Professional Documents

Culture Documents

Centrifuge Maintenance Sop Template

Centrifuge Maintenance Sop Template

Uploaded by

Claude JCopyright:

Available Formats

You might also like

- Hhmi Cell Cycle and Cancer - CompletedDocument3 pagesHhmi Cell Cycle and Cancer - CompletedAbel89% (9)

- Maintenance Manual - Varco ST-80 RoughneckDocument42 pagesMaintenance Manual - Varco ST-80 RoughneckCarlos Alberto Perdomo100% (3)

- H8 Service MannualDocument63 pagesH8 Service MannualMichael Tanglao100% (1)

- PX-300HF Operation Manual (111018)Document57 pagesPX-300HF Operation Manual (111018)Daniel Valderrama100% (1)

- MC450 User ManualDocument32 pagesMC450 User ManualCarlos Ubaldo100% (1)

- PX-300HF Service Manual (111018)Document85 pagesPX-300HF Service Manual (111018)Julian Vargas100% (3)

- Maintenance Manual Varco ST 80 Roughneck 2 PDFDocument42 pagesMaintenance Manual Varco ST 80 Roughneck 2 PDFNAMRAJ SHARMANo ratings yet

- 11.4159 USD2755 Remote Control Palltronic Flowstar IV Using OPC IFUDocument16 pages11.4159 USD2755 Remote Control Palltronic Flowstar IV Using OPC IFUseinNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- SIP5 7KE85 V07.80 Manual C018-6 en PDFDocument502 pagesSIP5 7KE85 V07.80 Manual C018-6 en PDFDoan Anh TuanNo ratings yet

- Centrifuge Maintenance SopDocument6 pagesCentrifuge Maintenance Sopkavaim001No ratings yet

- Centrifuge TB-07-06 V1.0Document5 pagesCentrifuge TB-07-06 V1.0Gadhavi jinalNo ratings yet

- 456 20110630 01 Major Proc CentrifugesDocument8 pages456 20110630 01 Major Proc CentrifugessantiNo ratings yet

- S CentrifugesafetyDocument4 pagesS CentrifugesafetyJohn WalleyNo ratings yet

- CIEHF Formative Usability Protocol 10 April 2020Document24 pagesCIEHF Formative Usability Protocol 10 April 2020ArmanNo ratings yet

- CNC 101 TDZ4 WSDocument19 pagesCNC 101 TDZ4 WSfabian muñoz molinaNo ratings yet

- Operating Instructions: DL-6MB High-Capacity Lowspeed Refrigerated CentrifugeDocument29 pagesOperating Instructions: DL-6MB High-Capacity Lowspeed Refrigerated CentrifugekedirNo ratings yet

- Ignition Coil Tester: Operating ManualDocument28 pagesIgnition Coil Tester: Operating ManualJason AguilarNo ratings yet

- 1 What Is Centrifuge MachineDocument16 pages1 What Is Centrifuge Machinebereketab demmelashNo ratings yet

- Centrifuging Serum and PlasmaDocument4 pagesCentrifuging Serum and Plasmapetty_atmadjaNo ratings yet

- Manual de Usuario - Centrifuga NF 048Document12 pagesManual de Usuario - Centrifuga NF 048Brevas CuchoNo ratings yet

- Penlon A-200 SP Circle Absorber - User ManualDocument40 pagesPenlon A-200 SP Circle Absorber - User ManualAnonymous oWnCVtEUQCNo ratings yet

- Centrifuge SafetyDocument2 pagesCentrifuge Safetyhazc5666No ratings yet

- Updated Startup Procedure - FD West - Hyduke - Phoenix Manual Rev 03Document31 pagesUpdated Startup Procedure - FD West - Hyduke - Phoenix Manual Rev 03Francisco Wilson Bezerra FranciscoNo ratings yet

- SOP - Safe and Proper Use of The Sorvall WX M UltracentrifugeDocument21 pagesSOP - Safe and Proper Use of The Sorvall WX M UltracentrifugeAngelosNo ratings yet

- Air Purge Tool Manual 5086900ADocument30 pagesAir Purge Tool Manual 5086900AOsmanyNo ratings yet

- ME 347 Fluid Mechanics Lab Experiments 7th EditionDocument117 pagesME 347 Fluid Mechanics Lab Experiments 7th EditionAnonymous SlyvspdBNo ratings yet

- Vacuum Pump Maintenance Sop TemplateDocument5 pagesVacuum Pump Maintenance Sop TemplateClaude JNo ratings yet

- 2023 SOP CentrifugeDocument7 pages2023 SOP CentrifugeParomita SarkerNo ratings yet

- HLR Rotary Lobe Pump: Installation, Service and Maintenance InstructionsDocument44 pagesHLR Rotary Lobe Pump: Installation, Service and Maintenance InstructionsabhairulzNo ratings yet

- mp6002 7502 9002 m-c5 FSM en Final 250512Document814 pagesmp6002 7502 9002 m-c5 FSM en Final 250512СергейNo ratings yet

- Phần Mềm Sửa Chữa Máy Aficio MP6001-MP9001Document760 pagesPhần Mềm Sửa Chữa Máy Aficio MP6001-MP9001Photocopy Tân PhúNo ratings yet

- Cpms College of Nursing: Assignment ON Setting, Use and Maintainance of Centrifuge MachineDocument6 pagesCpms College of Nursing: Assignment ON Setting, Use and Maintainance of Centrifuge MachineAmy Lalringhluani ChhakchhuakNo ratings yet

- Heraeus Biofuge Pico - User ManualDocument67 pagesHeraeus Biofuge Pico - User Manualluroguita-1No ratings yet

- TDS1000AInstallationManual 03May28AbridgedDocument20 pagesTDS1000AInstallationManual 03May28Abridgedbwd104No ratings yet

- Dynair Axial Omm Gulf 22sep20Document22 pagesDynair Axial Omm Gulf 22sep20Happy Man100% (1)

- Instructions Manual: Rotatory SieveDocument53 pagesInstructions Manual: Rotatory SieveBogdan PistolNo ratings yet

- Manual of HSC16Document281 pagesManual of HSC16johann medinaNo ratings yet

- Manualspectrafuge 16 DDocument16 pagesManualspectrafuge 16 DTan Hung LuuNo ratings yet

- FMS Staion 8 Robotic ArmDocument20 pagesFMS Staion 8 Robotic ArmatihzNo ratings yet

- Falcon c1000Document9 pagesFalcon c1000jlfyNo ratings yet

- XLC 2nd Stage Service Manual PDFDocument22 pagesXLC 2nd Stage Service Manual PDFCesc SimóNo ratings yet

- Manual Procesador UltrasónicoDocument22 pagesManual Procesador UltrasónicoYOHANANo ratings yet

- Bomba InoxpaDocument20 pagesBomba InoxpalcmpX86No ratings yet

- TEC5600 Service Manual PDFDocument303 pagesTEC5600 Service Manual PDFwamala benjaminNo ratings yet

- Nihon Kohden TEC-5600 Defibrillator - Service Manual - Compressed-1-144Document144 pagesNihon Kohden TEC-5600 Defibrillator - Service Manual - Compressed-1-144Francisco BaezNo ratings yet

- Safety Precautions and Practices in Operation and MaintenanceDocument8 pagesSafety Precautions and Practices in Operation and MaintenanceQwe AsdfNo ratings yet

- Content: Standard Operating Procedure (SOP) Use and Maintenance of A CentrifugeDocument9 pagesContent: Standard Operating Procedure (SOP) Use and Maintenance of A CentrifugenazmiNo ratings yet

- LG-R410, RB410, RV410, RD410 Manual de Serviço PDFDocument116 pagesLG-R410, RB410, RV410, RD410 Manual de Serviço PDFRenato AraujoNo ratings yet

- Led Display. Instruction Manual & Details: Pro-AnalyticalDocument12 pagesLed Display. Instruction Manual & Details: Pro-AnalyticalALFREDO LUIS ARROYO SANCHEZNo ratings yet

- 1.HF-525Plus VET (32kW, 400ma, 230Vor110V, XR5)Document207 pages1.HF-525Plus VET (32kW, 400ma, 230Vor110V, XR5)fortroniNo ratings yet

- User Manual: $',167580 (176 $'multifunction TesterDocument40 pagesUser Manual: $',167580 (176 $'multifunction TesterpanosNo ratings yet

- Manual PLC-01-05 2014 0219Document26 pagesManual PLC-01-05 2014 0219JanneDoee0% (1)

- Tabletop Low Speed Centrifuge: (Read The Instruction Carefully Before Operation)Document20 pagesTabletop Low Speed Centrifuge: (Read The Instruction Carefully Before Operation)haile negeraNo ratings yet

- HF-525Plus Service Manual (Rev. 2.2 Latest) 16 11 2011 PDFDocument142 pagesHF-525Plus Service Manual (Rev. 2.2 Latest) 16 11 2011 PDFFélix Nicolau100% (2)

- HF-525Plus Service Manual (Rev. 2.2 Latest)Document149 pagesHF-525Plus Service Manual (Rev. 2.2 Latest)Franklyn Acevedo100% (1)

- UrocapIV Standalone Quick Start Guide V04 (MAN400) UC4 UM02Document9 pagesUrocapIV Standalone Quick Start Guide V04 (MAN400) UC4 UM02Tanzimul IslamNo ratings yet

- Manual Active Chloride 160209Document234 pagesManual Active Chloride 160209the_pilotNo ratings yet

- Operation & Maintenance Manual FOR Non-Clog Type Pumps: Patterson Pump CompanyDocument30 pagesOperation & Maintenance Manual FOR Non-Clog Type Pumps: Patterson Pump CompanysumiNo ratings yet

- SVM-7500 - EnglishAG - NIHON KOHDENDocument85 pagesSVM-7500 - EnglishAG - NIHON KOHDENNizar MissaouiNo ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- Anode InfoDocument5 pagesAnode InfoEberg NlnoNo ratings yet

- Quail Farming Business Plan PDF OverviewDocument5 pagesQuail Farming Business Plan PDF OverviewhenrymcdoNo ratings yet

- Important Questions 2016Document57 pagesImportant Questions 2016Anonymous t9LFhvF100% (1)

- The Radiant Essence of OrangeDocument1 pageThe Radiant Essence of OrangePetru JocuriNo ratings yet

- 1.introduction To HydraulicsDocument32 pages1.introduction To HydraulicsJet Espejon JavierNo ratings yet

- PROPOSALDocument62 pagesPROPOSALJam Dela CruzNo ratings yet

- Structural Design Report 2017.12.25Document27 pagesStructural Design Report 2017.12.25Gihan ChathurangaNo ratings yet

- SM - 9 Automatic TransmissionDocument61 pagesSM - 9 Automatic TransmissionJoeNo ratings yet

- Catalytic Properties of Silver Nanoparticles Supported On Silica SpheresDocument6 pagesCatalytic Properties of Silver Nanoparticles Supported On Silica SpheresEduarddo Ravelo NietoNo ratings yet

- Gramatica LB EnglezeDocument85 pagesGramatica LB Englezemitiloi100% (1)

- Dwnload Full Laboratory Manual For Anatomy and Physiology 6th Edition Marieb Solutions Manual PDFDocument34 pagesDwnload Full Laboratory Manual For Anatomy and Physiology 6th Edition Marieb Solutions Manual PDFhelgasonrosario100% (12)

- Physics 158 Final Exam Review Package: UBC Engineering Undergraduate SocietyDocument22 pagesPhysics 158 Final Exam Review Package: UBC Engineering Undergraduate SocietySpam MailNo ratings yet

- Maryland Route 214 - WikipediaDocument9 pagesMaryland Route 214 - WikipediadwrreNo ratings yet

- FungiDocument100 pagesFungibhanklhonkNo ratings yet

- Roland Robertson - Beyond The Discourse of Globalization PDFDocument14 pagesRoland Robertson - Beyond The Discourse of Globalization PDFCamilaRivasNo ratings yet

- Dehyquart EDocument2 pagesDehyquart EarguijNo ratings yet

- ICT Equipments and Devices Specification FinalDocument54 pagesICT Equipments and Devices Specification FinalTemesgen AynalemNo ratings yet

- CitoVac EnglishDocument32 pagesCitoVac EnglishJulio C. Sierra PalominoNo ratings yet

- Sensorimotor Training A Global Approach For BalancDocument9 pagesSensorimotor Training A Global Approach For BalancVizaNo ratings yet

- MATH 5 Q4 Module 2 Vizualizing Volume of Cube and Rectangular PrismDocument21 pagesMATH 5 Q4 Module 2 Vizualizing Volume of Cube and Rectangular PrismAnj De Guzman75% (4)

- Notice: Buy America Waivers: Mars Electronics International Et Al.Document2 pagesNotice: Buy America Waivers: Mars Electronics International Et Al.Justia.comNo ratings yet

- Budget of Work in Mathematics IIIDocument7 pagesBudget of Work in Mathematics IIIWehn LustreNo ratings yet

- Fan Basics and Selection CriteriaDocument6 pagesFan Basics and Selection CriteriaSangamesh WaranNo ratings yet

- Traffic Flow - WikipediaDocument146 pagesTraffic Flow - WikipediaAngeline AgunatNo ratings yet

- Diss PrelimDocument2 pagesDiss PrelimRochelle Beatriz Mapanao100% (1)

- Lesson 3Document4 pagesLesson 3Justin Kean HakeemNo ratings yet

- LESSON 2 Occupational Safety and Health LawsDocument6 pagesLESSON 2 Occupational Safety and Health LawsMELCHOR CASTRONo ratings yet

- Redecon 2022 BrochureDocument4 pagesRedecon 2022 BrochurekarthiksampNo ratings yet

Centrifuge Maintenance Sop Template

Centrifuge Maintenance Sop Template

Uploaded by

Claude JOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Centrifuge Maintenance Sop Template

Centrifuge Maintenance Sop Template

Uploaded by

Claude JCopyright:

Available Formats

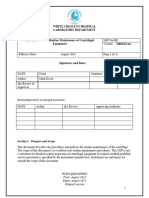

Standard Operating Procedures for Routine Maintenance of

Centrifugal Equipment

This is an SOP template and is not complete until:

1) Lab and equipment specific information is entered into the box below

2) Lab and equipment specific protocol/procedure is added to the protocol/procedure section

3) Lab and equipment specific information (highlighted in RED) is added to each section, and

4) SOP has been signed and dated by the Principal Investigator/Responsible Party and relevant

lab personnel.

Heading/Approval

Building/Room(s)/Centrifuges covered by this SOP:

Department:

Principal Investigator/Responsible Party Name:

Principal Investigator/Responsible Party Signature/Date:

This SOP was created by (if not PI): Name/Title/Date/Signature/Date:

Section 1 - Purpose and Scope

This document describes the procedures and policies for routine maintenance of the centrifuge. The

scope of this document is to establish user routine maintenance procedures. This SOP is not a substitute

for detailed routine inspection of centrifugal equipment by trained certified/qualified service personnel

as specified by the instrument manufacturer. Instrument use and repair are outside the scope of this

document.

Section 2 - Responsibilities

This document is maintained by the Principal Investigator (PI), Responsible Party (RP), or a designee. The

PI/RP or the designee is responsible for general maintenance and repairs of the equipment. If a user

feels that the equipment needs repair or is not operating correctly, please notify the PI/RP or designee

immediately.

All users must read this document and obtain training and approval and from the PI or designee prior to

performing maintenance of the equipment.

Users are responsible for following laboratory procedures after training is completed and documented.

This SOP describes routine maintenance of centrifugal equipment. Do not attempt repair or service of

damaged equipment. If service is required, Contact the PI/RP or designee immediately.

Section 3 - Definitions

Electric Motor/Motor Drive Function: The electrical software that runs the centrifuge. This part of the

centrifuge runs the rotors (both the run and stop functions).

Rotor: The part of the centrifuge where your sample is spun.

Inner Chamber: The area containing the rotor and the spindle.

Routine Maintenance of Centrifugal Equipment SOP │ www.ehs.washington.edu │ Date: 10/15/2021 │Page 1 of 5

Rotor Lid: The lid that covers the top of the rotor and protects from possible sample fragments and

aerosolized particles that may be produced.

Electrical Panel: The control panel of the centrifuge.

Ventilation System: The ventilation system keeps constant airflow within the centrifuge.

O-rings: O-rings are rubber rings that are found on the centrifuge rotor lid. These keep the centrifuge

sealed during use.

Aerosol containment safety cups: Safety devices to contain potential aerosols that could be generated

when centrifuging biohazards.

Centrifuge Lubricant: A lubricant that you can apply to the centrifuge rotor lid if it is not attaching

properly to the rotor.

Section 4 - Precautions [Insert/edit to include Lab Specific Information]

Ensure that all necessary routine maintenance has been performed prior to centrifuge use.

Equipment Manual

Always have a copy of the equipment users/operation manual available when performing routine

maintenance. If there is any type of error or system failure, refer to the manual and PI/RP for guidance.

Do not attempt to repair the equipment.

Electrical Shock Warning

To avoid any sort of electrical shock incidences when working with centrifugal equipment, always make

sure the power cord is firmly attached to an outlet source and never attempt to pull the cord while

touching the electrical prongs.

When servicing/maintaining your equipment, always make sure to unplug the equipment before

maintenance to avoid any hazards of electrical shock. During service/maintenance, the plug must

remain under exclusive control of the individual performing the work. Exclusive control means that the

authorized person is a position to prevent other individuals from re-energizing or starting the centrifuge

while performing the service/maintenance activity. In the event the centrifuge is not under the exclusive

control of the individual while performing maintenance (e.g. they need to leave to leave the equipment

unattended) hazardous energy control (lockout/tagout) procedures are required.

Rotor Compatibility

Ensure that the rotor is intended for and compatible with the centrifuge in use.

Rotor Speed Hazards

Do not exceed the maximum rotor speed of a specific rotor type. Always make sure that your samples

are properly balanced along the sample chambers to avoid unnecessary vibrations (which could cause

your rotor to tilt during a run and cause internal damage to the inner chamber).

Unbalanced Rotor

Unbalanced rotors can be a catastrophic event for the centrifuge and possibly the user. An unbalanced

rotor can cause unnecessary vibrations which could lead to damage to both the electrical motor and the

inner chamber. When an unbalanced rotor occurs, use the breaking system to stop the centrifuge if

possible. Turn off the centrifuge and cut the power source to the equipment. To avoid an unbalanced

rotor, make sure to evenly distribute the weight of your samples (e.g., place two samples that weigh the

same across from one another).

Routine Maintenance of Centrifugal Equipment SOP │ www.ehs.washington.edu │ Date: 10/15/2021 │Page 2 of 5

Ventilation

Centrifugal equipment’s have a built-in system allowing constant airflow in and out of the inner

chamber. Do not block the ventilation system of your equipment. This could lead to restricted airflow

into the centrifuge.

Spills

In the event a sample becomes compromised during a centrifuge run and a spill occurs, refer to your lab

specific protocol [specify here] on PPE and procedures required to manage specific chemicals or

biohazard spills. Always allow the centrifuge to sit for 30 minutes prior to opening to allow bioaerosols

to dissipate. In addition to lab-specific protocol, refer to the UW EH&S Spill Response Poster.

Section 5 - Personal Protective Equipment (PPE)

Use the proper PPE as required by user SOP [specify here] when performing routine maintenance on the

centrifuge.

Section 6 – Required Tools [Insert/edit to include Lab Specific Information]

Section 7 - Routine Maintenance Procedure

The following is a step-by-step description of a general routine maintenance procedure on centrifugal

equipment.

[Insert/edit to include Lab Specific Information]

Note: Each piece of equipment has unique features. Some steps may not be required, additional steps

may be required, or the order may vary.

1. Turn off your centrifuge by shutting down the equipment.

2. Unplug the equipment from its power source.

3. Start by removing the rotor from the inner chamber and setting it aside in a safe spot.

4. Take a cleaning cloth or a paper towel and use a neutral detergent to clean off any residues or

dust from the chamber and the inside of the centrifuge lid.

a. If using aerosol containment safety cups, wipe out with 10% bleach or another

appropriate disinfectant. Follow with an ethanol or water rinse to remove any residues.

5. Once you have cleaned out the chamber and lid, clean your rotor using a neutral detergent and

Inspect the rotor and sample chambers for any signs of physical wear or damage. If you detect

any wear or damage, contact your PI/RP or designee and record the wear or damage in the

comment section of your maintenance log. Lockout/tagout the centrifuge until further notice

and communicate the centrifuge’s offline status to affected persons.

6. If the rotor lid is difficult to screw back on top of the rotor, apply a pea size amount of centrifuge

lubricant on the attachment grooves.

7. Once the centrifuge has been fully cleaned, commence a standard test run of various centrifuge

speeds from 100, 500, 1000, and 2000 rpm [Edit test rpms specific to your equipment make and

model]. Make sure to record whether the runs were a success on the maintenance log (These

increments may vary depending on make and model of centrifugal equipment).

Routine Maintenance of Centrifugal Equipment SOP │ www.ehs.washington.edu │ Date: 10/15/2021 │Page 3 of 5

8. For centrifugal equipment with temperature control capabilities, test the equipment by setting

the centrifuge at a lower than room temperature and waiting five minutes. If there are any

extreme temperature fluctuations or if the temperature is being overshot or undershot, notify

your PI/RP or designee and record this in the comments section of the maintenance log.

Lockout/tagout the centrifuge until further notice and communicate the centrifuge’s offline

status to affected persons. If the first test is successful, repeat this test at a higher than room

temperature.

9. Once you have finished steps 1-8, record required information within the laboratory

maintenance log. (Remember: Do not hesitate to ask any questions concerning centrifuge use

and maintenance).

Section 8 - Emergency Procedures [Insert/edit to include Lab Specific Information]

If the centrifuge malfunctions, immediately stop the run and allow the centrifuge break system to

stop the rotor. Open the centrifuge and unplug it from its power source. Clear any type of debris

present. Use proper tools (e.g., tongs for sharp objects/broken glass) and wear proper PPE specified

in lab’s SOP for centrifugal equipment. Always be mindful of fire exits and fire extinguisher locations

as specified in EH&S’s Fire Extinguisher Training. Never try to fix the equipment yourself. Contact

your PI/RP or designee. Lockout/tagout the centrifuge until further notice and communicate the

centrifuge’s offline status to affected persons.

Section 9 - Related Documents

Appendix A: Instrument User Manual

Appendix B: Instrument Use SOP

Appendix C: User Log (example)

Appendix D: Maintenance Log (electronic link and paper example)

Section 10 - Implementation and Training [signature of all users is required]

Prior to performing routine maintenance procedures described in this SOP, laboratory

personnel must be trained on the hazards described in this SOP, how to protect themselves

from the hazards, and emergency procedures.

Ready access to this SOP, to the instrument user manual, and to any applicable Safety Data

Sheet for each hazardous materials described in the SOP must be made available in the lab

space(s) where these procedures are performed.

The Principal Investigator (PI), or Responsible Party (RP), if the activity does not involve a PI,

must ensure that their laboratory personnel have attended appropriate laboratory safety

training (and refresher training where applicable).

Training must be refreshed following any revision to the content of this SOP.

Training must be documented. This training sheet is provided as one option; other forms of

training documentation (including electronic) are acceptable, but records must be accessible

and immediately available upon request.

Routine Maintenance of Centrifugal Equipment SOP │ www.ehs.washington.edu │ Date: 10/15/2021 │Page 4 of 5

I have read and understand the content of this SOP:

Name Signature Date

Routine Maintenance of Centrifugal Equipment SOP │ www.ehs.washington.edu │ Date: 10/15/2021 │Page 5 of 5

You might also like

- Hhmi Cell Cycle and Cancer - CompletedDocument3 pagesHhmi Cell Cycle and Cancer - CompletedAbel89% (9)

- Maintenance Manual - Varco ST-80 RoughneckDocument42 pagesMaintenance Manual - Varco ST-80 RoughneckCarlos Alberto Perdomo100% (3)

- H8 Service MannualDocument63 pagesH8 Service MannualMichael Tanglao100% (1)

- PX-300HF Operation Manual (111018)Document57 pagesPX-300HF Operation Manual (111018)Daniel Valderrama100% (1)

- MC450 User ManualDocument32 pagesMC450 User ManualCarlos Ubaldo100% (1)

- PX-300HF Service Manual (111018)Document85 pagesPX-300HF Service Manual (111018)Julian Vargas100% (3)

- Maintenance Manual Varco ST 80 Roughneck 2 PDFDocument42 pagesMaintenance Manual Varco ST 80 Roughneck 2 PDFNAMRAJ SHARMANo ratings yet

- 11.4159 USD2755 Remote Control Palltronic Flowstar IV Using OPC IFUDocument16 pages11.4159 USD2755 Remote Control Palltronic Flowstar IV Using OPC IFUseinNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- SIP5 7KE85 V07.80 Manual C018-6 en PDFDocument502 pagesSIP5 7KE85 V07.80 Manual C018-6 en PDFDoan Anh TuanNo ratings yet

- Centrifuge Maintenance SopDocument6 pagesCentrifuge Maintenance Sopkavaim001No ratings yet

- Centrifuge TB-07-06 V1.0Document5 pagesCentrifuge TB-07-06 V1.0Gadhavi jinalNo ratings yet

- 456 20110630 01 Major Proc CentrifugesDocument8 pages456 20110630 01 Major Proc CentrifugessantiNo ratings yet

- S CentrifugesafetyDocument4 pagesS CentrifugesafetyJohn WalleyNo ratings yet

- CIEHF Formative Usability Protocol 10 April 2020Document24 pagesCIEHF Formative Usability Protocol 10 April 2020ArmanNo ratings yet

- CNC 101 TDZ4 WSDocument19 pagesCNC 101 TDZ4 WSfabian muñoz molinaNo ratings yet

- Operating Instructions: DL-6MB High-Capacity Lowspeed Refrigerated CentrifugeDocument29 pagesOperating Instructions: DL-6MB High-Capacity Lowspeed Refrigerated CentrifugekedirNo ratings yet

- Ignition Coil Tester: Operating ManualDocument28 pagesIgnition Coil Tester: Operating ManualJason AguilarNo ratings yet

- 1 What Is Centrifuge MachineDocument16 pages1 What Is Centrifuge Machinebereketab demmelashNo ratings yet

- Centrifuging Serum and PlasmaDocument4 pagesCentrifuging Serum and Plasmapetty_atmadjaNo ratings yet

- Manual de Usuario - Centrifuga NF 048Document12 pagesManual de Usuario - Centrifuga NF 048Brevas CuchoNo ratings yet

- Penlon A-200 SP Circle Absorber - User ManualDocument40 pagesPenlon A-200 SP Circle Absorber - User ManualAnonymous oWnCVtEUQCNo ratings yet

- Centrifuge SafetyDocument2 pagesCentrifuge Safetyhazc5666No ratings yet

- Updated Startup Procedure - FD West - Hyduke - Phoenix Manual Rev 03Document31 pagesUpdated Startup Procedure - FD West - Hyduke - Phoenix Manual Rev 03Francisco Wilson Bezerra FranciscoNo ratings yet

- SOP - Safe and Proper Use of The Sorvall WX M UltracentrifugeDocument21 pagesSOP - Safe and Proper Use of The Sorvall WX M UltracentrifugeAngelosNo ratings yet

- Air Purge Tool Manual 5086900ADocument30 pagesAir Purge Tool Manual 5086900AOsmanyNo ratings yet

- ME 347 Fluid Mechanics Lab Experiments 7th EditionDocument117 pagesME 347 Fluid Mechanics Lab Experiments 7th EditionAnonymous SlyvspdBNo ratings yet

- Vacuum Pump Maintenance Sop TemplateDocument5 pagesVacuum Pump Maintenance Sop TemplateClaude JNo ratings yet

- 2023 SOP CentrifugeDocument7 pages2023 SOP CentrifugeParomita SarkerNo ratings yet

- HLR Rotary Lobe Pump: Installation, Service and Maintenance InstructionsDocument44 pagesHLR Rotary Lobe Pump: Installation, Service and Maintenance InstructionsabhairulzNo ratings yet

- mp6002 7502 9002 m-c5 FSM en Final 250512Document814 pagesmp6002 7502 9002 m-c5 FSM en Final 250512СергейNo ratings yet

- Phần Mềm Sửa Chữa Máy Aficio MP6001-MP9001Document760 pagesPhần Mềm Sửa Chữa Máy Aficio MP6001-MP9001Photocopy Tân PhúNo ratings yet

- Cpms College of Nursing: Assignment ON Setting, Use and Maintainance of Centrifuge MachineDocument6 pagesCpms College of Nursing: Assignment ON Setting, Use and Maintainance of Centrifuge MachineAmy Lalringhluani ChhakchhuakNo ratings yet

- Heraeus Biofuge Pico - User ManualDocument67 pagesHeraeus Biofuge Pico - User Manualluroguita-1No ratings yet

- TDS1000AInstallationManual 03May28AbridgedDocument20 pagesTDS1000AInstallationManual 03May28Abridgedbwd104No ratings yet

- Dynair Axial Omm Gulf 22sep20Document22 pagesDynair Axial Omm Gulf 22sep20Happy Man100% (1)

- Instructions Manual: Rotatory SieveDocument53 pagesInstructions Manual: Rotatory SieveBogdan PistolNo ratings yet

- Manual of HSC16Document281 pagesManual of HSC16johann medinaNo ratings yet

- Manualspectrafuge 16 DDocument16 pagesManualspectrafuge 16 DTan Hung LuuNo ratings yet

- FMS Staion 8 Robotic ArmDocument20 pagesFMS Staion 8 Robotic ArmatihzNo ratings yet

- Falcon c1000Document9 pagesFalcon c1000jlfyNo ratings yet

- XLC 2nd Stage Service Manual PDFDocument22 pagesXLC 2nd Stage Service Manual PDFCesc SimóNo ratings yet

- Manual Procesador UltrasónicoDocument22 pagesManual Procesador UltrasónicoYOHANANo ratings yet

- Bomba InoxpaDocument20 pagesBomba InoxpalcmpX86No ratings yet

- TEC5600 Service Manual PDFDocument303 pagesTEC5600 Service Manual PDFwamala benjaminNo ratings yet

- Nihon Kohden TEC-5600 Defibrillator - Service Manual - Compressed-1-144Document144 pagesNihon Kohden TEC-5600 Defibrillator - Service Manual - Compressed-1-144Francisco BaezNo ratings yet

- Safety Precautions and Practices in Operation and MaintenanceDocument8 pagesSafety Precautions and Practices in Operation and MaintenanceQwe AsdfNo ratings yet

- Content: Standard Operating Procedure (SOP) Use and Maintenance of A CentrifugeDocument9 pagesContent: Standard Operating Procedure (SOP) Use and Maintenance of A CentrifugenazmiNo ratings yet

- LG-R410, RB410, RV410, RD410 Manual de Serviço PDFDocument116 pagesLG-R410, RB410, RV410, RD410 Manual de Serviço PDFRenato AraujoNo ratings yet

- Led Display. Instruction Manual & Details: Pro-AnalyticalDocument12 pagesLed Display. Instruction Manual & Details: Pro-AnalyticalALFREDO LUIS ARROYO SANCHEZNo ratings yet

- 1.HF-525Plus VET (32kW, 400ma, 230Vor110V, XR5)Document207 pages1.HF-525Plus VET (32kW, 400ma, 230Vor110V, XR5)fortroniNo ratings yet

- User Manual: $',167580 (176 $'multifunction TesterDocument40 pagesUser Manual: $',167580 (176 $'multifunction TesterpanosNo ratings yet

- Manual PLC-01-05 2014 0219Document26 pagesManual PLC-01-05 2014 0219JanneDoee0% (1)

- Tabletop Low Speed Centrifuge: (Read The Instruction Carefully Before Operation)Document20 pagesTabletop Low Speed Centrifuge: (Read The Instruction Carefully Before Operation)haile negeraNo ratings yet

- HF-525Plus Service Manual (Rev. 2.2 Latest) 16 11 2011 PDFDocument142 pagesHF-525Plus Service Manual (Rev. 2.2 Latest) 16 11 2011 PDFFélix Nicolau100% (2)

- HF-525Plus Service Manual (Rev. 2.2 Latest)Document149 pagesHF-525Plus Service Manual (Rev. 2.2 Latest)Franklyn Acevedo100% (1)

- UrocapIV Standalone Quick Start Guide V04 (MAN400) UC4 UM02Document9 pagesUrocapIV Standalone Quick Start Guide V04 (MAN400) UC4 UM02Tanzimul IslamNo ratings yet

- Manual Active Chloride 160209Document234 pagesManual Active Chloride 160209the_pilotNo ratings yet

- Operation & Maintenance Manual FOR Non-Clog Type Pumps: Patterson Pump CompanyDocument30 pagesOperation & Maintenance Manual FOR Non-Clog Type Pumps: Patterson Pump CompanysumiNo ratings yet

- SVM-7500 - EnglishAG - NIHON KOHDENDocument85 pagesSVM-7500 - EnglishAG - NIHON KOHDENNizar MissaouiNo ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- Anode InfoDocument5 pagesAnode InfoEberg NlnoNo ratings yet

- Quail Farming Business Plan PDF OverviewDocument5 pagesQuail Farming Business Plan PDF OverviewhenrymcdoNo ratings yet

- Important Questions 2016Document57 pagesImportant Questions 2016Anonymous t9LFhvF100% (1)

- The Radiant Essence of OrangeDocument1 pageThe Radiant Essence of OrangePetru JocuriNo ratings yet

- 1.introduction To HydraulicsDocument32 pages1.introduction To HydraulicsJet Espejon JavierNo ratings yet

- PROPOSALDocument62 pagesPROPOSALJam Dela CruzNo ratings yet

- Structural Design Report 2017.12.25Document27 pagesStructural Design Report 2017.12.25Gihan ChathurangaNo ratings yet

- SM - 9 Automatic TransmissionDocument61 pagesSM - 9 Automatic TransmissionJoeNo ratings yet

- Catalytic Properties of Silver Nanoparticles Supported On Silica SpheresDocument6 pagesCatalytic Properties of Silver Nanoparticles Supported On Silica SpheresEduarddo Ravelo NietoNo ratings yet

- Gramatica LB EnglezeDocument85 pagesGramatica LB Englezemitiloi100% (1)

- Dwnload Full Laboratory Manual For Anatomy and Physiology 6th Edition Marieb Solutions Manual PDFDocument34 pagesDwnload Full Laboratory Manual For Anatomy and Physiology 6th Edition Marieb Solutions Manual PDFhelgasonrosario100% (12)

- Physics 158 Final Exam Review Package: UBC Engineering Undergraduate SocietyDocument22 pagesPhysics 158 Final Exam Review Package: UBC Engineering Undergraduate SocietySpam MailNo ratings yet

- Maryland Route 214 - WikipediaDocument9 pagesMaryland Route 214 - WikipediadwrreNo ratings yet

- FungiDocument100 pagesFungibhanklhonkNo ratings yet

- Roland Robertson - Beyond The Discourse of Globalization PDFDocument14 pagesRoland Robertson - Beyond The Discourse of Globalization PDFCamilaRivasNo ratings yet

- Dehyquart EDocument2 pagesDehyquart EarguijNo ratings yet

- ICT Equipments and Devices Specification FinalDocument54 pagesICT Equipments and Devices Specification FinalTemesgen AynalemNo ratings yet

- CitoVac EnglishDocument32 pagesCitoVac EnglishJulio C. Sierra PalominoNo ratings yet

- Sensorimotor Training A Global Approach For BalancDocument9 pagesSensorimotor Training A Global Approach For BalancVizaNo ratings yet

- MATH 5 Q4 Module 2 Vizualizing Volume of Cube and Rectangular PrismDocument21 pagesMATH 5 Q4 Module 2 Vizualizing Volume of Cube and Rectangular PrismAnj De Guzman75% (4)

- Notice: Buy America Waivers: Mars Electronics International Et Al.Document2 pagesNotice: Buy America Waivers: Mars Electronics International Et Al.Justia.comNo ratings yet

- Budget of Work in Mathematics IIIDocument7 pagesBudget of Work in Mathematics IIIWehn LustreNo ratings yet

- Fan Basics and Selection CriteriaDocument6 pagesFan Basics and Selection CriteriaSangamesh WaranNo ratings yet

- Traffic Flow - WikipediaDocument146 pagesTraffic Flow - WikipediaAngeline AgunatNo ratings yet

- Diss PrelimDocument2 pagesDiss PrelimRochelle Beatriz Mapanao100% (1)

- Lesson 3Document4 pagesLesson 3Justin Kean HakeemNo ratings yet

- LESSON 2 Occupational Safety and Health LawsDocument6 pagesLESSON 2 Occupational Safety and Health LawsMELCHOR CASTRONo ratings yet

- Redecon 2022 BrochureDocument4 pagesRedecon 2022 BrochurekarthiksampNo ratings yet