Professional Documents

Culture Documents

Material Properties: HDPE Properties Technical Specifications

Material Properties: HDPE Properties Technical Specifications

Uploaded by

Bora0 ratings0% found this document useful (0 votes)

4 views1 pageHDPE Soil

Original Title

11

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHDPE Soil

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

4 views1 pageMaterial Properties: HDPE Properties Technical Specifications

Material Properties: HDPE Properties Technical Specifications

Uploaded by

BoraHDPE Soil

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Material Properties

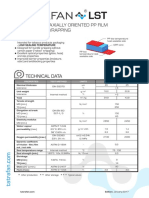

HDPE properties Technical specifications Pressure and heat during

Polyethylene (PE), is a semi crystalline

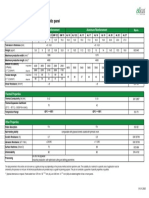

Unit Test method Value concrete pouring Diameter Wall thickness Allowed height (m)

Density at 23°C g/cm³ ISO 1183 0.954 (mm) (mm)

thermoplastic and is a generic term for When a pipe system is vertically installed

different kinds of PE. By colouring with Empty Filled with water

Elasticity modulus N/mm² ISO 527 850 into concrete the liquid concrete will cause

2% of ‘carbon black’ the PE gets its black 40 3.0 26.0 45.0

outer pressure, possibly exceeding the

colour. The following kinds of PE are Bending creep modulus N/mm² DIN 54852-Z4 1000 50 3.0 14.0 24.0

maximum ring stiffness depending on the

generally used: height of the installation. 56 3.0 7.0 12.0

Tensile strength at 23°C N/mm² ISO 527 22

63 3.0 7.0 12.0

O LDPE (Density 0.90-0.91 g/cm3) Elongation at break % ISO R 527 300 To increase the maximum installation 75 3.0 3.8 6.5

height the pipe can be filled with water 90 3.5 3.8 6.5

O MDPE (Density 0.93-0.94 g/cm ) 3 Linear expansion coefficient mm/mK DIN 53752 0.18 (and closed) to compensate for the outer 110 4.2 3.8 6.5

O HDPE (Density 0.94-0.97 g/cm3) Indentation hardness N/mm² ISO 2039 36 - 46 pressure. Refer to the table opposite for

125 4.8 3.8 6.5

the maximum allowed height depending

In pipe systems generally only HDPE is Ignition temperature °C - ~350 160 6.2 3.8 6.5

also on the wall thickness of the pipes and

used. HDPE has a high resistance against 200 6.2 2.0 3.5

Thermal conductivity W/m . K DIN 52612 0.37 - 0.43 fittings (at 30°C).

acids, bases and aqueous salt-solutions. 250 7.7 2.0 3.5

Below 60°C it is practically unsolvable Shore hardness ISO 868 61 315 9.7 2.0 3.5

in organic solutions. HDPE has a good 200 7.7 3.8 6.5

Crystallite melting range °C 125 - 131

resistance against light ionised radiation 250 9.6 3.8 6.5

without becoming radioactive itself. Operational temperature range °C - -40 - +80* 315 12.1 3.8 6.5

Melt Flow Rate MFR 190/5 g/10 min ISO 1133 0.43

* up to 100°C for short periods of time.

Ecological properties of HDPE Chemical resistance Embedding HDPE in concrete

Thermal movement of HDPE

Polyethylene consists of only carbon and When transporting chemical waste waters The HDPE system is suited to be

A physical principal is that all materials When installed at 30° a Marley HDPE pipe of 5m long will behave as follows:

hydrogen atoms. These substances are not the following factors have to be taken into embedded in concrete. Before pouring

expand as the temperature increases.

harmful to humans, animals and plants. account: the concrete all welds need to be cooled

If the temperature drops, the material

Marley uses High Density Polyethylene O The medium down and it is preferable to check the

contracts. Each material has its own 5000 mm

classified with recycle mark 3. pipe system for leakage. To prevent the

unique coefficient of expansion (ž).

O The concentration of this medium pipes from floating upwards the systems 30 °C

O Temperature needs to be properly bracketed to keep it For HDPE : ž = 0,18 mm/m • K

in place. The formula for length change is:

O Duration of exposure

O Volume ΔL = L x ž x ΔT 5027 mm

Refer to appendix A for a complete 60 °C

Quick drying concrete ΔL = length change of pipe system [mm]

chemical resistance table of Marley HDPE L = total pipe length [m]

on page 52. ΔT = difference with installation

Quick drying concrete will

undergo an exothermic temperature [°C]

4973 mm

Trace heating reaction which releases heat ž = 0,18 mm/m • °K

during its process. The heat 0 °C

Animal and vegetable-based oil and

will soften the HDPE pipe

ΔT 50° = 10 mm/m

grease discharged by commercial kitchens

Polyethylene is made from oil and and influence the maximum

are separated from the waste water

electricity without chemical additives allowed pressure. Adequate

by grease separators. HDPE is very well

released during production. It is not protection must be provided to

suited to connect the discharge fixtures

broken down by bacteria very fast and the HDPE system like filling the

to the grease separator. When the pipe In residential applications the maximum For downpipes and ground pipes the Please note that this is the temperature

has a long lifetime. The total energy system with water. For further

system has enough length, the grease can wall temperature difference of the maximum wall temperature difference difference over the complete circumference

consumption during production and information on embedding

accumulate and lead to serious blockage connector and collector pipes is 40°C, is 20°C. of the pipe, the variation in the discharge

transport is very low compared to steel, HDPE in concrete see page 43.

of the pipe system. The use of trace even during short periods of 80°C to 90°C temperature can be a lot higher.

copper or cast iron. In general for a long-lasting discharge of

heating and additional insulation may be temperature water discharge.

Because PE is a thermoplastic polymer it required to reduce heat loss. The trace high volume hot water the maximum wall

can be melted at the end of its technical heating element should not exceed 45°C. temperature difference is 60°C.

lifetime and used for other applications.

When PE is burnt, only non-toxic carbon

dioxide and water is released.

20 | MARLEY HDPE MARLEY HDPE | 21

You might also like

- Geomembrane Installation Reference ManualDocument20 pagesGeomembrane Installation Reference ManualErayNo ratings yet

- Diversity Factor-Carrier Hadbook PDFDocument2 pagesDiversity Factor-Carrier Hadbook PDFالوليد الديسطىNo ratings yet

- A New Physical TheoryDocument4 pagesA New Physical TheoryJocelyn RegalaNo ratings yet

- TDS-PH-Green Terramesh PoliMac 2019Document2 pagesTDS-PH-Green Terramesh PoliMac 2019jericquiminalesNo ratings yet

- KLINGERSIL C-4430plus Data SheetDocument3 pagesKLINGERSIL C-4430plus Data SheetMichael PhamNo ratings yet

- TDS SK Green Terramesh Galmac & PVC 8xrev Jul 14Document2 pagesTDS SK Green Terramesh Galmac & PVC 8xrev Jul 14Marjan JerbicNo ratings yet

- Neo Backer RodDocument2 pagesNeo Backer RodShibin PoulNo ratings yet

- Polyethylene Properties - VinidexDocument8 pagesPolyethylene Properties - VinidexalexNo ratings yet

- Repair SleeveDocument4 pagesRepair SleeveadiNo ratings yet

- 3M™ Adhesive Transfer Tape 9472LE - 20240628Document8 pages3M™ Adhesive Transfer Tape 9472LE - 20240628Nguyễn MyNo ratings yet

- Neo Backer RodDocument2 pagesNeo Backer RodhazelNo ratings yet

- HSS80 Heat Shrink Sleeve: Features & BenefitsDocument2 pagesHSS80 Heat Shrink Sleeve: Features & BenefitsAnonymous eEJDOR2100% (1)

- Ultra-Soft Thermal Conductive PadDocument2 pagesUltra-Soft Thermal Conductive PadArunkumar PBNo ratings yet

- 3M Adhesive Transfer Tape 950Document6 pages3M Adhesive Transfer Tape 950Michael McQueenNo ratings yet

- Datenblaetter A4 C-4324 eDocument2 pagesDatenblaetter A4 C-4324 eGeneration GrowthNo ratings yet

- Tube Clamp HydacDocument28 pagesTube Clamp Hydachisaj4uNo ratings yet

- PPSU Filament: Physical Conditions Test Method Typical ValueDocument2 pagesPPSU Filament: Physical Conditions Test Method Typical ValueRui MatiasNo ratings yet

- Siare Technologies - Test ReportDocument1 pageSiare Technologies - Test ReportnikhilbhorNo ratings yet

- PC 8B35 Ge Lexan PCDocument3 pagesPC 8B35 Ge Lexan PCbalu gunaNo ratings yet

- Esh M11P19 BDocument3 pagesEsh M11P19 Bjose luisNo ratings yet

- Cork SheetDocument2 pagesCork Sheetsaurabh bondeNo ratings yet

- Technical Characteristics 2023 ENDocument1 pageTechnical Characteristics 2023 ENmohammedsirajuddin777No ratings yet

- Adhesive Transfer Tapes With Adhesive 200: Technical Data September, 2002Document4 pagesAdhesive Transfer Tapes With Adhesive 200: Technical Data September, 2002Reza AbdolahiNo ratings yet

- Method Statement For Rectifying Cracks by Injection Method On Floor Slab - Wall - Ceiling of Precast Components - RfaDocument50 pagesMethod Statement For Rectifying Cracks by Injection Method On Floor Slab - Wall - Ceiling of Precast Components - Rfakomt qaqcNo ratings yet

- Coextruded Biaxially Oriented PP Film For Tobacco Wrapping: Technical DataDocument2 pagesCoextruded Biaxially Oriented PP Film For Tobacco Wrapping: Technical DataJan GawełNo ratings yet

- TDS FLEX 93A - enDocument1 pageTDS FLEX 93A - enmr.mennensNo ratings yet

- Cx3 9 Film Fact SheetDocument2 pagesCx3 9 Film Fact SheetCampaign MediaNo ratings yet

- Basalt Fibers: FeaturesDocument6 pagesBasalt Fibers: FeaturessrinilsukumarkhdNo ratings yet

- DIN 3015-1 Light Range DIN 3015-2 Heavy Range DIN 3015-3 Twin ClampsDocument28 pagesDIN 3015-1 Light Range DIN 3015-2 Heavy Range DIN 3015-3 Twin ClampsGeovanny Andres Cabezas SandovalNo ratings yet

- Technical Characteristics 2020 ENDocument1 pageTechnical Characteristics 2020 ENezzularabNo ratings yet

- Advaboard TDSDocument1 pageAdvaboard TDSMohammed AbugharbiehNo ratings yet

- Bitutherm: Extruded Polystyrene Thermal Insulation BoardDocument2 pagesBitutherm: Extruded Polystyrene Thermal Insulation BoardRhonzkie GapuzNo ratings yet

- Datasheet FBLT054049 en USDocument1 pageDatasheet FBLT054049 en USSuplidora Industrial 6 SigmaNo ratings yet

- Datasheet 2420K PDFDocument1 pageDatasheet 2420K PDFjavadmohammadiNo ratings yet

- GM - TDS-111: Europe North America AsiaDocument3 pagesGM - TDS-111: Europe North America AsiaMarjan ArhNo ratings yet

- Features: Property Units Methods Typical ValuesDocument1 pageFeatures: Property Units Methods Typical ValuesJavier Martinez CañalNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- 316 Tubeing TrisDocument1 page316 Tubeing Triscenter steel110No ratings yet

- Everest Multipurpose Fibre Cement Boards: Sizes and Thickness AvailableDocument2 pagesEverest Multipurpose Fibre Cement Boards: Sizes and Thickness AvailableSTRUCTURAL ENGG DEPT TDLCCSNo ratings yet

- CellrodDocument2 pagesCellrodjude tallyNo ratings yet

- Technical Data SheetDocument3 pagesTechnical Data Sheetrenaat.vanwayenbergeNo ratings yet

- Tech. Specification HDPE DUCT 50-43mmDocument2 pagesTech. Specification HDPE DUCT 50-43mmZaman MuhammadNo ratings yet

- TDS GLACE - enDocument1 pageTDS GLACE - enmr.mennensNo ratings yet

- Teleste Datasheet - Coaxial - Cable - S579590XVQ - 180123Document1 pageTeleste Datasheet - Coaxial - Cable - S579590XVQ - 180123polan78No ratings yet

- Klingersil: Klingersil C-4400 - Leading Soft Gasket Material For Safe and Reliable SealingDocument2 pagesKlingersil: Klingersil C-4400 - Leading Soft Gasket Material For Safe and Reliable SealingSamir ChaudharyNo ratings yet

- KNG1015 Pa6-Gf15Document2 pagesKNG1015 Pa6-Gf15pava16230.meNo ratings yet

- Anti-Corrosion Coating: StandardsDocument2 pagesAnti-Corrosion Coating: StandardsMuhamad Rizky KurniawanNo ratings yet

- Airex T90: The Fire Resistant Structural FoamDocument3 pagesAirex T90: The Fire Resistant Structural FoamJesse Garcia OlmosNo ratings yet

- Deesa Pipe Gasket Catal - 230310 - 121140Document10 pagesDeesa Pipe Gasket Catal - 230310 - 121140Pietro MachadoNo ratings yet

- FT Datenblaetter C-4300 - eDocument2 pagesFT Datenblaetter C-4300 - epercivalczNo ratings yet

- Raychem Heat-Shrinkable Halogen-Free Cable Caps For The Electrical Power IndustryDocument2 pagesRaychem Heat-Shrinkable Halogen-Free Cable Caps For The Electrical Power Industryarthur9mozoNo ratings yet

- Jna 33Document1 pageJna 33jaskaran singhNo ratings yet

- Pds Covalence Htlp60 v1 Oct14 Aarps 0193Document2 pagesPds Covalence Htlp60 v1 Oct14 Aarps 0193pepeNo ratings yet

- Inside: High Density PolyethyleneDocument1 pageInside: High Density PolyethylenePaul TambunanNo ratings yet

- Avm Imnr62 17aDocument2 pagesAvm Imnr62 17aRani HendrikusNo ratings yet

- TDS - Pipeclad HOT 120Document2 pagesTDS - Pipeclad HOT 120Long ChenNo ratings yet

- Ldpe 2426K PDFDocument1 pageLdpe 2426K PDFjavadmohammadiNo ratings yet

- 3M VHB Tape GPH 160GFDocument6 pages3M VHB Tape GPH 160GFasinghNo ratings yet

- SentryGlas Technische BrochureDocument40 pagesSentryGlas Technische BrochureMarco CervioNo ratings yet

- Rogers - Unknown - RO4400 Series BondplyDocument4 pagesRogers - Unknown - RO4400 Series BondplyHadi SaeidiManeshNo ratings yet

- New Laminates Enable 79 GHZ Technology AdvancementsDocument3 pagesNew Laminates Enable 79 GHZ Technology Advancements123 nigNo ratings yet

- Introduction To Floplast Soil & Waste SystemsDocument1 pageIntroduction To Floplast Soil & Waste SystemsBoraNo ratings yet

- Active Drainage Ventilation: HDPE BracketryDocument1 pageActive Drainage Ventilation: HDPE BracketryBoraNo ratings yet

- The Technical Experts in Plumbing & Drainage: HDPE Handling and StorageDocument1 pageThe Technical Experts in Plumbing & Drainage: HDPE Handling and StorageBoraNo ratings yet

- Soil & Waste Systems: 110mm Ring Seal SoilDocument1 pageSoil & Waste Systems: 110mm Ring Seal SoilBoraNo ratings yet

- Marley Co UkDocument1 pageMarley Co UkBoraNo ratings yet

- Sanitary Pipework DesignDocument1 pageSanitary Pipework DesignBoraNo ratings yet

- Design: WC Manifold System Combined Branch Waste Waste TrapsDocument1 pageDesign: WC Manifold System Combined Branch Waste Waste TrapsBoraNo ratings yet

- Appendix: Used SymbolsDocument1 pageAppendix: Used SymbolsBoraNo ratings yet

- Underground: Marleypd - Co.ukDocument1 pageUnderground: Marleypd - Co.ukBoraNo ratings yet

- HDPE Bracketry: 4. Underground Installation of HDPEDocument1 pageHDPE Bracketry: 4. Underground Installation of HDPEBoraNo ratings yet

- Soil & Waste Systems: AccreditationDocument1 pageSoil & Waste Systems: AccreditationBoraNo ratings yet

- HDPE Bracketry: Length de Ection Leg at Operating Temperature 25°C-100°CDocument1 pageHDPE Bracketry: Length de Ection Leg at Operating Temperature 25°C-100°CBoraNo ratings yet

- Trapped Floor GullyDocument1 pageTrapped Floor GullyBoraNo ratings yet

- HDPE Jointing Methods: Evaluating The Butt-WeldDocument1 pageHDPE Jointing Methods: Evaluating The Butt-WeldBoraNo ratings yet

- Product Specifications: Additional Sizes Are AvailableDocument1 pageProduct Specifications: Additional Sizes Are AvailableBoraNo ratings yet

- Installation HDPE Jointing MethodsDocument1 pageInstallation HDPE Jointing MethodsBoraNo ratings yet

- Installation Data: Jointing Techniques Marley Pipe Support SystemDocument1 pageInstallation Data: Jointing Techniques Marley Pipe Support SystemBoraNo ratings yet

- HDPE Jointing Methods: Butt-Weld ProcessDocument1 pageHDPE Jointing Methods: Butt-Weld ProcessBoraNo ratings yet

- Product Specifications: Pipe Length 5MDocument1 pageProduct Specifications: Pipe Length 5MBoraNo ratings yet

- HDPE Bracketry: Choice of Pipe Installation MethodsDocument1 pageHDPE Bracketry: Choice of Pipe Installation MethodsBoraNo ratings yet

- The Marley Soil & Waste Installation GuideDocument1 pageThe Marley Soil & Waste Installation GuideBoraNo ratings yet

- Transitions To Other Materials: SanitaryDocument1 pageTransitions To Other Materials: SanitaryBoraNo ratings yet

- HDPE Jointing Methods: ElectrofusionDocument1 pageHDPE Jointing Methods: ElectrofusionBoraNo ratings yet

- Two Piece Pipe Bracket Angle CleatDocument1 pageTwo Piece Pipe Bracket Angle CleatBoraNo ratings yet

- Eccentric Reducer: Soil and Vent ComponentsDocument1 pageEccentric Reducer: Soil and Vent ComponentsBoraNo ratings yet

- WC Manifold System: Manifold Branch SM41W With SM42W A B Cut Line Projection DropDocument1 pageWC Manifold System: Manifold Branch SM41W With SM42W A B Cut Line Projection DropBoraNo ratings yet

- Trapped Floor GullyDocument1 pageTrapped Floor GullyBoraNo ratings yet

- Marley Fire Protection Range Fire SleevesDocument1 pageMarley Fire Protection Range Fire SleevesBoraNo ratings yet

- Tubular 'P' Trap Slimline Pedestal Trap: Universal Compression Joint TrapsDocument1 pageTubular 'P' Trap Slimline Pedestal Trap: Universal Compression Joint TrapsBoraNo ratings yet

- Access Cap & Pressure Plug: Soil and Vent ComponentsDocument1 pageAccess Cap & Pressure Plug: Soil and Vent ComponentsBoraNo ratings yet

- Tle7 Ict TD q2 Mod3 v4Document34 pagesTle7 Ict TD q2 Mod3 v4Tobias LowrenceNo ratings yet

- Gas Turbine ControlDocument81 pagesGas Turbine ControlJonathan Anderson100% (1)

- 10 Math Tricks That Will Blow Your Mind: Multiplying by 6Document4 pages10 Math Tricks That Will Blow Your Mind: Multiplying by 6Erlinda SantosNo ratings yet

- Cellphones Major Parts FunctionsDocument3 pagesCellphones Major Parts FunctionsAima Bandian0% (1)

- Priest, S Hudson, J (1976)Document14 pagesPriest, S Hudson, J (1976)DyTreZxZNo ratings yet

- Chapter 10: Forouzan Data Communications and NetworksDocument3 pagesChapter 10: Forouzan Data Communications and NetworksMaithaNo ratings yet

- Measurements Mid TermDocument2 pagesMeasurements Mid TermabdallaNo ratings yet

- Management 13th Edition Schermerhorn Test BankDocument25 pagesManagement 13th Edition Schermerhorn Test BankAlyssaThomasnpsk100% (52)

- Chem52 Su13 PracticeExam1ADocument11 pagesChem52 Su13 PracticeExam1Aamarka01No ratings yet

- Arduino Micro Controller Processing For Everyone Part 1Document114 pagesArduino Micro Controller Processing For Everyone Part 1fashazee6750100% (1)

- 10 1002@14356007 A27049Document34 pages10 1002@14356007 A27049Adam Septiyono ArlanNo ratings yet

- Diplomado CCNPDocument172 pagesDiplomado CCNPalexis pedrozaNo ratings yet

- DDCA Ch1Document99 pagesDDCA Ch1Dheer MehrotraNo ratings yet

- Introduction To The Program FULLPROF Refinement ofDocument15 pagesIntroduction To The Program FULLPROF Refinement ofehagar60No ratings yet

- GSG DiffuserStyleBarrelPump E00612 PDFDocument5 pagesGSG DiffuserStyleBarrelPump E00612 PDFsukrisnoNo ratings yet

- Basic Measurements in EpidemiologyDocument58 pagesBasic Measurements in EpidemiologyRida AwwalNo ratings yet

- DP Barte: DesignsDocument1 pageDP Barte: DesignsJjammppong AcostaNo ratings yet

- How To Use The Tide Tables: Method To Find Times or Heights of High and Low WatersDocument2 pagesHow To Use The Tide Tables: Method To Find Times or Heights of High and Low Watersjoeven64No ratings yet

- Pipe Flow: Philosophy, Sizing, and Simulation: Presenter: RizaldiDocument55 pagesPipe Flow: Philosophy, Sizing, and Simulation: Presenter: RizaldiRizaldi RizNo ratings yet

- Manual Set Constant (Signal Generator) : Function Code 2Document2 pagesManual Set Constant (Signal Generator) : Function Code 2Bapiraju Marri100% (1)

- Real Time Embedded Systems Lab ManualDocument51 pagesReal Time Embedded Systems Lab ManualHamid SaeedNo ratings yet

- Pov Nori Apr2007Document31 pagesPov Nori Apr2007DMRNo ratings yet

- Stock Price Prediction Using Long Short Term Memory: International Research Journal of Engineering and Technology (IRJET)Document9 pagesStock Price Prediction Using Long Short Term Memory: International Research Journal of Engineering and Technology (IRJET)Amit SheoranNo ratings yet

- Configuring OSPF On Non-Broadcast NetworksDocument5 pagesConfiguring OSPF On Non-Broadcast NetworksWally RedsNo ratings yet

- AMR Concept Notes (Sessions 11-12)Document5 pagesAMR Concept Notes (Sessions 11-12)SHREYA UNNIKRISHNAN PGP 2019-21 BatchNo ratings yet

- Chilling Injury in Pineapple Fruit Fatty Acid Composition and Antioxidant MetabolismDocument7 pagesChilling Injury in Pineapple Fruit Fatty Acid Composition and Antioxidant MetabolismNgô Hoàng HuyNo ratings yet

- Hero MotoCorpDocument17 pagesHero MotoCorpsai4sarath4mavuriNo ratings yet