Professional Documents

Culture Documents

10 Hangspin

10 Hangspin

Uploaded by

bedoo54Copyright:

Available Formats

You might also like

- AT520JK Users ManualDocument15 pagesAT520JK Users ManualgerezairNo ratings yet

- Claas Jaguar Error CodesDocument20 pagesClaas Jaguar Error Codesbedoo54100% (2)

- 004 - Artificial Intelligence (3rd Ed.) by Elaine Rich Kevin Knight & Shivashankar NairDocument44 pages004 - Artificial Intelligence (3rd Ed.) by Elaine Rich Kevin Knight & Shivashankar NairNaveen Setty31% (16)

- Cummins - QSB4.5 CM2350Document18 pagesCummins - QSB4.5 CM2350bedoo54100% (2)

- UBC ASTM July 2017 To July 2018 UseDocument1,349 pagesUBC ASTM July 2017 To July 2018 UseAadelNo ratings yet

- Craftsman Scroll Saw ManualDocument7 pagesCraftsman Scroll Saw ManualrlrubenkingNo ratings yet

- Yaw Damper Installation GuideDocument12 pagesYaw Damper Installation GuideJamal Alshawesh0% (1)

- Sioux 2075Document22 pagesSioux 2075Marius AmaieiNo ratings yet

- 521 InstallDocument2 pages521 InstallmejmakNo ratings yet

- Training BookDocument44 pagesTraining BookItseed CorcaNo ratings yet

- PES6M InstrDocument1 pagePES6M Instrfdo.casanovaNo ratings yet

- Horizontal Sidewall SprinklerDocument5 pagesHorizontal Sidewall SprinklerRavi PrakashNo ratings yet

- CP360 Manual - 120v, HaskelDocument16 pagesCP360 Manual - 120v, HaskelbradygbutlerNo ratings yet

- Caladora DWaltDocument30 pagesCaladora DWaltAlejandro SalcedoNo ratings yet

- Instruction Manual Temperature SwitchesDocument4 pagesInstruction Manual Temperature Switchesdel110001No ratings yet

- SaltandSwim3C Owner Manual SASDocument24 pagesSaltandSwim3C Owner Manual SASkarkoxcmpcNo ratings yet

- Bow Thruster Installation InstructionsDocument9 pagesBow Thruster Installation InstructionsRovert AlonzoNo ratings yet

- Manual de Uso SOPLADOR NEUMATICODocument16 pagesManual de Uso SOPLADOR NEUMATICOannie 13No ratings yet

- Chave de Fluxo PotterDocument6 pagesChave de Fluxo PotterEduardo Cardoso FilhoNo ratings yet

- 02J 02M Shifter InstallDocument7 pages02J 02M Shifter Installjgilbertson314No ratings yet

- Phoenix Edge 540 - ManualDocument16 pagesPhoenix Edge 540 - ManualfrancNo ratings yet

- SG 4-4 - ManualDocument44 pagesSG 4-4 - ManualJose OlivaresNo ratings yet

- 垃圾处理器英文说明书Document6 pages垃圾处理器英文说明书joseflores888No ratings yet

- PGA Valve: Installation and Operating Instructions Troubleshooting GuideDocument8 pagesPGA Valve: Installation and Operating Instructions Troubleshooting GuidehakimNo ratings yet

- Submersible Sewage Ejector Pump: Safety InformationDocument8 pagesSubmersible Sewage Ejector Pump: Safety Informationallen_worstNo ratings yet

- Uai B 0214Document4 pagesUai B 0214Jose Puc ManzanillaNo ratings yet

- Instruction Manual G-550: Vertex Standard Co., Ltd. Vertex StandardDocument12 pagesInstruction Manual G-550: Vertex Standard Co., Ltd. Vertex Standardsdelpi5146No ratings yet

- Condensing Units: Installer's GuideDocument8 pagesCondensing Units: Installer's GuideHoàngViệtAnhNo ratings yet

- Cable Termination - Installation Instructions - 755LR - IsDocument5 pagesCable Termination - Installation Instructions - 755LR - Isvladimir_71No ratings yet

- 2013 Article Hopsprayer Construction v4Document9 pages2013 Article Hopsprayer Construction v42fercepolNo ratings yet

- 130 014 150 010 - OM 2 - Kawasaki - Z800Document12 pages130 014 150 010 - OM 2 - Kawasaki - Z800wawaneylahhNo ratings yet

- OriginalDocument11 pagesOriginaleddimambweNo ratings yet

- Model ZW209FP: Installation Start-Up Maintenance InstructionsDocument5 pagesModel ZW209FP: Installation Start-Up Maintenance InstructionsRanses RomanNo ratings yet

- ManualDocument4 pagesManualJose Van de KruisNo ratings yet

- L 2484DOMTrboInstMan5!30!07Document16 pagesL 2484DOMTrboInstMan5!30!07PIKO MOBNo ratings yet

- 2 TTB 3Document8 pages2 TTB 3mikecom21No ratings yet

- Freightliner Fld120 PDFDocument19 pagesFreightliner Fld120 PDFCopyMaster2No ratings yet

- WM 1255 AgsxenDocument76 pagesWM 1255 AgsxenFrancisco MNo ratings yet

- ST900 Ed12Document28 pagesST900 Ed12moisesNo ratings yet

- WheelHorse Snow Thrower Completing Package Manual 6-9111Document4 pagesWheelHorse Snow Thrower Completing Package Manual 6-9111Kevins Small Engine and Tractor ServiceNo ratings yet

- AAON CA Series Condensing Unit IOMDocument8 pagesAAON CA Series Condensing Unit IOMslghvacNo ratings yet

- Informacion Tecnica IMS 750 1000Document6 pagesInformacion Tecnica IMS 750 1000Carlo CanoNo ratings yet

- BH Liner HangerDocument9 pagesBH Liner HangerzhiqianxuNo ratings yet

- Ranger 7 Manual 102616Document24 pagesRanger 7 Manual 102616nathan.jennerNo ratings yet

- 1171-2171 IomDocument10 pages1171-2171 IomBladimir MontecinosNo ratings yet

- 1268Document20 pages1268ChiragNo ratings yet

- Operating Instruction Underbody ClampDocument2 pagesOperating Instruction Underbody ClampBe HappyNo ratings yet

- GR - WRDSP - Tech LiteratureDocument7 pagesGR - WRDSP - Tech LiteratureDigger Downhole ToolsNo ratings yet

- ASC Air Starter ST700 SeriesDocument29 pagesASC Air Starter ST700 SeriesLeonid KolesnikovNo ratings yet

- KipasDocument7 pagesKipasmuhdafifiNo ratings yet

- Dormont Hose Manual PDFDocument24 pagesDormont Hose Manual PDFAnonymous TDI8qdYNo ratings yet

- Jandy Check Valve Installation GuideDocument2 pagesJandy Check Valve Installation GuidejupodeNo ratings yet

- Quick Start Guide XR (H, V) S 336-506 CD APP 2954 6440 01 ENDocument2 pagesQuick Start Guide XR (H, V) S 336-506 CD APP 2954 6440 01 ENahmedNo ratings yet

- ADCOM Gfa - 5300manualDocument8 pagesADCOM Gfa - 5300manualLee JacksonNo ratings yet

- Alpha AX20Document7 pagesAlpha AX20Alan JayceeNo ratings yet

- Manuals K Lok Series 360 362 370 372 Keystone en en 5196826 PDFDocument8 pagesManuals K Lok Series 360 362 370 372 Keystone en en 5196826 PDFAnonymous T7zEN6iLHNo ratings yet

- 1288652GT SC PDFDocument1 page1288652GT SC PDFBellameriamNo ratings yet

- HYDRA Owner's ManualDocument12 pagesHYDRA Owner's ManualDiego BeltranNo ratings yet

- Habc InstallationDocument25 pagesHabc InstallationJoaquinDominguezNo ratings yet

- Sea 116 ManualDocument41 pagesSea 116 ManualnkejacqueNo ratings yet

- Bombas CentrifugasDocument4 pagesBombas CentrifugasmasanmartinfNo ratings yet

- AI 4500 Revita Air ManualDocument12 pagesAI 4500 Revita Air ManualRobert TuckerNo ratings yet

- Vrc4500 Ac 安装说明书Document119 pagesVrc4500 Ac 安装说明书wangbiao0109No ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- 7 CSG TallyDocument7 pages7 CSG Tallybedoo54No ratings yet

- Eg 2 CalibDocument1 pageEg 2 Calibbedoo54No ratings yet

- Tank VolumesDocument3 pagesTank Volumesbedoo54No ratings yet

- HangerordfhDocument1 pageHangerordfhbedoo54No ratings yet

- Connector Mapping Guide: Efi P/N GND B+ IGN GND B+ Ign MilDocument1 pageConnector Mapping Guide: Efi P/N GND B+ IGN GND B+ Ign Milbedoo54No ratings yet

- IdrollerordfhDocument1 pageIdrollerordfhbedoo54No ratings yet

- Case Backhoe Loader - 580N (Tier 4)Document326 pagesCase Backhoe Loader - 580N (Tier 4)bedoo54No ratings yet

- Systems Operation 3406Document32 pagesSystems Operation 3406bedoo54No ratings yet

- CAT Engine - C4.4 (For CAT Machines UENR0647-06) .Prefix 444Document8 pagesCAT Engine - C4.4 (For CAT Machines UENR0647-06) .Prefix 444bedoo54No ratings yet

- KOMATSU SAA4D95LE-7 SCR - DOC Emulator Plug and PlayDocument3 pagesKOMATSU SAA4D95LE-7 SCR - DOC Emulator Plug and Playbedoo54No ratings yet

- Failure Code (DX16KA) Fan Pump EPC Sol. DiscDocument2 pagesFailure Code (DX16KA) Fan Pump EPC Sol. Discbedoo54100% (1)

- فلم يلا لقتنت فيك فلملا مسا رييغت نود تن ةحفص يلع ةحفصلا ظفح Mission statement ةحفصلا لفسا فلملا مسا يلع رسيلاا سوملا رزب طغضلا دعب كلذ نكميDocument30 pagesفلم يلا لقتنت فيك فلملا مسا رييغت نود تن ةحفص يلع ةحفصلا ظفح Mission statement ةحفصلا لفسا فلملا مسا يلع رسيلاا سوملا رزب طغضلا دعب كلذ نكميbedoo54No ratings yet

- Latitude-E6420-Xfr - Service Manual - En-UsDocument81 pagesLatitude-E6420-Xfr - Service Manual - En-Usbedoo54No ratings yet

- To NitrogenDocument54 pagesTo Nitrogenbedoo54No ratings yet

- Special Instruction: Procedure For Installing Migration Kits On Certain C9.3-C15 ACERT Tier 4 Interim ProductsDocument1 pageSpecial Instruction: Procedure For Installing Migration Kits On Certain C9.3-C15 ACERT Tier 4 Interim Productsbedoo54No ratings yet

- Dell Latitude E6420 XFR: Real-World RuggedDocument2 pagesDell Latitude E6420 XFR: Real-World Ruggedbedoo54No ratings yet

- Setting The Pace: Hydraulic Crawler DrillsDocument8 pagesSetting The Pace: Hydraulic Crawler Drillsbedoo54100% (1)

- Axis PM User ManualDocument81 pagesAxis PM User Manualbedoo54No ratings yet

- Installation Instructions 31J K M N P Win7 H-2011-0216-HDocument11 pagesInstallation Instructions 31J K M N P Win7 H-2011-0216-Hbedoo54No ratings yet

- Fast Picture Viewer CheatsheetDocument1 pageFast Picture Viewer CheatsheetClay MannixNo ratings yet

- 31 SDMS 13Document27 pages31 SDMS 13I CNo ratings yet

- MiscDocument23 pagesMisccp2489No ratings yet

- Reservoir Vent FiltersDocument8 pagesReservoir Vent FiltersHesham MahdyNo ratings yet

- Web Development Technology ChecklistDocument2 pagesWeb Development Technology ChecklistAlex MercedNo ratings yet

- PM21 2011 Complete E1Document996 pagesPM21 2011 Complete E1Cesar_SERVIXNo ratings yet

- Disquietude Jan10Document3 pagesDisquietude Jan10chenamberNo ratings yet

- Sine Wavefor FormulaDocument158 pagesSine Wavefor FormulanmguravNo ratings yet

- SECTION 3.6 - ACSU - Rev 2016Document55 pagesSECTION 3.6 - ACSU - Rev 2016Osmahadzir OsrinNo ratings yet

- Project ProposalDocument4 pagesProject Proposalapi-318375436No ratings yet

- Common Asked Questions About SolarDocument36 pagesCommon Asked Questions About SolarnairsdocsNo ratings yet

- መጽሐፈ ፈውስDocument399 pagesመጽሐፈ ፈውስHabtamuAlemenew100% (3)

- Autocad Mechanical Detail Brochure enDocument14 pagesAutocad Mechanical Detail Brochure enVeera PandiNo ratings yet

- MoRTH - Pocketbook For Highway Engineers - 2002-2nd Rev PDFDocument222 pagesMoRTH - Pocketbook For Highway Engineers - 2002-2nd Rev PDFanugkumar8100% (1)

- Home GRIDDocument5 pagesHome GRIDramoradoNo ratings yet

- Solar Tracker ProjectDocument4 pagesSolar Tracker ProjectcritestachNo ratings yet

- Gravity Dam Solution KeyDocument3 pagesGravity Dam Solution KeyAmanda SmithNo ratings yet

- Bifpcl Question Solve - 2015: R 5+3+2 10 V 20+20 40 Sor 10 P 40 / (4 X 10)Document7 pagesBifpcl Question Solve - 2015: R 5+3+2 10 V 20+20 40 Sor 10 P 40 / (4 X 10)Mazharul HaqueNo ratings yet

- LPPT 25-2019Document68 pagesLPPT 25-2019Tweed3ANo ratings yet

- Trcking Sheet Drawing Update by 13-6-2023Document4 pagesTrcking Sheet Drawing Update by 13-6-2023Hossam H. HamedNo ratings yet

- Hannah Berk: Professional ExperienceDocument1 pageHannah Berk: Professional ExperienceAnonymous kE9KoTF2UGNo ratings yet

- 3.12 Three Phase AC CircuitsDocument8 pages3.12 Three Phase AC CircuitsnathmanojNo ratings yet

- Brenntag Case StudyDocument2 pagesBrenntag Case StudypriyabratamohantyNo ratings yet

- Selfdocs 600dpi A4Document678 pagesSelfdocs 600dpi A4ErdiApatayNo ratings yet

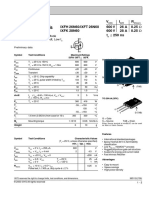

- Hiperfet Power Mosfets: V I R Ixfh 26N60/Ixft 26N60 600 V 26 A 0.25 Ixfk 28N60 600 V 28 A 0.25 T 250 NsDocument2 pagesHiperfet Power Mosfets: V I R Ixfh 26N60/Ixft 26N60 600 V 26 A 0.25 Ixfk 28N60 600 V 28 A 0.25 T 250 NsAmirNo ratings yet

- Ijigsp V7 N6 6 PDFDocument7 pagesIjigsp V7 N6 6 PDFShantala GiraddiNo ratings yet

- AISC Propiedades y Pesos v14 - TOTALDocument77 pagesAISC Propiedades y Pesos v14 - TOTALAlex RiosNo ratings yet

- Service Manual Ricoh Aficio 470wDocument231 pagesService Manual Ricoh Aficio 470wsangNo ratings yet

10 Hangspin

10 Hangspin

Uploaded by

bedoo54Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10 Hangspin

10 Hangspin

Uploaded by

bedoo54Copyright:

Available Formats

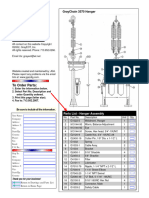

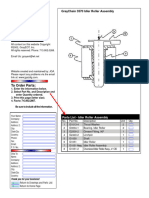

GraySpin Mark 10 & Drill Pipe Spinner

II. INSTALLATION

WARNING- The use of only one backup line can cause the

spinner to swing into the operator or floor personal and cause

injury. Use two backup cables.

A. HANGING SPINNER

C. ATTACHMENT OF SUPPLY LINES

The GRAYSPIN should be hung using wire rope 1/2" or

greater and in accordance with acceptable practices. Attach Typically a 1-1/2"” air line should be run to the rig floor. A valve is

wire rope through clevis at top of spring hanger assembly. required at this point in order to shut-off air when maintenance

on the tool is required.

WARNING: Check all spring hanger assembly clevises for

Click any link below. tightness.

Home Page WARNING: Check spring safety cables for soundness, (2 Install a 1-1/4", 200 PSI minimum, air hose from the valve to the

required). The spring hanger assembly is necessary to allow spinner. Keep the hose and piping as short as possible with as few

the spinner to rise and fall with threaded tool joint fittings as possible.

Our World movements.

Blow out the line prior to installation to remove any debris or

Use of the spinner without the spring hanger assembly will moisture.

About GrayEOT & shorten the life of the tool and cause improper operation

Blohm+Voss which may lead to accidents. (Disregard if counterbalance is

used.) D. PIPE SIZE ADJUSTMENT

GraySpin Mark 10 & 20 The spinner should be located between the rotary table and The GRAYSPIN spinner will initially be set with the arm to

Parts & Drawings drawworks (toward the off driller side) about 4 feet back from cylinder connecting pin placed in the forward position. This will

the center of the rotary table. It should hang about 4 to 5 accommodate most pipe sizes. If it is necessary to move the pin

feet above the floor as to contact the drill pipe and not the to the rear position, slowly activate the door valve until the pin is

GraySpin Mark 30 tool joint. The spinner should be easily pulled on and off the lined up to the slot in the top plate. This will occur with the doors

drill pipe and be completely out of the way when not in use. closed, (cylinders extended). Disconnect power source. Remove

Parts & Drawings

the locking sockethead capscrew and pull the pin up through the

top plate. Rotate the door to line up cylinder clevis with the rear

The tool can be leveled by turning the leveling screw atop the pin position and replace pin and locking capscrew. Repeat

GrayChain 3570 stationary hanger. procedure on the the opposite door. Reattach power source.

Parts & Drawings

B. BACKUP CABLES WARNING- Disconnect power source when changing arm pin

positions.

3570 Size Adjustment

The GRAYSPIN spinner will rotate drill pipe in both directions

and consequently swing in either direction. The GRAYSPIN Return to the Table of Contents

must be equipped with TWO BACKUP LINES. These two

backup lines or cables need to be attached to derrick legs or

comparable structure. Attachment should be made so that

the swinging movement of the spinner is restricted to less

All content on this website that one foot in either direction.

Copyright ©2002, GrayEOT,

Inc.

PO Box 79485

Houston, Texas 77279-9485

USA

7670 Woodway, Suite 175

Houston, Texas 77063 USA

713.952.0266

Fax: 713.952.2807

All rights reserved.

Email Us: grayeot@wt.net

Website created and

maintained by: JGA. Please

report any problems to:

www.jgazdig.com

file:///Files/GrayEOT%20Manuals/10hangspin.htm [6/24/2002 19:18:48]

You might also like

- AT520JK Users ManualDocument15 pagesAT520JK Users ManualgerezairNo ratings yet

- Claas Jaguar Error CodesDocument20 pagesClaas Jaguar Error Codesbedoo54100% (2)

- 004 - Artificial Intelligence (3rd Ed.) by Elaine Rich Kevin Knight & Shivashankar NairDocument44 pages004 - Artificial Intelligence (3rd Ed.) by Elaine Rich Kevin Knight & Shivashankar NairNaveen Setty31% (16)

- Cummins - QSB4.5 CM2350Document18 pagesCummins - QSB4.5 CM2350bedoo54100% (2)

- UBC ASTM July 2017 To July 2018 UseDocument1,349 pagesUBC ASTM July 2017 To July 2018 UseAadelNo ratings yet

- Craftsman Scroll Saw ManualDocument7 pagesCraftsman Scroll Saw ManualrlrubenkingNo ratings yet

- Yaw Damper Installation GuideDocument12 pagesYaw Damper Installation GuideJamal Alshawesh0% (1)

- Sioux 2075Document22 pagesSioux 2075Marius AmaieiNo ratings yet

- 521 InstallDocument2 pages521 InstallmejmakNo ratings yet

- Training BookDocument44 pagesTraining BookItseed CorcaNo ratings yet

- PES6M InstrDocument1 pagePES6M Instrfdo.casanovaNo ratings yet

- Horizontal Sidewall SprinklerDocument5 pagesHorizontal Sidewall SprinklerRavi PrakashNo ratings yet

- CP360 Manual - 120v, HaskelDocument16 pagesCP360 Manual - 120v, HaskelbradygbutlerNo ratings yet

- Caladora DWaltDocument30 pagesCaladora DWaltAlejandro SalcedoNo ratings yet

- Instruction Manual Temperature SwitchesDocument4 pagesInstruction Manual Temperature Switchesdel110001No ratings yet

- SaltandSwim3C Owner Manual SASDocument24 pagesSaltandSwim3C Owner Manual SASkarkoxcmpcNo ratings yet

- Bow Thruster Installation InstructionsDocument9 pagesBow Thruster Installation InstructionsRovert AlonzoNo ratings yet

- Manual de Uso SOPLADOR NEUMATICODocument16 pagesManual de Uso SOPLADOR NEUMATICOannie 13No ratings yet

- Chave de Fluxo PotterDocument6 pagesChave de Fluxo PotterEduardo Cardoso FilhoNo ratings yet

- 02J 02M Shifter InstallDocument7 pages02J 02M Shifter Installjgilbertson314No ratings yet

- Phoenix Edge 540 - ManualDocument16 pagesPhoenix Edge 540 - ManualfrancNo ratings yet

- SG 4-4 - ManualDocument44 pagesSG 4-4 - ManualJose OlivaresNo ratings yet

- 垃圾处理器英文说明书Document6 pages垃圾处理器英文说明书joseflores888No ratings yet

- PGA Valve: Installation and Operating Instructions Troubleshooting GuideDocument8 pagesPGA Valve: Installation and Operating Instructions Troubleshooting GuidehakimNo ratings yet

- Submersible Sewage Ejector Pump: Safety InformationDocument8 pagesSubmersible Sewage Ejector Pump: Safety Informationallen_worstNo ratings yet

- Uai B 0214Document4 pagesUai B 0214Jose Puc ManzanillaNo ratings yet

- Instruction Manual G-550: Vertex Standard Co., Ltd. Vertex StandardDocument12 pagesInstruction Manual G-550: Vertex Standard Co., Ltd. Vertex Standardsdelpi5146No ratings yet

- Condensing Units: Installer's GuideDocument8 pagesCondensing Units: Installer's GuideHoàngViệtAnhNo ratings yet

- Cable Termination - Installation Instructions - 755LR - IsDocument5 pagesCable Termination - Installation Instructions - 755LR - Isvladimir_71No ratings yet

- 2013 Article Hopsprayer Construction v4Document9 pages2013 Article Hopsprayer Construction v42fercepolNo ratings yet

- 130 014 150 010 - OM 2 - Kawasaki - Z800Document12 pages130 014 150 010 - OM 2 - Kawasaki - Z800wawaneylahhNo ratings yet

- OriginalDocument11 pagesOriginaleddimambweNo ratings yet

- Model ZW209FP: Installation Start-Up Maintenance InstructionsDocument5 pagesModel ZW209FP: Installation Start-Up Maintenance InstructionsRanses RomanNo ratings yet

- ManualDocument4 pagesManualJose Van de KruisNo ratings yet

- L 2484DOMTrboInstMan5!30!07Document16 pagesL 2484DOMTrboInstMan5!30!07PIKO MOBNo ratings yet

- 2 TTB 3Document8 pages2 TTB 3mikecom21No ratings yet

- Freightliner Fld120 PDFDocument19 pagesFreightliner Fld120 PDFCopyMaster2No ratings yet

- WM 1255 AgsxenDocument76 pagesWM 1255 AgsxenFrancisco MNo ratings yet

- ST900 Ed12Document28 pagesST900 Ed12moisesNo ratings yet

- WheelHorse Snow Thrower Completing Package Manual 6-9111Document4 pagesWheelHorse Snow Thrower Completing Package Manual 6-9111Kevins Small Engine and Tractor ServiceNo ratings yet

- AAON CA Series Condensing Unit IOMDocument8 pagesAAON CA Series Condensing Unit IOMslghvacNo ratings yet

- Informacion Tecnica IMS 750 1000Document6 pagesInformacion Tecnica IMS 750 1000Carlo CanoNo ratings yet

- BH Liner HangerDocument9 pagesBH Liner HangerzhiqianxuNo ratings yet

- Ranger 7 Manual 102616Document24 pagesRanger 7 Manual 102616nathan.jennerNo ratings yet

- 1171-2171 IomDocument10 pages1171-2171 IomBladimir MontecinosNo ratings yet

- 1268Document20 pages1268ChiragNo ratings yet

- Operating Instruction Underbody ClampDocument2 pagesOperating Instruction Underbody ClampBe HappyNo ratings yet

- GR - WRDSP - Tech LiteratureDocument7 pagesGR - WRDSP - Tech LiteratureDigger Downhole ToolsNo ratings yet

- ASC Air Starter ST700 SeriesDocument29 pagesASC Air Starter ST700 SeriesLeonid KolesnikovNo ratings yet

- KipasDocument7 pagesKipasmuhdafifiNo ratings yet

- Dormont Hose Manual PDFDocument24 pagesDormont Hose Manual PDFAnonymous TDI8qdYNo ratings yet

- Jandy Check Valve Installation GuideDocument2 pagesJandy Check Valve Installation GuidejupodeNo ratings yet

- Quick Start Guide XR (H, V) S 336-506 CD APP 2954 6440 01 ENDocument2 pagesQuick Start Guide XR (H, V) S 336-506 CD APP 2954 6440 01 ENahmedNo ratings yet

- ADCOM Gfa - 5300manualDocument8 pagesADCOM Gfa - 5300manualLee JacksonNo ratings yet

- Alpha AX20Document7 pagesAlpha AX20Alan JayceeNo ratings yet

- Manuals K Lok Series 360 362 370 372 Keystone en en 5196826 PDFDocument8 pagesManuals K Lok Series 360 362 370 372 Keystone en en 5196826 PDFAnonymous T7zEN6iLHNo ratings yet

- 1288652GT SC PDFDocument1 page1288652GT SC PDFBellameriamNo ratings yet

- HYDRA Owner's ManualDocument12 pagesHYDRA Owner's ManualDiego BeltranNo ratings yet

- Habc InstallationDocument25 pagesHabc InstallationJoaquinDominguezNo ratings yet

- Sea 116 ManualDocument41 pagesSea 116 ManualnkejacqueNo ratings yet

- Bombas CentrifugasDocument4 pagesBombas CentrifugasmasanmartinfNo ratings yet

- AI 4500 Revita Air ManualDocument12 pagesAI 4500 Revita Air ManualRobert TuckerNo ratings yet

- Vrc4500 Ac 安装说明书Document119 pagesVrc4500 Ac 安装说明书wangbiao0109No ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- 7 CSG TallyDocument7 pages7 CSG Tallybedoo54No ratings yet

- Eg 2 CalibDocument1 pageEg 2 Calibbedoo54No ratings yet

- Tank VolumesDocument3 pagesTank Volumesbedoo54No ratings yet

- HangerordfhDocument1 pageHangerordfhbedoo54No ratings yet

- Connector Mapping Guide: Efi P/N GND B+ IGN GND B+ Ign MilDocument1 pageConnector Mapping Guide: Efi P/N GND B+ IGN GND B+ Ign Milbedoo54No ratings yet

- IdrollerordfhDocument1 pageIdrollerordfhbedoo54No ratings yet

- Case Backhoe Loader - 580N (Tier 4)Document326 pagesCase Backhoe Loader - 580N (Tier 4)bedoo54No ratings yet

- Systems Operation 3406Document32 pagesSystems Operation 3406bedoo54No ratings yet

- CAT Engine - C4.4 (For CAT Machines UENR0647-06) .Prefix 444Document8 pagesCAT Engine - C4.4 (For CAT Machines UENR0647-06) .Prefix 444bedoo54No ratings yet

- KOMATSU SAA4D95LE-7 SCR - DOC Emulator Plug and PlayDocument3 pagesKOMATSU SAA4D95LE-7 SCR - DOC Emulator Plug and Playbedoo54No ratings yet

- Failure Code (DX16KA) Fan Pump EPC Sol. DiscDocument2 pagesFailure Code (DX16KA) Fan Pump EPC Sol. Discbedoo54100% (1)

- فلم يلا لقتنت فيك فلملا مسا رييغت نود تن ةحفص يلع ةحفصلا ظفح Mission statement ةحفصلا لفسا فلملا مسا يلع رسيلاا سوملا رزب طغضلا دعب كلذ نكميDocument30 pagesفلم يلا لقتنت فيك فلملا مسا رييغت نود تن ةحفص يلع ةحفصلا ظفح Mission statement ةحفصلا لفسا فلملا مسا يلع رسيلاا سوملا رزب طغضلا دعب كلذ نكميbedoo54No ratings yet

- Latitude-E6420-Xfr - Service Manual - En-UsDocument81 pagesLatitude-E6420-Xfr - Service Manual - En-Usbedoo54No ratings yet

- To NitrogenDocument54 pagesTo Nitrogenbedoo54No ratings yet

- Special Instruction: Procedure For Installing Migration Kits On Certain C9.3-C15 ACERT Tier 4 Interim ProductsDocument1 pageSpecial Instruction: Procedure For Installing Migration Kits On Certain C9.3-C15 ACERT Tier 4 Interim Productsbedoo54No ratings yet

- Dell Latitude E6420 XFR: Real-World RuggedDocument2 pagesDell Latitude E6420 XFR: Real-World Ruggedbedoo54No ratings yet

- Setting The Pace: Hydraulic Crawler DrillsDocument8 pagesSetting The Pace: Hydraulic Crawler Drillsbedoo54100% (1)

- Axis PM User ManualDocument81 pagesAxis PM User Manualbedoo54No ratings yet

- Installation Instructions 31J K M N P Win7 H-2011-0216-HDocument11 pagesInstallation Instructions 31J K M N P Win7 H-2011-0216-Hbedoo54No ratings yet

- Fast Picture Viewer CheatsheetDocument1 pageFast Picture Viewer CheatsheetClay MannixNo ratings yet

- 31 SDMS 13Document27 pages31 SDMS 13I CNo ratings yet

- MiscDocument23 pagesMisccp2489No ratings yet

- Reservoir Vent FiltersDocument8 pagesReservoir Vent FiltersHesham MahdyNo ratings yet

- Web Development Technology ChecklistDocument2 pagesWeb Development Technology ChecklistAlex MercedNo ratings yet

- PM21 2011 Complete E1Document996 pagesPM21 2011 Complete E1Cesar_SERVIXNo ratings yet

- Disquietude Jan10Document3 pagesDisquietude Jan10chenamberNo ratings yet

- Sine Wavefor FormulaDocument158 pagesSine Wavefor FormulanmguravNo ratings yet

- SECTION 3.6 - ACSU - Rev 2016Document55 pagesSECTION 3.6 - ACSU - Rev 2016Osmahadzir OsrinNo ratings yet

- Project ProposalDocument4 pagesProject Proposalapi-318375436No ratings yet

- Common Asked Questions About SolarDocument36 pagesCommon Asked Questions About SolarnairsdocsNo ratings yet

- መጽሐፈ ፈውስDocument399 pagesመጽሐፈ ፈውስHabtamuAlemenew100% (3)

- Autocad Mechanical Detail Brochure enDocument14 pagesAutocad Mechanical Detail Brochure enVeera PandiNo ratings yet

- MoRTH - Pocketbook For Highway Engineers - 2002-2nd Rev PDFDocument222 pagesMoRTH - Pocketbook For Highway Engineers - 2002-2nd Rev PDFanugkumar8100% (1)

- Home GRIDDocument5 pagesHome GRIDramoradoNo ratings yet

- Solar Tracker ProjectDocument4 pagesSolar Tracker ProjectcritestachNo ratings yet

- Gravity Dam Solution KeyDocument3 pagesGravity Dam Solution KeyAmanda SmithNo ratings yet

- Bifpcl Question Solve - 2015: R 5+3+2 10 V 20+20 40 Sor 10 P 40 / (4 X 10)Document7 pagesBifpcl Question Solve - 2015: R 5+3+2 10 V 20+20 40 Sor 10 P 40 / (4 X 10)Mazharul HaqueNo ratings yet

- LPPT 25-2019Document68 pagesLPPT 25-2019Tweed3ANo ratings yet

- Trcking Sheet Drawing Update by 13-6-2023Document4 pagesTrcking Sheet Drawing Update by 13-6-2023Hossam H. HamedNo ratings yet

- Hannah Berk: Professional ExperienceDocument1 pageHannah Berk: Professional ExperienceAnonymous kE9KoTF2UGNo ratings yet

- 3.12 Three Phase AC CircuitsDocument8 pages3.12 Three Phase AC CircuitsnathmanojNo ratings yet

- Brenntag Case StudyDocument2 pagesBrenntag Case StudypriyabratamohantyNo ratings yet

- Selfdocs 600dpi A4Document678 pagesSelfdocs 600dpi A4ErdiApatayNo ratings yet

- Hiperfet Power Mosfets: V I R Ixfh 26N60/Ixft 26N60 600 V 26 A 0.25 Ixfk 28N60 600 V 28 A 0.25 T 250 NsDocument2 pagesHiperfet Power Mosfets: V I R Ixfh 26N60/Ixft 26N60 600 V 26 A 0.25 Ixfk 28N60 600 V 28 A 0.25 T 250 NsAmirNo ratings yet

- Ijigsp V7 N6 6 PDFDocument7 pagesIjigsp V7 N6 6 PDFShantala GiraddiNo ratings yet

- AISC Propiedades y Pesos v14 - TOTALDocument77 pagesAISC Propiedades y Pesos v14 - TOTALAlex RiosNo ratings yet

- Service Manual Ricoh Aficio 470wDocument231 pagesService Manual Ricoh Aficio 470wsangNo ratings yet