Professional Documents

Culture Documents

MSP300 0078 Conica 35

MSP300 0078 Conica 35

Uploaded by

aktivrudarpOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MSP300 0078 Conica 35

MSP300 0078 Conica 35

Uploaded by

aktivrudarpCopyright:

Available Formats

NEVER TOUCH.

Turning the pulley by hand is important as this will show inappropriate contact of Mantle

and Concave, misalignment of gears or possible problems with bushings and bearings, whereas turning

under power may not.

2. Switch the machine on. The MSP cone is designed to be choke fed, operating empty for 5 minute

intervals is acceptable only for set up and testing. Do not operate empty for extended periods of time. After

reaching full speed, watch the movement of the ampere meter needle.

The Lubrication Oil Pressure will vary with ambient air temperature, oil temperature, oil viscosity, etc.

Normally, pressure is high at the start of operation when the oil temperature is low. The pressure should

gradually decrease and become constant as the temperature of the oil increases. When the oil temperature

is 50℃ (122℉), the oil pressure is approximately 1.5 kg/cm² (21 PSI).

9.6 Loaded Operation

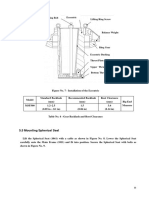

Start the oil pump and confirm the return oil to the tank. Switch the Cone Crusher on. Feed ore to the

machine, dropping it into the center of the Tightening Nut (4060) as shown in Figure No. 4. Irregular or

uneven feed decreases the capacity of the Cone Crusher, makes the grain size distribution coarse and uneven,

causes localized abrasion of Concave & Mantle and actuates the release cylinders too frequently. Ensure

even choke feed of material at all times. Operating with less than choke fed crushing chamber for longer

than 5 minutes can result in head slap, increased and/or uneven eccentric bushing (3021) wear, increased

and/or uneven spherical seat (1111) wear, as well as reduced quality of production. Never run the cone with

an empty chamber unattended.

When operating the Cone Crusher, monitor the following:

① Action of the release cylinders

② Temperature of each bearing

③ Temperature of return oil and pressure of oil delivery

④ Variations of power Amperage

⑤ Lubrication oil pressure and flow.

9.7 Stopping the Cone Crusher

First, stop ore feed. Allow all material to pass through the crushing chamber (formed by mantle and

concave) as any material left over will make starting the cone difficult or be harmful for the machine. After

the crushing chamber is empty, you may switch off the Cone Crusher. Wait thirty seconds, as indicated on

the timer screen, for the Cone Crusher to cool down before turning off the lubrication oil pump.

27

You might also like

- Pratt & Whitney R-1340 Engine Operating SupplementDocument7 pagesPratt & Whitney R-1340 Engine Operating Supplementarizonaflyer1_732976100% (1)

- r185nm ManualDocument36 pagesr185nm Manualjohnysonycum100% (3)

- Ball Milling Machine Optg ManualDocument7 pagesBall Milling Machine Optg ManualPaul Saria100% (1)

- Engine Oil DraftDocument4 pagesEngine Oil Draftapi-327987286100% (2)

- Wafer Biscuit PlantDocument9 pagesWafer Biscuit Planttechnocrat_vspNo ratings yet

- Thornycroft Marine Engine PDFDocument42 pagesThornycroft Marine Engine PDFAnonymous 3xJyAmc100% (1)

- Operators Manuel International Cub Cadet 72, 104, 105, 124, ZND 125 TractorsDocument44 pagesOperators Manuel International Cub Cadet 72, 104, 105, 124, ZND 125 Tractorsfundreamer1100% (1)

- Theory, Applications, and Cases: Managerial EconomicsDocument71 pagesTheory, Applications, and Cases: Managerial EconomicsSanjay Pudasaini100% (1)

- SE 75 30 - 40 Eng 1998 PDFDocument439 pagesSE 75 30 - 40 Eng 1998 PDFDavid PlazillaNo ratings yet

- Booth Multiplier VHDL CodeDocument1 pageBooth Multiplier VHDL CodeSameera Somisetty50% (4)

- Dimensions and Weights of Spades (Paddle Blank) and Ring Spacers (Paddle Spacer) ASME B16.47 For Installation Between ASME B16.47 Series A Flanges. 26 Inch To 60 InchDocument6 pagesDimensions and Weights of Spades (Paddle Blank) and Ring Spacers (Paddle Spacer) ASME B16.47 For Installation Between ASME B16.47 Series A Flanges. 26 Inch To 60 InchPozii Ziipunii PaulNo ratings yet

- 80 GHZ Integrated Antenna ALFOplus80HDHDX Installation and Alignment ProcedureDocument11 pages80 GHZ Integrated Antenna ALFOplus80HDHDX Installation and Alignment ProcedureDan MereanuNo ratings yet

- Bomba Aceite MorgoDocument8 pagesBomba Aceite Morgoeduardo castaldiNo ratings yet

- 53 Bowl MillDocument13 pages53 Bowl MillShashank PrasadNo ratings yet

- Gear Oil: The Trademark and Name of Commendatory Gear OilDocument12 pagesGear Oil: The Trademark and Name of Commendatory Gear OilPreett Rajin MenabungNo ratings yet

- Please Read Carefully Before ProceedingDocument3 pagesPlease Read Carefully Before Proceedingeduardo castaldiNo ratings yet

- How To Change Engine OilsDocument1 pageHow To Change Engine OilsSon OsterNo ratings yet

- Introduction of Palm Oil Press MachineDocument2 pagesIntroduction of Palm Oil Press MachineChia PeterNo ratings yet

- Every 500 Hours MaintenanceDocument7 pagesEvery 500 Hours Maintenancerolandaaprian9No ratings yet

- PowerPro Gas EngineDocument16 pagesPowerPro Gas Enginefrostserv6019No ratings yet

- PI482Document18 pagesPI482Reijean Alexfer Dos Santos SantosNo ratings yet

- MSP300 0078 Conica 30Document1 pageMSP300 0078 Conica 30aktivrudarpNo ratings yet

- Paramotor Manual Engl-Snap100s Ciscomotors ParapenteDocument29 pagesParamotor Manual Engl-Snap100s Ciscomotors ParapentewildfloNo ratings yet

- Palm Kernel Oirl Expeller Model BL-101-K-Operation ManualDocument10 pagesPalm Kernel Oirl Expeller Model BL-101-K-Operation ManualIldebrando Montaño MedinaNo ratings yet

- Do's & Don'Ts For TurbochargersDocument7 pagesDo's & Don'Ts For Turbochargersvikrant GarudNo ratings yet

- Zenoah G230PU Petrol EngineDocument4 pagesZenoah G230PU Petrol EngineJarkko PuustinenNo ratings yet

- SHE73 LubricaciónDocument48 pagesSHE73 Lubricacióngonzalo valderramaNo ratings yet

- Reasons and Causes For Cam Failure: Tech BulletinDocument2 pagesReasons and Causes For Cam Failure: Tech BulletinForesight MisrNo ratings yet

- Purifier Manual Starting StoppingDocument3 pagesPurifier Manual Starting Stoppingavm4343No ratings yet

- Eccentric Weight Housing Oil - Change: Operation and Maintenance ManualDocument3 pagesEccentric Weight Housing Oil - Change: Operation and Maintenance ManualLuis AugustoNo ratings yet

- Manual Operación - Prensa P15 PMTDocument15 pagesManual Operación - Prensa P15 PMTMorales Pérez MarianaNo ratings yet

- RNM-12 400Document18 pagesRNM-12 400Matija ŠobanNo ratings yet

- En EspañolDocument42 pagesEn EspañolEdgardo RomeroNo ratings yet

- 8792 - Kaya Casting InstructionsDocument9 pages8792 - Kaya Casting InstructionsGlenn MartynNo ratings yet

- 054930Document8 pages054930Хелфор УкраинаNo ratings yet

- 6D105 Series O&M ManualDocument49 pages6D105 Series O&M Manualjobin joyNo ratings yet

- B&S SM 270962 Single Cyl L-Head Sec08 LubricationDocument9 pagesB&S SM 270962 Single Cyl L-Head Sec08 LubricationBruno PilieciNo ratings yet

- Advance Workshop Exam SolvedDocument41 pagesAdvance Workshop Exam SolvedVinesh ThulasyNo ratings yet

- Swissauto 250 - Break-In ProcedureDocument3 pagesSwissauto 250 - Break-In ProcedureSimon CooperNo ratings yet

- WBHE ManualDocument3 pagesWBHE ManualBruno DelgadoNo ratings yet

- MOPX Operation IsntructionsDocument28 pagesMOPX Operation IsntructionsEser67% (3)

- Engine Oil Level: Always Read Top Side of Dipstick To Properly Check Oil Level in CrankcaseDocument3 pagesEngine Oil Level: Always Read Top Side of Dipstick To Properly Check Oil Level in CrankcaseDennisNo ratings yet

- 140 Series O&M ManualDocument48 pages140 Series O&M ManualhassanHyro4350% (2)

- Starting of Cent. PurifierDocument5 pagesStarting of Cent. PurifiermichaelNo ratings yet

- Starting of Cent. PurifierDocument5 pagesStarting of Cent. PurifiermichaelNo ratings yet

- Task 06Document8 pagesTask 06sachin mishraNo ratings yet

- FLUCHING LUB SYSTEM NOHAB W25 W25SG W25DF 9197400200eDocument2 pagesFLUCHING LUB SYSTEM NOHAB W25 W25SG W25DF 9197400200eLIVIANo ratings yet

- 1d Dvs B&W Man 6s60mc-c Vol5 Fitting & Accesores 613Document613 pages1d Dvs B&W Man 6s60mc-c Vol5 Fitting & Accesores 613tomo1973No ratings yet

- Cyl LubricationDocument7 pagesCyl LubricationThuria TunNo ratings yet

- Oil Pump SpindleDocument3 pagesOil Pump SpindleAsefshaNo ratings yet

- Manual Starting MAN 9L2738Document4 pagesManual Starting MAN 9L2738GunawanAdiWicaksanaNo ratings yet

- Centrifugal Pump OperationDocument24 pagesCentrifugal Pump Operationlanggono_01No ratings yet

- Zenoah 3366 G620PUDocument8 pagesZenoah 3366 G620PUMuhammad Indra RespatiNo ratings yet

- 11 - Appendix (July 2009) PDFDocument7 pages11 - Appendix (July 2009) PDFValeriy DomashenkoNo ratings yet

- Manual Operaciones r140w - 9sDocument32 pagesManual Operaciones r140w - 9svaleria niñoNo ratings yet

- 2BK Carb-ManualDocument2 pages2BK Carb-Manualfildan211No ratings yet

- GRP - Composite Air Operated Grease Pump5Document3 pagesGRP - Composite Air Operated Grease Pump5rquinchia1No ratings yet

- Honda F200 Operator ManualDocument31 pagesHonda F200 Operator ManualJörn MatthaeiNo ratings yet

- 6.0L Oil Change GuideDocument2 pages6.0L Oil Change GuidejegoodNo ratings yet

- Motorcraft 6 0L Diesel Oil Chage Reference SheetDocument2 pagesMotorcraft 6 0L Diesel Oil Chage Reference SheetivanNo ratings yet

- ZENO2012 AAaa G620PU, G620PU-1Document8 pagesZENO2012 AAaa G620PU, G620PU-1Martin Leonardo Arias PazNo ratings yet

- Drill Head Inspectionand Oil LevelsDocument6 pagesDrill Head Inspectionand Oil LevelsSipa1109No ratings yet

- Is Oil Factory. Oil: at LN ofDocument1 pageIs Oil Factory. Oil: at LN ofherasetiawanNo ratings yet

- L495-113 Operating and Maintenace ManualDocument13 pagesL495-113 Operating and Maintenace Manualingcalderon100% (1)

- Learn to Drive: Everything New Drivers Need to KnowFrom EverandLearn to Drive: Everything New Drivers Need to KnowRating: 4 out of 5 stars4/5 (1)

- MSP300 0078 Conica 61Document1 pageMSP300 0078 Conica 61aktivrudarpNo ratings yet

- MSP300 0078 Conica 36Document1 pageMSP300 0078 Conica 36aktivrudarpNo ratings yet

- MSP300 0078 Conica 65Document1 pageMSP300 0078 Conica 65aktivrudarpNo ratings yet

- MSP300 0078 Conica 48Document1 pageMSP300 0078 Conica 48aktivrudarpNo ratings yet

- MSP300 0078 Conica 52Document1 pageMSP300 0078 Conica 52aktivrudarpNo ratings yet

- MSP300 0078 Conica 49Document1 pageMSP300 0078 Conica 49aktivrudarpNo ratings yet

- MSP300 0078 Conica 43Document1 pageMSP300 0078 Conica 43aktivrudarpNo ratings yet

- MSP300 0078 Conica 39Document1 pageMSP300 0078 Conica 39aktivrudarpNo ratings yet

- MSP300 0078 Conica 67Document1 pageMSP300 0078 Conica 67aktivrudarpNo ratings yet

- Cytec Solutions 2013 39Document1 pageCytec Solutions 2013 39aktivrudarpNo ratings yet

- MSP300 0078 Conica 50Document1 pageMSP300 0078 Conica 50aktivrudarpNo ratings yet

- MSP300 0078 Conica 23Document1 pageMSP300 0078 Conica 23aktivrudarpNo ratings yet

- MSP300 0078 Conica 40Document1 pageMSP300 0078 Conica 40aktivrudarpNo ratings yet

- MSP300 0078 Conica 21Document1 pageMSP300 0078 Conica 21aktivrudarpNo ratings yet

- MSP300 0078 Conica 2Document1 pageMSP300 0078 Conica 2aktivrudarpNo ratings yet

- Cytec Solutions 2013 46Document1 pageCytec Solutions 2013 46aktivrudarpNo ratings yet

- MSP300 0078 Conica 45Document1 pageMSP300 0078 Conica 45aktivrudarpNo ratings yet

- MSP300 0078 Conica 19Document1 pageMSP300 0078 Conica 19aktivrudarpNo ratings yet

- MSP300 0078 Conica 3Document1 pageMSP300 0078 Conica 3aktivrudarpNo ratings yet

- Cytec Solutions 2013 50Document1 pageCytec Solutions 2013 50aktivrudarpNo ratings yet

- MSP300 0078 Conica 5Document1 pageMSP300 0078 Conica 5aktivrudarpNo ratings yet

- MSP300 0078 Conica 4Document1 pageMSP300 0078 Conica 4aktivrudarpNo ratings yet

- Cytec Solutions 2013 42Document1 pageCytec Solutions 2013 42aktivrudarpNo ratings yet

- Cytec Solutions 2013 45Document1 pageCytec Solutions 2013 45aktivrudarpNo ratings yet

- Cytec Solutions 2013 34Document1 pageCytec Solutions 2013 34aktivrudarpNo ratings yet

- Cytec Solutions 2013 35Document1 pageCytec Solutions 2013 35aktivrudarpNo ratings yet

- Cytec Solutions 2013 31Document1 pageCytec Solutions 2013 31aktivrudarpNo ratings yet

- Cytec Solutions 2013 18Document1 pageCytec Solutions 2013 18aktivrudarpNo ratings yet

- Cytec Solutions 2013 23Document1 pageCytec Solutions 2013 23aktivrudarpNo ratings yet

- Cytec Solutions 2013 6Document1 pageCytec Solutions 2013 6aktivrudarpNo ratings yet

- Effective and Extensible Feature Extraction Method Using Genetic Algorithm-Based Frequency-Domain Feature Search For Epileptic EEG Multi-ClassificationDocument17 pagesEffective and Extensible Feature Extraction Method Using Genetic Algorithm-Based Frequency-Domain Feature Search For Epileptic EEG Multi-ClassificationRaynald SumampouwNo ratings yet

- 19MT1201 MFE Course Material 2019-20 PDFDocument125 pages19MT1201 MFE Course Material 2019-20 PDFsai teja0% (1)

- Family Background, Parental Involvement, and Academic Achievement in Canadian Schools James McintoshDocument23 pagesFamily Background, Parental Involvement, and Academic Achievement in Canadian Schools James McintoshYenyen Quirog-PalmesNo ratings yet

- Structural Geology Laboratory Manual: Fourth EditionDocument204 pagesStructural Geology Laboratory Manual: Fourth EditionLionNo ratings yet

- Talent and Olympiad Exams Resource Book Class 7 Math Brain MappingDocument10 pagesTalent and Olympiad Exams Resource Book Class 7 Math Brain MappingANUPAMNo ratings yet

- DXM100-Sx Wireless Modbus Slave: Instruction ManualDocument43 pagesDXM100-Sx Wireless Modbus Slave: Instruction ManualJEYSONNo ratings yet

- AP Chemistry Multiple-Choice Review Tips NotesDocument4 pagesAP Chemistry Multiple-Choice Review Tips Noteserwin golovashkinNo ratings yet

- Do 66 Pen Type Dissolved Oxygen Tester Meter For Aquarium Fish Tank AquacultureDocument3 pagesDo 66 Pen Type Dissolved Oxygen Tester Meter For Aquarium Fish Tank AquacultureJuan José Bonilla ReinosoNo ratings yet

- Sweatt Mines 0052N 10653Document102 pagesSweatt Mines 0052N 10653Abdou KarimNo ratings yet

- Grilla Grade Gridcouplings: Serie Series SérieDocument8 pagesGrilla Grade Gridcouplings: Serie Series SérievandollanoNo ratings yet

- Test Certificate For Vista Superplast Hs 400 Consignee: Dhariwal Buildtech Ltd. Quantity: 22.022 MT Date: 14-12-2022 Batch No.: VK/2022-23/228Document1 pageTest Certificate For Vista Superplast Hs 400 Consignee: Dhariwal Buildtech Ltd. Quantity: 22.022 MT Date: 14-12-2022 Batch No.: VK/2022-23/228Deepak PachauriaNo ratings yet

- C Programming FaqDocument432 pagesC Programming FaqharshabalamNo ratings yet

- 950f - 950f - Series - II - and - 960fDocument5 pages950f - 950f - Series - II - and - 960falexander_1985100% (1)

- Maintenance NotificationDocument41 pagesMaintenance NotificationHala TAMIMENo ratings yet

- MIP S2 Section ADocument3 pagesMIP S2 Section Akabli ilyassNo ratings yet

- 2007 Bomet District Paper 1Document16 pages2007 Bomet District Paper 1Ednah WambuiNo ratings yet

- Maswali Ya Applied Econometric Tutorial Set 1Document4 pagesMaswali Ya Applied Econometric Tutorial Set 1V2c FungamezaNo ratings yet

- Preparation Books For JEE and IIT JEE Study MaterialDocument14 pagesPreparation Books For JEE and IIT JEE Study MaterialAyush VarshneyNo ratings yet

- Unit Iii Bevel Worm and Cross Helical GearsDocument3 pagesUnit Iii Bevel Worm and Cross Helical GearsAyush SinghalNo ratings yet

- Fashion Concepts and Merchandising: Elements and Principles of DesignDocument19 pagesFashion Concepts and Merchandising: Elements and Principles of DesignAvantika RathoreNo ratings yet

- Experiment 8 EvaporationDocument7 pagesExperiment 8 EvaporationtracyymendozaNo ratings yet

- Module 2 - Assembly - Language - Programming - With - Data - Transfer - Notes PDFDocument28 pagesModule 2 - Assembly - Language - Programming - With - Data - Transfer - Notes PDFIvan-Jeff AlcantaraNo ratings yet

- Harmonic Analysis of SVPWM Based Three Phase Inverter Using MATLAB SimulinkDocument6 pagesHarmonic Analysis of SVPWM Based Three Phase Inverter Using MATLAB SimulinkEditor IJTSRDNo ratings yet

- Seismic Inversion by Newtonian Machine Learning: Yuqing Chen and Gerard T. SchusterDocument16 pagesSeismic Inversion by Newtonian Machine Learning: Yuqing Chen and Gerard T. SchusterAlNo ratings yet

- Exercise 2 The Laws of Reflection Solutions 1 PDFDocument5 pagesExercise 2 The Laws of Reflection Solutions 1 PDFhexu wangNo ratings yet