Professional Documents

Culture Documents

Report RT 17 Februari 24 KRS Mta (Tahura)

Report RT 17 Februari 24 KRS Mta (Tahura)

Uploaded by

wahyudi140417Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Report RT 17 Februari 24 KRS Mta (Tahura)

Report RT 17 Februari 24 KRS Mta (Tahura)

Uploaded by

wahyudi140417Copyright:

Available Formats

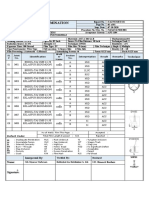

RADIOGRAPHIC EXAMINATION REPORT

USER : PT. PERTAMINA Radiation Source : Ir. 192 SFD OD Report No. : /MTA/KRS/RT/24

Work Order Curies 30 Ci Density : 2-4 Sheet No.

Cost Centre Focal Spot : 3 x 3 mm Penetrameter : ASTM 1B Date of Insp' : 17 FEBRUARI 2024

Job Location MTA SHOP KRS Kvp :- Sensitivity : 2%

IPAS No. mA :- Screen - Front : 0.125 mm

Drawing No. S/N of Camera : D.222040 Screen - Back : 0.125 mm

Procedure No. : PO /AE.MIG-OPS/29.1 S/N Survey Meter : 113334 Technique : DWSI

Acceptance Criteria : API 1104 Expire Date : 21 Agustus 2024 Material : Carbon Steel

Material Film Size RESULT

Weld WELD INDICATION

Welder Film 4" x 10 4" x 15"

No. IDENTIFICATION No.or REMARKS

Stamp Dia Thick. Position 14" x 17" ACC REPAIR

Part No. Por CP WH HB IC BT ISI ESI TI IF IP EP UC CR

1 SPOOL MINIMANIFOLD 1 SW 12 K 4" S 80 0-5 1 ACC

TAHURA 4 & 7 5 - 10 1 ACC

10 - 0 1 ACC

2 SW 16 K 4" S 80 0-5 1 ACC

5 - 10 1 ACC

10 - 0 1 ACC

INTERPRETER AUTHORIZED INSPECTOR

LEGEND Total Weld 2 Jts

- Por : Porosity - ESI : Elongated Slag Inclusion Total Accepted 2 Jts

- CP : Cluster Porosity - TI : Tungsten Inclusion Total Repair Jts

- WH : Worm Hole - IF : Incomplete Fusion Total Film 4" x 10" 6 Shts Kaco hartono Wahyudi

- HB : Hollow Bead - IP : Incomplete Penetration 4" x 15" Shts REVIEWED CLIENT REPRESENTATIVE

- IC : Internal Concavity - EP : Excessive Penetration 14" x 17" Shts

- BT : Burn Through - UC : Undercut PERSONNELS

- ISI : Isolated Slag Inclusion - CR : Crack Rad. Insp. LVL. II (AR) Kaco hartono

Rad. Oprt. LVL. I (OR) Khaerul .z Hadi S Frans E Ginting

FOR/SMR-AE.MIG/009 Rev.00 Tgl. Berlaku : 01/08/2019 Hal . 1 dari 1

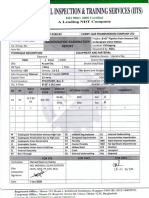

RADIOGRAPHIC EXAMINATION REPORT

USER : PT. PERTAMINA Radiation Source : Ir. 192 SFD OD Report No. : /MTA/KRS/RT/24

Work Order Curies 30 Ci Density : 2-4 Sheet No.

Cost Centre Focal Spot : 3 x 3 mm Penetrameter : ASTM 1B Date of Insp' : 17 FEBRUARI 2024

Job Location MTA SHOP KRS Kvp :- Sensitivity : 2%

IPAS No. mA :- Screen - Front : 0.125 mm

Drawing No. S/N of Camera : D.222040 Screen - Back : 0.125 mm

Procedure No. : PO /AE.MIG-OPS/29.1 S/N Survey Meter : 113334 Technique : DWSI

Acceptance Criteria : API 1104 Expire Date : 21 Agustus 2024 Material : Carbon Steel

Material Film Size RESULT

Weld WELD INDICATION

Welder Film 4" x 10 4" x 15"

No. IDENTIFICATION No.or REMARKS

Stamp Dia Thick. Position 14" x 17" ACC REPAIR

Part No. Por CP WH HB IC BT ISI ESI TI IF IP EP UC CR

1 SPOOL MINIMANIFOLD 2 SW 1 K 6" S 80 0-7 1 ACC

TAHURA 4 & 7 7 - 14 1 ACC

14 - 0 1 ACC

2 SW 6 K 6" S 80 0-7 1 ACC

7 - 14 1 ACC

14 - 0 1 ACC

3 SW 10 K 6" S 80 0-7 1 ACC

7 - 14 1 ACC

14 - 0 1 ACC

INTERPRETER AUTHORIZED INSPECTOR

LEGEND Total Weld 3 Jts

- Por : Porosity - ESI : Elongated Slag Inclusion Total Accepted 3 Jts

- CP : Cluster Porosity - TI : Tungsten Inclusion Total Repair Jts

- WH : Worm Hole - IF : Incomplete Fusion Total Film 4" x 10" 9 Shts Kaco hartono Wahyudi

- HB : Hollow Bead - IP : Incomplete Penetration 4" x 15" Shts REVIEWED CLIENT REPRESENTATIVE

- IC : Internal Concavity - EP : Excessive Penetration 14" x 17" Shts

- BT : Burn Through - UC : Undercut PERSONNELS

- ISI : Isolated Slag Inclusion - CR : Crack Rad. Insp. LVL. II (AR) Kaco hartono

Rad. Oprt. LVL. I (OR) Khaerul .z Hadi S Frans E Ginting

FOR/SMR-AE.MIG/009 Rev.00 Tgl. Berlaku : 01/08/2019 Hal . 1 dari 1

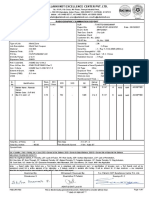

RADIOGRAPHIC EXAMINATION REPORT

USER : PT. PERTAMINA Radiation Source : Ir. 192 SFD OD Report No. : /MTA/KRS/RT/24

Work Order Curies 30 Ci Density : 2-4 Sheet No.

Cost Centre Focal Spot : 3 x 3 mm Penetrameter : ASTM 1B Date of Insp' : 17 FEBRUARI 2024

Job Location MTA SHOP KRS Kvp :- Sensitivity : 2%

IPAS No. mA :- Screen - Front : 0.125 mm

Drawing No. S/N of Camera : D.222040 Screen - Back : 0.125 mm

Procedure No. : PO /AE.MIG-OPS/29.1 S/N Survey Meter : 113334 Technique : DWSI

Acceptance Criteria : API 1104 Expire Date : 21 Agustus 2024 Material : Carbon Steel

Material Film Size RESULT

Weld WELD INDICATION

Welder Film 4" x 10 4" x 15"

No. IDENTIFICATION No.or REMARKS

Stamp Dia Thick. Position 14" x 17" ACC REPAIR

Part No. Por CP WH HB IC BT ISI ESI TI IF IP EP UC CR

1 SPOOL MINIMANIFOLD 1 SW 17 K 6" S 80 0-7 1 ACC

TAHURA 4 & 7 7 - 14 1 ACC

14 - 0 1 ACC

INTERPRETER AUTHORIZED INSPECTOR

LEGEND Total Weld 1 Jts

- Por : Porosity - ESI : Elongated Slag Inclusion Total Accepted 1 Jts

- CP : Cluster Porosity - TI : Tungsten Inclusion Total Repair Jts

- WH : Worm Hole - IF : Incomplete Fusion Total Film 4" x 10" 3 Shts Kaco hartono Wahyudi

- HB : Hollow Bead - IP : Incomplete Penetration 4" x 15" Shts REVIEWED CLIENT REPRESENTATIVE

- IC : Internal Concavity - EP : Excessive Penetration 14" x 17" Shts

- BT : Burn Through - UC : Undercut PERSONNELS

- ISI : Isolated Slag Inclusion - CR : Crack Rad. Insp. LVL. II (AR) Kaco hartono

Rad. Oprt. LVL. I (OR) Khaerul .z Hadi S Frans E Ginting

FOR/SMR-AE.MIG/009 Rev.00 Tgl. Berlaku : 01/08/2019 Hal . 1 dari 1

RADIOGRAPHIC EXAMINATION REPORT

USER : PT. PERTAMINA Radiation Source : Ir. 192 SFD OD Report No. : /MTA/KRS/RT/24

Work Order Curies 30 Ci Density : 2-4 Sheet No.

Cost Centre Focal Spot : 3 x 3 mm Penetrameter : ASTM 1B Date of Insp' : 17 FEBRUARI 2024

Job Location MTA SHOP KRS Kvp :- Sensitivity : 2%

IPAS No. mA :- Screen - Front : 0.125 mm

Drawing No. S/N of Camera : D.222040 Screen - Back : 0.125 mm

Procedure No. : PO /AE.MIG-OPS/29.1 S/N Survey Meter : 113334 Technique : DWSI

Acceptance Criteria : API 1104 Expire Date : 21 Agustus 2024 Material : Carbon Steel

Material Film Size RESULT

Weld WELD INDICATION

Welder Film 4" x 10 4" x 15"

No. IDENTIFICATION No.or REMARKS

Stamp Dia Thick. Position 14" x 17" ACC REPAIR

Part No. Por CP WH HB IC BT ISI ESI TI IF IP EP UC CR

1 SPOOL MINIMANIFOLD 1 SW 1 K 6" S 80 0-7 1 V ACC

TAHURA 4 & 7 7 - 14 1 ACC

14 - 0 1 ACC

2 SW 2 K 6" S 80 0-7 1 ACC

7 - 14 1 ACC

14 - 0 1 ACC

3 SW 6 K 6" S 80 0-7 1 ACC

7 - 14 1 ACC

14 - 0 1 ACC

4 SW 13 K 6" S 80 0-7 1 ACC

7 - 14 1 ACC

14 - 0 1 ACC

INTERPRETER AUTHORIZED INSPECTOR

LEGEND Total Weld 4 Jts

- Por : Porosity - ESI : Elongated Slag Inclusion Total Accepted 4 Jts

- CP : Cluster Porosity - TI : Tungsten Inclusion Total Repair Jts

- WH : Worm Hole - IF : Incomplete Fusion Total Film 4" x 10" 12 Shts Kaco hartono Wahyudi

- HB : Hollow Bead - IP : Incomplete Penetration 4" x 15" Shts REVIEWED CLIENT REPRESENTATIVE

- IC : Internal Concavity - EP : Excessive Penetration 14" x 17" Shts

- BT : Burn Through - UC : Undercut PERSONNELS

- ISI : Isolated Slag Inclusion - CR : Crack Rad. Insp. LVL. II (AR) Kaco hartono

Rad. Oprt. LVL. I (OR) Khaerul .z Hadi S Frans E Ginting

FOR/SMR-AE.MIG/009 Rev.00 Tgl. Berlaku : 01/08/2019 Hal . 1 dari 1

RADIOGRAPHIC EXAMINATION REPORT

USER : PT. PERTAMINA Radiation Source : Ir. 192 SFD OD Report No. : /MTA/KRS/RT/24

Work Order Curies 30 Ci Density : 2-4 Sheet No.

Cost Centre Focal Spot : 3 x 3 mm Penetrameter : ASTM 1B Date of Insp' : 17 FEBRUARI 2024

Job Location MTA Kvp :- Sensitivity : 2%

IPAS No. mA :- Screen - Front : 0.125 mm

Drawing No. S/N of Camera : D.222040 Screen - Back : 0.125 mm

Procedure No. : PO /AE.MIG-OPS/29.1 S/N Survey Meter : 113334 Technique : DWSI

Acceptance Criteria : API 1104 Expire Date : 21 Agustus 2024 Material : Carbon Steel

Material Film Size RESULT

Weld WELD INDICATION

Welder Film 4" x 10 4" x 15"

No. IDENTIFICATION No.or REMARKS

Stamp Dia Thick. Position 14" x 17" ACC REPAIR

Part No. Por CP WH HB IC BT ISI ESI TI IF IP EP UC CR

1 F / L MTA TAHURA 4 FW 7 K 6" S 80 0-7 1 ACC

UG 1 LOWER 7 - 14 1 ACC

14 - 0 1 ACC

2 FW 11 K 6" S 80 0-7 1 ACC

7 - 14 1 ACC

14 - 0 1 ACC

3 FW 12 K 6" S 80 0-7 1 ACC

7 - 14 1 ACC

14 - 0 1 ACC

4 FW 2 K 6" S 80 0-7 1 V ACC

SPOOL TEMPORARY 7 - 14 1 ACC

14 - 0 1 ACC

INTERPRETER AUTHORIZED INSPECTOR

LEGEND Total Weld 4 Jts

- Por : Porosity - ESI : Elongated Slag Inclusion Total Accepted 4 Jts

- CP : Cluster Porosity - TI : Tungsten Inclusion Total Repair Jts

- WH : Worm Hole - IF : Incomplete Fusion Total Film 4" x 10" 12 Shts Kaco hartono Wahyudi

- HB : Hollow Bead - IP : Incomplete Penetration 4" x 15" Shts REVIEWED CLIENT REPRESENTATIVE

- IC : Internal Concavity - EP : Excessive Penetration 14" x 17" Shts

- BT : Burn Through - UC : Undercut PERSONNELS

- ISI : Isolated Slag Inclusion - CR : Crack Rad. Insp. LVL. II (AR) Kaco hartono

Rad. Oprt. LVL. I (OR) Khaerul .z Hadi S Frans E Ginting

FOR/SMR-AE.MIG/009 Rev.00 Tgl. Berlaku : 01/08/2019 Hal . 1 dari 1

RADIOGRAPHIC EXAMINATION REPORT

USER : PT. PERTAMINA Radiation Source : Ir. 192 SFD OD Report No. : /MTA/KRS/RT/24

Work Order Curies 30 Ci Density : 2-4 Sheet No.

Cost Centre Focal Spot : 3 x 3 mm Penetrameter : ASTM 1B Date of Insp' : 17 FEBRUARI 2024

Job Location MTA Kvp :- Sensitivity : 2%

IPAS No. mA :- Screen - Front : 0.125 mm

Drawing No. S/N of Camera : D.222040 Screen - Back : 0.125 mm

Procedure No. : PO /AE.MIG-OPS/29.1 S/N Survey Meter : 113334 Technique : DWSI

Acceptance Criteria : API 1104 Expire Date : 21 Agustus 2024 Material : Carbon Steel

Material Film Size RESULT

Weld WELD INDICATION

Welder Film 4" x 10 4" x 15"

No. IDENTIFICATION No.or REMARKS

Stamp Dia Thick. Position 14" x 17" ACC REPAIR

Part No. Por CP WH HB IC BT ISI ESI TI IF IP EP UC CR

1 F / L MTA TAHURA 4 FW 8 K 6" S 80 0-7 1 ACC

UG 1 UPPER 7 - 14 1 ACC

14 - 0 1 ACC

2 FW 9 K 6" S 80 0-7 1 ACC

7 - 14 1 ACC

14 - 0 1 ACC

INTERPRETER AUTHORIZED INSPECTOR

LEGEND Total Weld 2 Jts

- Por : Porosity - ESI : Elongated Slag Inclusion Total Accepted 2 Jts

- CP : Cluster Porosity - TI : Tungsten Inclusion Total Repair Jts

- WH : Worm Hole - IF : Incomplete Fusion Total Film 4" x 10" 6 Shts Kaco hartono Wahyudi

- HB : Hollow Bead - IP : Incomplete Penetration 4" x 15" Shts REVIEWED CLIENT REPRESENTATIVE

- IC : Internal Concavity - EP : Excessive Penetration 14" x 17" Shts

- BT : Burn Through - UC : Undercut PERSONNELS

- ISI : Isolated Slag Inclusion - CR : Crack Rad. Insp. LVL. II (AR) Kaco hartono

Rad. Oprt. LVL. I (OR) Khaerul .z Hadi S Frans E Ginting

FOR/SMR-AE.MIG/009 Rev.00 Tgl. Berlaku : 01/08/2019 Hal . 1 dari 1

RADIOGRAPHIC EXAMINATION REPORT

USER : PT. PERTAMINA Radiation Source : Ir. 192 SFD OD Report No. : /MTA/KRS/RT/24

Work Order Curies 30 Ci Density : 2-4 Sheet No.

Cost Centre Focal Spot : 3 x 3 mm Penetrameter : ASTM 1B Date of Insp' : 17 FEBRUARI 2024

Job Location MTA Kvp :- Sensitivity : 2%

IPAS No. mA :- Screen - Front : 0.125 mm

Drawing No. S/N of Camera : D.222040 Screen - Back : 0.125 mm

Procedure No. : PO /AE.MIG-OPS/29.1 S/N Survey Meter : 113334 Technique : DWSI

Acceptance Criteria : API 1104 Expire Date : 21 Agustus 2024 Material : Carbon Steel

Material Film Size RESULT

Weld WELD INDICATION

Welder Film 4" x 10 4" x 15"

No. IDENTIFICATION No.or REMARKS

Stamp Dia Thick. Position 14" x 17" ACC REPAIR

Part No. Por CP WH HB IC BT ISI ESI TI IF IP EP UC CR

1 F / L MTA TAHURA 7 FW 14 K 6" S 80 0-7 1 ACC

UG 1 LOWER 7 - 14 1 ACC

14 - 0 1 ACC

2 FW 2 K 6" S 80 0-7 1 ACC

SPOOL TEMORARY 7 - 14 1 ACC

14 - 0 1 ACC

INTERPRETER AUTHORIZED INSPECTOR

LEGEND Total Weld 2 Jts

- Por : Porosity - ESI : Elongated Slag Inclusion Total Accepted 2 Jts

- CP : Cluster Porosity - TI : Tungsten Inclusion Total Repair Jts

- WH : Worm Hole - IF : Incomplete Fusion Total Film 4" x 10" 6 Shts Kaco hartono Wahyudi

- HB : Hollow Bead - IP : Incomplete Penetration 4" x 15" Shts REVIEWED CLIENT REPRESENTATIVE

- IC : Internal Concavity - EP : Excessive Penetration 14" x 17" Shts

- BT : Burn Through - UC : Undercut PERSONNELS

- ISI : Isolated Slag Inclusion - CR : Crack Rad. Insp. LVL. II (AR) Kaco hartono

Rad. Oprt. LVL. I (OR) Khaerul .z Hadi S Frans E Ginting

FOR/SMR-AE.MIG/009 Rev.00 Tgl. Berlaku : 01/08/2019 Hal . 1 dari 1

RADIOGRAPHIC EXAMINATION REPORT

USER : PT. PERTAMINA Radiation Source : Ir. 192 SFD OD Report No. : /MTA/KRS/RT/24

Work Order Curies 30 Ci Density : 2-4 Sheet No.

Cost Centre Focal Spot : 3 x 3 mm Penetrameter : ASTM 1B Date of Insp' : 17 FEBRUARI 2024

Job Location MTA Kvp :- Sensitivity : 2%

IPAS No. mA :- Screen - Front : 0.125 mm

Drawing No. S/N of Camera : D.222040 Screen - Back : 0.125 mm

Procedure No. : PO /AE.MIG-OPS/29.1 S/N Survey Meter : 113334 Technique : DWSI

Acceptance Criteria : API 1104 Expire Date : 21 Agustus 2024 Material : Carbon Steel

Material Film Size RESULT

Weld WELD INDICATION

Welder Film 4" x 10 4" x 15"

No. IDENTIFICATION No.or REMARKS

Stamp Dia Thick. Position 14" x 17" ACC REPAIR

Part No. Por CP WH HB IC BT ISI ESI TI IF IP EP UC CR

1 F / L MTA TAHURA 7 FW 7 K 6" S 80 0-7 1 ACC

UG 1 LOWER 7 - 14 1 ACC

14 - 0 1 ACC

2 FW 10 K 6" S 80 0-7 1 ACC

7 - 14 1 ACC

14 - 0 1 ACC

3 FW 12 K 6" S 80 0-7 1 ACC

7 - 14 1 ACC

14 - 0 1 ACC

4 FW 13 K 6" S 80 0-7 1 ACC

7 - 14 1 ACC

14 - 0 1 V ACC

INTERPRETER AUTHORIZED INSPECTOR

LEGEND Total Weld 4 Jts

- Por : Porosity - ESI : Elongated Slag Inclusion Total Accepted 4 Jts

- CP : Cluster Porosity - TI : Tungsten Inclusion Total Repair Jts

- WH : Worm Hole - IF : Incomplete Fusion Total Film 4" x 10" 12 Shts Kaco hartono Wahyudi

- HB : Hollow Bead - IP : Incomplete Penetration 4" x 15" Shts REVIEWED CLIENT REPRESENTATIVE

- IC : Internal Concavity - EP : Excessive Penetration 14" x 17" Shts

- BT : Burn Through - UC : Undercut PERSONNELS

- ISI : Isolated Slag Inclusion - CR : Crack Rad. Insp. LVL. II (AR) Kaco hartono

Rad. Oprt. LVL. I (OR) Khaerul .z Hadi S Frans E Ginting

FOR/SMR-AE.MIG/009 Rev.00 Tgl. Berlaku : 01/08/2019 Hal . 1 dari 1

RADIOGRAPHIC EXAMINATION REPORT

USER : PT. PERTAMINA Radiation Source : Ir. 192 SFD OD Report No. : /MTA/KRS/RT/24

Work Order Curies 30 Ci Density : 2-4 Sheet No.

Cost Centre Focal Spot : 3 x 3 mm Penetrameter : ASTM 1B Date of Insp' : 17 FEBRUARI 2024

Job Location MTA Kvp :- Sensitivity : 2%

IPAS No. mA :- Screen - Front : 0.125 mm

Drawing No. S/N of Camera : D.222040 Screen - Back : 0.125 mm

Procedure No. : PO /AE.MIG-OPS/29.1 S/N Survey Meter : 113334 Technique : DWSI

Acceptance Criteria : API 1104 Expire Date : 21 Agustus 2024 Material : Carbon Steel

Material Film Size RESULT

Weld WELD INDICATION

Welder Film 4" x 10 4" x 15"

No. IDENTIFICATION No.or REMARKS

Stamp Dia Thick. Position 14" x 17" ACC REPAIR

Part No. Por CP WH HB IC BT ISI ESI TI IF IP EP UC CR

1 F / L MTA TAHURA 7 FW 7 K 6" S 80 0-7 1 ACC

UG 1 UPPER 7 - 14 1 ACC

14 - 0 1 V ACC

2 FW 9 K 6" S 80 0-7 1 ACC

7 - 14 1 ACC

14 - 0 1 ACC

3 FW 10 K 6" S 80 0-7 1 ACC

7 - 14 1 ACC

14 - 0 1 ACC

4 FW 11 K 6" S 80 0-7 1 ACC

7 - 14 1 ACC

14 - 0 1 ACC

INTERPRETER AUTHORIZED INSPECTOR

LEGEND Total Weld 4 Jts

- Por : Porosity - ESI : Elongated Slag Inclusion Total Accepted 4 Jts

- CP : Cluster Porosity - TI : Tungsten Inclusion Total Repair Jts

- WH : Worm Hole - IF : Incomplete Fusion Total Film 4" x 10" 12 Shts Kaco hartono Wahyudi

- HB : Hollow Bead - IP : Incomplete Penetration 4" x 15" Shts REVIEWED CLIENT REPRESENTATIVE

- IC : Internal Concavity - EP : Excessive Penetration 14" x 17" Shts

- BT : Burn Through - UC : Undercut PERSONNELS

- ISI : Isolated Slag Inclusion - CR : Crack Rad. Insp. LVL. II (AR) Kaco hartono

Rad. Oprt. LVL. I (OR) Khaerul .z Hadi S Frans E Ginting

FOR/SMR-AE.MIG/009 Rev.00 Tgl. Berlaku : 01/08/2019 Hal . 1 dari 1

RADIOGRAPHIC EXAMINATION REPORT

USER : PT. PERTAMINA Radiation Source : Ir. 192 SFD OD Report No. : /MTA/KRS/RT/24

Work Order Curies 30 Ci Density : 2-4 Sheet No.

Cost Centre Focal Spot : 3 x 3 mm Penetrameter : ASTM 1B Date of Insp' : 17 FEBRUARI 2024

Job Location MTA Kvp :- Sensitivity : 2%

IPAS No. mA :- Screen - Front : 0.125 mm

Drawing No. S/N of Camera : D.222040 Screen - Back : 0.125 mm

Procedure No. : PO /AE.MIG-OPS/29.1 S/N Survey Meter : 113334 Technique : DWSI

Acceptance Criteria : API 1104 Expire Date : 21 Agustus 2024 Material : Carbon Steel

Material Film Size RESULT

Weld WELD INDICATION

Welder Film 4" x 10 4" x 15"

No. IDENTIFICATION No.or REMARKS

Stamp Dia Thick. Position 14" x 17" ACC REPAIR

Part No. Por CP WH HB IC BT ISI ESI TI IF IP EP UC CR

1 F / L MTA TAHURA 4 FW 3 K 4" S 80 0-5 1 ACC

RDX 1 UPPER 5 - 10 1 ACC

10 - 0 1 ACC

2 FW 5 K 4" S 80 0-5 1 ACC

5 - 10 1 ACC

10 - 0 1 ACC

3 FW 6 K 4" S 80 0-5 1 ACC

5 - 10 1 ACC

10 - 0 1 ACC

4 FW 8 K 4" S 80 0-5 1 ACC

5 - 10 1 ACC

10 - 0 1 ACC

INTERPRETER AUTHORIZED INSPECTOR

LEGEND Total Weld 4 Jts

- Por : Porosity - ESI : Elongated Slag Inclusion Total Accepted 4 Jts

- CP : Cluster Porosity - TI : Tungsten Inclusion Total Repair Jts

- WH : Worm Hole - IF : Incomplete Fusion Total Film 4" x 10" 12 Shts Kaco hartono Wahyudi

- HB : Hollow Bead - IP : Incomplete Penetration 4" x 15" Shts REVIEWED CLIENT REPRESENTATIVE

- IC : Internal Concavity - EP : Excessive Penetration 14" x 17" Shts

- BT : Burn Through - UC : Undercut PERSONNELS

- ISI : Isolated Slag Inclusion - CR : Crack Rad. Insp. LVL. II (AR) Kaco hartono

Rad. Oprt. LVL. I (OR) Khaerul .z Hadi S Frans E Ginting

FOR/SMR-AE.MIG/009 Rev.00 Tgl. Berlaku : 01/08/2019 Hal . 1 dari 1

RADIOGRAPHIC EXAMINATION REPORT

USER : PT. PERTAMINA Radiation Source : Ir. 192 SFD OD Report No. : /MTA/KRS/RT/24

Work Order Curies 30 Ci Density : 2-4 Sheet No.

Cost Centre Focal Spot : 3 x 3 mm Penetrameter : ASTM 1B Date of Insp' : 17 FEBRUARI 2024

Job Location MTA Kvp :- Sensitivity : 2%

IPAS No. mA :- Screen - Front : 0.125 mm

Drawing No. S/N of Camera : D.222040 Screen - Back : 0.125 mm

Procedure No. : PO /AE.MIG-OPS/29.1 S/N Survey Meter : 113334 Technique : DWSI

Acceptance Criteria : API 1104 Expire Date : 21 Agustus 2024 Material : Carbon Steel

Material Film Size RESULT

Weld WELD INDICATION

Welder Film 4" x 10 4" x 15"

No. IDENTIFICATION No.or REMARKS

Stamp Dia Thick. Position 14" x 17" ACC REPAIR

Part No. Por CP WH HB IC BT ISI ESI TI IF IP EP UC CR

1 F / L MTA TAHURA 4 FW 3 K 4" S 80 0-5 1 ACC

RDX 1 LOWER 5 - 10 1 ACC

10 - 0 1 ACC

2 FW 5 K 4" S 80 0-5 1 ACC

5 - 10 1 ACC

10 - 0 1 V ACC

3 FW 6 K 4" S 80 0-5 1 ACC

5 - 10 1 ACC

10 - 0 1 ACC

4 FW 8 K 4" S 80 0-5 1 ACC

5 - 10 1 ACC

10 - 0 1 ACC

INTERPRETER AUTHORIZED INSPECTOR

LEGEND Total Weld 4 Jts

- Por : Porosity - ESI : Elongated Slag Inclusion Total Accepted 4 Jts

- CP : Cluster Porosity - TI : Tungsten Inclusion Total Repair Jts

- WH : Worm Hole - IF : Incomplete Fusion Total Film 4" x 10" 12 Shts Kaco hartono Wahyudi

- HB : Hollow Bead - IP : Incomplete Penetration 4" x 15" Shts REVIEWED CLIENT REPRESENTATIVE

- IC : Internal Concavity - EP : Excessive Penetration 14" x 17" Shts

- BT : Burn Through - UC : Undercut PERSONNELS

- ISI : Isolated Slag Inclusion - CR : Crack Rad. Insp. LVL. II (AR) Kaco hartono

Rad. Oprt. LVL. I (OR) Khaerul .z Hadi S Frans E Ginting

FOR/SMR-AE.MIG/009 Rev.00 Tgl. Berlaku : 01/08/2019 Hal . 1 dari 1

RADIOGRAPHIC EXAMINATION REPORT

USER : PT. PERTAMINA Radiation Source : Ir. 192 SFD OD Report No. : /MTA/KRS/RT/24

Work Order Curies 30 Ci Density : 2-4 Sheet No.

Cost Centre Focal Spot : 3 x 3 mm Penetrameter : ASTM 1B Date of Insp' : 17 FEBRUARI 2024

Job Location MTA Kvp :- Sensitivity : 2%

IPAS No. mA :- Screen - Front : 0.125 mm

Drawing No. S/N of Camera : D.222040 Screen - Back : 0.125 mm

Procedure No. : PO /AE.MIG-OPS/29.1 S/N Survey Meter : 113334 Technique : DWSI

Acceptance Criteria : API 1104 Expire Date : 21 Agustus 2024 Material : Carbon Steel

Material Film Size RESULT

Weld WELD INDICATION

Welder Film 4" x 10 4" x 15"

No. IDENTIFICATION No.or REMARKS

Stamp Dia Thick. Position 14" x 17" ACC REPAIR

Part No. Por CP WH HB IC BT ISI ESI TI IF IP EP UC CR

1 F / L MTA TAHURA 7 FW 3 K 4" S 80 0-5 1 ACC

RDX 1 LOWER 5 - 10 1 ACC

10 - 0 1 ACC

2 FW 5 K 4" S 80 0-5 1 ACC

5 - 10 1 ACC

10 - 0 1 ACC

3 FW 6 K 4" S 80 0-5 1 ACC

5 - 10 1 ACC

10 - 0 1 ACC

4 FW 8 K 4" S 80 0-5 1 V ACC

5 - 10 1 ACC

10 - 0 1 ACC

INTERPRETER AUTHORIZED INSPECTOR

LEGEND Total Weld 4 Jts

- Por : Porosity - ESI : Elongated Slag Inclusion Total Accepted 4 Jts

- CP : Cluster Porosity - TI : Tungsten Inclusion Total Repair Jts

- WH : Worm Hole - IF : Incomplete Fusion Total Film 4" x 10" 12 Shts Kaco hartono Wahyudi

- HB : Hollow Bead - IP : Incomplete Penetration 4" x 15" Shts REVIEWED CLIENT REPRESENTATIVE

- IC : Internal Concavity - EP : Excessive Penetration 14" x 17" Shts

- BT : Burn Through - UC : Undercut PERSONNELS

- ISI : Isolated Slag Inclusion - CR : Crack Rad. Insp. LVL. II (AR) Kaco hartono

Rad. Oprt. LVL. I (OR) Khaerul .z Hadi S Frans E Ginting

FOR/SMR-AE.MIG/009 Rev.00 Tgl. Berlaku : 01/08/2019 Hal . 1 dari 1

RADIOGRAPHIC EXAMINATION REPORT

USER : PT. PERTAMINA Radiation Source : Ir. 192 SFD OD Report No. : /MTA/KRS/RT/24

Work Order Curies 30 Ci Density : 2-4 Sheet No.

Cost Centre Focal Spot : 3 x 3 mm Penetrameter : ASTM 1B Date of Insp' : 17 FEBRUARI 2024

Job Location MTA Kvp :- Sensitivity : 2%

IPAS No. mA :- Screen - Front : 0.125 mm

Drawing No. S/N of Camera : D.222040 Screen - Back : 0.125 mm

Procedure No. : PO /AE.MIG-OPS/29.1 S/N Survey Meter : 113334 Technique : DWSI

Acceptance Criteria : API 1104 Expire Date : 21 Agustus 2024 Material : Carbon Steel

Material Film Size RESULT

Weld WELD INDICATION

Welder Film 4" x 10 4" x 15"

No. IDENTIFICATION No.or REMARKS

Stamp Dia Thick. Position 14" x 17" ACC REPAIR

Part No. Por CP WH HB IC BT ISI ESI TI IF IP EP UC CR

1 F / L MTA TAHURA 7 FW 3 K 4" S 80 0-5 1 ACC

RDX 1 UPPER 5 - 10 1 V ACC

10 - 0 1 ACC

2 FW 5 K 4" S 80 0-5 1 ACC

5 - 10 1 ACC

10 - 0 1 ACC

3 FW 6 K 4" S 80 0-5 1 ACC

5 - 10 1 ACC

10 - 0 1 ACC

4 FW 8 K 4" S 80 0-5 1 ACC

5 - 10 1 ACC

10 - 0 1 ACC

INTERPRETER AUTHORIZED INSPECTOR

LEGEND Total Weld 4 Jts

- Por : Porosity - ESI : Elongated Slag Inclusion Total Accepted 4 Jts

- CP : Cluster Porosity - TI : Tungsten Inclusion Total Repair Jts

- WH : Worm Hole - IF : Incomplete Fusion Total Film 4" x 10" 12 Shts Kaco hartono Wahyudi

- HB : Hollow Bead - IP : Incomplete Penetration 4" x 15" Shts REVIEWED CLIENT REPRESENTATIVE

- IC : Internal Concavity - EP : Excessive Penetration 14" x 17" Shts

- BT : Burn Through - UC : Undercut PERSONNELS

- ISI : Isolated Slag Inclusion - CR : Crack Rad. Insp. LVL. II (AR) Kaco hartono

Rad. Oprt. LVL. I (OR) Khaerul .z Hadi S Frans E Ginting

FOR/SMR-AE.MIG/009 Rev.00 Tgl. Berlaku : 01/08/2019 Hal . 1 dari 1

You might also like

- UCSP Q1 Mod4 Becoming A Member of A SocietyDocument37 pagesUCSP Q1 Mod4 Becoming A Member of A SocietyPot Alo71% (7)

- A Description of Homeopathic MiasmsDocument24 pagesA Description of Homeopathic Miasmstobrienmsc100% (6)

- Report RT 01 April 24 PR T UnaDocument1 pageReport RT 01 April 24 PR T Unawahyudi140417No ratings yet

- REPORT RT 03 Februari 2024 (SANGA SANGA)Document8 pagesREPORT RT 03 Februari 2024 (SANGA SANGA)wahyudi140417No ratings yet

- Invoice WPQT PTMDocument5 pagesInvoice WPQT PTMFerdie OSNo ratings yet

- Report RTDocument4 pagesReport RTwahyudi140417No ratings yet

- 22 Maret (Anggana)Document2 pages22 Maret (Anggana)wahyudi140417No ratings yet

- Report RT 08 Maret 24 Rja SambojaDocument4 pagesReport RT 08 Maret 24 Rja Sambojawahyudi140417No ratings yet

- Invoice-WPQT Welder PTMDocument5 pagesInvoice-WPQT Welder PTMFerdie OSNo ratings yet

- A3 To CPF RT Report 220224Document1 pageA3 To CPF RT Report 220224Arvind SahaniNo ratings yet

- UTG - LPG - Tank (12) (Updated)Document1 pageUTG - LPG - Tank (12) (Updated)Ali TahirNo ratings yet

- Phased Array Examination Report: Nexus Inspectorate Private LimitedDocument1 pagePhased Array Examination Report: Nexus Inspectorate Private LimitedNexus InspectorateNo ratings yet

- Valve RT Report 1Document2 pagesValve RT Report 1Shubham ShuklaNo ratings yet

- Epz NCS RT 02Document1 pageEpz NCS RT 02Mijanur RahmanNo ratings yet

- Pt. Gintam Tehnik: InspeksiDocument5 pagesPt. Gintam Tehnik: Inspeksirizky youlandaNo ratings yet

- RT Request: Hail Surface FacilitiesDocument4 pagesRT Request: Hail Surface FacilitiesAnonymous AdofXEYAgENo ratings yet

- Zppg-Aico-Sas-Rt-0698 - 21-10-2018 (Pew)Document1 pageZppg-Aico-Sas-Rt-0698 - 21-10-2018 (Pew)Ahmed ThaerNo ratings yet

- SLM360 Clamp BoltDocument1 pageSLM360 Clamp BoltTony CeNo ratings yet

- Zppg-Aico-Sas-Rt-0608 - 01-07-2018 (Pew)Document1 pageZppg-Aico-Sas-Rt-0608 - 01-07-2018 (Pew)Ahmed ThaerNo ratings yet

- JNK India Pvt. LTD.: Radiographic Examination ReportDocument337 pagesJNK India Pvt. LTD.: Radiographic Examination ReportAvishek GuptaNo ratings yet

- Material Specification: Astm A 193 Gr. B7: Ed-2021Document2 pagesMaterial Specification: Astm A 193 Gr. B7: Ed-2021Precision EngineeringNo ratings yet

- Radiographic Examination: Safik Safik Safik Safik Safik Safik Safik SafikDocument2 pagesRadiographic Examination: Safik Safik Safik Safik Safik Safik Safik SafikMijanur RahmanNo ratings yet

- Welding Visual ReportDocument1 pageWelding Visual ReportRichard AdolfNo ratings yet

- Ocs Engineering & Construction (India) PVT LTD: Quality Assurance DepartmentDocument1 pageOcs Engineering & Construction (India) PVT LTD: Quality Assurance DepartmentvinothNo ratings yet

- DS 02994Document2 pagesDS 02994Giovanni ValentinoNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Shell Kecil Osp08Document3 pagesShell Kecil Osp08Adnan FrrNo ratings yet

- Pwri All RT ReportsDocument130 pagesPwri All RT ReportsEswar ReddyNo ratings yet

- Collar Cam Chain Guide Roller PdirDocument1 pageCollar Cam Chain Guide Roller PdirPreetam KumarNo ratings yet

- Ge P643 TF PanelDocument93 pagesGe P643 TF PanelRAJESH BODDUNA100% (1)

- Doc001 PDFDocument12 pagesDoc001 PDFSoufiane KhiriNo ratings yet

- Daily Welding Record LPDocument27 pagesDaily Welding Record LProbby moneNo ratings yet

- Magnetic Particle Inspection: NDT Service - Marine Consultant - Engineering ServiceDocument4 pagesMagnetic Particle Inspection: NDT Service - Marine Consultant - Engineering ServiceSulthan HanifNo ratings yet

- WQT Parameter Recording SheetDocument13 pagesWQT Parameter Recording Sheetsonuanupam14No ratings yet

- Classe de Matériel Tuyauterie 100CP11: 6117-XH-SL-STC-2/3Document17 pagesClasse de Matériel Tuyauterie 100CP11: 6117-XH-SL-STC-2/3Guillaume de PluviéNo ratings yet

- Classe de Matériel Tuyauterie 150CP11: 6117-XH-SL-STC-2/3Document17 pagesClasse de Matériel Tuyauterie 150CP11: 6117-XH-SL-STC-2/3Guillaume de PluviéNo ratings yet

- Industriat Training (IITS) A I-Eading NF) T: Inspection CornparryDocument1 pageIndustriat Training (IITS) A I-Eading NF) T: Inspection Cornparryআশার আলোNo ratings yet

- UT PLTU BTG Turbine 1-DikonversiDocument2 pagesUT PLTU BTG Turbine 1-DikonversiWawan KurniawanNo ratings yet

- MI Plan For NDC Expected Order Date 05-06-2018 Rev 1 With VF50 - String 3Document29 pagesMI Plan For NDC Expected Order Date 05-06-2018 Rev 1 With VF50 - String 3EduardNo ratings yet

- Etce P2803 000 00Document65 pagesEtce P2803 000 00汪成文No ratings yet

- 110004774-10 170KV 630dia 1T With CK BaseDocument5 pages110004774-10 170KV 630dia 1T With CK Basetragi oyeNo ratings yet

- Industrial Training Sir//Ices A L-Eading ND:F: Inspection (Iits) CornpanyDocument1 pageIndustrial Training Sir//Ices A L-Eading ND:F: Inspection (Iits) Cornpanyআশার আলোNo ratings yet

- RT Request For Sivert Date 13-Apr-17: Hail Surface FacilitiesDocument1 pageRT Request For Sivert Date 13-Apr-17: Hail Surface FacilitiesAnonymous AdofXEYAgENo ratings yet

- RT Request-036 On 05-04-2017Document1 pageRT Request-036 On 05-04-2017Anonymous AdofXEYAgENo ratings yet

- ARKAN SHADES Welding Inspection & Paint InspectionDocument2 pagesARKAN SHADES Welding Inspection & Paint InspectionSpectex dubaiNo ratings yet

- Ut Report - 018 - Fab Tech Abudhabi LLC 19.04.2018Document2 pagesUt Report - 018 - Fab Tech Abudhabi LLC 19.04.2018ADOBEENo ratings yet

- Report-Mt 20.10.2022.M C TinhDocument7 pagesReport-Mt 20.10.2022.M C TinhNhien ManNo ratings yet

- SICIM S.p.A. Milano EPC OfficeDocument16 pagesSICIM S.p.A. Milano EPC OfficeMohamed Wasim ShaikhNo ratings yet

- 08-03-24. Water Injection Pump SambojaDocument1 page08-03-24. Water Injection Pump Sambojawahyudi140417No ratings yet

- 18-12-23. Gaslift Skid MTA M-23Document4 pages18-12-23. Gaslift Skid MTA M-23Ferdie OSNo ratings yet

- Pallakki NDT Excellence Center Pvt. LTD.: Radiographic Examination ReportDocument1 pagePallakki NDT Excellence Center Pvt. LTD.: Radiographic Examination ReportCharles JacobNo ratings yet

- Updated Standard Qap 14.07.22Document6 pagesUpdated Standard Qap 14.07.22Karna Satish KumarNo ratings yet

- Daily Drilling Fluid Report (041A) - 01 April 16-1Document1 pageDaily Drilling Fluid Report (041A) - 01 April 16-1Lenin FontanaNo ratings yet

- RT Request: Hail Surface Facilities Eps ProjectDocument4 pagesRT Request: Hail Surface Facilities Eps ProjectAnonymous AdofXEYAgENo ratings yet

- Column Calculation Sheet: Title DescriptionDocument16 pagesColumn Calculation Sheet: Title DescriptionRick-baezNo ratings yet

- RT Request: Hail Surface Facilities Eps ProjectDocument1 pageRT Request: Hail Surface Facilities Eps ProjectSomnath MandalNo ratings yet

- 26.QA-NPD-26 Sani Moulds-Defrost Arm Ace 16-01Document24 pages26.QA-NPD-26 Sani Moulds-Defrost Arm Ace 16-01delightplasticsNo ratings yet

- RT Request: Hail Surface Facilities Eps ProjectDocument4 pagesRT Request: Hail Surface Facilities Eps ProjectAnonymous AdofXEYAgENo ratings yet

- Radiographic Inspection Report: TNDT-CPP-PIP-RT-1250Document19 pagesRadiographic Inspection Report: TNDT-CPP-PIP-RT-1250Hendra SembiringNo ratings yet

- Gas Development Project For Unitization of The Jambaran - Tiung Biru FieldDocument2 pagesGas Development Project For Unitization of The Jambaran - Tiung Biru FieldBintang AtdiNo ratings yet

- SmartLEDShield ESP32 V0 BOMDocument1 pageSmartLEDShield ESP32 V0 BOMpangymylyNo ratings yet

- REPORT RT 03 Februari 2024 (SANGA SANGA)Document8 pagesREPORT RT 03 Februari 2024 (SANGA SANGA)wahyudi140417No ratings yet

- Report RT 01 April 24 PR T UnaDocument1 pageReport RT 01 April 24 PR T Unawahyudi140417No ratings yet

- Report RT 08 Maret 24 Rja SambojaDocument4 pagesReport RT 08 Maret 24 Rja Sambojawahyudi140417No ratings yet

- 08-03-24. Water Injection Pump SambojaDocument1 page08-03-24. Water Injection Pump Sambojawahyudi140417No ratings yet

- Ciam T10Document3 pagesCiam T10Nino SilvaNo ratings yet

- Week 2 LAS Philosophy New FormatDocument5 pagesWeek 2 LAS Philosophy New Formatzein lopezNo ratings yet

- DE THI TUYEN SINH CUA S 4 Năm NayDocument17 pagesDE THI TUYEN SINH CUA S 4 Năm Nay[][][][][][][][]No ratings yet

- Letting Go of Stress, Anxiety, and Fear During Study and Test TakingDocument3 pagesLetting Go of Stress, Anxiety, and Fear During Study and Test TakingRamonNo ratings yet

- Dark Heresy Character Sheet - Ace Character (Unfinished)Document2 pagesDark Heresy Character Sheet - Ace Character (Unfinished)Alasdair GoudieNo ratings yet

- The Metropolitan Museum of Art Bulletin - 1968 - The New Visionaries - Sobre Unbuilt - Impresso - Arthur RosenblattDocument12 pagesThe Metropolitan Museum of Art Bulletin - 1968 - The New Visionaries - Sobre Unbuilt - Impresso - Arthur RosenblattThais AnastacioNo ratings yet

- Lee Moi Wong Chief Research Officer Kuala LumpurDocument2 pagesLee Moi Wong Chief Research Officer Kuala LumpurTony MathewNo ratings yet

- Brazil To Host COP30 Article Review by JForrest EnglishDocument6 pagesBrazil To Host COP30 Article Review by JForrest EnglishraduNo ratings yet

- Writing Style APA FormatDocument2 pagesWriting Style APA FormatsenyorakathNo ratings yet

- An Historicist Perspective On Daniel 11Document343 pagesAn Historicist Perspective On Daniel 11רודריקNo ratings yet

- Maths Class Vi Practice Test 04 Fractions Decimals and Data Handlings 1Document3 pagesMaths Class Vi Practice Test 04 Fractions Decimals and Data Handlings 1Volety Sai SudheerNo ratings yet

- Standard Penetration TestDocument4 pagesStandard Penetration TestIrita Kayna Gobile100% (1)

- HRM Notes Part 2Document34 pagesHRM Notes Part 2Vanessa BatallaNo ratings yet

- Full Ebook of Mathematical Foundations of Data Science 1St Edition Tomas Hrycej Online PDF All ChapterDocument69 pagesFull Ebook of Mathematical Foundations of Data Science 1St Edition Tomas Hrycej Online PDF All Chapterjohnwright726426100% (5)

- Boric AciddDocument2 pagesBoric Acidddinesh111180No ratings yet

- TrustAutomation WP LinearDigitalDrivesDocument7 pagesTrustAutomation WP LinearDigitalDrivesvnetawzNo ratings yet

- EKS83 Service Manual SkyAzulDocument30 pagesEKS83 Service Manual SkyAzulM Refai100% (2)

- The Results Are inDocument1 pageThe Results Are inIvanka VasenskaNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityBhavesh PatelNo ratings yet

- Macine Element I Worksheet For Final ExamDocument4 pagesMacine Element I Worksheet For Final Examdagimawgchew777No ratings yet

- 2021 Utm PSC Sho CiDocument5 pages2021 Utm PSC Sho Cisawsheng59No ratings yet

- Jensen: Unit 4 Pretest ReviewDocument11 pagesJensen: Unit 4 Pretest ReviewKarma TenzinNo ratings yet

- Assignment 1 Psychology and EducationDocument2 pagesAssignment 1 Psychology and EducationRheque GnarNo ratings yet

- Adhesive Systems Important Aspects Related To TheiDocument8 pagesAdhesive Systems Important Aspects Related To TheiHachko GiragosyanNo ratings yet

- LOG708 Applied Statistics 4 Feb 2021Document9 pagesLOG708 Applied Statistics 4 Feb 2021Mahbub Hasan YenNo ratings yet

- The Legend of Malin KundangDocument3 pagesThe Legend of Malin KundangSiti Evayanti100% (3)

- Jesuitas, Shannen Mikhaela BSACC 1-Y1-3 STAS111Document4 pagesJesuitas, Shannen Mikhaela BSACC 1-Y1-3 STAS111Feizhen MaeNo ratings yet

- EPC Lab (BE303) - 2022 Scheme !ST Cycle ExperimentsDocument51 pagesEPC Lab (BE303) - 2022 Scheme !ST Cycle Experimentsm1947ashaNo ratings yet