Professional Documents

Culture Documents

Secomak - Model-5403 Last

Secomak - Model-5403 Last

Uploaded by

ghazijCopyright:

Available Formats

You might also like

- Microscope Column-EM410 - Front001Document36 pagesMicroscope Column-EM410 - Front001Bingo BoyNo ratings yet

- Sony KP Fx432m91Document220 pagesSony KP Fx432m91Iftikhar DaniNo ratings yet

- 0K4285-D SG 050 6.8L FORD INDUSTRIAL H-100 27 Jul 2015Document6 pages0K4285-D SG 050 6.8L FORD INDUSTRIAL H-100 27 Jul 2015GustavoCalderonNo ratings yet

- (Catalog - Microturbine) Dokumen - Tips - Ingersoll-Rand-Mt250-Microturbine-Product-Spec-080ltbDocument2 pages(Catalog - Microturbine) Dokumen - Tips - Ingersoll-Rand-Mt250-Microturbine-Product-Spec-080ltbppourmoghaddamNo ratings yet

- Secomak Model-5402Document2 pagesSecomak Model-5402ghazijNo ratings yet

- CM20200320 39552 31fa9Document4 pagesCM20200320 39552 31fa9johnward19951995No ratings yet

- RVQG5500 SpecDocument4 pagesRVQG5500 SpecMickey BrignacNo ratings yet

- 0186720SBY-B Core Power HSB Model 005837-0Document4 pages0186720SBY-B Core Power HSB Model 005837-0apelectricNo ratings yet

- DQLB PMGDocument4 pagesDQLB PMGMohammad TolounezhadNo ratings yet

- 6kW Off Grid Spec Sheet 061610Document4 pages6kW Off Grid Spec Sheet 061610apelectricNo ratings yet

- Industrial Spark-Ignited Generator Set: Standby Power RatingDocument6 pagesIndustrial Spark-Ignited Generator Set: Standby Power RatingYuritzi Sánchez TéllezNo ratings yet

- Cylinder Combustion SensorDocument4 pagesCylinder Combustion SensorgosoriobNo ratings yet

- 8 To 14 K WDocument4 pages8 To 14 K WapelectricNo ratings yet

- Diesel Generator Set Kubota Series Engine: Power GenerationDocument4 pagesDiesel Generator Set Kubota Series Engine: Power GenerationsdasdNo ratings yet

- Diesel Generator Sets: Cat Diesel Engine GCCP Control PanelsDocument4 pagesDiesel Generator Sets: Cat Diesel Engine GCCP Control PanelsnoorNo ratings yet

- Standby 4 8 0 e K W 6 0 0 K V A 50 HZ 1500 RPM 400 Volts: Diesel Generator SetDocument6 pagesStandby 4 8 0 e K W 6 0 0 K V A 50 HZ 1500 RPM 400 Volts: Diesel Generator SetRainier AyapNo ratings yet

- Diesel Generator Data Sheet: Power by Cummins Model: AC45Document4 pagesDiesel Generator Data Sheet: Power by Cummins Model: AC45serge misseyNo ratings yet

- Cummins 3000 Kva Qsk78 Series Diesel Generator c3000d5Document4 pagesCummins 3000 Kva Qsk78 Series Diesel Generator c3000d5Douglas Alberto Gomez MartinezNo ratings yet

- Cum IsDocument5 pagesCum Ischivi_2010No ratings yet

- 0185620SBYDocument6 pages0185620SBYParrisNo ratings yet

- Industrial Diesel Generator Set: Standby Power RatingDocument6 pagesIndustrial Diesel Generator Set: Standby Power RatingJuly E. Maldonado M.No ratings yet

- 8 To 14 SpecatsDocument4 pages8 To 14 SpecatsManuel OteroNo ratings yet

- Industrial Diesel Generator Set: Standby Power RatingDocument6 pagesIndustrial Diesel Generator Set: Standby Power RatingJuly E. Maldonado M.No ratings yet

- 40 - 50 - 63kVA Spec SheetDocument4 pages40 - 50 - 63kVA Spec SheetMaynard Joshua CorpuzNo ratings yet

- KUBOTA 10-30 kVA: Technical SpecificationsDocument2 pagesKUBOTA 10-30 kVA: Technical SpecificationsThành Long NguyễnNo ratings yet

- Spec Sheet 26RCA (L) - G4-315 (10-23c)Document4 pagesSpec Sheet 26RCA (L) - G4-315 (10-23c)cuatro2009No ratings yet

- Weber WVS 250Document4 pagesWeber WVS 250Express Backup54No ratings yet

- Kohler 100reozmd GeneratorDocument5 pagesKohler 100reozmd GeneratorkuraimundNo ratings yet

- 0181830sby (1) Gereac GasolinaDocument4 pages0181830sby (1) Gereac GasolinaRobertoHerediaJacoboNo ratings yet

- Standby Generators: Air-Cooled Gas Engine Generator SetsDocument4 pagesStandby Generators: Air-Cooled Gas Engine Generator Setsdriver12531No ratings yet

- Weber - WPS 500Document4 pagesWeber - WPS 500Express Backup54No ratings yet

- Industrial Diesel Generator Set: Standby Power RatingDocument6 pagesIndustrial Diesel Generator Set: Standby Power RatingJuly E. Maldonado M.No ratings yet

- 10 KW & 13 KW: Air-Cooled Gas Engine Generator SetsDocument5 pages10 KW & 13 KW: Air-Cooled Gas Engine Generator SetshumbertoNo ratings yet

- 40 - 50 - 63kVA Spec SheetDocument4 pages40 - 50 - 63kVA Spec SheetDharmendra SharmaNo ratings yet

- Industrial Diesel Generator Set: Standby Power RatingDocument7 pagesIndustrial Diesel Generator Set: Standby Power RatingJavier SilvaNo ratings yet

- Industrial Diesel Generator Set: Standby Power RatingDocument6 pagesIndustrial Diesel Generator Set: Standby Power RatingJuly E. Maldonado M.No ratings yet

- C65 High Pressure Natural GasDocument2 pagesC65 High Pressure Natural Gas江华No ratings yet

- Industrial Diesel Generator Set: Standby Power RatingDocument6 pagesIndustrial Diesel Generator Set: Standby Power RatingJuly E. Maldonado M.No ratings yet

- NT855 G6 PDFDocument2 pagesNT855 G6 PDFnaveed100% (1)

- Industrial Diesel Generator Set: Standby Power RatingDocument6 pagesIndustrial Diesel Generator Set: Standby Power Ratingalcibiades romeroNo ratings yet

- 100kva Perkins GeneratoraDocument1 page100kva Perkins GeneratoraAli EndrisNo ratings yet

- Dvigatel Cummins Nta855 g4Document2 pagesDvigatel Cummins Nta855 g4HanNo ratings yet

- 60kva Perkins GeneratorDocument1 page60kva Perkins Generatorhmdawu baslNo ratings yet

- 2000reozm4 10aDocument4 pages2000reozm4 10aShahzad AliNo ratings yet

- Cat G3520H: 60 HZ Continuous Gas Generator SetsDocument7 pagesCat G3520H: 60 HZ Continuous Gas Generator SetsSaman LifeNo ratings yet

- X25 G2Document2 pagesX25 G2nageshNo ratings yet

- AI Power: Diesel Generator Data SheetDocument4 pagesAI Power: Diesel Generator Data SheetAlbertoNo ratings yet

- Cat G3520H: 60 HZ Continuous Gas Generator SetsDocument7 pagesCat G3520H: 60 HZ Continuous Gas Generator SetsAshfaq Ahmed Khawer bhattiNo ratings yet

- QSX15 G8 Cummins Engine PDFDocument3 pagesQSX15 G8 Cummins Engine PDFCahuapaza Gilmer100% (2)

- QSX15 G8 1 PDFDocument11 pagesQSX15 G8 1 PDFMd MkNo ratings yet

- Op Amps: Design, Application, and TroubleshootingFrom EverandOp Amps: Design, Application, and TroubleshootingRating: 5 out of 5 stars5/5 (2)

- The Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationFrom EverandThe Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationNo ratings yet

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Especificaciones de Prueba-Test Bx4Document29 pagesEspecificaciones de Prueba-Test Bx4pabloNo ratings yet

- Lab 5 Basic Logic GatesDocument5 pagesLab 5 Basic Logic GatesJermain PeartNo ratings yet

- Basic DC Circuits ExperimentDocument2 pagesBasic DC Circuits ExperimentTez HarrietNo ratings yet

- Gigabyte GA-M68MT-S2 Rev 3.11 СхемаDocument25 pagesGigabyte GA-M68MT-S2 Rev 3.11 СхемаАндрей АндреевNo ratings yet

- Rs4-Cargo Stowage and StoresDocument14 pagesRs4-Cargo Stowage and StoresGerald Bawalan100% (1)

- Sonodyne Solutions Catalogue - 2024Document32 pagesSonodyne Solutions Catalogue - 2024kuhooNo ratings yet

- LTGDocument4 pagesLTGMohammed AatifNo ratings yet

- 320 KVA To 625 KVADocument8 pages320 KVA To 625 KVAganesh318No ratings yet

- Datasheet OPCom Particle Monitor 10051 EN USDocument4 pagesDatasheet OPCom Particle Monitor 10051 EN USmetinNo ratings yet

- F3 Fence Controllers DatasheetDocument2 pagesF3 Fence Controllers DatasheetUdo IheanachoNo ratings yet

- An 41299Document3 pagesAn 41299Herb UlyssesNo ratings yet

- Omron Adept Ecobra Robot User'S Guide: Covers The Ecobra 600, 800, and 800 Inverted RobotsDocument140 pagesOmron Adept Ecobra Robot User'S Guide: Covers The Ecobra 600, 800, and 800 Inverted RobotsBobyNo ratings yet

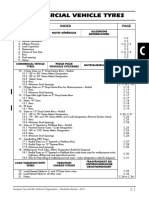

- European Tyre and Rim Technical Organisation - Standards Manual - 2021Document1 pageEuropean Tyre and Rim Technical Organisation - Standards Manual - 2021Arif MohammadNo ratings yet

- Instrução de Montagem Comando DM50Document18 pagesInstrução de Montagem Comando DM50Marcelo LeandroNo ratings yet

- 3DD13009 LgeDocument2 pages3DD13009 Lgeelvariste jerryNo ratings yet

- CD 3 ProjectdocumentationpdfDocument49 pagesCD 3 ProjectdocumentationpdfKHoirul Imam75% (8)

- Republic Act No. 4136Document3 pagesRepublic Act No. 4136Mīc'hāēl Cā'līōlīōNo ratings yet

- PRO Series 100 - 400V2 Pre-Service and Calibration Manual: (Models 110 - 410)Document42 pagesPRO Series 100 - 400V2 Pre-Service and Calibration Manual: (Models 110 - 410)quankddNo ratings yet

- Loop Breaker ManualDocument62 pagesLoop Breaker ManualmchrupaloNo ratings yet

- 74HC14 74HCT14: 1. General DescriptionDocument20 pages74HC14 74HCT14: 1. General DescriptiontrbvnNo ratings yet

- Spare Parts Catalog: 16 S 2230 TO Material Number: 1367.002.045 Current Date: 26.04.2017Document80 pagesSpare Parts Catalog: 16 S 2230 TO Material Number: 1367.002.045 Current Date: 26.04.2017Wang Sze Shian100% (1)

- Hitung KapasitasDocument2 pagesHitung Kapasitastsurya suryanaNo ratings yet

- Welding and Hot Work English QuizDocument5 pagesWelding and Hot Work English QuizUmair SohailNo ratings yet

- Catalog Gear CouplingsDocument2 pagesCatalog Gear CouplingsDev Misra0% (1)

- Sylvania Q-Line Series Industrial Reflector Fluorescent Spec Sheet 10-67Document4 pagesSylvania Q-Line Series Industrial Reflector Fluorescent Spec Sheet 10-67Alan MastersNo ratings yet

- Maxwell Catalog-Temperature ControllerDocument12 pagesMaxwell Catalog-Temperature ControllerPablo Ezequiel GomezNo ratings yet

- Diesel Engine Power PlantDocument13 pagesDiesel Engine Power PlantUtol JasonNo ratings yet

- Epcc/kch400/wo8630 0Document7 pagesEpcc/kch400/wo8630 0spnaikNo ratings yet

Secomak - Model-5403 Last

Secomak - Model-5403 Last

Uploaded by

ghazijOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Secomak - Model-5403 Last

Secomak - Model-5403 Last

Uploaded by

ghazijCopyright:

Available Formats

Model 540/3

BOOSTED PRESSURE FOR CHP,

BOILERS & BURNERS

F E AT U R E S A N D B E N E F I T S

• Secomak & British Gas created the first gas

booster in 1966

• Available for Natural Gas, Town Gas and

Biogas

• Sealed bearing assemblies repel dust and dirt

• Ribbed fan chambers for additional strength

• Compliant to British Standard 8487 (2007 &

2013)

• Compatible with Building Management

Systems

• Industrial affiliate member of IGEM

Motor 4kW

Weight 72kg

Phase 3

Product supplied may differ from image based on pressure requirements.

Noise level 84 dB(A) Image represents Package Gas Booster including controls.

Voltage 415V

Frequency 50Hz

PERFORMANCE CURVE

Start current 14A

Run current 3.6A

Inlet flange DN100

Outlet flange DN80

GAS BOOSTERS

Available as a Package or Stand-Alone system.

Available packages overleaf.

Installation Kit Included with all Package Gas Boosters.

Model 540/3

AVAILABLE PACKAGES

APS INVERTER SYSTEM

• Automatic Pressure Setpoint System Maintains Consistent Outlet Pressure Setpoint

• If Inlet Pressure Dips, The APS Inverter Compensates

• Soft-Start Technology Reduces Shock and Load on the Motor and Bearings

• Extend the Potential Lifespan of Components

• Reduced Electrical Consumption

DUTY STANDBY

• Alternates Automatically Between Two

Boosters Every Seven Days

• Equalise Wear On Bearings and Drives

• Maintenence Never Interrupts Supply

• Eliminate Downtime

• Ideal When Supply Is Critical

GAS SENSOR SYSTEM

• Combined with the Acoustic Enclosure

• “Sniffer” Sensor Detects Potential Gas Leaks

• Visual and Audible Pre-Alarm Warnings

• Automatic Safety Cut Off

GAS BOOSTERS

• ATEX Rated Motor

ACOUSTIC ENCLOSURE

• Reduce operational noise levels by 10-15dB (A)

• Maintain Performance and Motor Cooling

• Fully Demountable

• Quick Release Panels

• Required for Gas Sensor Systems

You might also like

- Microscope Column-EM410 - Front001Document36 pagesMicroscope Column-EM410 - Front001Bingo BoyNo ratings yet

- Sony KP Fx432m91Document220 pagesSony KP Fx432m91Iftikhar DaniNo ratings yet

- 0K4285-D SG 050 6.8L FORD INDUSTRIAL H-100 27 Jul 2015Document6 pages0K4285-D SG 050 6.8L FORD INDUSTRIAL H-100 27 Jul 2015GustavoCalderonNo ratings yet

- (Catalog - Microturbine) Dokumen - Tips - Ingersoll-Rand-Mt250-Microturbine-Product-Spec-080ltbDocument2 pages(Catalog - Microturbine) Dokumen - Tips - Ingersoll-Rand-Mt250-Microturbine-Product-Spec-080ltbppourmoghaddamNo ratings yet

- Secomak Model-5402Document2 pagesSecomak Model-5402ghazijNo ratings yet

- CM20200320 39552 31fa9Document4 pagesCM20200320 39552 31fa9johnward19951995No ratings yet

- RVQG5500 SpecDocument4 pagesRVQG5500 SpecMickey BrignacNo ratings yet

- 0186720SBY-B Core Power HSB Model 005837-0Document4 pages0186720SBY-B Core Power HSB Model 005837-0apelectricNo ratings yet

- DQLB PMGDocument4 pagesDQLB PMGMohammad TolounezhadNo ratings yet

- 6kW Off Grid Spec Sheet 061610Document4 pages6kW Off Grid Spec Sheet 061610apelectricNo ratings yet

- Industrial Spark-Ignited Generator Set: Standby Power RatingDocument6 pagesIndustrial Spark-Ignited Generator Set: Standby Power RatingYuritzi Sánchez TéllezNo ratings yet

- Cylinder Combustion SensorDocument4 pagesCylinder Combustion SensorgosoriobNo ratings yet

- 8 To 14 K WDocument4 pages8 To 14 K WapelectricNo ratings yet

- Diesel Generator Set Kubota Series Engine: Power GenerationDocument4 pagesDiesel Generator Set Kubota Series Engine: Power GenerationsdasdNo ratings yet

- Diesel Generator Sets: Cat Diesel Engine GCCP Control PanelsDocument4 pagesDiesel Generator Sets: Cat Diesel Engine GCCP Control PanelsnoorNo ratings yet

- Standby 4 8 0 e K W 6 0 0 K V A 50 HZ 1500 RPM 400 Volts: Diesel Generator SetDocument6 pagesStandby 4 8 0 e K W 6 0 0 K V A 50 HZ 1500 RPM 400 Volts: Diesel Generator SetRainier AyapNo ratings yet

- Diesel Generator Data Sheet: Power by Cummins Model: AC45Document4 pagesDiesel Generator Data Sheet: Power by Cummins Model: AC45serge misseyNo ratings yet

- Cummins 3000 Kva Qsk78 Series Diesel Generator c3000d5Document4 pagesCummins 3000 Kva Qsk78 Series Diesel Generator c3000d5Douglas Alberto Gomez MartinezNo ratings yet

- Cum IsDocument5 pagesCum Ischivi_2010No ratings yet

- 0185620SBYDocument6 pages0185620SBYParrisNo ratings yet

- Industrial Diesel Generator Set: Standby Power RatingDocument6 pagesIndustrial Diesel Generator Set: Standby Power RatingJuly E. Maldonado M.No ratings yet

- 8 To 14 SpecatsDocument4 pages8 To 14 SpecatsManuel OteroNo ratings yet

- Industrial Diesel Generator Set: Standby Power RatingDocument6 pagesIndustrial Diesel Generator Set: Standby Power RatingJuly E. Maldonado M.No ratings yet

- 40 - 50 - 63kVA Spec SheetDocument4 pages40 - 50 - 63kVA Spec SheetMaynard Joshua CorpuzNo ratings yet

- KUBOTA 10-30 kVA: Technical SpecificationsDocument2 pagesKUBOTA 10-30 kVA: Technical SpecificationsThành Long NguyễnNo ratings yet

- Spec Sheet 26RCA (L) - G4-315 (10-23c)Document4 pagesSpec Sheet 26RCA (L) - G4-315 (10-23c)cuatro2009No ratings yet

- Weber WVS 250Document4 pagesWeber WVS 250Express Backup54No ratings yet

- Kohler 100reozmd GeneratorDocument5 pagesKohler 100reozmd GeneratorkuraimundNo ratings yet

- 0181830sby (1) Gereac GasolinaDocument4 pages0181830sby (1) Gereac GasolinaRobertoHerediaJacoboNo ratings yet

- Standby Generators: Air-Cooled Gas Engine Generator SetsDocument4 pagesStandby Generators: Air-Cooled Gas Engine Generator Setsdriver12531No ratings yet

- Weber - WPS 500Document4 pagesWeber - WPS 500Express Backup54No ratings yet

- Industrial Diesel Generator Set: Standby Power RatingDocument6 pagesIndustrial Diesel Generator Set: Standby Power RatingJuly E. Maldonado M.No ratings yet

- 10 KW & 13 KW: Air-Cooled Gas Engine Generator SetsDocument5 pages10 KW & 13 KW: Air-Cooled Gas Engine Generator SetshumbertoNo ratings yet

- 40 - 50 - 63kVA Spec SheetDocument4 pages40 - 50 - 63kVA Spec SheetDharmendra SharmaNo ratings yet

- Industrial Diesel Generator Set: Standby Power RatingDocument7 pagesIndustrial Diesel Generator Set: Standby Power RatingJavier SilvaNo ratings yet

- Industrial Diesel Generator Set: Standby Power RatingDocument6 pagesIndustrial Diesel Generator Set: Standby Power RatingJuly E. Maldonado M.No ratings yet

- C65 High Pressure Natural GasDocument2 pagesC65 High Pressure Natural Gas江华No ratings yet

- Industrial Diesel Generator Set: Standby Power RatingDocument6 pagesIndustrial Diesel Generator Set: Standby Power RatingJuly E. Maldonado M.No ratings yet

- NT855 G6 PDFDocument2 pagesNT855 G6 PDFnaveed100% (1)

- Industrial Diesel Generator Set: Standby Power RatingDocument6 pagesIndustrial Diesel Generator Set: Standby Power Ratingalcibiades romeroNo ratings yet

- 100kva Perkins GeneratoraDocument1 page100kva Perkins GeneratoraAli EndrisNo ratings yet

- Dvigatel Cummins Nta855 g4Document2 pagesDvigatel Cummins Nta855 g4HanNo ratings yet

- 60kva Perkins GeneratorDocument1 page60kva Perkins Generatorhmdawu baslNo ratings yet

- 2000reozm4 10aDocument4 pages2000reozm4 10aShahzad AliNo ratings yet

- Cat G3520H: 60 HZ Continuous Gas Generator SetsDocument7 pagesCat G3520H: 60 HZ Continuous Gas Generator SetsSaman LifeNo ratings yet

- X25 G2Document2 pagesX25 G2nageshNo ratings yet

- AI Power: Diesel Generator Data SheetDocument4 pagesAI Power: Diesel Generator Data SheetAlbertoNo ratings yet

- Cat G3520H: 60 HZ Continuous Gas Generator SetsDocument7 pagesCat G3520H: 60 HZ Continuous Gas Generator SetsAshfaq Ahmed Khawer bhattiNo ratings yet

- QSX15 G8 Cummins Engine PDFDocument3 pagesQSX15 G8 Cummins Engine PDFCahuapaza Gilmer100% (2)

- QSX15 G8 1 PDFDocument11 pagesQSX15 G8 1 PDFMd MkNo ratings yet

- Op Amps: Design, Application, and TroubleshootingFrom EverandOp Amps: Design, Application, and TroubleshootingRating: 5 out of 5 stars5/5 (2)

- The Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationFrom EverandThe Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationNo ratings yet

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Especificaciones de Prueba-Test Bx4Document29 pagesEspecificaciones de Prueba-Test Bx4pabloNo ratings yet

- Lab 5 Basic Logic GatesDocument5 pagesLab 5 Basic Logic GatesJermain PeartNo ratings yet

- Basic DC Circuits ExperimentDocument2 pagesBasic DC Circuits ExperimentTez HarrietNo ratings yet

- Gigabyte GA-M68MT-S2 Rev 3.11 СхемаDocument25 pagesGigabyte GA-M68MT-S2 Rev 3.11 СхемаАндрей АндреевNo ratings yet

- Rs4-Cargo Stowage and StoresDocument14 pagesRs4-Cargo Stowage and StoresGerald Bawalan100% (1)

- Sonodyne Solutions Catalogue - 2024Document32 pagesSonodyne Solutions Catalogue - 2024kuhooNo ratings yet

- LTGDocument4 pagesLTGMohammed AatifNo ratings yet

- 320 KVA To 625 KVADocument8 pages320 KVA To 625 KVAganesh318No ratings yet

- Datasheet OPCom Particle Monitor 10051 EN USDocument4 pagesDatasheet OPCom Particle Monitor 10051 EN USmetinNo ratings yet

- F3 Fence Controllers DatasheetDocument2 pagesF3 Fence Controllers DatasheetUdo IheanachoNo ratings yet

- An 41299Document3 pagesAn 41299Herb UlyssesNo ratings yet

- Omron Adept Ecobra Robot User'S Guide: Covers The Ecobra 600, 800, and 800 Inverted RobotsDocument140 pagesOmron Adept Ecobra Robot User'S Guide: Covers The Ecobra 600, 800, and 800 Inverted RobotsBobyNo ratings yet

- European Tyre and Rim Technical Organisation - Standards Manual - 2021Document1 pageEuropean Tyre and Rim Technical Organisation - Standards Manual - 2021Arif MohammadNo ratings yet

- Instrução de Montagem Comando DM50Document18 pagesInstrução de Montagem Comando DM50Marcelo LeandroNo ratings yet

- 3DD13009 LgeDocument2 pages3DD13009 Lgeelvariste jerryNo ratings yet

- CD 3 ProjectdocumentationpdfDocument49 pagesCD 3 ProjectdocumentationpdfKHoirul Imam75% (8)

- Republic Act No. 4136Document3 pagesRepublic Act No. 4136Mīc'hāēl Cā'līōlīōNo ratings yet

- PRO Series 100 - 400V2 Pre-Service and Calibration Manual: (Models 110 - 410)Document42 pagesPRO Series 100 - 400V2 Pre-Service and Calibration Manual: (Models 110 - 410)quankddNo ratings yet

- Loop Breaker ManualDocument62 pagesLoop Breaker ManualmchrupaloNo ratings yet

- 74HC14 74HCT14: 1. General DescriptionDocument20 pages74HC14 74HCT14: 1. General DescriptiontrbvnNo ratings yet

- Spare Parts Catalog: 16 S 2230 TO Material Number: 1367.002.045 Current Date: 26.04.2017Document80 pagesSpare Parts Catalog: 16 S 2230 TO Material Number: 1367.002.045 Current Date: 26.04.2017Wang Sze Shian100% (1)

- Hitung KapasitasDocument2 pagesHitung Kapasitastsurya suryanaNo ratings yet

- Welding and Hot Work English QuizDocument5 pagesWelding and Hot Work English QuizUmair SohailNo ratings yet

- Catalog Gear CouplingsDocument2 pagesCatalog Gear CouplingsDev Misra0% (1)

- Sylvania Q-Line Series Industrial Reflector Fluorescent Spec Sheet 10-67Document4 pagesSylvania Q-Line Series Industrial Reflector Fluorescent Spec Sheet 10-67Alan MastersNo ratings yet

- Maxwell Catalog-Temperature ControllerDocument12 pagesMaxwell Catalog-Temperature ControllerPablo Ezequiel GomezNo ratings yet

- Diesel Engine Power PlantDocument13 pagesDiesel Engine Power PlantUtol JasonNo ratings yet

- Epcc/kch400/wo8630 0Document7 pagesEpcc/kch400/wo8630 0spnaikNo ratings yet