Professional Documents

Culture Documents

Global Line Audit Report

Global Line Audit Report

Uploaded by

paul0 ratings0% found this document useful (0 votes)

5 views15 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

5 views15 pagesGlobal Line Audit Report

Global Line Audit Report

Uploaded by

paulCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 15

+ Contract No. GTC 2421ABI03 &

“Third Party Services

Linear Alkyl Benzene (LAB) Project Noe”

Germanischer Lloyd

Offshore and Industrial Services

DOCUMENT TRANSMITTAL

Qatar Petroleum

Branch Office Doha

LAB Complex P.O, Box 3288

P.O. Box 50033 Doha

Mesaieed State of Qatar.

Qatar Phone +974 466 1909

Att. : Mr, Raad Al Abdi Head of QA/QC Fax +974 466 1969

H E-mail: gl-doha@gl-

CC : Mir. Issa Al-Mosimani, DPM & EM seal alc

CC : Mr. Ahmed Al-Hitmi, Project Manager ine Aas ore

Your reference Your etter of ur ee. (fing sys.) Date 04/08/2008

GLO-A-17-0432

Subject: QA AUDIT REPORT FOR GLOBAL LINE

Enclosed please find IT REPORT(GLO-0-2 3.00} BAL LINE.

Please

Note (7) Review

‘Comment [x] Acknowledge

[—] settle [—] clarity SREY

Call Return TS ocjas

[J Supplement [| Keep for your fites bppsedenaasgtcanES

Action X | Forward : to -- GSE&C for 1A)

Due

Action req. : TEL

uz [a

egg) [oa

Best regards, tos (het

Germanischer Lloyd weyal | | dbs

Offshore and Industrial Service pat BD

4 7 is

Resident chief inspector

RECEIVED ABOVE DOCUMENTS

PRINTED NAME: ‘SIGNATURE: DATE:

‘CADOCUMIBNTS AND SETTINGSWISERMY DOCUMENTSIGLITRANSMITTALSIGLO-A-I7.0432.D0CRed

‘Managing Director: HartigC. Schoenbach

Germanischer Lloyd Ofhore avd Undusrial Services Gmblt» Registered Office Hamburg, HR B 69980

Place of performace and rections ambwrg, Ti lates editon af de General Terms ord Conlon is aplteabe. German av apie

| QPALNEAR ALKYL BENZENE (LAB) PROJECT

CONTRACT NO. GTC 242A A803

‘THIRD PARTY GNOG (INSPECTION) SERVICES

(GL Orde No 0at208-05550-30

Germanischer Lloyd

Offshore and Industrial Services

GLRel. No: GLO-0-2.3.0011

Report of Quality Assurance Audit

4. General

‘Name of firm: GLOBAL LINE CO, W.LL "GL"

Address: QP LAB PROJECT- MESAIEED ~STATE OF QATAR,

Tel. No: +974 - 5506473

Date of application 30/4/05..

2, Details on aut

Standard, specifications andlor regulations.

© GLIGP Contract

© GLauditplan,

© QP/LG Contract,

© Project Quality Plan.

© 180 9001-2000 quality systems requirement ISO 14000.

© GLOBAL quality manual.

Kind of audit 2 party audit (compound audit)

Current No. 1

Place and date: Mesaieed facilities 30/4/6..

GL experts involved in the audit:

Namo(s) Department / function

A.Nassef Resident chief inspector

Mohamed A. El Ganzory QA Engineer / Lead Auditor

‘Hesham El Khady QA Engineer "GL Doha”

QP experts involved in the aucit.

Name(s) Department / function

Abd E-Hameed Abo Ameera Senior QA8 QC Engineer

Cites of Saline Doesnt GLAUDITION ADT 1 GLORA INDIA suse #1GLOBAL LE doz

Plas of performance ond juredeton i Hambar. The ltt don of the “Ganerl Terms ancl Cenctions™ ae applicable 7

GermanlcherLayd” Offlore ond hnasral Services Goh agltned Office Hanbrg, HB 69980,

Form 3.03

2040608

+ OP-LINEAR ALKYL BENZENE (.A8) PROJECT

CONTRACT NO, Gro 242148103

‘THIRD PARTY GA/OC (INSPECTION) SERVICES

{GL Odor io. 0942.04 0888080

Germanischer Lloyd

Offshore and Industrial Services

LG Attendees :

Name(s) Department function

SS.Lee QARQC Mgr.

D.C.Bantisla CAS Inspector...

GLOBAL LINE Auditee's involved in the audit

Name(s) Department function

Y.G PARK Site Manager.

JK, SEO Admin, & planning Mag.

PN Castillo QA8QC supervisor....

3, Details on firm

Size of enterprise: Total number ofemployees: 154

Site Manager 1

Construction Manager 1

Total QAQC 5

Planning Manager 1

‘Administration Manager 1

Total HSE 3

Total technical (Direct) 109

Indirect Labour 33

4, Employees interviewed

Name(s) Department / function/position

PN. Castillo QA&QC inspector

R Mecetangay Safety officer

R Natividad PC operator

Scope of Work:

Global ine provides all construction services required forthe fabrication and installation of Above & Underground

piping, steel structures installation, plumping and grouting. , Equipment erection and completion.

Construction services include but not limited to provision of manpower, plant and equipment tools temporary

facilities, qualty assurance and quality contol, and HSE.

‘C:ADocuments and Settings\User\My Documents\GLAUDITIQA AUDIT 11 GLOBAL LINE\GA audit report 11GLOBAL

LINE. doc 6

| QPAINEAR ALK BENZENE (LAB) PROJECT

CONTRACT NO. GTC 2421803

"THIRD PARTY QOS (INSPECTION) SERVICES

{GL One Ho 0542.94 05850-90

Germanischer Lloyd

Offshore and Industrial Services

Overall Assessment

5.1. Documentation submitted

Quality Assurance Manual No: 4

Description of sub-contraotor. yes

Organization chart yes

Quality management system yes

Method statement yes

5.2 Audit performance:

The Audit was performed according to the attached quality plan & audit matrix. The concemed

personnel have been interviewed end the related quality documents were checked at specified

locations in two days.

© 4 day audit start at 08:30 AM to02:30 PM

© 2%! day audit start at 01:00 PM to 02:45 PM

5.21 OPENING MEETING

Quality audit star at 08:30 AM in GLOBAL LINE office at site, with presence of the above auditors, attendees

and auditee's introducing the scope of the audit activities (audit plan matrix) and the reason of this audit

5.2.2 Audit results :

Although GLOBAL LINE have not an ISO Certification but they submit their quality assurance manual,

Project Inspection & Test plan, quality procedures and method statements

GLOBAL LINE did not submit offictally their quality management procedure which covers the

Fequirements of ISO 9001 to QP/GL .

The following are the audit results for each audited item:

5.2.2.4 Quality management systems requirements & management responsibilities.

© Although GLOBAL LINE has no ISO 9001-2000 certificate as required by the Contract, but it is under

processing (the Sub-contractor submit thelr evidence ).

© Although GLOBAL LINE presented their quality management procedures during the audit activities but

these procedures sill not completed or approved . NCR No.GLO-Q-2.4-0014

© GLOBAL LINE has an updated organization chart and mobilization chart

© GLOBAL LINE management & key personnel responsibliies & duties were clear to their staff and

their files ware recognized and indexes were complete.

© The sub-contractor managers & key personal hold a weekly meeting to discuss the project QC

activities, and they review their intemal audit and self check findings

© Although GLOBAL LINE have a Quality Policy and their staff was aware about its requirements but the

company policy is not signed by the executive director and need to be revised to reflect ISO 900'-

2000 warding See Obs.GLO-Q.2.4-0026

C:ADocuments and Settings\User\My Documents\GLIAUDITIGA AUDIT 11 GLOBAL LINE\QA audit report 11GLOBAL

LINE doc

ws

(OP-LINEAR ALKYL BENZENE (LAB) PROJECT

(CONTRACT NO. GTC 242188103

THIRD PARTY QNOC (INSPECTION) SERVICES

GL Order No 0542.4.05850.90

Germanischer Lloyd

Offshore and Industrial Services

5.2.2.2Resources management

GLOBAL LINE has no clear training plan for their staff but they hrave @ record forall training done to

their staff including safety matters.

© GLOBAL LINE keeps its staff CV's and certificates filed. This found reflecting their qualification to

cover the Project activities.

5.2.2.3Product realization

GLOBAL LINE kept all the latest revision of the method statements and procedures

in organized fles

© Welding MIC and ovens were maintained in Good, calibrated & certified Condition.

‘© Allliting equipments were maintained in Good, calibrated & certified Condition

5.2.2.4 Process control (fabrication, erection, installation & welding)

‘Al drawings were latest edition and they comply with the document approval procedure ( the old

revision stamped superseded )

Workshops and erection site use the approved welding procedure, using the proper tools, and

equipment (calibrated and verified)

‘All welders have an approved ID cards and weld certificates, end found using proper welding electrodes

‘The welding supervisor and QC inspectors control the Welding electrode drying cycles, and transfer the

heat No, for each plece of material.

‘Although Global line has 2 good control system on physical workshop and site on the material

traceability, but during the audit activity to check a sample of underground hydro test packages ., the

auditors found a wrong heat no. in the history sheet compared to the daily welding report and QC

welding maps which need high care and precision corrective action

‘See NCR No.GLO-Q-2.4-0015

5.2.2.5 Monitoring & corrective action

GLOBAL LINE conduct intemal audits on their site activities.

5.2.2.6 Self Check & Auditing

GLOBAL LINE has a procedure for auditing , audit schedule and they conduct internat audits, On their

project activities

5.2.2.7 System Improvement

GLOBAL LINE has a procedure availabe for project improvement and they do their best to correct and

prevent any deficiencies in their systems.

5.2.2.8 Filing , Storage & Handling

All method statements are up to date

‘CADocuments and Settings\Use/\My Dooumenis\GLIAUDITIQA AUDIT 11 GLOBAL LINE\QA audit report 11GLOBAL

LINE.doc M6

‘OP-LINEAR ALKYL BENZENE (LAB) PROJET

CONTRACT HO. GTC 242LAB1S

‘THIRD PARTY GNC (INSPECTION) SERVICES

(GL Orie No 054204-08550-90

Germanischer Lloyd

Offshore and Industrial Services

‘Work environment was satisfactory and suitable

‘The project Codes and standerus in hard copy were available

5.2.2.9 Maintenance of Documentation

Filing system was aveitable forthe project fles and most indexes were completed,

5.2.2.10 Environmental , safety & emergency

‘Atthough GLOBAL LINE has a safety manual but they have no safety policy or emergency procedure. See NCR

GLO-0-2.4-0016,

GLOBAL LINE has enough safety personnel who can cover all the project activities

5.22.11 Close Mecting

Aer review all the findings by the Auditors, Attendees & Auditees with all the findings were explained to

GLOBAL LINE

Auditors have found that the sub-contractor (GLOBAL LINE) comply with the project spectfication and epproved

procedures on the project activites, and they are considered good example in project management whichis

reflected in their good performance in controling the project The finding as mentioned above was minor excapt

the Non conformance in material traceability which need high attention and accurate corrective action

‘The finding ists attached to this report

A. Nassef

(GL/ Resident chief Inspector) a4

NOUSTRIAL SERVICES Lee

SERVES

Place, Date 20347 20352

OP LAB PROJECT - MESAIEED

e4jo a

des Jeses

C:\Documents and Settings\UseriMy Documents\GLIAUDITIQA AUDIT 11 GLOBAL LINE\QA audit report 11GLOBAL

LINE.doc ws

. OPANEAR ALKYL BENZENE (LAB) PROJECT

CONTRACT NO. GTo2A2/LABD3

THIRD PARTY GNC (INSPECTION SERVICES

Oster to,

op42-0¢- 0565080,

Germanischer Lloyd

Offshore and Industrial Services

5.N.O

DEFICIENCES DESCRIPTION

CLASS OF

DEFICIENCIES

Although GLOBAL LINE presented their quality management procedures during

the audit activities but their procedure stil not complete or approved.

GLOBAL LINE has no ISO 9001-2000 certificate.

NCR .GLO-Q-2.4-0014|

‘Alihough GLOBAL LINE have @ Quality Policy and their staff was aware about is

requirements but the policy is not signed by the executive director and need to be

revised to reflect {SO 9001-2000 warding

Obs.GLO--2.5-0026)

Although Global line has a good control system on workshop and site for material

traceability, but during the audit activity to check sample of underground hydro

lest packages ., the auditors found @ wrong heal no. in the history sheet

compared with the dally welding report and QC welding maps which need high

care and precision corrective action

NOR GLO-0-24-0015

GLOBAL LINE has no safety policy or emergency plan.

NCR GLO-0-24.0016

Als BE

C:\Documents and Settings\User\My Documents\GLIAUDITIQA AUDIT 11 GLOBAL LINE\QA audit report 11GLOBAL

LINE.doc

‘QP-LINEAR ALKYL BENZENE (LAB) PROJECT

‘CONTRACT HO. GTC 2421ABI3

THIRD PARTY AC (INSPECTION) SERVICES

GL Ordor No. 0842-08-0565050,

Germanischer Lloyd

Offshore and Industrial Services

GL Site Office |

Mesiset ote! QA AUDIT NCR | No. GLO-G2.4-014

‘ATT. Mr. Read AlAbdi, QA&QC MGR :

CCl Issa Al-Mosimani, DPM & EM FROM : Ae Masse atnspector | DATE: 04.05.2005

Mr. Ahmed ALHitmi, Project MGR Pe

DEFICIENCY DETAILS:

During GL audit activities which were conducted to GLOBALLINE on 30™ of April 2005, it was

found that GLOBALLINE has no ISO 9001-2000 Certificate, Although GLOBALLINE presented

their Quality Management Procedures but their procedure was not approved.

Based on the above deficiency contractor is requested to take corrective action,

ae ‘aS

aa 4ffe

M.ELGANZORY A. NASSEF

gspesior 0 GL Sinopec

RESPONSE REQUIRED WITHIN 72_| HOURS

‘OP-LIVEAR ALKYL BENZENE (LAB) PROJECT

‘CONTRACT NO. GTC 2¢2LABIN3

THIRD PARTY QA (INSPECTION) SERVICES

GGL Order No, 0942.04.95680:90,

Germanischer Lloyd

Offshore and Industrial Services

DATE: 04.05.2005 QA AUDIT NCR No: GLO-Q-2.4- 014

ACTION PROPOSED {TO BE COMPLETED BY LG RESPONSIBLE PERSON)

CONCESSION REQUEST YES | No

CONTRACTOR A/C MANAGER GLAPPROVED NOT APPROVED

SIGNATURE SIGNATURE:

NAME: NAME:

DATE: DATE:

CORRECTIVE ACTION COMPLETION

DATE SIGNATURE

COMPLETED: RESPONSIBLE PERSON (LG)

ACTION APPROVAL (GL)

SIGNATURE NO FURTHER ACTION o

POSITION Resident Chief Inspector FURTHER ACTION REQUIRED

DATE

CC: GL Doha Office

CC: Gl Head Office

2a erste pacreay

“GP-LINEAR ALKYL BENZENE (LAB) PROJECT

CONTRACT NO. GTC 242. ABI03

‘THIRD PARTY GQA/QG (INSPECTION) SERVICES

GL Order No, eoe2 8 o6850-99

Germanischer Lloyd

Offshore and Industrial Services

GL Site Office

Mesaieed, Qatar.

QA AUDIT NCR

No. GLO-Q-2.4+ 045

ATT. Mr. Read AlAbdi, GABQC MGR :

CC.Mr. Issa AL-Mosimani, DPM & EM FROM tee yaset afinspector | DATE: 04.05.2008

Mr. Ahmed AL-Hitmi, Project MGR P

DEFICIENCY DETAILS:

During GL audit activities which were conducted to GLOBALLINE on 30™ of April 2005, it was

found that GLOBALLINE Traceability system is suffering a deficiencies in the way that the

Traceability data is transferred through different fabrication stages, ultimately the history sheet is

not matching the actual data of material installed.

Contractor is requested to propose the corrective measures for system integrity.

‘fe

A. NASSEF

Surveyor e-Gt

RESPONSE REQUIRED WITHIN

2

HOURS

COP-LIEAR ALKYL BENZENE (LAB) PROJECT

(CONTRACT No. GTC 242/LABI0G

JTARD PARTY GA/QC (WSPECTION) SERVICES

GL Onder Mo. 00420896580-90

Germanischer Lloyd

Offshore and Industrial Services

DATE: 04.05.2005

QA AUDIT NCR

No: GLO-0.24-015

ACTION PROPOSED (TO BE COMPLETED BY LG RESPONSIBLE PERSON)

CONCESSION REQUEST YES

CONTRACTOR QA / QC MANAGER GLAPPROVED ] NOT APPROVED

SIGNATURE: ‘SIGNATURE:

NAME: NAME:

DATE: DATE:

CORRECTIVE ACTION COMPLETION

DATE SIGNATURE

COMPLETED: RESPONSIBLE PERSON (LG)

‘ACTION APPROVAL (GL)

SIGNATURE NO FURTHER ACTION oO

POSITION Resident Chief Inspector FURTHER ACTION REQUIRED 1

DATE

CC: GL Doha Office

CC: GL Head Office

enarsp0cmesy

+ QP-LINEAR ALKYL BENZENE (LAB) PROJECT

CONTRACT NO, GTC 2421.

THRO PARTY GNOC (NSPECTION SERVICES

GL.OnderWo.o342.0¢. 0565080

Germanischer Lloyd

Offshore and Industrial Services

GL Site Office

Mesaieed, Qatar.

QA AUDIT NCR

No, GLO-.2.4- 016

ATT. Mr, Raad Al Abdi, QA&QC MGR iq

CC.Mr. Issa A-Mosimani, DPM & EM Fae eee geet afinspector | DATE: 04.05.2005

Mr, Ahmed Al-Hitmi, Project MGR Pe I

DEFICIENCY DETAILS:

During GL audit activities which were conducted to GLOBALLINE on 30™ of April 2005, it was

found that GLOBALLINE has no Safety Policy or Emergency plan.

Based on the above deficiency contractor is required to take corrective action.

Gow Ly

MEL! Seagony

q

RESPONSE REQUIRED WITHIN

+ GP-LINEAR ALKYL BENZENE (LAB) PROJECT

CONTRACT WO. GTC 242. ABN

THIRD PARTY GNQC (NSPECTION SERVICES

GL Onis No-0042.04-06580-90

Germanischer Lloyd

Offshore and Industrial Services

DATE: 04.05.2005 QA AUDIT NCR No: GLO-Q-24-016

ACTION PROPOSED (TO BE COMPLETED BY LG RESPONSIBLE PERSON)

“CONCESSION REQUEST YES | NO

CONTRACTOR QA / QC MANAGER GL APPROVED NOT APPROVED

SIGNATURE: SIGNATURE:

NAME: NAME:

DATE: DATE:

CORRECTIVE ACTION COMPLETION

DATE SIGNATURE

COMPLETED: RESPONSIBLE PERSON (LG)

‘ACTION APPROVAL (GL)

SIGNATURE NO FURTHER ACTION o

POSITION Resident Chief Inspector FURTHER ACTION REQUIRED 0

DATE

CC: GL Doha Office

| CC: GL Head Office

net nexorepocrele

+ P-UINEAR ALKYL BENZENE (LAB) PROJECT

(CONTRACT HO. GTC 24a/.ABIOG

‘HIRD PARTY QNQC (INSPECTION SERVICES

BL Order No: 042-08 0555090,

Germanischer Lloyd

Offshore and Industrial Services

GL Site Office

Mesaieed, Qatar. QA AUDIT OBSERVATION No. GLO-0-2.5- 026

‘ATT. Mr. Raad AI Abdi, QABQC MGR :

CC.Mr. Issa A-Mosimani, DPM & EM Fao ae ae iefinspector | DATE: 04.05.2008

Mr. Ahmed Al-Hitmi, Project MGR Ps

DEFICIENCY DETAILS:

During GL audit activities which were conducted to GLOBALLINE on 30™ of APRIL 2005.

GL auditors found that GLOBAL LINE has @ Quality policy and their staff were aware of its

requirements, but the policy is not signed by its Executive director and it is to be revised to reflect

180 9001-2000.

Based on the above deficiency Contractor is requested to take both Corrective Action.

coy

EL Gi

ir to GL

RESPONSE REQUIRED WITHIN 72 | HOURS

ous. 000Reter

(PLN ALKYL BENZENE (8) PROJECT

ComRACT NO. GTC 2z2LABItS

Hl

PARTY GAIQC (INSPECTION) SERVICES

0

(GL Order No, 0942062665

Germanischer Lloyd

Offshore and Industrial Services

DATE: 04.05.2005

QA AUDIT OBSERVATION No:

GLO-Q-2.5 - 026

| ACTION PROPOSED (TO BE COMPLETED BY LG RESPONSIBLE PERSON):

CC: GL Doha Office

CC: GL Head Office

“CONCESSION REQUEST YES No

CONTRACTOR QA QC MANAGER GLAPPROVED NOT APPROVED

SIGNATURE: SIGNATURE:

NAME: NAME:

DATE: DATE

CORRECTIVE ACTION COMPLETION

DATE SIGNATURE

COMPLETED: RESPONSIBLE PERSON (LG)

"ACTION APPROVAL (GL)

SIGNATURE NO FURTHER ACTION oO

POSITION __ Resident Chief Inspector FURTHER ACTION REQUIRED ©

DATE

awa

consouocnatty

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

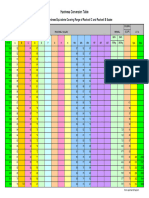

- Brinell Hardness TestsDocument1 pageBrinell Hardness TestspaulNo ratings yet

- Pre HeatDocument1 pagePre HeatpaulNo ratings yet

- Hardness Conversion TableDocument7 pagesHardness Conversion TablepaulNo ratings yet

- Quality Audit HandbookDocument160 pagesQuality Audit HandbookpaulNo ratings yet

- QC - Manual Asme CourseDocument8 pagesQC - Manual Asme CoursepaulNo ratings yet

- Purchase - Order Asme CourseDocument1 pagePurchase - Order Asme CoursepaulNo ratings yet

- Re Heat CrackingDocument1 pageRe Heat CrackingpaulNo ratings yet

- WPS 1310Document2 pagesWPS 1310paulNo ratings yet

- Solidification CracksDocument1 pageSolidification CrackspaulNo ratings yet

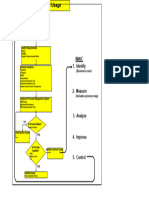

- Tool Usage RoadmapDocument1 pageTool Usage RoadmappaulNo ratings yet

- Swi Compulsory QuestionDocument2 pagesSwi Compulsory QuestionpaulNo ratings yet

- SWI 2a Duties SWIDocument12 pagesSWI 2a Duties SWIpaulNo ratings yet

- Swi Q7 & UpDocument10 pagesSwi Q7 & UppaulNo ratings yet

- ASME Course Materails HandlingDocument32 pagesASME Course Materails HandlingpaulNo ratings yet