Professional Documents

Culture Documents

FP Design Guide General

FP Design Guide General

Uploaded by

Conroy LawrenceOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FP Design Guide General

FP Design Guide General

Uploaded by

Conroy LawrenceCopyright:

Available Formats

General Design Notes

FirePro Design & Installation Guidelines

Designing for FirePro is an engineering process where the FirePro Design Calculation must be used in the

first instance. The second process in determining the appropriate solution is to look at the physical

characteristics of the area to be protected (Risk) and consider:

• The layout of the Risk.

• Review any openings or ventilation in the Risk and assess the impact on Fire System Design.

• The configuration of objects within the Risk – giving special attention to the items or objects which

would be the source of a fire.

• The use of the Risk – special consideration to whether the risk will be normally manned.

• Clearances which need to be observed for safe egress from the Risk.

• Clearances from objects for the FirePro units

• The methods selected for detection of a fire and activation of the Aerosol Generators.

• When selecting the particular FirePro units need to ensure that the aerosol will be able to be

distributed throughout the Risk,

• Once FirePro units selected look at bracket selection and consider the use of Heavy Duty Brackets.

• When installing the units consider the strength of the wall or roof compared the weight of the

FirePro unit being installed.

• If using electrical activation Shielded Fire Rated cable must be used to ensure that the system will

not be affected by induced current from other devices.

FirePro Generator Models can be divided in 4 categories:

SMALL Volumetric Enclosures

• Small Panels Up to 0.8m3 FP20, FP40, FP80

• Small electric cubicles

MEDIUM Volumetric Enclosures Up to 10m3 FP100, FP200, FP500

• Large electrical panels

LARGE Volumetric Enclosures

• Computer Server rooms

• Electrical rooms Up to 500m3 FP1200, FP2000, FP3000

• Plant-rooms

• Telecom rooms etc

VERY LARGE Volumetric Enclosures

• Warehouses

Over 500m3 FP5700

• Archive rooms

• Large Plant-rooms etc

Design & Installation Guidelines

1. Follow installation temperature tables – Always allow for recommended clearance between generator

discharge outlet and equipment installed within the subject room (especially sensitive

equipment/electronics)

2. In case of cabinets, never direct the Aerosol Stream/flow on sensitive electronics.

3. Follow/consult Stream-Length capabilities table for each model

FirePro General Design Guide Page 1

4. When protecting spaces, install generators with their discharging outlet facing the likely source of fire

e.g. the floor and ensure the homogeneous distribution of Aerosol within the protected space

5. Use proper concentrations according to the subject room highest Hazard classification

6. Use suitable model for the application intended

7. Select small units for small volumetric enclosures and ensure that their capabilities/properties are

suitable for the purpose intended – use nozzles when protecting sensitive electronics. Do not use the

FP8 model for the protection of sensitive electronics. Again, never direct the Aerosol stream on

sensitive electronics

8. FP1200, FP2000 & FP3000 - Good for almost all applications – Exceptionally suitable for computer, IT

rooms and similar type of applications.

9. FP5700 use for the protection of very large volumes and for installations of 4m+ in height.

10. Aerosol designed concentration must be calculated properly and additional Aerosol concentration /

Safety Factor must be provided in case of infiltration to other areas.

11. Always ensure air-tightening of room protected.

Installation Clearance - the Do’s & Don’ts

Wrong Installation Proper Installation

Aerosol cannot reach unobstructed the likely source Aerosol easily reaches the likely source of fire and

of fire, e.g. the floor good even distribution is achieved.

Typical FirePro Installation

FirePro General Design Guide Page 2

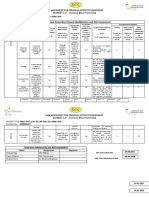

Specifications for the Aerosol Generators

Stream Discharge Temperature Discharge Time

Model No of Outlets Length L1 L2 L3

Min Max

(mm) (mm) (mm) (mm)

FP-0020 2 300 - - 100 3 6

FP-0040 2 1200 - - 100 5 10

FP-0080 2 2000 - - 100 4 8

FP-0100 1 1000 - - 100 5 10

FP-0200 1 1500 - 100 300 5 10

FP-0500 1 2500 - 200 500 5 10

FP-1200 1 3500 - 200 1200 10 15

FP-2000 1 3500 - 200 1200 10 15

FP-3000 1 4000 - 700 1700 15 20

FP-5700 1 8000 - 800 1800 15 20

L1 = Distance in mm between the outlet and the point where the temperature is > 300oC

L2 = Distance in mm between the outlet and the point where the temperature is < 200oC

L3 = Distance in mm between the outlet and the point where the temperature is < 75oC

AS 4487 (2013) Requirements FOR System Installation and Commissioning

The requirements for fixed aerosol systems are the same as for all Fixed System Installation

• Time Delay Device – a pre-discharge alarm sufficient to all evacuation prior to discharge.

• Automatic/Manual Switch required to allow system to be placed in manual mode when

protected area is occupied.

• System Isolate Switch required to prevent discharge during maintenance.

• All these functions are standard on AS approved panels

AS 1851 Maintenance

• FirePro® Aerosol Generators are to be maintained in accordance with AS 1851.

• Periodic - visual Inspections of all major components. Monthly / Quarterly / Bi-annual. This

period is determined by an evaluation of the environment for the installation.

• Annual - Testing, cleaning of all components and detailed review of system. (1 Hour)

• Log Book required for each system.

• System test equipment is required to perform annual testing.

FirePro General Design Guide Page 3

You might also like

- Crucial Conversations - NotesDocument11 pagesCrucial Conversations - NotesEmilia Longwood80% (5)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Crisis Communication LectureDocument27 pagesCrisis Communication LectureNeil SawantNo ratings yet

- 50 Successful Habits Ebook OnlineDocument60 pages50 Successful Habits Ebook Onlinemkpai-10% (1)

- Fireclass Fcfireray5000 Prezentacio Angol PDFDocument92 pagesFireclass Fcfireray5000 Prezentacio Angol PDFnastyn-1No ratings yet

- SIPROTEC Compact 7SK80 V4.6 Motor Protection: Technical Data Extract From Manual E50417-G1140-C344-A4, Chapter 4Document70 pagesSIPROTEC Compact 7SK80 V4.6 Motor Protection: Technical Data Extract From Manual E50417-G1140-C344-A4, Chapter 4Surachat SannokNo ratings yet

- EHS8000 Housing Installation Manual 110818Document32 pagesEHS8000 Housing Installation Manual 110818DP DiariesNo ratings yet

- Fire SafetyDocument26 pagesFire SafetySharon Lambert100% (1)

- F1000 User's ManualDocument17 pagesF1000 User's Manualismailatmaca467No ratings yet

- Jet FansDocument8 pagesJet FansTin ThanNo ratings yet

- Manual Supplement: European ATEX Directive InformationDocument2 pagesManual Supplement: European ATEX Directive InformationKARIMNo ratings yet

- Jetfoil - Tunnel Fans PDFDocument16 pagesJetfoil - Tunnel Fans PDFJovan MitrevskiNo ratings yet

- AD OPTIFLUX2000 4000 IFC100 ATEX-IECEx en 140916 7312092200 R02Document20 pagesAD OPTIFLUX2000 4000 IFC100 ATEX-IECEx en 140916 7312092200 R02SofiaNo ratings yet

- 0665 FFE Fireray 50 100 US Jan17 WEB PDFDocument2 pages0665 FFE Fireray 50 100 US Jan17 WEB PDFafie pio pioNo ratings yet

- 0665 FFE Fireray 50 100 US Jan17 WEB PDFDocument2 pages0665 FFE Fireray 50 100 US Jan17 WEB PDFMahesh DeokarNo ratings yet

- B800 Series Frequency Inverter: Bedford (Quanzhou) Electronic Co., LTDDocument32 pagesB800 Series Frequency Inverter: Bedford (Quanzhou) Electronic Co., LTDAthaNo ratings yet

- Mah Sahu 021 2015Document26 pagesMah Sahu 021 2015Karthikeyan SankarrajanNo ratings yet

- CF3000 User ManualDocument114 pagesCF3000 User ManualmurilonetoNo ratings yet

- Toshiba Medium Voltage Motor SolutionsDocument6 pagesToshiba Medium Voltage Motor Solutionsحازم صبحى100% (1)

- Transistor Inverter: TOSVERT™ Inverter Dedicated To Fan and Pump For HVACDocument2 pagesTransistor Inverter: TOSVERT™ Inverter Dedicated To Fan and Pump For HVACMaitry ShahNo ratings yet

- Furuno Ds80 InstallationDocument82 pagesFuruno Ds80 Installationtangocanh80100% (3)

- M-200 and M-600 Appliance Hardware ReferenceDocument56 pagesM-200 and M-600 Appliance Hardware ReferenceAbel De Los SantosNo ratings yet

- Onicon Flow MeterDocument38 pagesOnicon Flow Metersiva_nagesh_2No ratings yet

- PowerFlex 40Document161 pagesPowerFlex 40Fabricio DalioNo ratings yet

- Siemens MotorsDocument7 pagesSiemens MotorslifttecNo ratings yet

- OXY-Gas - Manual Do UsuarioDocument25 pagesOXY-Gas - Manual Do UsuarioMagno DelmiroNo ratings yet

- Aislador Epoxi Catalogo 2011 ENGDocument56 pagesAislador Epoxi Catalogo 2011 ENGmk116dNo ratings yet

- DTC2M5000W: 5000W - Broadcast FM Power Combiner ModuleDocument5 pagesDTC2M5000W: 5000W - Broadcast FM Power Combiner ModuleTato YudayanaNo ratings yet

- FT400 SeriesDocument12 pagesFT400 SeriesAutomatizacionNo ratings yet

- Why A Fixed Refrigerant Leak Detection System?Document4 pagesWhy A Fixed Refrigerant Leak Detection System?Murco Gas DetectionNo ratings yet

- Transistor Inverter: You Thought They Were All The SameDocument2 pagesTransistor Inverter: You Thought They Were All The SameMaitry ShahNo ratings yet

- Lut400 Quick Start Guide PDFDocument422 pagesLut400 Quick Start Guide PDFJoni MoonNo ratings yet

- Pre-Installation FOM2 English Ver3Document19 pagesPre-Installation FOM2 English Ver3bouchaib elfatiniNo ratings yet

- Encoders Catalog 2012Document28 pagesEncoders Catalog 2012sreelakshmisnr100% (1)

- FW Jetfoil Fan BrochureDocument9 pagesFW Jetfoil Fan BrochuremajortayNo ratings yet

- B800-1 ManualEDocument35 pagesB800-1 ManualESLAMET PAMBUDINo ratings yet

- Anyhz FST 500Document114 pagesAnyhz FST 500pphau.electricNo ratings yet

- Minipurge Interface Unit (Miu/D) Manual Ml303Document40 pagesMinipurge Interface Unit (Miu/D) Manual Ml303Santiago Morales ContrerasNo ratings yet

- Bellingham + Stanley RFM300Document74 pagesBellingham + Stanley RFM300Dao Quang AiNo ratings yet

- AFE Group JM Aerofoil Bifurcated PDFDocument6 pagesAFE Group JM Aerofoil Bifurcated PDFjacleeNo ratings yet

- Mitsubishi F700 VFD BrochureDocument8 pagesMitsubishi F700 VFD BrochureMROstop.comNo ratings yet

- 1SXU150093L0201Document2 pages1SXU150093L0201KO PhyoNo ratings yet

- Service Manual: Data ProjectorDocument113 pagesService Manual: Data Projectorafranio batistaNo ratings yet

- Inverter FR-A800 Installation GuidelineDocument82 pagesInverter FR-A800 Installation Guidelineprsking187No ratings yet

- Champ FMV NR Floodlights 6L: Industry Best For Ease of InstallationDocument4 pagesChamp FMV NR Floodlights 6L: Industry Best For Ease of InstallationMartin MartinezNo ratings yet

- Axial-Fan Transformers enDocument36 pagesAxial-Fan Transformers enEko SusantoNo ratings yet

- Axial Fan 7028 PDFDocument9 pagesAxial Fan 7028 PDFHuyNo ratings yet

- N300p ManualDocument155 pagesN300p Manualشركة مصاعد الزيدي Alzaedy elevators co.No ratings yet

- Rittal Roof-Mounted Fans - Efficiency On TopDocument14 pagesRittal Roof-Mounted Fans - Efficiency On TopKaushal SawantNo ratings yet

- Robust Electric Fan Heaters For Difficult EnvironmentsDocument6 pagesRobust Electric Fan Heaters For Difficult EnvironmentsDana LoreNo ratings yet

- Champ FMV NR HID FloodlightsDocument4 pagesChamp FMV NR HID Floodlightsyasararafat1No ratings yet

- m3814 OmegaDocument8 pagesm3814 OmegaNelson GodoyNo ratings yet

- Lse-Lfse IommDocument32 pagesLse-Lfse Iommgenas7265No ratings yet

- Watlow Cartridge HeatersDocument49 pagesWatlow Cartridge HeatersEliasNo ratings yet

- Pocket Guide For Firestopping Inspection ManualDocument12 pagesPocket Guide For Firestopping Inspection Manualodemircioglu2No ratings yet

- Shimadzu UV-1700 Users GuideDocument115 pagesShimadzu UV-1700 Users Guideminhhoan2006100% (1)

- FBL4000 Pro&5000 ProUser Manual PDFDocument16 pagesFBL4000 Pro&5000 ProUser Manual PDFahmad khanNo ratings yet

- Jetfoil - Tunnel FansDocument16 pagesJetfoil - Tunnel FansCallGRNo ratings yet

- Bien Tan Fr-d700 CatalogDocument33 pagesBien Tan Fr-d700 CatalogNguyen DinhNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- New Registration Forms 2024Document7 pagesNew Registration Forms 2024Conroy LawrenceNo ratings yet

- PRBOI AE TC3001 680 148 05A Ex 3001 UserDocument1 pagePRBOI AE TC3001 680 148 05A Ex 3001 UserConroy LawrenceNo ratings yet

- Firepro Technical Manual FPC 1 Fire DeteDocument7 pagesFirepro Technical Manual FPC 1 Fire DeteConroy LawrenceNo ratings yet

- Psira 2001451Document43 pagesPsira 2001451Conroy LawrenceNo ratings yet

- SIGMA Wide - Quick Installation Guide (293732930-G)Document2 pagesSIGMA Wide - Quick Installation Guide (293732930-G)Conroy LawrenceNo ratings yet

- Market Segmentation - Research Proposal - Chapter 1 To 3Document35 pagesMarket Segmentation - Research Proposal - Chapter 1 To 3Seradallab Ch RishNo ratings yet

- A Working Party Report On The Use of Corrosion Inhibitors in Oil and Gas Production (EFC39)Document20 pagesA Working Party Report On The Use of Corrosion Inhibitors in Oil and Gas Production (EFC39)Bambang WicaksonoNo ratings yet

- Risk Assessment & Method StatementsDocument1 pageRisk Assessment & Method StatementsAgnes BNo ratings yet

- Annual Accounts 2018Document162 pagesAnnual Accounts 2018Basit RazaNo ratings yet

- Functional Safety and IEC 61508 A Basic Guide PDFDocument9 pagesFunctional Safety and IEC 61508 A Basic Guide PDFfitasmounirNo ratings yet

- Bank LendingDocument14 pagesBank LendingNadia VirkNo ratings yet

- Cases and Readings in Corporate FinanceDocument9 pagesCases and Readings in Corporate FinanceAbdillah FaizNo ratings yet

- Accident Incident Report ProcedureDocument15 pagesAccident Incident Report ProcedureMouctar GUINDONo ratings yet

- WCPTDocument46 pagesWCPTVadivelan KanniappanNo ratings yet

- FULLTEXT01Document25 pagesFULLTEXT01KejstoNo ratings yet

- Health, Environment and Climate Change: Report by The Director-GeneralDocument7 pagesHealth, Environment and Climate Change: Report by The Director-GeneralBoni MagtibayNo ratings yet

- ARELLANO - SEISMIC VULNERABILITY ASSESSMENT OF BUILDINGS AMONG BPSU CAMPUSES IN BATAAN USING RVS METHOD 1 AutosavedDocument18 pagesARELLANO - SEISMIC VULNERABILITY ASSESSMENT OF BUILDINGS AMONG BPSU CAMPUSES IN BATAAN USING RVS METHOD 1 AutosavedRhea BasilioNo ratings yet

- Avila Energy: Established and DiversifiedDocument23 pagesAvila Energy: Established and DiversifiedJames HudsonNo ratings yet

- Co-Benefits of Mitigation - FINAL Report v8-1 PDFDocument112 pagesCo-Benefits of Mitigation - FINAL Report v8-1 PDFNebojsa RedzicNo ratings yet

- Risk Analysis-Production Dept ISODocument4 pagesRisk Analysis-Production Dept ISODevashrigodboleNo ratings yet

- BFMDocument28 pagesBFMPratik RambhiaNo ratings yet

- ISS-ABRA-TECH-04 R1 - DG - Preventive Maintenance (Monthly)Document7 pagesISS-ABRA-TECH-04 R1 - DG - Preventive Maintenance (Monthly)Varun GuptaNo ratings yet

- Pro Active ManagementDocument54 pagesPro Active ManagementPaul TorresNo ratings yet

- 2.17 - Hazard Identification Form - Footwear (Foot Protection)Document2 pages2.17 - Hazard Identification Form - Footwear (Foot Protection)Sn AhsanNo ratings yet

- GSM SAS Standard v3 3Document28 pagesGSM SAS Standard v3 3Shamsul Abdul RahmanNo ratings yet

- Nebosh Model Q & ADocument7 pagesNebosh Model Q & AmurugaNo ratings yet

- FMSA 69970 Aspect-Impact EnvironmentDocument11 pagesFMSA 69970 Aspect-Impact EnvironmentAhmad Assad mredn0% (1)

- Bsbrsk501b Task 2Document6 pagesBsbrsk501b Task 2manroop100% (6)

- Microbiological Risk Assessment - Quality Assurance & Food SafetyDocument7 pagesMicrobiological Risk Assessment - Quality Assurance & Food SafetyAnnaNo ratings yet

- Igc Learner Guide v3Document14 pagesIgc Learner Guide v3ammadNo ratings yet

- Failure Mode and Effects Analysis: IFX QM-ToolDocument66 pagesFailure Mode and Effects Analysis: IFX QM-ToolYusranNo ratings yet

- MELC HE Cookery G7-8Document2 pagesMELC HE Cookery G7-8Edilbert Bonifacio Gayo0% (1)