5 5 Iso Valve, VG-326B T-0806B Mechanical Spade/Blind (Installed / Installed Removed Installed 23-15

(+300000373058) Removed)

6 6 Iso Valve, VG-779B 08-TRV-012B Mechanical Spade/Blind (Installed / Installed Removed Installed 23-16

(+300000341376) Removed)

7 7 VC-015B nrv Mechanical Spade/Blind (Installed / Installed Removed Installed 23-17

Removed)

8 8 Foam Non-Return Valve, VC-115B Mechanical Spade/Blind (Installed / Installed Removed Installed 23-18

SP-23 (+300000341531) Removed)

9 9 Level Gauge, 08-LG-2301B SP-23 Electrical Low Cable Connections Disconnected Connected Disconnec P-11

(+300000333863) Voltage (Disc / Conn) ted

10 10 Pressure Ind Trans, 08-PIT-2301B Electrical Low Cable Connections Disconnected Connected Disconnec P-12

SP-23 (+300000255751) Voltage (Disc / Conn) ted

11 11 Level Transmitter, 08-LT-2301B ATG Electrical Low Cable Connections Disconnected Connected Disconnec P-13

SP-23 (+300000255750) Voltage (Disc / Conn) ted

12 12 Level Switch HH, 08-LSHH-2301B Electrical Low Cable Connections Disconnected Connected Disconnec P-14

SP-23 (+300000195547) Voltage (Disc / Conn) ted

P240-00-6761810 25/03/2024 09:25 Page 16 of 47

De-Isolation Scheme

Nr. PT ID Isolation Point Comments Type Method(s) Current State De-isolated Isolated lockout box Lockout UTI

state state no Key

1 12 Level Switch HH, 08-LSHH-2301B Lock# E112 Electrical Low Cable Connections Disconnected Connected Disconnec P-14

SP-23 (+300000195547) Voltage (Disc / Conn) ted

2 11 Level Transmitter, 08-LT-2301B Lock# E113 Electrical Low Cable Connections Disconnected Connected Disconnec P-13

ATG SP-23 (+300000255750) Voltage (Disc / Conn) ted

3 10 Pressure Ind Trans, 08-PIT-2301B Lock# E114 Electrical Low Cable Connections Disconnected Connected Disconnec P-12

SP-23 (+300000255751) Voltage (Disc / Conn) ted

4 9 Level Gauge, 08-LG-2301B SP-23 Lock# E115 Electrical Low Cable Connections Disconnected Connected Disconnec P-11

(+300000333863) Voltage (Disc / Conn) ted

5 8 Foam Non-Return Valve, VC-115B Positive Isolated Tag# P-23-11 Mechanical Spade/Blind (Installed / Installed Removed Installed 23-18

SP-23 (+300000341531) Removed)

6 7 VC-015B nrv Positive Isolated Tag# P-23-12 Mechanical Spade/Blind (Installed / Installed Removed Installed 23-17

Removed)

7 6 Iso Valve, VG-779B 08-TRV-012B Positive Isolated Tag# P-23-13 Mechanical Spade/Blind (Installed / Installed Removed Installed 23-16

(+300000341376) Removed)

8 5 Iso Valve, VG-326B T-0806B Positive Isolated Tag# P-23-14 Mechanical Spade/Blind (Installed / Installed Removed Installed 23-15

(+300000373058) Removed)

9 4 Iso Valve, VG-320B 08-TRV-011B Positive Isolated Tag# P-23-15 Mechanical Spade/Blind (Installed / Installed Removed Installed 23-14

(+300000341371) Removed)

10 3 VG-334B Drain line valve Positive Isolated Tag# P-23-16 Mechanical Spade/Blind (Installed / Installed Removed Installed 23-13

Removed)

11 2 Vg-901B receipt line Positive Isolated Tag# P-23-17 Mechanical Spade/Blind (Installed / Installed Removed Installed 23-12

Removed)

12 1 250-p08-178B-11011 dispatch line Positive Isolated Tag# P-23-18 Mechanical Spade/Blind (Installed / Installed Removed Installed 23-11

Removed)

P240-00-6761810 25/03/2024 09:25 Page 17 of 47

Date: 30th May, 2023 CERTIFICATE OF TRAINING

Ref No: ENV/N&S/WAHR/HSE/004/23

This Certificate is awarded to

Mr. Aziz KHAN

42000-0391388-5

Of

NASEEM & SON

For completing the course

Certificate No: ENV-N&S-WAHR-004-23

WORK AT HEIGHT & RESCUER

From

The ENV International, Pakistan

At SHELL LOBP KEMARI

Karachi - Pakistan

REMARKS: This certificate is issued after theoretical and practical evaluation of the individual. Where refresher session

Head of Inspection, Training &

is recommended after 01 year.

Certification

P240-00-6761810 25/03/2024 09:25 Page 18 of 47

The ENV International, Pakistan

S# 22, Faqeer Muhammad Goth, Opposite

Fast National University Bin Qasim Landhi Karachi- Pakistan

P: 021-34512244 | C: 0300-0062244

E: info@env.com.pk | W: http://www.env.com.pk

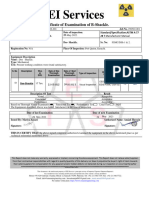

Inspection Certificate Of Sandblasting Unit

Client: Naseem & Son

Location: LOBP Kemari Terminal Karachi

Job reference: ENV/NS/0104/22

Inspection Date: 06th Dec, 2023

Next Inspection Date: 05th Dec, 2024

Code & Standard: OSHA -

Manufacturer & Year : AIRMAN P0707

Inspection Object: Compressor, Hooper, Hose Pipe

Certificate No.: ENV/NS/SBC-01/22

Over View of Sandblasting Unit

This document is issued by the The ENV International. Attention is drawn to the limitation of liability, indemnification and jurisdiction issues defined therein. Any other holder of this

document is advised that information contained hereon reflects the Company’s findings at the time of its intervention only and within the limits of Client’s instructions, if any. The

Company’s sole responsibility is to its Client and this document does not exonerate parties to a transaction from exercising all their rights and obligations under the transaction documents.

Any unauthorized alteration, forgery or falsification of the content or appearance of this document is unlawful and offenders may be prosecuted to the fullest extent of the law.

The ENV International, Pakistan

P240-00-6761810 S# 22, Faqeer Muhammad Goth,25/03/2024

Opposite, Fast09:25

National University Bin Qasim Landhi Karachi- Pakistan Page 19 of 47

P: 021-34512244 | C: 0300-0062244, E: info@env.com.pk | W: http://www.env.com.pk

The ENV International, Pakistan

S# 22, Faqeer Muhammad Goth, Opposite

Fast National University Bin Qasim Landhi Karachi- Pakistan

P: 021-34512244 | C: 0300-0062244

E: info@env.com.pk | W: http://www.env.com.pk

Inspection Activities:

Visual check of Hooper was carried out on the basis of its apparent condition.

1. Over all condition of the sandblasting unit found satisfactory.

2. Battery of the compressor was also found satisfactory along with its terminal.

3. Tire pressure was not proper inflated that has to be inflated at all time.

4. All pressure gauges of the compressor found satisfactory.

This document is issued by the The ENV International. Attention is drawn to the limitation of liability, indemnification and jurisdiction issues defined therein. Any other holder of this

document is advised that information contained hereon reflects the Company’s findings at the time of its intervention only and within the limits of Client’s instructions, if any. The

Company’s sole responsibility is to its Client and this document does not exonerate parties to a transaction from exercising all their rights and obligations under the transaction documents.

Any unauthorized alteration, forgery or falsification of the content or appearance of this document is unlawful and offenders may be prosecuted to the fullest extent of the law.

The ENV International, Pakistan

P240-00-6761810 S# 22, Faqeer Muhammad Goth,25/03/2024

Opposite, Fast09:25

National University Bin Qasim Landhi Karachi- Pakistan Page 20 of 47

P: 021-34512244 | C: 0300-0062244, E: info@env.com.pk | W: http://www.env.com.pk

The ENV International, Pakistan

S# 22, Faqeer Muhammad Goth, Opposite

Fast National University Bin Qasim Landhi Karachi- Pakistan

P: 021-34512244 | C: 0300-0062244

E: info@env.com.pk | W: http://www.env.com.pk

5. Spark arrestor was also installed at the compressor.

6. Condition of the hose pipe of compressor was found satisfactory

7. Overall condition of hooper hose was found satisfactory.

This document is issued by the The ENV International. Attention is drawn to the limitation of liability, indemnification and jurisdiction issues defined therein. Any other holder of this

document is advised that information contained hereon reflects the Company’s findings at the time of its intervention only and within the limits of Client’s instructions, if any. The

Company’s sole responsibility is to its Client and this document does not exonerate parties to a transaction from exercising all their rights and obligations under the transaction documents.

Any unauthorized alteration, forgery or falsification of the content or appearance of this document is unlawful and offenders may be prosecuted to the fullest extent of the law.

The ENV International, Pakistan

P240-00-6761810 S# 22, Faqeer Muhammad Goth,25/03/2024

Opposite, Fast09:25

National University Bin Qasim Landhi Karachi- Pakistan Page 21 of 47

P: 021-34512244 | C: 0300-0062244, E: info@env.com.pk | W: http://www.env.com.pk

The ENV International, Pakistan

S# 22, Faqeer Muhammad Goth, Opposite

Fast National University Bin Qasim Landhi Karachi- Pakistan

P: 021-34512244 | C: 0300-0062244

E: info@env.com.pk | W: http://www.env.com.pk

8. There is No such abnormal noise and leakage found in the compressor engine.

9. Overall condition of the hooper was found satisfactory.

10. Dead man switch was found satisfactory.

This document is issued by the The ENV International. Attention is drawn to the limitation of liability, indemnification and jurisdiction issues defined therein. Any other holder of this

document is advised that information contained hereon reflects the Company’s findings at the time of its intervention only and within the limits of Client’s instructions, if any. The

Company’s sole responsibility is to its Client and this document does not exonerate parties to a transaction from exercising all their rights and obligations under the transaction documents.

Any unauthorized alteration, forgery or falsification of the content or appearance of this document is unlawful and offenders may be prosecuted to the fullest extent of the law.

The ENV International, Pakistan

P240-00-6761810 S# 22, Faqeer Muhammad Goth,25/03/2024

Opposite, Fast09:25

National University Bin Qasim Landhi Karachi- Pakistan Page 22 of 47

P: 021-34512244 | C: 0300-0062244, E: info@env.com.pk | W: http://www.env.com.pk

The ENV International, Pakistan

S# 22, Faqeer Muhammad Goth, Opposite

Fast National University Bin Qasim Landhi Karachi- Pakistan

P: 021-34512244 | C: 0300-0062244

E: info@env.com.pk | W: http://www.env.com.pk

11. Presssure test of hoses was also found satisfactory.

12. Breathing face shield hood was found satisfactory but inside of the hood foam filter on air pipe can be installed for more

efficient work.

Findings: No significant defects were observed during visual examination.

Note: Based on Visual Examination found satisfactory. (Fit for intended use)

Prepared By Approved By

Atif Zaman Muhammad Sadiq

This document is issued by the The ENV International. Attention is drawn to the limitation of liability, indemnification and jurisdiction issues defined therein. Any other holder of this

document is advised that information contained hereon reflects the Company’s findings at the time of its intervention only and within the limits of Client’s instructions, if any. The

Company’s sole responsibility is to its Client and this document does not exonerate parties to a transaction from exercising all their rights and obligations under the transaction documents.

Any unauthorized alteration, forgery or falsification of the content or appearance of this document is unlawful and offenders may be prosecuted to the fullest extent of the law.

The ENV International, Pakistan

P240-00-6761810 S# 22, Faqeer Muhammad Goth,25/03/2024

Opposite, Fast09:25

National University Bin Qasim Landhi Karachi- Pakistan Page 23 of 47

P: 021-34512244 | C: 0300-0062244, E: info@env.com.pk | W: http://www.env.com.pk

FIRE WATCH TRAINING

Date: 01th Dec, 2022

Ref No: ENV/N&S/FWT/HSE/018/22 CERTIFICATE OF TRAINING

This Certificate is awarded to

Mr. Bakshi ROWAN

Of

NASEEM & SON

Certificate No: ENV-N&S-018-22

For completing the course

From

The ENV International, Pakistan

At SHELL LOBP KEMARI

Karachi - Pakistan

REMARKS: This certificate is issued after theoretical and practical evaluation of the individual. Where refresher session

Head of Inspection, Training &

is recommended after 01 year.

Certification

P240-00-6761810 25/03/2024 09:25 Page 24 of 47

Emergency Response Plan

Naseem & Son

(ERP)

Naseem & Son

Emergency Response Plan

Scope:

Rescue Plan for Ground Level Activity

Emergency during working at height

Emergency of fire at work place / alarms sounds

Emergency during confined space (CS)

P240-00-6761810 25/03/2024 09:25 Page 25 of 47

Emergency Response Plan

(ERP)

Naseem & SON

Emergency Response/ Rescue Plan for Ground Level

Activity

Procedure for rescuing a suspended worker:

• All work will be immediately stopped

• Make verbal contact with the employee to help him stay calm

• The rescuers will start the rescue operation while the on-duty supervisor will inform the

Emergency Response Coordinators and the First Aid Team

• Meanwhile the rescuers took the charge for the few times to control the situation and respond to effected or

victim worker

• If the condition is normal so the work will resume after the short break of freshness.

• If something seems to be abnormal or any unsatisfied condition or the victim is not responding

• So, the rescuers will ease the victim into the stretcher.

• The victim will be sat on the ground for 15 minutes with his legs stretched W Shape to avoid

any impacts from trauma

• The first aid team will provide first aid to the victim and if needed, the victim may be

transported to a nearby hospital

• Before shifting victim to hospital inform to terminal in charge

• The supervisor will consult the ERP before resuming any activity

Rescue Team:

Aqil shah, Aziz khan, Qaim Shah

Rescue Equipment:

• Stretcher

• First aid kit

P240-00-6761810 25/03/2024 09:25 Page 26 of 47

Emergency Response Plan

(ERP)

Naseem & SON

Emergency Response/ Rescue Plan for Working at Height

Emergency Response/ Rescue Plan forWorking at Height

Procedure for rescuing a suspended worker:

• All work will be immediately stopped

• Make verbal contact with the employee to help him stay calm

• The rescuers will start the rescue operationwhile the on-duty supervisor will inform the

Emergency Response Coordinators and the First Aid Team

• 2 rescuers wearing safety harness will climb up to the platform with stretcher

• They will attach the stretcher with one end of the lifeline

• The rescuerson the scaffold will then release the D-ring of victim’s harness to free him from

the lanyard

• The 2 on-ground rescuers will confirm thatthey have full control of the lifeline and that the

lifeline is successfully supporting the victim

• The rescuers will ease the victim into the stretcher

• The on-ground rescuers will gradually lower the victim to the ground level

• The victim will be sat on the ground for 15 minutes with his legs stretched W Shape to avoid

any impacts from fall trauma

• The first aidteam will provide first aid to the victim and if needed, the victim may be

transported to a nearby hospital

• Before shifting victim to hospital inform to terminal incharge

• The supervisor will consult the ERP before resuming any activity

Rescue Team:

• Qaim Shah(Lifeline Operator) All the time will be on ground

• Mirwas Khan(Lifeline Operator) All the time will be on ground

• Sheraz Khan(Rescue at Roof)

• Aziz Khan(Rescue at Roof)

Rescue Equipment:

• Lifeline attached to a pulley mounted on the top of the fixed structure

• Stretcher

• 2 sets of safety harness for rescuers

• First aid kit

P240-00-6761810 25/03/2024 09:25 Page 27 of 47

Emergency Response Plan

(ERP)

Naseem & SON

Alternative Incident

Commander / First Incident Commander

Aider

Arshad

Qaim Shah

One Worker At call

Worker to move

Fire watch point (communication

stretcher

coordinator)

Rehman/Bakshi

Workers

Arshad

Worker to Move

Stretcher

Aqil & Aziz Khan

Sr. Details Contact #

1.

Project Manager 0300-2149743

2.

Alternative Incident Commander Qaim Shah

3.

Incident Commander 0315-2558624

4. One Worker At Call Point

( Communication coordinator) 0315-2558624

5.

Ambulance 115

6.

Police 15

7.

Fire DEPT 16

8.

Ranger’s Helpline 1101

9.

First Aider Abdul Rehman/ Sheraz

P240-00-6761810 25/03/2024 09:25 Page 28 of 47

Emergency Response Plan

(ERP)

Naseem & SON

Fire / Evacuation

Emergency Procedure

Laydown Area / Temporary site facilities

IN CASE OF EMERGENCY CONTROLLED EVACUATION

1. Leave the area and close doors In Non-fire situations threatening safety, such as

2. Activate wall mounted fire alarm building services interruption or hazardous

3. Fire watcher will extinguish fire or another material spill, building are evacuated underperson if he can

do direction of fire warden and emergency response

4. Report any information about fire to Shell team. The fire alarm should not be used toFIRE and

Safety Department evacuates a building without approval.

IF YOU AREON FIRE IF UNABLE TO EVACUATE

STOP where you are, DROP to floor or ground Call Emergency Number or VFX-224 & 225

and ROLL your body to smother the fire. Shell Emergency Number and N&S ERP

fire watcher will contain the fire Administration for emergency.

On spot by using fire extinguisher.

WHENFIRE ALRMSOUNDS

1. Calmly evacuate the building / container and Proceed to Assembly Point

3. Use an alternate route, if you encounter smoke or fire.

4. Follow instruction of emergency response services and fire wardens.

5. Report any one suspected remaining in the facility.

6. Reach to the assembly point leaving clear access foremergency services

7. Do not re-enteruntil authorized by fire / HSSE Department

P240-00-6761810 25/03/2024 09:25 Page 29 of 47

P240-00-6761810 25/03/2024 09:25 Page 30 of 47

Date: 30th May, 2023 CERTIFICATE OF TRAINING

Ref No: ENV/N&S/WAHR/HSE/007/23

This Certificate is awarded to

Mr. Aqil Farhan SHAH

42401-6207713-1

Of

NASEEM & SON

Certificate No: ENV-N&S-WAHR-007-23

For completing the course

WORK AT HEIGHT & RESCUER

From

The ENV International, Pakistan

At SHELL LOBP KEMARI

Karachi - Pakistan

REMARKS: This certificate is issued after theoretical and practical evaluation of the individual. Where refresher session

Head of Inspection, Training &

is recommended after 01 year.

Certification

P240-00-6761810 25/03/2024 09:25 Page 31 of 47

P240-00-6761810 25/03/2024 09:25 Page 32 of 47

P240-00-6761810 25/03/2024 09:25 Page 33 of 47

P240-00-6761810 25/03/2024 09:25 Page 34 of 47

P240-00-6761810 25/03/2024 09:25 Page 35 of 47

P240-00-6761810 25/03/2024 09:25 Page 36 of 47

P240-00-6761810 25/03/2024 09:25 Page 37 of 47

FIRE WATCH TRAINING

Date: 01th Dec, 2022

Ref No: ENV/N&S/FWT/HSE/016/22 CERTIFICATE OF TRAINING

This Certificate is awarded to

Mr. Abdul REHMAN

Of

NASEEM & SON

Certificate No: ENV-N&S-016-22

For completing the course

From

The ENV International, Pakistan

At SHELL LOBP KEMARI

Karachi - Pakistan

REMARKS: This certificate is issued after theoretical and practical evaluation of the individual. Where refresher session

Head of Inspection, Training &

is recommended after 01 year.

Certification

P240-00-6761810 25/03/2024 09:25 Page 38 of 47

FIRST AID TRAINING

Date: 01th Dec, 2022

Ref No: ENV/N&S/FAT/HSE/022/22 CERTIFICATE OF TRAINING

This Certificate is awarded to

Mr. Sheroz KHAN

Of

NASEEM & SON

Certificate No: ENV-N&S-022-22

For completing the course

From

The ENV International, Pakistan

At SHELL LOBP KEMARI

Karachi - Pakistan

REMARKS: This certificate is issued after theoretical and practical evaluation of the individual. Where refresher session

Head of Inspection, Training &

is recommended after 01 year.

Certification

P240-00-6761810 25/03/2024 09:25 Page 39 of 47

FIRST AID TRAINING

Date: 01th Dec, 2022

Ref No: ENV/N&S/FAT/HSE/017/22 CERTIFICATE OF TRAINING

This Certificate is awarded to

Mr. Abdul REHMAN

Of

NASEEM & SON

Certificate No: ENV-N&S-017-22

For completing the course

From

The ENV International, Pakistan

At SHELL LOBP KEMARI

Karachi - Pakistan

REMARKS: This certificate is issued after theoretical and practical evaluation of the individual. Where refresher session

Head of Inspection, Training &

is recommended after 01 year.

Certification

P240-00-6761810 25/03/2024 09:25 Page 40 of 47

Date: 30th May, 2023 CERTIFICATE OF TRAINING

Ref No: ENV/N&S/WAHR/HSE/005/23

This Certificate is awarded to

Mr. Qaim SHAH

42401-5264817-7

Of

NASEEM & SON

Certificate No: ENV-N&S-WAHR-005-23

For completing the course

WORK AT HEIGHT & RESCUER

From

The ENV International, Pakistan

At SHELL LOBP KEMARI

Karachi - Pakistan

REMARKS: This certificate is issued after theoretical and practical evaluation of the individual. Where refresher session

Head of Inspection, Training &

is recommended after 01 year.

Certification

P240-00-6761810 25/03/2024 09:25 Page 41 of 47

CLIENT: SHELL PAKISTAN LIMITED

Naseem & Son

CONTRACTOR: Naseem and Son

PROJECT TITLE: Grit blasting of roof plates of SP-23

METHOD STATEMENT:

Grit blasting of roof plates of

SP-23

Sign

Muhammad

Arshad

0 08-03-2024

ISSUED FOR Muhammad

APPROVAL Arshad

First submission

Rev Revision Description Prepared by Reviewed by Approved by

Date

Document reference number: P240-00-6693635

P240-00-6761810 25/03/2024 09:25 Page 42 of 47

REVISION LOG

Rev. Rev. Date Revised Revision Descriptions Remarks

No. page(s)

P240-00-6761810 25/03/2024 09:25 Page 43 of 47

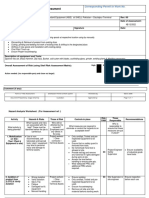

Corresponding Permit to Work No.

Method Statement

F P240-00-6693635

The Permit Issuer, when developing the respective Permit forms, will use the Method Statement supplied.

Company: Naseem & Son Project: Grit blasting of roof plate Date: 09/03/2024

of SP-23

1. Description of works

What the work entails?

Grit blasting of roof plate of SP-23

How is it going to be completed? Summarise the operation

• Site Preparation – Installation of green net with roof reeling for enclosed space

• Grit blasting of Roof plate of SP-23

• Barricade & green net after grit blasting.

• Housekeeping & Demobilization

Where is the work going to be completed? (Summary – more details on section 5)

See detail in section 5

Duration of the work? (Stating any times when access to the Terminal will not be required.)

15 working Days.

Include site location drawings if appropriate?

NA

Are there any restrictions e.g. overhead power lines?

Nil

Are local permits required (Local regulations)?

Yes

Any other details

NA

2. Names of Responsible persons

Who is going to be working on the project?

Muhammad Arshad

Who will be in charge?

Muhammad Arshad

Who has specific responsibilities? E.g. Plant, personnel, materials, etc.

Muhammad Arshad, M Tehseen Khan

Who is to make contact with local authorities?

Muhammad Arshad

Any other details

3. Plant and Equipment

What plant equipment and tools are required to do the job?

Blasting unit, compressor, grit, hopper, paint, roller and other general hand tools

Scaffolding

no

• Loading of

materials (No)

• Others, specify

Nill

Form F – Method of Statement Distribution Permit to Work

Procedure System Version 3.0 May 2007 Page 1 of 2

P240-00-6761810 25/03/2024 09:25 Page 44 of 47

What certificates, if any, are required for plant or equipment?

Blasting Unit

What training, if any, is required for operatives?

Safety Orientation

4. Communications with the workforce

How are the procedures, hazards to be communicated to the workforce?

➢ After getting desired work permits, a group communication meeting shall be conducted to

convey the action plan in case of any change in condition, like bad weather (rain/ storm etc) or

any change in plant/process area in the form of fire, leak of gas/oil/water etc. and also in case

of fire alarm/hooter

➢ In case of any emergency and where alarm goes on, all personnel must be evacuated

immediately from the work place and must be report to muster point. Extreme care should be

considered to avoid any unlikely injury caused by panic

➢ In case of any injury occurred then rescue team shell be called up at the scene with all safety

precautions and take out the injured person using the stretcher and shift him at safe place to

provide him first aid or in case of severe injury the team should rush to nearest

hospital/medical Centre

➢ The incident shall be reported verbally to permit issuer and later incident report shall

beprepared and submit to client accordingly

Toolbox talks, safety meetings etc.

Toolbox meeting at the start of work regarding safe work.

Include records of any such meetings and record attendance.

Yes, toolbox form shall be filled on daily basis.

Other, specify.

PROPER HOUSE KEEPING.

5. How will the work be completed, i.e. Procedure step by step

Proposed Start date

08/03/2024

Step 1: Mobilization of Tools, Equipment’s to Site.

• Visual inspection of tools must be performed.

• Mobilize equipment and hand tools to site by using wheel barrow

• Equipment and tool will be mobilized to site with the help of persons and wheel barrow.

• Trained and competent resources must be deployed.

Step 2: Site Preparation – Installation of green net with roof reeling for enclosed space grit blasting

Purpose

• Ensure inspection before each use

• Ensure proper PPEs suitable with the task

• Ensure fixed spanners only

• Trained and competent resources must be deployed.

• Never use damaged tools & Equipment

• Ensure Use of walkways

• Ensure Lifesaving rules & Golden rules

Form F – Method of Statement Distribution Permit to WorkSystem

Procedure Version 3.0 May 2007 Page 4 of 5

P240-00-6761810 25/03/2024 09:25 Page 45 of 47

Step3 : Grit blasting of roof plate of SP-23

• Ensure Gas testing before starting work

• Ensure inspection before each use

• Ensure Blasting hood during blasting activity

• Ensure Ear Muffs during grit blasting for noise hazard

• Ensure Proper Dust Masks during grit blasting activity

• Ensure Area barricading & Safety Signage’s on site

• Ensure Housekeeping on site on daily basis

• Ensure Blasting unit is third party certified

• Ensure All tools and equipment’s is third party certified

• Ensure safe manual handling Techniques

• Ensure Painting after grit blasting on grit blasted area manually by using roller

• Ensure Proper Mask KN-95 during painting activity

• Ensure Housekeeping of Area

• Ensure fire extinguisher on site

Step 4: Removal of Hard Barricade & green net after grit blasting.

• Ensure inspection before each use

• Ensure proper PPEs suitable with the task

• Ensure fixed spanners only

• Trained and competent resources must be deployed.

• Never use damaged tools & Equipment

• Ensure Use of walkways

• Ensure Lifesaving rules & Golden rules

Step 5: Demobilization

• Ensure Proper Segregation of material

• Ensure Safe manual handling techniques

• Ensure Load is secured on trolley

Step 6: Housekeeping

• After completion of work housekeeping will be ensured

P240-00-6761810 25/03/2024 09:25 Page 46 of 47

The ENV International, Pakistan

S# 22, Faqeer Muhammad Goth, Opposite

Fast National University Bin Qasim Landhi Karachi- Pakistan

P: 021-34512244 | C: 0300-0062244

E: info@env.com.pk | W: http://www.env.com.pk

EXAMINATION REPORT OF PULLEY

Supplier/Owner: Naseem & Son.

Place of Inspection: Shell LOBP - Karachi, Pakistan

Standard Reference: OSHA

Job Ref. No.: ENV/NS/INS-0456/23

Report No.: ENV/RINS/0456 (Rev-00)

Tag No.: ENV/NS/MPLY/001

Date of Examination: 02-October-2023

SCOPE OF WORK: VISUAL & OPERATIONAL EXAMINATION

Sr. Type of

Manufacturer Capacity Model TAG No. Remarks

No. Equipment

Pulley N/A 500 Kg N/A ENV/NS/MPLY/001 Satisfactory

01

Findings / Remarks:

Subject Pulley is approved for operations after visual inspection and operational Check, against provided Specification by

Client/Supplier.

Recommendation:

1) Ensure all safety instructions are clearly understood and that the operators are familiar with the winch controls.

2) Keep body parts and clothing away from all moving parts as well as the rope.

3) Never exceed the maximum load specified for the winch.

4) Avoid sudden shock or movement of the winch under load and use a slow consistent speed.

5) Always wear approved, appropriate Personal Protective Equipment (PPE)

6) Always ensure clear communication between the operator and other personnel involved with the task.

Conclusion:

It is found in Satisfactory Condition at the time of inspection for intended use only.

VALIDITY OF THIS CERTIFICATE 01 YEAR, FROM DATE OF INSPECTION 02nd October, 2023 to 01st October, 2024

This Certificate does not make any warranty/indemnity expressed or implied, relating to the above equipment. This Certificate

does not relieve seller/suppliers from their contractual responsibilities with regard to quality/quantity of this delivery nor does it

discrimination the buyer’s right of claim towards their seller/suppliers for compensation for any apparent and/or hidden defects

not detected during our inspection & testing or occurring thereafter.

INSPECTED BY REVIEWED BY

Atif Zaman (Senior Inspection Engineer) Muhammad Sadiq (Operation Manager)

P240-00-6761810 25/03/2024 09:25 Page 47 of 47

Page 1 of 1

You might also like

- JSA For HVAC WorkDocument8 pagesJSA For HVAC Worksathakathulla100% (3)

- SHELL Retail Permit To Work System - 5 1 - FormsDocument4 pagesSHELL Retail Permit To Work System - 5 1 - FormsAlberto Sánchez Armenta80% (5)

- Permit Number P240-00-6693635 State Live (16 Mar 09:31 - 16 Mar 19:00) Lifetime Expires On 20-03-2024Document4 pagesPermit Number P240-00-6693635 State Live (16 Mar 09:31 - 16 Mar 19:00) Lifetime Expires On 20-03-2024Sagar SharmaNo ratings yet

- Permit Number P290-00-5713663 State Waiting For Verification Lifetime Expires OnDocument13 pagesPermit Number P290-00-5713663 State Waiting For Verification Lifetime Expires OnNaseemandson TeamNo ratings yet

- Permit Number P289-00-6723327 State Waiting For Verification Lifetime Expires OnDocument53 pagesPermit Number P289-00-6723327 State Waiting For Verification Lifetime Expires OnSagar SharmaNo ratings yet

- PTWDocument22 pagesPTWaliabdallah20232023No ratings yet

- Eil Daily Safety ChecklistDocument2 pagesEil Daily Safety ChecklistAvesh ChauahanNo ratings yet

- PTW SystemDocument21 pagesPTW SystemJaouad IDBOUBKERNo ratings yet

- BINDERDocument17 pagesBINDERprakashNo ratings yet

- Hot Work PermitDocument1 pageHot Work Permitjnatraders6No ratings yet

- Eil Permit For Energy Isolation & De-IsolationDocument1 pageEil Permit For Energy Isolation & De-IsolationAvesh ChauahanNo ratings yet

- Cold Work Permit: Smg1 Flowline ProjectDocument2 pagesCold Work Permit: Smg1 Flowline Projectghazi kallelNo ratings yet

- Hot Work PermitDocument2 pagesHot Work PermitrvrsafetybangaloreNo ratings yet

- MKS-1904-HF-01 - Site Induction ChecklistDocument3 pagesMKS-1904-HF-01 - Site Induction ChecklistNindy FebrianiNo ratings yet

- General Permit To WorkDocument1 pageGeneral Permit To WorkAndy PrasetyoNo ratings yet

- Deviation Permit Feb 25, 2022Document2 pagesDeviation Permit Feb 25, 2022EILA545 QAQCNo ratings yet

- MSOG-M2014-C-JMS-001 - For Grating Cover InstallationDocument9 pagesMSOG-M2014-C-JMS-001 - For Grating Cover Installationshaiful annuarNo ratings yet

- Permit To Work ProcedureDocument52 pagesPermit To Work Procedurejerome pillienNo ratings yet

- CMEC-HSE-PR-15-F-009 Permit To Work Form - CCEED-MMC Tracker Installation Work BlanckDocument1 pageCMEC-HSE-PR-15-F-009 Permit To Work Form - CCEED-MMC Tracker Installation Work BlanckaNo ratings yet

- 06 Hot Work PermitDocument1 page06 Hot Work PermitSrini VasuluNo ratings yet

- HSE Hot Work PermitDocument3 pagesHSE Hot Work PermitCSD shakthiNo ratings yet

- Drywall Work Installatin Method StatementDocument10 pagesDrywall Work Installatin Method Statementtumelo makgabutlaneNo ratings yet

- Constrution of SubstationDocument24 pagesConstrution of SubstationHassan100% (1)

- New PTW PDB 2016 - 4Document153 pagesNew PTW PDB 2016 - 4Mohd Shaizan100% (5)

- PDB PTW 2019 Ra and WL Vol. 1 10-11 Nov 2020Document255 pagesPDB PTW 2019 Ra and WL Vol. 1 10-11 Nov 2020Syed AmzarNo ratings yet

- TIPCO-HSE-OCP-046. PTW ProcedureDocument7 pagesTIPCO-HSE-OCP-046. PTW ProcedureibrahimNo ratings yet

- RAMS - PR#7727, Dismanteling of Warehouse (Updated)Document20 pagesRAMS - PR#7727, Dismanteling of Warehouse (Updated)Muhammad niazNo ratings yet

- Permit Number A081-00-4135188 State Live (12 Jul 07:59 - 12 Jul 17:00) Lifetime Expires On 11-08-2022Document5 pagesPermit Number A081-00-4135188 State Live (12 Jul 07:59 - 12 Jul 17:00) Lifetime Expires On 11-08-2022CFSNo ratings yet

- EHSWP004 - Hot Work Permit PDFDocument2 pagesEHSWP004 - Hot Work Permit PDFRand raiNo ratings yet

- Night Works ProcedureDocument15 pagesNight Works Procedurejerome pillienNo ratings yet

- MS-West Portal Link Road + Ventilation Tunnel Access RoadDocument84 pagesMS-West Portal Link Road + Ventilation Tunnel Access RoadFarooq AzizNo ratings yet

- ADNOC Letter - PTW Signatory Authorizing LimitDocument2 pagesADNOC Letter - PTW Signatory Authorizing LimitMohammad SaalimNo ratings yet

- 002 - WMS - For - Scaffolding & Erection of Pipe Rack Area PS29 To PS38Document7 pages002 - WMS - For - Scaffolding & Erection of Pipe Rack Area PS29 To PS38alla malikNo ratings yet

- 742 Method Statement 2011Document20 pages742 Method Statement 2011kikokiko KarimNo ratings yet

- CL #06 CPTW PDFDocument11 pagesCL #06 CPTW PDFmoNo ratings yet

- General or Cold PTWDocument2 pagesGeneral or Cold PTWVijayakumar KarunanidhiNo ratings yet

- 02 Hot Work PermitDocument2 pages02 Hot Work PermitFaisal Abdul GhaffarNo ratings yet

- Cold Work PermitDocument3 pagesCold Work Permitnakul kushwahaNo ratings yet

- Marine Permit: Cold Work: Permit To Work Office No.: Refer To The Last PageDocument3 pagesMarine Permit: Cold Work: Permit To Work Office No.: Refer To The Last PagewaseemNo ratings yet

- VAU CN FM 0042 Prestart FormDocument2 pagesVAU CN FM 0042 Prestart FormCung Manh TuanNo ratings yet

- JSA-004-Hot Work Activity Revise动火作业 04Document15 pagesJSA-004-Hot Work Activity Revise动火作业 04caovanthien10121992No ratings yet

- EHSWP004 - Hot Work PermitDocument2 pagesEHSWP004 - Hot Work Permitsameer.patilNo ratings yet

- Diesel Generator E-PermitDocument7 pagesDiesel Generator E-PermitNoman AliNo ratings yet

- WorkPermitDetails 20 09 2023Document3 pagesWorkPermitDetails 20 09 2023gulamsafiNo ratings yet

- HSE CP-21 Work Permit SystemDocument215 pagesHSE CP-21 Work Permit SystemAprie SubektiNo ratings yet

- P24020 30 99 97 1616 1 04 - ColorDocument40 pagesP24020 30 99 97 1616 1 04 - Colorshajahan eNo ratings yet

- HSE Permit TemplatesDocument24 pagesHSE Permit TemplatesBrijgopal YadavNo ratings yet

- MIP17 - HSE - PP - 004 Short Serviece Employee Program PKG 17 REV 1Document10 pagesMIP17 - HSE - PP - 004 Short Serviece Employee Program PKG 17 REV 1AmeerHamzaWarraichNo ratings yet

- PCD-OSH-SF-35 PTW For Confine Space KotaSASDocument2 pagesPCD-OSH-SF-35 PTW For Confine Space KotaSASrizal azizanNo ratings yet

- Method Statement & Risk Assessment: Project Name: Location of The Works: Title of Method Statement: Scope of WorksDocument17 pagesMethod Statement & Risk Assessment: Project Name: Location of The Works: Title of Method Statement: Scope of WorksSiti Noor Rahimah IbarahimNo ratings yet

- MD 216 2500 QD Ix Itp 1001 c01 Itp Hcis Fencing Installation For Ms AdvaconDocument5 pagesMD 216 2500 QD Ix Itp 1001 c01 Itp Hcis Fencing Installation For Ms AdvaconjuberNo ratings yet

- 4.2.11 PTW General WorksDocument2 pages4.2.11 PTW General Works2830093188No ratings yet

- Permit To Work Procedure: TitleDocument31 pagesPermit To Work Procedure: TitleWale OyeludeNo ratings yet

- Road Closure Certificate Rev02 2016Document1 pageRoad Closure Certificate Rev02 2016Imran KhanNo ratings yet

- Method-Statement-CMC TowerDocument5 pagesMethod-Statement-CMC TowerEkram AliNo ratings yet

- PCD-OSH-SF-35 PTW For Confine SpaceDocument2 pagesPCD-OSH-SF-35 PTW For Confine Spacerizal azizanNo ratings yet

- SWP CHECKLISTS - Welding Cutting and HeatingDocument3 pagesSWP CHECKLISTS - Welding Cutting and HeatingSrinivas Dumpala HSE100% (1)

- Testing & Commisioning Procedure For Fire Fighting Pumps & Fire Alarm SystemDocument29 pagesTesting & Commisioning Procedure For Fire Fighting Pumps & Fire Alarm Systemmohdshahul543No ratings yet

- 8 - WMS - Turpentine - Plinth BeamDocument4 pages8 - WMS - Turpentine - Plinth BeamVikramaditya NayakNo ratings yet

- Angle Grinder BG-01Document1 pageAngle Grinder BG-01Sagar SharmaNo ratings yet

- B ShackleDocument1 pageB ShackleSagar SharmaNo ratings yet

- Permit Number P240-00-6693635 State Live (16 Mar 09:31 - 16 Mar 19:00) Lifetime Expires On 20-03-2024Document4 pagesPermit Number P240-00-6693635 State Live (16 Mar 09:31 - 16 Mar 19:00) Lifetime Expires On 20-03-2024Sagar SharmaNo ratings yet

- Permit Number P289-00-6723327 State Waiting For Verification Lifetime Expires OnDocument53 pagesPermit Number P289-00-6723327 State Waiting For Verification Lifetime Expires OnSagar SharmaNo ratings yet

- Manual Lifting PlanDocument2 pagesManual Lifting PlanSagar SharmaNo ratings yet

- D ShackleDocument1 pageD ShackleSagar SharmaNo ratings yet

- Rescue Plan Working at HeightDocument2 pagesRescue Plan Working at HeightSagar SharmaNo ratings yet

- Ilovepdf MergedDocument8 pagesIlovepdf MergedSagar SharmaNo ratings yet

- Chain Block CB NS.010 2T - 2Document1 pageChain Block CB NS.010 2T - 2Sagar SharmaNo ratings yet

- JSA For NSE ProjectDocument7 pagesJSA For NSE ProjectSagar SharmaNo ratings yet

- New EntryDocument1 pageNew EntrySagar SharmaNo ratings yet

- Progress Report 32Document2 pagesProgress Report 32Sagar SharmaNo ratings yet

- Progress Report 33Document2 pagesProgress Report 33Sagar SharmaNo ratings yet

- Naseem & Son: Emergency Response PlanDocument7 pagesNaseem & Son: Emergency Response PlanSagar SharmaNo ratings yet

- Emergency Response/ Rescue Plan Forworking at Height: First Aider: Abdul Samad Rescuer: Noman & RaheelDocument1 pageEmergency Response/ Rescue Plan Forworking at Height: First Aider: Abdul Samad Rescuer: Noman & RaheelSagar SharmaNo ratings yet

- Method StatementDocument3 pagesMethod StatementSagar SharmaNo ratings yet

- Progress Report 31Document2 pagesProgress Report 31Sagar SharmaNo ratings yet

- MS SKP-08 For Internal Grit BlastingDocument9 pagesMS SKP-08 For Internal Grit BlastingSagar SharmaNo ratings yet

- Safety Walk Report by ClientDocument3 pagesSafety Walk Report by ClientSagar SharmaNo ratings yet

- Work at Height Rescue PlanDocument1 pageWork at Height Rescue PlanSagar SharmaNo ratings yet

- Method Statement: Company: Naseem & Son Project: Date: 21/05/2022 1. Description of WorksDocument3 pagesMethod Statement: Company: Naseem & Son Project: Date: 21/05/2022 1. Description of WorksSagar SharmaNo ratings yet

- Rescue Plan For HeightDocument2 pagesRescue Plan For HeightSagar SharmaNo ratings yet

- Risk Assessment: Corresponding Permit To Work NoDocument4 pagesRisk Assessment: Corresponding Permit To Work NoSagar SharmaNo ratings yet

- SSE-ST-GL-009-11 Routine Lift Plan: Lifting & Hoisting - Loading of SPL-11 Roof Scrap Plates On TruckDocument4 pagesSSE-ST-GL-009-11 Routine Lift Plan: Lifting & Hoisting - Loading of SPL-11 Roof Scrap Plates On TruckSagar SharmaNo ratings yet

- SHELL SMEP Lifting and Hoisting Manual Rev 1 0Document349 pagesSHELL SMEP Lifting and Hoisting Manual Rev 1 0Sagar SharmaNo ratings yet

- Naseem & Son: Report of Internal AuditDocument5 pagesNaseem & Son: Report of Internal AuditSagar SharmaNo ratings yet

- Key Performance Indicator Naseem & SonDocument1 pageKey Performance Indicator Naseem & SonSagar SharmaNo ratings yet

- Assessment Report Naseem & SonDocument2 pagesAssessment Report Naseem & SonSagar SharmaNo ratings yet

- Method Statement: Company: Naseem & Son Project: Maintinance (SKP-09) Date: 05-12-2021 1. Description of WorksDocument2 pagesMethod Statement: Company: Naseem & Son Project: Maintinance (SKP-09) Date: 05-12-2021 1. Description of WorksSagar SharmaNo ratings yet

- All Safety Inspection ChecklistsDocument30 pagesAll Safety Inspection ChecklistsSagar Sharma50% (2)

- Specification For Painting of Structural SteelDocument11 pagesSpecification For Painting of Structural SteelJames LeeNo ratings yet

- Den Jet Accessory Catalog 2023Document52 pagesDen Jet Accessory Catalog 2023Julien RichouNo ratings yet

- Belzona 1212 Specification SheetDocument4 pagesBelzona 1212 Specification Sheetamin32No ratings yet

- TO THE POINT HSE NotesDocument64 pagesTO THE POINT HSE NotesRashid Jamil100% (1)

- Chemco Industrial BrochureDocument20 pagesChemco Industrial BrochureaixinngNo ratings yet

- 3 - TarcoatDocument8 pages3 - Tarcoatkrishna KumarNo ratings yet

- QC Multi Inspector CV - 2023Document7 pagesQC Multi Inspector CV - 2023Kshama RaiNo ratings yet

- 8-Hot Tapping - 12-06-2015Document12 pages8-Hot Tapping - 12-06-2015AmeerHamzaWarraichNo ratings yet

- Cabinet CS48Document10 pagesCabinet CS48Cahyo DheeNgkellNo ratings yet

- A8t PD-TemperKote850Document2 pagesA8t PD-TemperKote850Janet BastidaNo ratings yet

- Office Copy ThesisDocument109 pagesOffice Copy ThesisJoel ArumbakanNo ratings yet

- Patna Dairy Project - Molasses Storage TankDocument13 pagesPatna Dairy Project - Molasses Storage TankAlfredoNo ratings yet

- 29000.ENG - CPI.STD - Paintings and CoatingsDocument62 pages29000.ENG - CPI.STD - Paintings and CoatingsMatteo100% (1)

- Instruction Manual SandblastDocument21 pagesInstruction Manual SandblastGunawanNo ratings yet

- Fosroc - Nitofill-UR63-crack RepairDocument3 pagesFosroc - Nitofill-UR63-crack Repairjohn paulNo ratings yet

- ENG-DUQM-101 - Painting Procedure - Rev 3.Document269 pagesENG-DUQM-101 - Painting Procedure - Rev 3.Shiva RajNo ratings yet

- R-AX0109-003-QA-820-0001 Rev 01Document17 pagesR-AX0109-003-QA-820-0001 Rev 01phani prabhakarNo ratings yet

- High Pressure Cleaning MachinesDocument6 pagesHigh Pressure Cleaning MachinesNIKOSNo ratings yet

- Surface Preparation and Painting Shop: Group 5Document33 pagesSurface Preparation and Painting Shop: Group 5Yumul RenceNo ratings yet

- Application Spec Sheet - Chemline 1150Document4 pagesApplication Spec Sheet - Chemline 1150Yair Sánchez blancoNo ratings yet

- Quotation List: Jinan Truepro International Co.,LtdDocument17 pagesQuotation List: Jinan Truepro International Co.,Ltdhamdadnadim1No ratings yet

- RA Sandblasting and Painting of SheetsSpoolsDocument3 pagesRA Sandblasting and Painting of SheetsSpoolshashibpervez.shvenergybdNo ratings yet

- Jotamastic 70Document9 pagesJotamastic 70Muhammad HanafiNo ratings yet

- C4 40 Years WebsiteDocument9 pagesC4 40 Years Websitemàrio ferreiraNo ratings yet

- Topic 5.2 - Composites & Non MetalDocument138 pagesTopic 5.2 - Composites & Non MetalelyanasofeaNo ratings yet

- PEB MFGDocument70 pagesPEB MFGshalabh guptaNo ratings yet

- Easy 47700 AIDocument4 pagesEasy 47700 AIGrimmo1979No ratings yet

- Report BitirmeDocument6 pagesReport BitirmeSude DillioğluNo ratings yet

- Epoxy Painting & Sand Blasting JobDocument11 pagesEpoxy Painting & Sand Blasting JobStrategic ThinkingNo ratings yet

- Lampiran V - Spesifikasi Umum Dan Teknis Tugboat 1200 HPDocument24 pagesLampiran V - Spesifikasi Umum Dan Teknis Tugboat 1200 HParieznavalNo ratings yet