Professional Documents

Culture Documents

NG20 Flayer 03 2009

NG20 Flayer 03 2009

Uploaded by

govindaraj171Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NG20 Flayer 03 2009

NG20 Flayer 03 2009

Uploaded by

govindaraj171Copyright:

Available Formats

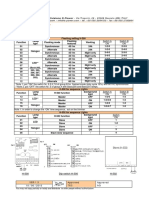

M U LT I F U N C T I O N P R O T E C T I O N F O R S Y N C H R O N O U S

G E N E R AT O R S O R N O T S E L F - S TA R T E D S Y N C H R O N O U S M O T O R S

Application

Several functions, required for synchronous generators and not

self-started synchronous motors are included.

Protective functions

26 Thermal protection with RTD probes (optional)

27 Undervoltage

32R Active reverse power

37P Active underpower

40 Loss of field

46 Negative sequence overcurrent

49 Thermal image

50/51 Phase overcurrent

51V Voltage restraint overcurrent

50N/51N Residual overcurrent (90% stator earth fault)

or high impedance restricted earth fault

55 Minimum power factor (out of step)

59 Overvoltage

59N Residual overvoltage (90% stator earth fault)

81O/81U Over & underfrequency

BF Circuit breaker failure

NG20 NG20

52

52

74TCS

81O 81U 74TCS

59N 27 59 74VT 59N 27 59 81U 74VT

GS 32R 37P 40 51V 46 32R 37P 40 55

26

46 49 50/51 BF 74CT

74CT BF 50/51 49

METERING

50N 51N - I L1..I L3,I E,UL1..UL3,UE..

Control functions

- Oscillography

&

- Events & Faults log

50N 51N Logic selectivity

26 COMMUNICATION

COMMUNICATION

METERING - RS232 MS - RS232

- I L1..I L3,I E,UL1..UL3,UE.. - Modbus RS485 Control functions - Modbus RS485

- Oscillography - Modbus TCP/IP & - Modbus TCP/IP

- Events & Faults log - IEC 870-5-103/DNP3 Logic selectivity - IEC 870-5-103/DNP3

NG20 - Flayer - 03 - 2009

Construction Blocking input/outputs

According to the hardware configurations, the NG20 protection One output blocking circuit (motor protection) and one input

relay can be shipped in various case styles depending on the blocking circuit (generator protection) are provided.

required mounting options (flush, projecting mounting, rack or The output blocking circuits of one or several Pro_N relays,

with separate operator panel). shunted together, must be connected to the input blocking cir-

cuit of the protection relay, which is installed upstream in the

Firmware updating electric plant. The output circuit works as a simple contact,

The use of flash memory units allows on-site firmware updating. whose condition is detected by the input circuit of the upstream

protection relay.

Measuring inputs

• Three phase current inputs and one residual current input, Output relays

with nominal currents independently selectable at 1 A or 5 A Six output relays are available (two changeover, three make and

through DIP-switches. one break contacts); each relay may be individually programmed

• Three phase voltage inputs with programmable nominal volt- as normal state (normally energized, de-energized or pulse) and

ages within range 50...130 V (UR=100 V) or 200...520 V (UR=400 V) reset mode (manual or automatic).

and one residual voltage input, with programmable nominal A programmable timer is provided for each relay (minimum

voltage within range 50...130 V (UER=100 V). pulse width). The user may program the function of each relay

• Height input for Pt100 iprobes (optional by means external according to a matrix (tripping matrix) structure.

MPT module).

MMI (Man Machine Interface)

Modular design The user interface comprises a membrane keyboard, a backlight

In order to extend I/O capability, the NG20 hardware can be cus- LCD alphanumeric display and eight LEDs.

tomized through external auxiliary modules: The green ON LED indicates auxiliary power supply and self di-

• MRI - Output relays and LEDs (provided with NA80) agnostics, two LEDs are dedicated to the Start and Trip (yellow

• MID16 - Binary inputs for Start, red for Trip) and five red LEDs are user assignable.

• MCI - 4...20 mA converters

• MPT - Pt100 probe inputs.

Programming and settings

All relay programming and adjustment operations may be per-

Binary inputs formed through MMI (Keyboard and display) or using a Personal

Two binary inputs are available with programmable active state Computer with the aid of the ThySetter software.

(active-ON/active-OFF) and programmable timer (active to OFF/ The same PC setup software is required to set, monitor and con-

ON or ON/OFF transitions). figure all Pro_N devices.

Several presettable functions can be associated to each input. Full access to the available data is provided:

• Read status and measures.

• Read/edit settings (on-line or off-line edit).

Two session level (User or Administrator) with password for sen-

sible data access are provided.

2 NG20 - Flayer - 03 - 2009

Communication Metering

Multiple communication interfaces are implemented: NG20 provides metering values for phase and residual currents,

• One RS232 local communication front-end interface for com- phase and residual voltage, making them available for reading

munication with ThySetter setup software. on a display or to communication interfaces.

• Two back-end interfaces for communication with remote mon- Input signals are sampled 24 times per period and the RMS value

itoring and control systems by: of the fundamental component is measured using the DFT (Dis-

- RS485 port using ModBus® RTU, IEC 60870-5-103 or DNP3 crete Fourier Transform) algorithm and digital filtering.

protocol. On the base of the direct measurements, several calculated

- Ethernet port (RJ45 or optical fiber), ModBus/TCP protocol. (min, max, average,...), phase displacement, sequence, power,

harmonic, demand and energy measures are processed.

Control and monitoring Measures can be displayed with reference to nominal values or

Several predefined functions are implemented: directly expressed in amperes and volts.

• Activation of two set point profiles.

• Phase CTs and VTs monitoring (74CT and 74VT).

Frequency tracking

In the 20...70 Hz range a frequency tracking algorithm adjusts the

• Logic selectivity.

sample frequency so that the number of samples for any cycle

• Trip circuit supervision (74TCS).

is fixed.

• Circuit Breaker commands and diagnostic.

The frequency measure is performed on the best next signal

Moreover user defined logic must be customized in accordance

from the input voltages; if all voltage are lower than 1 % En, the

with IEC 61131-3 protocol by means programmable logic control-

frequency measure is performed on the best next signal from the

ler (PLC).

input currents.

Circuit Breaker If all current inputs are lower than 0.15 In and all voltage inputs

Several diagnostic, monitoring and control functions are provided: are lower than 1 % En, the sampling frequency is tied to the nom-

• Health thresholds can be set; when the accumulated duty (ΣI inal value (fn = 50 o 60 Hz).

or ΣI2t), the number of operations or the opening time exceeds If the line frequency is out of the tracking range, the sampling

the threshold an alarm is activated. frequency is tied to the extreme limit (20 o 70 Hz).

• Breaker failure (BF); breaker status is monitored by means Event storage

52a-52b and/or through line current measurements. Several useful data are stored for diagnostic purpose.

• Trip circuit supervision (74TCS). They are graded from the newest to the older after the “Events

• Breaker control; opening and closing commands can be car- reading” command (ThySetter) is issued:

ried out locally or remotely. • Sequence of Event Recorder (SER).

Logic selectivity The event recorder runs continuously capturing in circular

With the aim of providing a fast selective protection system mode the last three hundred events upon trigger of binary in-

some protective functions may be blocked (pilot wire accelerat- put/output.

ed logic). To guarantee maximum fail-safety, the relay performs a • Sequence of Fault Recorder (SFR).

run time monitoring for pilot wire continuity and pilot wire short- The fault recorder runs continuously capturing in circular

ing. Exactly the output blocking circuit periodically produces a mode the last twenty faults upon trigger of binary input/output

pulse, having a small enough width in order to be ignored as and/or element pickup (start-trip).

an effective blocking signal by the input blocking circuit of the • Trip counters.

upstream protection, but suitable to prove the continuity of the Digital Fault Recorder (Oscillography)

pilot wire. Upon trigger of tripping/starting of each function or external sig-

Furthermore a permanent activation (or better, with a duration nals, the relay records in COMTRADE format:

longer than a preset time) of the blocking signal is identified, as • Oscillography with instantaneous values for transient analysis.

a warning for a possible short circuit in the pilot wire or in the • RMS values for long time periods analysis.

output circuit of the downstream protection. • Logic states (binary inputs and output relays).

NG20 - Flayer - 03 - 2009 3

SPECIF IC AT IONS

GENERAL INPUT CIRCUITS

Mechanical data Auxiliary power supply UAUX

Mounting: flush, projecting, rack or separated operator panel Nominal value (range) 24...48 Vac/dc

Mass (flush mounting case) 2.0 kg 115...230 Vac/110...220 Vdc

Operative range (each one of the above nominal values) 19...60 Vac/dc

Insulation tests 85...265 Vac/75...300 Vdc

Reference standards EN 60255-5 Power consumption:

High voltage test 50 Hz 2 kV 60 s • Maximum (energized relays, Ethernet TX) 10 W (20 VA)

Impulse voltage withstand (1.2/50 μs) 5 kV • Maximum (energized relays, Ethernet FX) 15 W (25 VA)

Insulation resistance >100 MΩ

Phase current inputs

Voltage dip and interruption Nominal current In 1 A or 5 A selectable by DIP Switches

Reference standards EN 61000-4-29 Permanent overload 25 A

Thermal overload (1s) 500 A

EMC tests for interference immunity Rated consumption (for any phase) ≤ 0.002 VA (In = 1 A)

1 MHz damped oscillatory wave EN 60255-22-1 1 kV-2.5 kV ≤ 0.04 VA (In = 5 A)

Electrostatic discharge EN 60255-22-2 8 kV

Fast transient burst (5/50 ns) EN 60255-22-4 4 kV Residual current input

Conducted radio-frequency fields EN 60255-22-6 10 V Nominal current IEn 1 A or 5 A selectable by DIP Switch

Radiated radio-frequency fields EN 60255-4-3 10 V/m Permanent overload 25 A

High energy pulse EN 61000-4-5 2 kV Thermal overload (1s) 500 A

Magnetic field 50 Hz EN 61000-4-8 1 kA/m Rated consumption ≤ 0.006 VA (IEn = 1 A)

Damped oscillatory wave EN 61000-4-12 2.5 kV ≤ 0.012 VA (IEn = 5 A)

Ring wave EN 61000-4-12 2 kV

Conducted common mode (0...150 kHz) EN 61000-4-16 10 V Voltage inputs

Reference voltage UR 100 V or 400 V selectable on order

Emission Nominal voltage Un 50...130 V or 200...520 V adjustable via sw

Reference standards EN 61000-6-4 (ex EN 50081-2) Permanent overload 1.3 UR

Conducted emission 0.15...30 MHz Class A 1s overload 2 UR

Radiated emission 30...1000 MHz Class A Rated consumption (for any phase) ≤ 0.5 VA

Climatic tests Residual voltage input

Reference standards IEC 60068-x, ENEL R CLI 01, CEI 50 Reference voltage UER 100 V

Nominal voltage UEn 50...130 V adjustable via sw

Permanent overload 1.3 UER

Mechanical tests 1s overload 2 UER

Reference standards EN 60255-21-1, 21-2, 21-3 Rated consumption ≤ 0.5 VA

Safety requirements Binary inputs

Reference standards EN 61010-1 Quantity 2

Pollution degree 3 Type dry inputs

Reference voltage 250 V Max permissible voltage 19...265 Vac/19...300 Vdc

Overvoltage III Max consumption, energized 3 mA

Pulse voltage 5 kV

Reference standards EN 60529

Protection degree: Block input (Logic selectivity)

• Front side IP52 Quantity 1

• Rear side, connection terminals IP20 Type polarized wet input (powered by internal isolated supply)

Max consumption, energized 5 mA

Environmental conditions RTD inputs (MPT optional external module)

Ambient temperature -25...+70 °C Quantity 8

Storage temperature -40...+85 °C Type Pt100

Relative humidity 10...95 % Range 0...200 °C

Atmospheric pressure 70...110 kPa

OUTPUT CIRCUITS

Certifications

Product standard for measuring relays EN 50263 Output relays K1...K6

CE conformity Quantity 6

• EMC Directive 89/336/EEC • Type of contacts K1, K2 changeover (SPDT, type C)

• Low Voltage Directive 73/23/EEC • Type of contacts K3, K4, K5 make (SPST-NO, type A)

Type tests IEC 60255-6 • Type of contacts K6 break (SPST-NC, type B)

Nominal current 8A

Nominal voltage/max switching voltage 250 Vac/400 Vac

COMMUNICATION INTERFACES

Breaking capacity:

Local PC RS232 19200 bps • Direct current (L/R = 40 ms) 50 W

Network: • Alternating current (λ = 0,4) 1250 VA

• RS485 1200...57600 bps Make 1000 W/VA

• Ethernet 100BaseT 100 Mbps Short duration current (0,5 s) 30 A

Protocol ModBus® RTU/IEC 60870-5-103/DNP3-TCP/IP

4 NG20 - Flayer - 03 - 2009

Block output (Logic selectivity) U<< Element

Quantity 1 Definite time

Type optocoupler • 27 Second threshold definite time (U <<def) 0.05...1.10 U n /E n

• U<<def Operating time (t U<<def ) 0.07...100.0 s

LEDs Note [1] - With U ph-ph setting all threshold are in p.u. U n

Quantity 8 With U ph-n setting all threshold are in p.u. E n

• ON/fail (green) 1 Note [2] - The mathematical formula for INVERSE curves is:

• Start (yellow) 1 t = 0.75 · t U< inv / [1 - (U /U <inv)]

• Trip (red) 1

• Allocatable (red) 5 where:

t = trip time (in seconds)

t U< inv = operating time setting (in seconds)

GENERAL SETTINGS U = input voltage

U<inv = threshold setting

Rated values

Relay nominal frequency (f n) 50, 60 Hz

Relay phase nominal current (In) 1 A, 5 A Active reverse power - 32R

Phase CT nominal primary current (Inp) 1 A...10 kA P-> Element

Relay residual nominal current (IEn) 1 A, 5 A • P-> Reset time delay (t P-> RES) 0.0...10.0 s

Residual CT nominal primary current (IEnp) 1 A...10 kA • 32R First threshold definite time (P-> def ) -0.01...-1.00 Pn

Relay nominal voltage (phase-to-phase) (Un) 50...130 V or 200...520 V • P-> def Operating time (t P-> def ) 0.07...100.0 s

Relay nominal voltage (phase-to-ground) En= Un/√3

Line VT primary nominal voltage (phase-to-phase) (Unp) 50 V..500 kV Active underpower - 37P

Relay residual nominal voltage (direct measure) (UEn) 50...130 V P+< Element

Residual primary nominal voltage (phase-to-phase) · √3 (UEnp) • 37 First threshold definite time (P+<def ) 0.01...1.20 Pn

50 V...500 kV • P+<def Operating time (t P+< def ) 0.07...100.0 s

Nominal active power Pn = √3UnIn = 3EnIn

Nominal reactive power Qn = √3UnIn = 3EnIn Loss of field - 40

Nominal apparent power Sn = √3UnIn = 3EnIn • Common configuration:

Phase nominal impedance Znf = Un/√3In = En / In • Operating mode Motor/Generator

• Undervoltage threshold (U SUP< ) 0.50...1.00 Un

Binary input timers Alarm Element

ON delay time (IN1 tON...IN10 tON) 0.00...100.0 s • 40AL Alpha angle α 10...75°

OFF delay time (IN1 tOFF, IN2 tOFF) 0.00...100.0 s • 40AL Operating time (t40AL ) 0.07...100.0 s

Logic Active-ON/Active-OFF

XC1-XD1 Element

Relay output timers • XC1 Absolute center coordinate (XC1) 0.00...+4.50 Znf

Minimum pulse width 0.000...0.500 s • XD1 Diameter (XD1) 0.20...+5.00 Znf

• XC1-XD1 Operating time (t XC1-XD1) 0.07...100.0 s

• XC1-XD1 Reset time delay (t XC1XD1-RES) 0.0...10.0 s

FUNCTIONS

XC2-XD2 Element

Base current IB • XC2 Absolute center coordinate (XC2 ) 0.00...+4.50 Znf

Base current (IB) 0.40...1.50 In • XD2 Diameter (XD2 ) 0.20...+5.00 Znf

• XC2-XD2 Operating time (t XC2-XD2 ) 0.07...100.0 s

Note: the basic current IB represents the nominal current of the line or trans- • XC2-XD2 Reset time delay (t XC1XD2-RES) 0.0...10.0 s

former, referred to the nominal current of the CT’s for thermal image pro-

tection. If the secondary rated current of the line CT’s equals the rated

Negative sequence overcurrent - 46

current of the NG20 relay, as usually happens, the IB value is the ratio

Common configuration:

between the rated current of the protected element and the primary

• Heating time constant Kheat 0.1...40.0 s

rated current of the CT’s

• Cooling time constant Kcool 0.1...40.0 s

• Minimum operating time t 2MIN 0.07...100.0 s

Thermal protection with RTD probes - 26 • Maximum operating time t 2MAX 500...2000 s

Alarm element

• 26 alarm threshold definite time θALx, (x=1...8) 0...200 °C I2AL> Element

• Operating time t θALx (x=1...8) 0....100 s Definite time

• 46 First alarm threshold (I2AL > def ) 0.03...0.50 IB

Trip element • Operating time I2AL > def (t 2AL > def ) 0.07...100.0 s

• 26 threshold definite time θ>x, (x=1...8) 0...200 °C

• Operating time t θ >x (x=1...8) 0....100 s I2>> Element

Inverse time

Undervoltage - 27 • 46 Second threshold (I2 >>inv) 0.05...0.50 IB

Common configuration: Note - Inverse time curve: t = Kheat /(I2/IB)2

• Voltage measurement type for 27 (Utype27) [1] U ph-ph /U ph-n

• 27 Operating logic (Logic27) AND/OR Thermal image - 49

Common configuration:

U< Element

• Initial thermal image ΔθIN (Dth IN ) 0.0...1.0 ΔθB

• U< Curve type (U<Curve) DEFINITE

• Reduction factor at inrush (KINR) 1.0...3.0

INVERSE [2]

• Heating thermal time constant τ+ (T+) 1...200 min

Definite time

• Cooling thermal time constant τ− (T-) 1.0...6.0 τ+

• 27 First threshold definite time (U <def) 0.05...1.10 U n /E n

• Negative sequence coefficient (K2) 0...10

• U<def Operating time (t U<def ) 0.07...100.0 s

Inverse time DthAL1 Element

• 27 First threshold inverse time (U <inv) 0.05...1.10 U n /E n • 49 First alarm threshold ΔθAL1 (Dth AL1) 0.3...1.1 ΔθB

• U<inv Operating time (t U<inv) 0.10...100.0 s

Dth> Element

• 49 Trip threshold Δθ (Dth>) 1.2 ΔθB

NG20 - Flayer - 03 - 2009 5

Phase overcurrent - 50/51 Minimum power factor - 55 (Out of step)

I> Element CPhi< Element

• I> Curve type (I>Curve) DEFINITE • CB55 Delay (tARM-CPhi<) 0.07...300 s

IEC/BS A, B, C

Definite time

ANSI/IEEE MI, VI, EI

• CPhiLAG< Threshold definite time (CPhiLAG<) 0.1...0.9

I2t or EM

• CPhiLAG< Operating time (t CPhiLAG<) 0.04...100.0 s

• I> Reset time delay (t > RES) 0.00...100.0 s

• CPhiLEAD< Threshold definite time (CPhiLEAD<) 0.1...0.9

Definite time • CPhiLEAD< Operating time (t CPhiLEAD<) 0.04...100.0 s

• 50/51 First threshold definite time (I> def ) 0.100...40.0 In

• I> def Operating time (t > def ) 0.04...200 s Overvoltage - 59

Inverse time Common configuration:

• 50/51 First threshold inverse time (I>inv) 0.100...10.00 In • Voltage measurement type for 59 (Utype59) [1] U ph-ph /U ph-n

• I>inv Operating time (t >inv) 0.02...60.0 s • 59 Operating logic (Logic59) AND/OR

I>> Element

• Type characteristic (I>>Curve) DEFINITE/I2t U> Element

• I>> Reset time delay (t >> RES) 0.00...100.0 s • U> Curve type (U>Curve) DEFINITE

Definite time INVERSE [2]

• 50/51 Second threshold definite time (I>> def ) 0.100...40.0 In Definite time

• I>> def Operating time (t >> def ) 0.03...10.00 s • 59 First threshold definite time (U >def) 0.50...1.50 U n /E n

Inverse time • U>def Operating time (t U> def ) 0.03...100.0 s

• 50/51 Second threshold inverse time (I>>inv) 0.100...20.00 In Inverse time

• I>>inv Operating time (t >>inv) 0.02...10.00 s • 59 First threshold inverse time (U >inv) 0.50...1.50 U n /E n

• U>inv Operating time (t U>inv) 0.10...100.0 s

I>>> Element

• I>>> Reset time delay (t >>> RES) 0.00...100.0 s U>> Element

Definite time Definite time

• 50/51 Third threshold definite time (I>>> def ) 0.100...40.0 In • 59 Second threshold definite time (U >>def) 0.50...1.50 U n /E n

• I>>>def Operating time (t >>> def ) 0.03...10.00 s • U>>def Operating time (t U>> def ) 0.07...100.0 s

Note [1] - With U ph-ph setting all threshold are in p.u. U n

Voltage restraint overcurrent - 51V

With U ph-n setting all threshold are in p.u. E n

Common configuration:

• Operating mode (Mode51V) Note [2] - The mathematical formula for INVERSE curves is:

Voltage restraint/Voltage controlled t = 0.5 ∙ t U>inv /[(U/U>inv) - 1]

• Voltage restraint threshold (U-51CV <) 0.10...1.00 U n where:

• Voltage controlled first threshold (U 1-51AV <) 0.10...1.00 U n t = trip time (in seconds)

• Voltage controlled second threshold (U2-51AV<) 0.10...1.00 Un t U> inv = operating time setting (in seconds)

• Reduction factor (K) 0.10...1.00 U = input voltage

I51V > Element U>inv = threshold setting

• I51V > Reset time delay (t- 51V>RES) 0.00...100.0 s

Definite time Residual overvoltage - 59N

• 51V First threshold definite time (I - I/U>def) 0.20...10.00 I n U E > Element

• I - I/U > defOperating time (tI-51V>) 0.07...100.0 s • U E > Curve type (U E >Curve) DEFINITE

INVERSE [1]

I51V >> Element • U E> Reset time delay (t UE>RES) 0.00...100.0 s

Definite time Definite time

• I51V >> Reset time delay (t- 51V>>RES) 0.00...100.0 s • 59N First threshold definite time (U E >def) 0.01...0.70 U En

• 51V Second threshold definite time (I - I/U>def>) 0.20...20.00 I n • U E>def Operating time (t UE >def) 0.07...100.0 s

• I - I/U >>def Operating time (tI-51V>>) 0.07...100.0 s Inverse time

• 59N First threshold inverse time (U E >inv) 0.01...0.50 U En

Residual overcurrent - 50N/51N or High impedance • U E>inv Operating time (t UE >inv) 0.10...100.0 s

restricted earth fault - 87N

IE> Element U E >> Element

• IE> Curve type (IE>Curve) DEFINITE • U E>> Reset time delay (t UE>>RES) 0.00...100.0 s

IEC/BS A, B, C • 59N Second threshold definite time (U E >>def) 0.01...0.70 U En

ANSI/IEEE MI, VI, EI, EM • U E>>def Operating time (t UE >>def) 0.07...100.0 s

• IE> Reset time delay (t E> RES) 0.00...100.0 s

Note [1] - The mathematical formula for INVERSE curves is:

Definite time t = 0.5 ∙ t UE>inv/[(UE/UE>inv) - 1]

• 50N/51N First threshold definite time (I E>def) 0.002...10.00 IEn where:

• IE>def Operating time (t E> def) 0.04...200 s t = trip time (in seconds)

Inverse time t UE> inv = operating time setting (in seconds)

• 50N/51N First threshold inverse time (IE >inv) 0.002...2.00 IEn UE = residual input voltage

• IE>inv Operating time (t E>inv) 0.02...60.0 s U E> inv = threshold setting

IE>> Element

• IE>> Reset time delay (t E>> RES) 0.00...100.0 s Underfrequency - 81U

Definite time f< Element

• 50N/51N Second threshold definite time (IE>>def) 0.002...10.00 IEn Definite time

• IE>>def Operating time (t E>> def ) 0.03...10.00 s • 81U First threshold definite time (f<def) 0.800...1.000 fn

• f<def Operating time (t f<def ) 0.07...100.0 s

IE>>> Element

• IECLP >>> Reset time delay (t E>>> RES) 0.00...100.0 s f<< Element

Definite time Definite time

• 50N/51N Third threshold definite time (I E>>>def) 0.002...10.00 IEn • 81U Second threshold definite time (f<<def) 0.800...1.000 fn

• IECLP >>> def Operating time (t E>>> def ) 0.03...10.00 s • f<<def Operating time (t f<<def ) 0.07...100.0 s

6 NG20 - Flayer - 03 - 2009

Overfrequency - 81O • Average voltage between U L1-U L 2 -U L 3 UL

f>Element • Maximum voltage between U 12 -U 23 -U 31 U max

Definite time • Average voltage between U 12 -U 23 -U 31 U

• 81O First threshold definite time (f>def) 1.000....1.200 fn

• f>def Operating time (t f> def ) 0.07...100.00 s Phase:

• Displacement angle of I L1 respect to U L1 PhiL1

f>Element • Displacement angle of I L 2 respect to U L 2 PhiL2

Definite time • Displacement angle of I L 3 respect to U L 3 PhiL3

• 81O Second threshold definite time (f>>def) 1.000....1.200 fn

• f>def Operating time f>>def (t f>> def ) 0.07...100.00 s Sequence:

• Positive sequence current I1

Selective block - BLOCK2 • Negative sequence current I2

Selective block IN: • Negative sequence current/positive sequence current ratio I 2 /I 1

• BLIN Max activation time for phase protections (t B-IPh) • Positive sequence voltage U1

0.10...10.00 s • Negative sequence voltage U2

• BLIN Max activation time for ground protections (t B-IE )

0.10...10.00 s Impedance:

• L1 phase impedance (40 element) Z L1

Selective block OUT: • Resistive component of the L1 phase impedance ±R L1

• BLOUT Dropout time delay for phase protections (t F-IPh)0.00...1.00 s • Reactive component of the L1 phase impedance ±X L1

• BLOUT Dropout time delay for ground protections (t F-IE )0.00...1.00 s

• BLOUT Drop-out time delay for phase and ground protections Temperature:

(t F-IPh/IE) 0.00...1.00 s • Temperature Pt1...Pt8 -40...240 °C

Power:

Breaker failure - BF

• Total active power ±P

CT position (CTPOSITION) Star side/Line side

• Total reactive power ±Q

BF Phase current threshold (IBF >) 0.05...1.00 In

• Total apparent power ±S

BF Residual current threshold (IEBF >) 0.01..2.00 IEn

• Power factor ±cosPhi

BF Time delay (t BF) 0.06...10.00 s

• Phase active powers ±P L1, ±P L 2 , ±P L 3

• Phase reactive powers ±Q L1, ±Q L 2 , ±Q L 3

VT supervision - 74VT

• Phase power factors ±cosPhiL1, ±cosPhiL2, ±cosPhiL3

74VT Negative sequence overvoltage threshold (U2VT>) 0.05...0.50 En

74VT Negative sequence overvoltage threshold (I2VT>) 0.05...0.50 In Demand phase currents:

74VT Phase undervoltage threshold (U VT<) 0.05...0.50 En • Phase fixed currents demand I L1FIX , I L 2FIX , I L 3FIX

74VT Minimum change of current threshold 74VT (DIVT<) 0.05...0.50 In • Phase rolling currents demand I L1ROL , I L 2ROL , I L 3ROL

74VT Undercurrent inhibition threshold (I VT<) 0.100...40.0 In • Phase peak currents demand I L1MA X , I L 2MA X , I L 3MA X

74VT Alarm time delay (t V T-A L ) 0.0...10.0 s • Phase minimum currents demand I L1MIN , I L 2MIN , I L 3MIN

CT supervision - 74CT Demand power:

Residual overcurrent threshold 74CT (IECT >) 0.08...4.00 IEn • Fixed active power demand ±P FIX

Residual undervoltage threshold 74CT (U ECT<) 0.01...0.50 UEn • Fixed reactive power demand ±Q FIX

74CT operating time (t CT-AL ) 0....10.0 s • Rolling active power demand ±P ROL

• Rolling reactive power demand ±Q ROL

Circuit Breaker supervision • Peak active power demand ±P MA X

Number of CB trips (N.Open) 0...10000 • Peak reactive power demand ±Q MA X

Cumulative CB tripping currents (SumI) 0...5000 In • Minimum active power demand ±P MIN

CB opening time for I^2t calculation (t break ) 0.05...1.00 s • Minimum reactive power demand ±Q MIN

Cumulative CB tripping I^2t (SumI^2t) 0...5000 I n2.s Energy:

CB max allowed opening time (t break >) 0.05...1.00 s • Total active energy ±E A

• Total reactive energy ±E R

Pilot wire diagnostic

BLOUT1 Diagnostic pulses period (PulseBLOUT1) Event storage

OFF - 0.1-1-5-10-60-120 s

BLIN1 Diagnostic pulses control time interval (PulseBLIN1) Sequence of Event Recorder (SER)

OFF - 0.1-1-5-10-60-120 s Number of events 300

Recording mode circular

METERING

Trigger:

Measured parameters • Output relays switching K1...K6...K10

Direct: • Binary inputs switching IN1, IN2...INx

• Frequency f • Setting changes

• Fundamental RMS phase currents I L1, I L 2 , I L 3 Data recorded:

• Fundamental RMS phase voltages U L1, U L 2 , U L 3 • Event counter (resettable by ThySetter) 0...10 9

• Fundamental RMS residual current IE • Event cause binary input/output relay/setting changes

• Fundamental RMS residual voltage UE • Time stamp Date and time

Calculated:

• Calculated residual current I EC

• Thermal image DTheta

• Fundamental RMS phase-to-phase voltages U 12 , U 23 , U 31

• Maximum current between I L1-I L 2 -I L 3 I Lmax

• Minimum current between I L1-I L 2 -I L 3 I Lmin

• Average current between I L1-I L 2 -I L 3 IL

• Maximum voltage between U L1-U L 2 -U L 3 U Lmax

NG20 - Flayer - 03 - 2009 7

Sequence of Fault Recorder (SFR) Trigger setup:

Number of faults 20 • Pre-trigger time 0.05...1.00 s

Recording mode circular • Post-trigger time 0.05...60.00 s

• Trigger from inputs IN1...IN2...INx

Trigger: • Trigger from outputs K1...K6...K10

• External trigger (binary inputs) IN1...IN2...INx • Communication ThySetter

• Element pickup (OFF-ON transition) Start/Trip

Set sample channels:

Data recorded: • Instantaneous currents i L1, i L2, i L3, i E

• Time stamp Date and time • Instantaneous voltages u L1, u L2, u L3, u E

• Fault cause start, trip, binary input

• Fault counter (resettable by ThySetter) 0...10 9 Set analog channels (Analog 1...12):

• Fundamental RMS phase currents I L1r, I L 2r, I L 3r • Frequency f

• Fundamental RMS residual current I Er • Fundamental RMS phase currents I L1, I L 2 , I L 3

• Fundamental RMS phase voltages U L1r, U L 2r, U L 3r • Fundamental RMS residual current IE

• Fundamental RMS phase-to-phase voltages U 12r, U 23r, U 31r • Fundamental RMS phase voltages U L1, U L 2 , U L 3

• Fundamental RMS residual voltages (measured and calculated) • Fundamental RMS residual voltage UE

U Er • Fundamental RMS phase-to-phase voltages U 12 , U 23 , U 31

• Displacement angles (IL1-UL1, IL2-UL2, IL3-UL3) PhiL1r, PhiL2r, PhiL3r • Fundamental RMS calculated residual voltage U EC

• Thermal image DTheta- r • Displacement angles (IL1-UL1, IL2-UL2, IL3-UL3) PhiL1, PhiL2, PhiL3

• Binary inputs state IN1...IN2...INx

• Output relays state K1...K6...K10 Set digital channels (Digital 1...12):

• Fault cause info (operating phase) L1, L2, L3 • Output relays state K1...K6...K10

• Binary inputs state IN1...IN2...INx

Digital Fault Recorder (Oscillography)

Note [1] - For instance, with following setting:

File format COMTRADE

• Pre-trigger time 0.25 s

Records depending on setting [1]

• Post-trigger time 0.25 s

Recording mode circular • Sampled channels i L1, i L2 , i L3 , i E

Sampling rate 24 per power frequency cycle • Analog channels I L1, I L2 , I L3 , I E

• Digital channels K1, K2, K3, K4, K5, K6, IN1,N2

More than four hundred records can be stored when f = 50 Hz

Oscillography (DFR)

8 NG20 - Flayer - 03 - 2009

Connection diagram example - synchronous generators with CTs positioned on the star point

L1

L2

L3

NG20

K1 A3

A N n a B1

A4

TRIP 32R, 40

B N n b UL1 A5

B2

C N n c K2 A6

B3 A7

OUTPUT RELAYS

UL2 A8

B4 K3 A9

B5

A10

GS B6 UL3

K4

A11

K5 A12

K6 A13

P2 A14

S2

S1 C1

P1 F1

IL1

C2 F2

RS485

C3 F3

B- F4 Supervision

IL2

C4 A+ F5 unit

C5

IL3

C6

ETHERNET

P1 C7 D1

S1 HUB

IE

S2 C8

P2

B7

UE

B8

THYBUS

E1 54 53 52 51 50 49 48 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33 32 31 30 29 28

OUTPUT INPUT

A1

RUN

BUS

≅

ON

MODULO PT100

MPT

PT100 MODULE

UAUX

A2 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27

BLOCK OUT

BLOCK IN

A17 BLOUT-

A15

N.8 Pt100

BLOUT+

A18 A16

BINARY INPUTS

A19

IN1

A20

FRONT PANEL

RS232

A21

IN2

A22

NG20 - Flayer - 03 - 2009 9

Connection diagram example - synchronous motors

L1

L2

L3

NG20

K1 A3

A N n a B1

A4

B N n b UL1 A5

B2

C N n c K2 A6

B3 A7

OUTPUT RELAYS

UL2 A8

B4 K3 A9

TRIP 40

TRIP 32R

B5

K4 A10

UL3

B6

A11

K5 A12

P2 K6 A13

S2

A14

S1 C1

P1

IL1

C2 F1

C3 F2

RS485

IL2 F3

C4 B- F4 Supervision

C5 A+ F5 unit

IL3

C6

ETHERNET

P1 C7

S1 D1

IE HUB

S2 C8

P2

B7

UE

B8

THYBUS

E1 54 53 52 51 50 49 48 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33 32 31 30 29 28

MS A1 ≅

OUTPUT INPUT

RUN

BUS

ON

MODULO PT100

MPT

PT100 MODULE

UAUX

A2 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27

BLOCK OUT

BLOCK IN

A17 BLOUT-

A15 N.8 Pt100

BLOUT+

A18 A16

BINARY INPUTS

A19

IN1

A20

FRONT PANEL

RS232

A21

IN2

A22

10 NG20 - Flayer - 03 - 2009

DIMENSIONS

FRONT VIEWS REAR VIEWS

128.5

107 120 101 ø 4.5 110

D1 D1

A1 A1

A2 A2

C1 C2 C1 C2

ø 4.5 A3

A4 RX

F1

F2

A3

A4 RX

F1

F2

A5 F3 A5 F3

A6 TX F4 A6 TX F4

A7 F5 A7 F5

A8 C3 C4 A8 C3 C4

A9 B1 A9 B1

A10 B2 A10 B2

177

171

149

200

168

A11 B3 A11 B3

A12 B4 A12 B4

ON 1 2 3 4 5 START ON 1 2 3 4 5 START

A13 B5 A13 B5

80

TRIP TRIP A14 C5 C6 B6 A14 C5 C6 B6

A15 B7 A15 B7

A16 B8 A16 B8

A17 A17

A18 A18

A19 A19

A20 C7 C8 A20 C7 C8

A21 A21

A22 A22

31

E1 E1

20

FLUSH MOUNTING PROJECTING MOUNTING FLUSH MOUNTING PROJECTING MOUNTING

(Separate operator panel)

SIDE VIEWS

212.5 275

25 15

205 30 5 30 ø 4.5

170

FLUSH MOUNTING SEPARATE PROJECTING MOUNTING PROJECTING MOUNTING

OPERATOR PANEL (Separate operator panel) (Stand alone)

RACK MOUNTING FLUSH MOUNTING CUTOUT

482.6 102.5 ±0.3

465 70

177 (4U)

161

101.6

154

ON 1 2 3 4 5 START ON 1 2 3 4 5 START ON 1 2 3 4 5 START ON 1 2 3 4 5 START

TRIP TRIP TRIP TRIP

N.4 holes ø 3.5

NG20 - Flayer - 03 - 2009 11

www.pro-n.it

A PERSONALISED SERVICE OF THE PRODUCTION,

A RAPID DELIVERY, A COMPETITIVE PRICE

AND AN ATTENTIVE EVALUATION OF OUR

CUSTOMERS NEEDS, HAVE ALL CONTRIBUTED

IN MAKING US ONE OF THE BEST AND MOST

RELIABLE PRODUCERS OF PROTECTIVE RELAYS.

FORTY YEARS OF EXPERIENCE HAS MADE

STANDARD THESE ADVANTAGES THAT ARE

GREATLY APPRECIATED BY LARGE COMPANIES

THAT DEAL ON THE INTERNATIONAL MARKET.

A HIGHLY QUALIFIED AND MOTIVATED STAFF

PERMITS US TO OFFER AN AVANT-GARDE

PRODUCT AND SERVICE WHICH MEET ALL

SAFETY AND CONTINUITY DEMANDS, VITAL

IN THE GENERATION OF ELECTRIC POWER. OUR

COMPANY PHILOSOPHY HAS HAD A POSITIVE

REACTION FROM THE MARKET BY BACKING

OUR COMMITMENT AND HENCE STIMULATING

OUR GROWTH.

Headquarters: 20139 Milano - Piazza Mistral, 7 - Tel. +39 02 574 957 01 ra - Fax +39 02 574 037 63

Factory: 35127 Padova - Z.I. Sud - Via dell’Artigianato, 48 - Tel. +39 049 894 770 1 ra - Fax +39 049 870 139 0

www.thytronic.it thytronic@thytronic.it www.pro-n.it

You might also like

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- ESU NT: Service ManualDocument58 pagesESU NT: Service ManualJonathan Flores Gutang100% (1)

- Bushing Failures in Medium VoltageDocument4 pagesBushing Failures in Medium VoltageDunstan Amaratunga100% (1)

- Protection Relays: Bank Capacitor Protection RelayDocument8 pagesProtection Relays: Bank Capacitor Protection RelayMustapha ElecNo ratings yet

- Motor Protection Relay: Multifunction Protection For Large Size MotorsDocument12 pagesMotor Protection Relay: Multifunction Protection For Large Size MotorsAnonymous UbwGTAcKlsNo ratings yet

- Exclusively Distributed By: Montrelec Inc.: Feeder&Lom Protection RelayDocument8 pagesExclusively Distributed By: Montrelec Inc.: Feeder&Lom Protection Relaysajid munirNo ratings yet

- The Comprehensive Solution For Capacitor Bank ProtectionDocument8 pagesThe Comprehensive Solution For Capacitor Bank Protectionwindreader1No ratings yet

- Relay NM 10Document8 pagesRelay NM 10Ayahnya Rizla Atha RayyanNo ratings yet

- Micom P922 Voltage / Frequency Relay: ApplicationsDocument2 pagesMicom P922 Voltage / Frequency Relay: Applicationsdave chaudhuryNo ratings yet

- Datasheet UT7R2XLR816Document51 pagesDatasheet UT7R2XLR816Deepa DevarajNo ratings yet

- DB en MCR SLP 1 5 Ui 0 SW 5087439Document5 pagesDB en MCR SLP 1 5 Ui 0 SW 5087439zakaria rizaNo ratings yet

- Feeder Protection RelayDocument8 pagesFeeder Protection RelayUtkan BALABANNo ratings yet

- NG 10 Flyer 09 2011 627d145122Document8 pagesNG 10 Flyer 09 2011 627d145122SatheeshNo ratings yet

- NG 10 Flyer 09 2011 627d145123Document4 pagesNG 10 Flyer 09 2011 627d145123SatheeshNo ratings yet

- Transformer Monitoring : Protective RelaysDocument7 pagesTransformer Monitoring : Protective Relaysgaurang1111No ratings yet

- Micom p12xDocument8 pagesMicom p12xAnonymous G1Hm2qpMVkNo ratings yet

- NG 10 Flyer 09 2011 627d14514Document3 pagesNG 10 Flyer 09 2011 627d14514SatheeshNo ratings yet

- SIF5600Document4 pagesSIF5600Sejahtra AbadiNo ratings yet

- EN FANOX DATA SILG FeederGeneratorProtection ProtectionRelays R016Document13 pagesEN FANOX DATA SILG FeederGeneratorProtection ProtectionRelays R016giauNo ratings yet

- R5601T Series: Lithium-Ion/ Lithium Polymer Battery Management Analog Front-EndDocument32 pagesR5601T Series: Lithium-Ion/ Lithium Polymer Battery Management Analog Front-EndBenjamin garcia buronNo ratings yet

- Akai Combo TV ctd1390 - Service - ManualDocument36 pagesAkai Combo TV ctd1390 - Service - ManualarisNo ratings yet

- PD300Document20 pagesPD300ecplpraveen100% (1)

- Q85 Series: Long Range Diffuse SensorsDocument2 pagesQ85 Series: Long Range Diffuse SensorsLEONARDO HERNANDEZNo ratings yet

- EN FANOX DATA SILS FeederCurrentVoltageFrequency ProtectionRelays R03Document11 pagesEN FANOX DATA SILS FeederCurrentVoltageFrequency ProtectionRelays R03kais abdaouiNo ratings yet

- NT10 BrochureDocument12 pagesNT10 Brochuremaykoll edwards ortiz castilloNo ratings yet

- Micom P12X/Y: Three Phase and Earth Fault Overcurrent RelaysDocument8 pagesMicom P12X/Y: Three Phase and Earth Fault Overcurrent Relaysrenjithas2005No ratings yet

- SPAU140C Synch Check RelayDocument72 pagesSPAU140C Synch Check RelaymentongNo ratings yet

- LM5026 Active Clamp Current Mode PWM Controller: 1 Features 3 DescriptionDocument40 pagesLM5026 Active Clamp Current Mode PWM Controller: 1 Features 3 DescriptionqeqeNo ratings yet

- LM5026 - DatasheetDocument41 pagesLM5026 - DatasheetntchtdNo ratings yet

- Installation and Operating Manual: (Translation of The German Original)Document20 pagesInstallation and Operating Manual: (Translation of The German Original)Rao WaqasNo ratings yet

- NM20 Flyer 08 2012 PDFDocument12 pagesNM20 Flyer 08 2012 PDFandy175No ratings yet

- Phase Control An-3006Document6 pagesPhase Control An-3006Tantri Rahmawati100% (1)

- PL SeriesDocument49 pagesPL Seriesgoogle manNo ratings yet

- Relay Uar4n VoltajesDocument40 pagesRelay Uar4n VoltajesDan Storytime RodriguezNo ratings yet

- User Manual: HAT560N Series (HAT560N/HAT560NB) Ats ControllerDocument28 pagesUser Manual: HAT560N Series (HAT560N/HAT560NB) Ats ControllerWilmer Alfredo CondeNo ratings yet

- Master K BiginnerDocument136 pagesMaster K Biginnerrosthe_trobanNo ratings yet

- MCF 8316 ADocument168 pagesMCF 8316 ARudolf RiehlNo ratings yet

- P139 TechnicalDataSheet EN 30B PDFDocument39 pagesP139 TechnicalDataSheet EN 30B PDFCarlos Alberto Morales AguirreNo ratings yet

- Hardware DesDocument116 pagesHardware DesMehdiNo ratings yet

- Um2933 Getting Started With The Stevalplc001v1 Industrial PLC Evaluation Board With Hmi Interface StmicroelectronicsDocument42 pagesUm2933 Getting Started With The Stevalplc001v1 Industrial PLC Evaluation Board With Hmi Interface StmicroelectronicsivanreyNo ratings yet

- NG 10 Flyer 09 2011 627d145122Document2 pagesNG 10 Flyer 09 2011 627d145122SatheeshNo ratings yet

- Earth Fault RelayDocument52 pagesEarth Fault RelayAgung MohamadNo ratings yet

- WW-MFR2 (Multifunction Relay)Document4 pagesWW-MFR2 (Multifunction Relay)KT MENONNo ratings yet

- Thy TronicDocument9 pagesThy Tronicgrigore mirceaNo ratings yet

- Ingepac pl300 Fy27iptt01 A PDFDocument2 pagesIngepac pl300 Fy27iptt01 A PDFAl Habsyi Yesa SkbNo ratings yet

- To Win1d enDocument26 pagesTo Win1d enKamel BoulelliNo ratings yet

- EN FANOX DATA SILC FeederGeneratorProtection ProtectionRelays R10Document14 pagesEN FANOX DATA SILC FeederGeneratorProtection ProtectionRelays R10giauNo ratings yet

- NA 011 Flyer 10 2013 0dca893fe2Document8 pagesNA 011 Flyer 10 2013 0dca893fe2Ingenieria 2No ratings yet

- L99DZ100G, L99DZ100GPDocument197 pagesL99DZ100G, L99DZ100GPVenezuela is the 51st stateNo ratings yet

- Manual Epcos Powerfactor ControllerDocument28 pagesManual Epcos Powerfactor Controllerhchico2010100% (1)

- Single Aisle Technical Training Manual T1 (CFM 56) (LVL 2&3) LightsDocument44 pagesSingle Aisle Technical Training Manual T1 (CFM 56) (LVL 2&3) LightsarunNo ratings yet

- AD9mark PDFDocument14 pagesAD9mark PDFLe DungNo ratings yet

- Notes A 320 Neo LightDocument44 pagesNotes A 320 Neo LightAnurag MishraNo ratings yet

- Brochure P101 PDFDocument11 pagesBrochure P101 PDFBudi Ibud DubiNo ratings yet

- LM 5023Document38 pagesLM 5023Kartik hegdeNo ratings yet

- Over Current ProctectionDocument25 pagesOver Current ProctectionSarah FrazierNo ratings yet

- Gu641a Genset Control.Document55 pagesGu641a Genset Control.semerucoccsNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Rex 521 Confe NaDocument126 pagesRex 521 Confe Nagovindaraj171No ratings yet

- Over Current PRDDocument56 pagesOver Current PRDgovindaraj171No ratings yet

- SoftstartersDocument58 pagesSoftstartersgovindaraj171No ratings yet

- EDITORIAL 2002 03 en Phasor Measurements Recording South SweDocument5 pagesEDITORIAL 2002 03 en Phasor Measurements Recording South Swegovindaraj171No ratings yet

- Iec 34-1Document13 pagesIec 34-1govindaraj171No ratings yet

- Tech Data & CurvesDocument30 pagesTech Data & Curvesgovindaraj171No ratings yet

- Iec 34-1Document57 pagesIec 34-1govindaraj171No ratings yet

- High Impedance Technical ReportDocument4 pagesHigh Impedance Technical Reportgovindaraj171No ratings yet

- Chapter 13 - Magnetic Effects of Electric Current: Class - X ScienceDocument18 pagesChapter 13 - Magnetic Effects of Electric Current: Class - X ScienceGovind DabralNo ratings yet

- Emi Notes (Cbse Class 12 2021-22)Document5 pagesEmi Notes (Cbse Class 12 2021-22)Shaku JoshiNo ratings yet

- Type of Earthing SystemDocument6 pagesType of Earthing SystemMokr AchourNo ratings yet

- Excitation SystemDocument6 pagesExcitation Systemsanjay sharmaNo ratings yet

- Presented by Abinaya.T Ananthi.T Mohana.T: Wireless Power Transmission Mobile Charger Circuit Using Inductive CouplingDocument20 pagesPresented by Abinaya.T Ananthi.T Mohana.T: Wireless Power Transmission Mobile Charger Circuit Using Inductive CouplingMuthamil SelviNo ratings yet

- 9A04604 Electronic Measurements and InstrumentationDocument4 pages9A04604 Electronic Measurements and InstrumentationsivabharathamurthyNo ratings yet

- BS5501 1Document42 pagesBS5501 1rajuhaveriNo ratings yet

- Circulating Current and ZVS On of A Dual Active Bridge DC DC Converter A ReviewDocument12 pagesCirculating Current and ZVS On of A Dual Active Bridge DC DC Converter A ReviewAn TranNo ratings yet

- Transmission MediaDocument37 pagesTransmission MediaAbhishek singhNo ratings yet

- Pipe WeldingDocument6 pagesPipe Weldingravi00098No ratings yet

- Otc 21300 MS P PDFDocument8 pagesOtc 21300 MS P PDFLucilene MaduroNo ratings yet

- PANASONIC CApacitor PDFDocument2 pagesPANASONIC CApacitor PDFLuisNo ratings yet

- H-500 (Master) H-502 (Slave) : Technical SheetDocument1 pageH-500 (Master) H-502 (Slave) : Technical Sheetnikname08No ratings yet

- 4 ElectromagnetismDocument38 pages4 ElectromagnetismCart Kartika100% (1)

- Cap Level SwitchDocument13 pagesCap Level SwitchsrinuvoodiNo ratings yet

- Applied Multiple Choice - Typical QuestionsDocument10 pagesApplied Multiple Choice - Typical Questionsexe.dave.qNo ratings yet

- G740 - Control Unit & Terminal Unit - RevB1 PDFDocument53 pagesG740 - Control Unit & Terminal Unit - RevB1 PDFsrmohapatra5086No ratings yet

- Power Ups PDFDocument7 pagesPower Ups PDFtsraj10No ratings yet

- Substation Operator DutiesDocument3 pagesSubstation Operator DutiesVishal VnNo ratings yet

- SICES Genset ControllersDocument25 pagesSICES Genset ControllershusnainNo ratings yet

- Science Application of Microwaves PresentationDocument11 pagesScience Application of Microwaves PresentationMiyu YaginumaNo ratings yet

- NiteljosDocument41 pagesNiteljosnative112472No ratings yet

- Smart Grid ReportDocument10 pagesSmart Grid ReportPriyadarshi MNo ratings yet

- PFT - 401CEF: PFT Series - AC High Voltage Dielectric Test SetDocument1 pagePFT - 401CEF: PFT Series - AC High Voltage Dielectric Test SetAndrew SetiawanNo ratings yet

- Tos Epas G-11Document2 pagesTos Epas G-11Paul Senen Didulo100% (1)

- Safe Lift CatalogueDocument4 pagesSafe Lift CatalogueArvindNo ratings yet

- Questions Answers Com FinalDocument16 pagesQuestions Answers Com FinalankitsprajapatiNo ratings yet

- Rphdoc e Z 04Document75 pagesRphdoc e Z 04ThiagoPinheiroNo ratings yet

- 120electric ManualDocument97 pages120electric ManualJohancy Cordero100% (1)