Professional Documents

Culture Documents

Topboard - 12mm-TDS-ASK

Topboard - 12mm-TDS-ASK

Uploaded by

moataz9410Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Topboard - 12mm-TDS-ASK

Topboard - 12mm-TDS-ASK

Uploaded by

moataz9410Copyright:

Available Formats

C O N S O L I DAT E D

TopBoard

ISO 9001:2015 ISO 14001:2015 ISO 45001:2018

No.: 92200062 No.: 142200063 No.: 452200064

DESCRIPTION APPLICATION

TopBoard is composed of Portland • Wall cladding

cement, high purity silica sand, • Roof underlay

reinforcing pulp recycled in our facilities • Soffit and eaves lining

and additives for water, and fire • False ceiling

resistance properties. • Partition walls

• Dry lining

TopBoard is a state-of-the-art asbestos

free, highly durable and practical board

used in many finishing applications;

partition walls, dry linings, suspended

ceilings, flooring. TopBoard is impact FEATURES

resistant, durable and requires low • Non-combustible

maintenance. • Provides thermal and acoustic insulation

• Simple installation

All materials are certified based on • Low maintenance

ASTM and EN standards and tested in

approved laboratories.

Advanced impact Termite Fire Durable

resistance resistance resistance

PROPERTIES

SURFACE FINISHING EDGE TYPES STANDARDS DIMENSIONS

Painted (water or oil base paint) Squared edge ASTM C1186 Width

1200mm, 1220mm

Cladding (wallpaper, vinyl, wood…) Length

ASTM E84

2400mm,3000mm

Joint filling with Ccoat™ All Purpose Tapered edge

ASTM C518 Thickness

Joint Compound 4.5mm, 6mm, 8mm,

9mm, 10mm, 12mm,

15mm, 16mm, 18mm

20mm

*Varying dimensions are available upon request

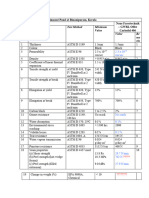

PHYSICAL SPECIFICATIONS

SPECIFICATIONS UNIT VALUE STANDARDS

Thickness mm 12 ASTM C 1186

Weight Kg/m² 15.7 ASTM C 1186

Density Kg/m³ 1309 ASTM C 1186

Flexural strength longitudinal direction MPa 12.74 ASTM C 1186

Flexural strength transversal direction MPa 7.24 ASTM C 1186

Water absorption % 31.98 ASTM C 1186

Moisture content % 9.86 ASTM C 1186

Linear change % 0.09 ASTM C 1186

Direct screw withdrawal N 742 ASTM C 1186

pH - 9.9 ASTM C 1186

Thermal conductivity W/m.K 0.2 ASTM C 518

Reaction to fire - Class A ASTM E 84

Flame spread index (FSI) - 0 ASTM E 84

Smoke development index (SDI) - 5 ASTM E 84

Water tightness No water drops seeping through the sheets.

RECOMMENDATIONS

• Cut the board using an electrical saw.

• Use zinc self-tapping screws with a metal frame of less than 0.7mm to fix the boards.

• Use zinc self-drilling for a metal frame greater than 0.7mm to fix the boards.

• Vertical screw spacing for the first layer of TopBoard is 25cm, 50cm for the second, and 75cm

for the third.

STORAGE AND HANDLING

• Avoid contact with moisture or temperatures higher than 50°C for prolonged periods of time.

• Store in a dry/ventilated area above ground level (not in direct contact with the ground).

• Cover boards with plastic sheets.

• Avoid direct rain or sunlight.

• Avoid cracking or damaging the boards during installation.

The information herein and recommendations set forth are presented in good faith and believed to be correct as of the date hereof, ASK Gypsum

Factory Ltd., and its affiliated, and sister companies do not make representations or warranties as to the completeness or accuracy thereof.

Information is supplied upon the condition that the persons receiving the same will make their own determination as to its suitability for their

purpose prior to use. In no event will ASK Gypsum Factory Ltd. and its affiliated and sister companies be responsible for indirect, consequential,

or incidental damages arising out of the use of, or inability to use this product. Our liability, if any, shall be capped to the price of the product

purchased.

All specifications reflect averages derived from product sample testing and are provided as guidance only. They are subject to inherent variances

and may be changed without notice to improve reliability, function, or design or otherwise.

Manufactured according to ASTM & EN standards by ASK Gypsum Factory Ltd.

ASK Gypsum Factory Ltd,Yanbu Industrial City, Light industrial Area, Al Razi Street, Road 10, KSA

Tel: +966 12 613 0000

You might also like

- FR Gboard Tds21Document1 pageFR Gboard Tds21rangarajan1989100% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Gamma PLTDocument2 pagesGamma PLTEgyp XsNo ratings yet

- 09 - BoardDocument4 pages09 - Boardakankshas06No ratings yet

- CAT - LAMINADO - Meiah Anti-Static HPL C2 - RIHINODocument4 pagesCAT - LAMINADO - Meiah Anti-Static HPL C2 - RIHINOFausto Javier Llerena RengelNo ratings yet

- Poly FlameDocument2 pagesPoly Flamemk779900mkNo ratings yet

- Polycarbonate Data SheetDocument1 pagePolycarbonate Data SheetJoseph Cloyd Lamberte100% (1)

- H6105JUDocument1 pageH6105JUhunghiepvanNo ratings yet

- Knauf Gypsum Wall Board (GWR)Document2 pagesKnauf Gypsum Wall Board (GWR)isd constructionNo ratings yet

- Polyken 930: Product Data SheetDocument2 pagesPolyken 930: Product Data SheetAgustina De Winne100% (1)

- PDS Polyken 980 955 V5 Sep20 Aarps 0285Document2 pagesPDS Polyken 980 955 V5 Sep20 Aarps 0285Andrea Pamela León AlgarañazNo ratings yet

- Astm Property IM17VDocument2 pagesAstm Property IM17VSaketh VandeNo ratings yet

- 81 Imi ImpermitDocument2 pages81 Imi ImpermitEngr KamalNo ratings yet

- Polyken 930: Product Data SheetDocument2 pagesPolyken 930: Product Data SheetEdwin Bustamante Cabrera100% (1)

- 88 Imi ImiplastDocument2 pages88 Imi ImiplastEngr KamalNo ratings yet

- PolyflameDocument2 pagesPolyflameumn_mlkNo ratings yet

- Pa6 GF20 - RTP Company RTP Pa6 20 GFDocument1 pagePa6 GF20 - RTP Company RTP Pa6 20 GFarmandoNo ratings yet

- Hdpe 080M60Document1 pageHdpe 080M60pbNo ratings yet

- BinanizincspecsDocument6 pagesBinanizincspecsJimmy ThomasNo ratings yet

- SCG D777CDocument1 pageSCG D777Cbhoopendra singhNo ratings yet

- GRI-GM30: Weld Easier. Install Faster. Contain BetterDocument2 pagesGRI-GM30: Weld Easier. Install Faster. Contain BetterAndreas Erdian WijayaNo ratings yet

- Poly GlasDocument2 pagesPoly Glasmk779900mkNo ratings yet

- Interior Ceiling Data Sheet e 2201ctgDocument2 pagesInterior Ceiling Data Sheet e 2201ctgBessyNo ratings yet

- Lldpe 20100326-165732-Tds-02-Uf1810t-1Document1 pageLldpe 20100326-165732-Tds-02-Uf1810t-1Addison FregilNo ratings yet

- Imperseal 7000Xl: Salient FeaturesDocument2 pagesImperseal 7000Xl: Salient FeaturesJeff GajeNo ratings yet

- Hivorex mf5000Document1 pageHivorex mf5000Chu ChuNo ratings yet

- Technical Data Sheet (ABS) - SmithsDocument1 pageTechnical Data Sheet (ABS) - SmithsKelvin Tai Wei LimNo ratings yet

- Adding A New Dimension To Impact Resistant Glazing and CladdingDocument1 pageAdding A New Dimension To Impact Resistant Glazing and CladdingOmer TahaNo ratings yet

- Geomembrana Hdpe 1.5 AmpDocument1 pageGeomembrana Hdpe 1.5 AmpRicardo SanchezNo ratings yet

- 1030TCDocument1 page1030TCaman1406krNo ratings yet

- Epilay Epistik Plus FeaturesDocument2 pagesEpilay Epistik Plus FeaturesFatma IbrahimNo ratings yet

- Parche CRP 65 - Ficha Técnica - en InglesDocument2 pagesParche CRP 65 - Ficha Técnica - en IngleserwinvillarNo ratings yet

- Technical Data Sheet AlublockDocument1 pageTechnical Data Sheet AlublocklasNo ratings yet

- Torch SealDocument2 pagesTorch Sealmk779900mkNo ratings yet

- Thumb 20180521C775Document2 pagesThumb 20180521C775Alle LunagNo ratings yet

- Detailed Specification Kadi TholDocument22 pagesDetailed Specification Kadi TholMAULIK RAVALNo ratings yet

- Detailed Tech Spec For ItemsDocument16 pagesDetailed Tech Spec For ItemsABCDNo ratings yet

- PDS Polyken 980 955Document2 pagesPDS Polyken 980 955David100% (1)

- Corian Exterior Cladding: Technical BulletinDocument6 pagesCorian Exterior Cladding: Technical BulletinnaheedahmedNo ratings yet

- 1110mg Iocl PP Injection Moulding GranulesDocument1 page1110mg Iocl PP Injection Moulding Granulessantosh.bhattNo ratings yet

- 002DP48 PDFDocument2 pages002DP48 PDFDiadam SharmaNo ratings yet

- High Density Polyethylene Injection Molding: Provisional Technical Data SheetDocument1 pageHigh Density Polyethylene Injection Molding: Provisional Technical Data SheetQuality teamNo ratings yet

- 004DP44 PDFDocument1 page004DP44 PDFDiadam SharmaNo ratings yet

- PDS Polyken 980 955 V3 Jan19 Aarps 0285Document2 pagesPDS Polyken 980 955 V3 Jan19 Aarps 0285Irawan FajarNo ratings yet

- Trimdek: Design and Installation GuideDocument6 pagesTrimdek: Design and Installation GuideHarold SanaresNo ratings yet

- Premcote 101 DatasheetDocument1 pagePremcote 101 DatasheetHuythuong NguyenNo ratings yet

- Iocl PPCP Injection Molding 11 Mfi 4100mhDocument1 pageIocl PPCP Injection Molding 11 Mfi 4100mhAparesh GantaitNo ratings yet

- Tikidan TDS - Selfdan Ipe Plus, R3Document3 pagesTikidan TDS - Selfdan Ipe Plus, R3sandeepNo ratings yet

- 199 Imi EkoguardDocument2 pages199 Imi EkoguardEngr KamalNo ratings yet

- Everest Multipurpose Fibre Cement Boards: Sizes and Thickness AvailableDocument2 pagesEverest Multipurpose Fibre Cement Boards: Sizes and Thickness AvailableSTRUCTURAL ENGG DEPT TDLCCSNo ratings yet

- LL7410D1Document1 pageLL7410D1Nitin MaheshwariNo ratings yet

- Mineral Wool Pipe InsulationDocument4 pagesMineral Wool Pipe InsulationMiguel Martinez GuerreroNo ratings yet

- 8.19.3 Laying: 8.20 Curtain W T T ALL W W With Aluminium Composite Panels (Acp) Cladding P P 8.20.1 GeneralDocument5 pages8.19.3 Laying: 8.20 Curtain W T T ALL W W With Aluminium Composite Panels (Acp) Cladding P P 8.20.1 GeneralAnshuman RathNo ratings yet

- Innoplus (GC Marketing) LL7835ADocument1 pageInnoplus (GC Marketing) LL7835AOscar Tan IIINo ratings yet

- Special Characteristics:: Innoplus Ll7420DDocument1 pageSpecial Characteristics:: Innoplus Ll7420DFahad MohamedNo ratings yet

- Viton Cord DatasheetDocument1 pageViton Cord DatasheetGokul royalveritasNo ratings yet

- CANUSA Wrapid TapeDocument2 pagesCANUSA Wrapid TapeHalimNo ratings yet

- Polyflame Garden - I & IIDocument2 pagesPolyflame Garden - I & IIAbdul Jaleel MohammedNo ratings yet

- 1.incoming Register July 2014Document24 pages1.incoming Register July 2014BeLlCoNtInEnT MNo ratings yet

- Description 2016 Ashrae Handbook-Hvac Systems and EquipmentDocument6 pagesDescription 2016 Ashrae Handbook-Hvac Systems and EquipmentthakrarhitsNo ratings yet

- Nagpur CSRDocument337 pagesNagpur CSRArvind Bajpai50% (2)

- Spine Girder - Prestress DesignDocument109 pagesSpine Girder - Prestress Designarif_rubinNo ratings yet

- Cooling Capacity Calculation PrintingDocument1 pageCooling Capacity Calculation PrintingJay PatelNo ratings yet

- Iscodes For BMCP - 16390284 - 2023 - 03 - 08 - 18 - 48Document5 pagesIscodes For BMCP - 16390284 - 2023 - 03 - 08 - 18 - 48kiran868626No ratings yet

- SECTION 07 21 23 Loose-Fill InsulationDocument5 pagesSECTION 07 21 23 Loose-Fill InsulationJuanPaoloYbañezNo ratings yet

- 12 - Need & Function of Pile FoundationDocument2 pages12 - Need & Function of Pile FoundationMUTHUKKUMARAMNo ratings yet

- PDS Superlastic S600 Final v2Document5 pagesPDS Superlastic S600 Final v2sofyanNo ratings yet

- 2020 Lista de Exercício 01 Bruno Monteiro Costa 569125Document8 pages2020 Lista de Exercício 01 Bruno Monteiro Costa 569125Bruno CostaNo ratings yet

- Energy Efficient Panel Heaters - Amaze-HeaterDocument16 pagesEnergy Efficient Panel Heaters - Amaze-HeaterChris FederarNo ratings yet

- HeatingDocument6 pagesHeatingTony D. MolinaNo ratings yet

- Cladding Systems: Protecting Your InsulationDocument11 pagesCladding Systems: Protecting Your InsulationHaytham ElsayedNo ratings yet

- Yb21080 Er - Arunachalam St04-Floor Beam Details Structural DrawingDocument1 pageYb21080 Er - Arunachalam St04-Floor Beam Details Structural DrawingBoopathi YoganathanNo ratings yet

- Complex Roof Framing HandoutDocument23 pagesComplex Roof Framing HandoutMaria ComanNo ratings yet

- Seminar: Industrial ChimneysDocument12 pagesSeminar: Industrial Chimneysmanu_696No ratings yet

- 2019 Guard House Detailed EstimateDocument7 pages2019 Guard House Detailed EstimateMarianne Sheena Sarah SablanNo ratings yet

- Shot CreteDocument6 pagesShot CreteR.RAVINDRANNo ratings yet

- SatipDocument5 pagesSatipMuhammad Abdul Kadher100% (3)

- Unit 5 - Construction Technology - WWW - Rgpvnotes.inDocument6 pagesUnit 5 - Construction Technology - WWW - Rgpvnotes.inRitesh Agarwal OYOwalaNo ratings yet

- Difference Between Aac and CLC - Foam Generator Suppliers in Pune, CLC Block Making Plant in Mumbai, Pune, Gujarat, Nashik, Akola, Nellore - Foam Generator Manfacturer IndiaDocument2 pagesDifference Between Aac and CLC - Foam Generator Suppliers in Pune, CLC Block Making Plant in Mumbai, Pune, Gujarat, Nashik, Akola, Nellore - Foam Generator Manfacturer IndiaGitesh Gaurav0% (1)

- Glass in BuildingDocument18 pagesGlass in BuildingkarthiksampNo ratings yet

- Qcs 2010 Section 15 Part 3 Cold Stores PDFDocument5 pagesQcs 2010 Section 15 Part 3 Cold Stores PDFbryanpastor106No ratings yet

- Rocket Stove Mass HeaterDocument14 pagesRocket Stove Mass Heaterdanut_doc100% (1)

- Plumbing InstallationDocument38 pagesPlumbing InstallationPrakash PanneerselvamNo ratings yet

- Final Quotation (With Material) 238D BlockDocument12 pagesFinal Quotation (With Material) 238D BlockRizwanAli100% (2)

- Quotation For Material ContractDocument2 pagesQuotation For Material Contractsatishprabu83% (6)

- Gsa Usc Shell UtilityDocument14 pagesGsa Usc Shell UtilitysereneNo ratings yet

- BT 03Document66 pagesBT 03VINCE NIETONo ratings yet

- NFPA-13-Sprinkler-System Plan ReviewDocument5 pagesNFPA-13-Sprinkler-System Plan ReviewVenkatram AnnamdevaraNo ratings yet