Professional Documents

Culture Documents

L18 Failure and Safety

L18 Failure and Safety

Uploaded by

evilgamerspgCopyright:

Available Formats

You might also like

- MCQ CAG StandardsDocument11 pagesMCQ CAG StandardsAjay Singh PhogatNo ratings yet

- Failure Modes and Effect Analysis of Electro-Pneumatics SystemDocument9 pagesFailure Modes and Effect Analysis of Electro-Pneumatics SystemmutluNo ratings yet

- Koh Kiar Sing Wpa (Paper 4)Document32 pagesKoh Kiar Sing Wpa (Paper 4)Muhamad HarizNo ratings yet

- Medicinal PlantsDocument10 pagesMedicinal PlantsAnurag GoelNo ratings yet

- Failure Mode and Effects Analysis of Hotwell System Motor Operated Butterfly ValveDocument19 pagesFailure Mode and Effects Analysis of Hotwell System Motor Operated Butterfly ValveBalan SelvanNo ratings yet

- Eggert - Ch10Document31 pagesEggert - Ch10GeorgeNo ratings yet

- Hirarc of Soil Investigation at Gadang Construction SiteDocument21 pagesHirarc of Soil Investigation at Gadang Construction Sitesyafiq ishakNo ratings yet

- Anirudh Acharya FA Exp 1Document5 pagesAnirudh Acharya FA Exp 1Anirudh AcharyaNo ratings yet

- 13 Fmea 1Document36 pages13 Fmea 1hello2er.ajayNo ratings yet

- Failure Mode and Effects Analysis of PCB For Quality Control ProcessDocument10 pagesFailure Mode and Effects Analysis of PCB For Quality Control Processapurav_27No ratings yet

- FMEADocument3 pagesFMEAyadiNo ratings yet

- FmeaDocument6 pagesFmeaUmerNo ratings yet

- Prediction and Assessment of LHD Machine Breakdowns Using Failure Mode Effect Analysis (Fmea)Document8 pagesPrediction and Assessment of LHD Machine Breakdowns Using Failure Mode Effect Analysis (Fmea)julio beniscelliNo ratings yet

- Software Risk ManagementDocument20 pagesSoftware Risk ManagementAye CleofasNo ratings yet

- FMEA Failure Mode Effect AnalysisDocument61 pagesFMEA Failure Mode Effect AnalysisAbhijeet RandhirNo ratings yet

- 3 FmeaDocument24 pages3 FmeaSiddhant TemghareNo ratings yet

- Design and Process Failure Mode and Effect Analysis (Dfmea & Pfmea)Document19 pagesDesign and Process Failure Mode and Effect Analysis (Dfmea & Pfmea)Mohammed KassemNo ratings yet

- Hydro Static Test: Risk AssessmentDocument10 pagesHydro Static Test: Risk Assessmentmohammed a hseNo ratings yet

- Safety at OffshoreDocument51 pagesSafety at OffshoreRavi Kant TripathiNo ratings yet

- FEMEA Ranking TablesDocument3 pagesFEMEA Ranking TablesAhmed KsibiNo ratings yet

- Support Your Business Goals With SKF Maintenance Strategy ReviewDocument4 pagesSupport Your Business Goals With SKF Maintenance Strategy ReviewAndresNo ratings yet

- E P R I 4.0 E: Valuation of Rocess Isks in Ndustry NvironmentDocument10 pagesE P R I 4.0 E: Valuation of Rocess Isks in Ndustry NvironmentxxxxxNo ratings yet

- Cost Based Process Failure Mode Effect Analysis of Blanking, Forming and Piercing of Hinge L NovaDocument6 pagesCost Based Process Failure Mode Effect Analysis of Blanking, Forming and Piercing of Hinge L NovaRahul MishraNo ratings yet

- "Fmea & Case Study": Kelompok: Rohmat Setiawan Titin NuryawatiDocument41 pages"Fmea & Case Study": Kelompok: Rohmat Setiawan Titin Nuryawatirohmat_setiawan77No ratings yet

- SF 011 Hazard Risk AseessmentDocument3 pagesSF 011 Hazard Risk AseessmentShahid RazaNo ratings yet

- Fmea Notes-1Document6 pagesFmea Notes-1sagarvadhel78No ratings yet

- Failure Management in Distribution Logistics Applying FMEA ApproachDocument7 pagesFailure Management in Distribution Logistics Applying FMEA ApproachKamal RajNo ratings yet

- Topic 4 Relevant Notes Part 2 - FireExtinguisherDocument18 pagesTopic 4 Relevant Notes Part 2 - FireExtinguisherNazrina RinaNo ratings yet

- Risk ManagementDocument5 pagesRisk ManagementmominNo ratings yet

- Generic RA FSDocument5 pagesGeneric RA FSStephenNo ratings yet

- STM KPI Contractor 2023 DraftDocument32 pagesSTM KPI Contractor 2023 Draftsafety.acm.askimahciwimandiriNo ratings yet

- 20040616-Zero Human Errors (112pag)Document112 pages20040616-Zero Human Errors (112pag)gonzaloNo ratings yet

- Risk Assessment For Blinding Concrete - 01Document6 pagesRisk Assessment For Blinding Concrete - 01Bulent Ak100% (1)

- Evaluation Chart For Ranking Equipment Edge MillingDocument6 pagesEvaluation Chart For Ranking Equipment Edge MillingParesh ValaNo ratings yet

- Fmea Failure Mode and Effects Analysis: Adapted From Presentation by Dr. StamperDocument23 pagesFmea Failure Mode and Effects Analysis: Adapted From Presentation by Dr. Stamperhasan_taşkınNo ratings yet

- 8-8 Nail-Risk Management Report PDFDocument12 pages8-8 Nail-Risk Management Report PDFDiana Rodriguez ParodiNo ratings yet

- Dfmea TemplateDocument5 pagesDfmea TemplateHerbert WeigeltNo ratings yet

- Risk Assessment For CONCRETE WORKS - SUBSTRUCTURE - 01Document6 pagesRisk Assessment For CONCRETE WORKS - SUBSTRUCTURE - 01Bulent AkNo ratings yet

- Irjet V8i4373Document5 pagesIrjet V8i4373gadhang dewanggaNo ratings yet

- WS4 - Risk Estimation & EvaluationDocument6 pagesWS4 - Risk Estimation & EvaluationKaren Bangibang WalayNo ratings yet

- WS4 - Risk Estimation & EvaluationDocument6 pagesWS4 - Risk Estimation & EvaluationKaren Bangibang WalayNo ratings yet

- 80DA0AAAd01 PDFDocument19 pages80DA0AAAd01 PDFdelviyolandaNo ratings yet

- Risk Assessment For Excavation and BackfillingDocument5 pagesRisk Assessment For Excavation and BackfillingBulent AkNo ratings yet

- A19-Article 1673103804Document11 pagesA19-Article 1673103804Safiye SencerNo ratings yet

- AMEF Entrenamiento 1st StageDocument41 pagesAMEF Entrenamiento 1st StagevictorvillegasNo ratings yet

- Lecture 11 - Six Sigma 1 - FMEADocument67 pagesLecture 11 - Six Sigma 1 - FMEAMenadžment Vusb100% (1)

- SFSDFDocument6 pagesSFSDFali shahNo ratings yet

- SeverityDocument10 pagesSeverityVijayamalar AmruthalingamNo ratings yet

- HIRARC Table Dosh OfficeDocument4 pagesHIRARC Table Dosh OfficeeimanmunirahNo ratings yet

- Risk Assessment / Job Hazard Analysis (Jha) FormDocument7 pagesRisk Assessment / Job Hazard Analysis (Jha) FormZameel KhanNo ratings yet

- RGU MEng Risk Presentation 2910017Document28 pagesRGU MEng Risk Presentation 2910017iJordanScribdNo ratings yet

- 31.0.11 ALR - Temporary Electrical InstallationDocument3 pages31.0.11 ALR - Temporary Electrical InstallationGerritNo ratings yet

- All+Rating+Guidelines ServiceDocument4 pagesAll+Rating+Guidelines ServiceSegu PratheekNo ratings yet

- Aea 1305 WC El MS 0002Document14 pagesAea 1305 WC El MS 0002Adil HasanovNo ratings yet

- T05 Fault Tree IntroductionDocument149 pagesT05 Fault Tree IntroductionEkky BudiyantoNo ratings yet

- Patient Records System 2Document12 pagesPatient Records System 2bhargaviNo ratings yet

- 203 LSS Gbo - FmeaDocument47 pages203 LSS Gbo - FmeaRocker byNo ratings yet

- 333 - Element 5.02.78 Working On Gantries and Heights (EPCM)Document8 pages333 - Element 5.02.78 Working On Gantries and Heights (EPCM)contrax8No ratings yet

- Risk AnalysisDocument5 pagesRisk AnalysisZack ANo ratings yet

- Gas Cylinders Risk AssessmentDocument3 pagesGas Cylinders Risk AssessmentMAB AliNo ratings yet

- Equipment Criticality White PaperDocument6 pagesEquipment Criticality White Papercderin2000No ratings yet

- Introduction to Enterprise Risk Management: A Guide to Risk Analysis and Control for Small and Medium EnterprisesFrom EverandIntroduction to Enterprise Risk Management: A Guide to Risk Analysis and Control for Small and Medium EnterprisesNo ratings yet

- Concept of C ProgrammingDocument74 pagesConcept of C ProgrammingAbhishek KumarNo ratings yet

- BSC 6600Document11 pagesBSC 6600Naldo Baskara ArmandNo ratings yet

- Flat Iron BuildingDocument17 pagesFlat Iron BuildingGargi KoulNo ratings yet

- ADIS - COURSE Information SheetDocument1 pageADIS - COURSE Information SheetPriteshJangamNo ratings yet

- Aerospace Power System For A 1U Cubesat Built by SSU StudentsDocument1 pageAerospace Power System For A 1U Cubesat Built by SSU StudentsWes WatsonNo ratings yet

- Imagist Poems - Class of 2021 1.: PetrichorDocument3 pagesImagist Poems - Class of 2021 1.: PetrichorPaulaNo ratings yet

- Water Pollution SEDocument4 pagesWater Pollution SEaveri0% (1)

- 1438 The Development of Sociology As A DisciplineDocument3 pages1438 The Development of Sociology As A Disciplinejeneille belfonNo ratings yet

- Membrane Potential Summary - FinalDocument6 pagesMembrane Potential Summary - FinalAlfred BajarNo ratings yet

- 12 Speed Gear BoxDocument19 pages12 Speed Gear BoxMurugesan Ramesh100% (1)

- Tashni-Ann Dubroy Professional ResumeDocument5 pagesTashni-Ann Dubroy Professional ResumeKeshaNo ratings yet

- SDL1909 Monstrous Pages - Genius Loci (2019)Document21 pagesSDL1909 Monstrous Pages - Genius Loci (2019)Aqua Yang0% (1)

- Microsoft Access 2016 - Stewart MelartDocument74 pagesMicrosoft Access 2016 - Stewart Melartmaidanez_ro324133% (3)

- Olompia UnderpassDocument60 pagesOlompia UnderpassEngineeri TadiyosNo ratings yet

- Q4 ICT CSS 7 - 8 Week1Document4 pagesQ4 ICT CSS 7 - 8 Week1melanieNo ratings yet

- Chapter9 PDFDocument28 pagesChapter9 PDFSayantan RoyChowdhuryNo ratings yet

- Boss FDR-1 Fender '65 Deluxe Reverb - Ranked #49 in Multi Effects Pedals EquipboardDocument1 pageBoss FDR-1 Fender '65 Deluxe Reverb - Ranked #49 in Multi Effects Pedals EquipboardPietro RainoneNo ratings yet

- Resistance Welding Applications and ControlsDocument65 pagesResistance Welding Applications and ControlssunhuynhNo ratings yet

- Consultant: Project: Designed By: Case: Date: Design of Masonry Retaining WallDocument4 pagesConsultant: Project: Designed By: Case: Date: Design of Masonry Retaining WallSamuel Gezahegn100% (1)

- Ozone Layer Depletion & Greenhouse EffectDocument34 pagesOzone Layer Depletion & Greenhouse EffectAhad Kanak ProttoyNo ratings yet

- Handling Missing ValueDocument12 pagesHandling Missing ValueNarendra SinghNo ratings yet

- Packing Slip Template ExcelDocument15 pagesPacking Slip Template ExcelAlan Isai Valdez CastrejónNo ratings yet

- Metrosils For High Impedance RelaysDocument4 pagesMetrosils For High Impedance RelaysPramod B.WankhadeNo ratings yet

- Python-Cluster Documentation: Release 1.4.2Document26 pagesPython-Cluster Documentation: Release 1.4.2César Anderson HNNo ratings yet

- 32-Bit Power Architecture MCU For Automotive General Purpose Applications - Chorus FamilyDocument139 pages32-Bit Power Architecture MCU For Automotive General Purpose Applications - Chorus FamilyEcus ElectronicsNo ratings yet

- Aco 08 DS 2020 08 31 en A4Document2 pagesAco 08 DS 2020 08 31 en A4omarrg7No ratings yet

- Exercise 2Document19 pagesExercise 2Jenn AguilarNo ratings yet

L18 Failure and Safety

L18 Failure and Safety

Uploaded by

evilgamerspgCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

L18 Failure and Safety

L18 Failure and Safety

Uploaded by

evilgamerspgCopyright:

Available Formats

ENG 1430

Design for X: Failure and Safety

Thursday, Mar. 14, 2024

2

Objective

• By the end of today’s class, you will be able to:

• Give examples of engineering failures

• Calculate a Risk Priority Number for FMEA

• Recommend safety considerations in engineering design

ENG 1430 | 2024

3

Agenda

• FMEA

• Safety Definitions

• Safety in Project 2

• Engineering Failures

ENG 1430 | 2024

6

How do Engineers Fail?

• Knowingly doing the wrong thing

• BIG mistake; ethical wrongdoing

• Failure to gather the right data

• Wrong priority

• Solving the wrong problem

• Poor calculations

• Not acting when they should

ENG 1430 | 2024

7

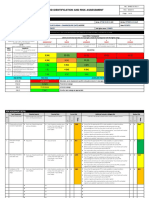

Hazard Analysis Procedures (Identifying Failure Points)

• To identify and mitigate risks, some strategies

may be employed:

• Failure mode and effects analysis (FMEA)

• Fault tree analysis

• Risk score analysis

• Task analysis

ENG 1430 | 2024

8

Failure Mode and Effects Analysis (FMEA)

• FMEA: Method to systematically identify and

correct potential product or process

deficiencies before they occur

• Eliminate the causes of the potential failure

modes and/or reduce the severity of the

failure (ex. Crack progression identified

rather than immediate breakage); Mitigation

Strategies

• “Measure” risk with a Risk Priority Number

ENG 1430 | 2024

9

Measuring the Risk of a Failure Mode

• Risk Priority Number (RPN): a rating for each

mode of failure

𝑅𝑃𝑁 = 𝑆𝑒𝑣𝑒𝑟𝑖𝑡𝑦 𝑅𝑎𝑡𝑖𝑛𝑔 𝑂𝑐𝑐𝑢𝑟𝑟𝑒𝑛𝑐𝑒 𝑟𝑎𝑡𝑖𝑛𝑔 𝐷𝑒𝑡𝑒𝑐𝑡𝑖𝑜𝑛 𝑟𝑎𝑡𝑖𝑛𝑔

= 𝑆𝑂𝐷

• S, O, D rated from 1-10

• RPN will range from 1 (low risk) to 1000 (high

risk)

ENG 1430 | 2024

10

Severity Rating (S) – How severe is the failure?

Severity (S)

Rating Type of effects Description

Causes injury to people, property and or the

10 Catastrophic Example:

environment

Causes damage to product, property or Phone

9 Extremely Harmful

environment update

8 Very Harmful Causes damage to product causing

7 Harmful Major degradation of function random

6 Moderate Causes partial malfunction of product restarts every

5 Significant Performance loss causes customer complaints 2-4 hours

4 Annoying Loss of function is annoying, cannot be overcome

3 Minor Some loss of performance, but can be overcome S~4

2 Insignificant Very little function degradation

1 None No noticeable effects in function or harm to others

ENG 1430 | 2024

11

Occurrence Rating (O) – How often is the failure likely to occur?

Occurence (O)

Rating Likelihood Description

10 Expected >30 % > One per day Example:

9 Very likely 30 % (3 per 10) Phone

8 Probable 5 % (5 per 100) One per week update

7 Occasional 1 % ( 1 per 100) One per month causing

6 More plausible 0.3 % (3 per 1,000) One per three months random

5 Plausible restarts every

5

4 Remote 0.006 % (6 per 10 ) One per year 2-4 hours

7

3 Unlikely 0.00006 % (6 per 10 ) One per three years

2 Very unlikely

9 O ~ 10

1 Improbable < 2 per 10 events > five years per failure

ENG 1430 | 2024

12

Detection Rating (D) – How easy is the fault to detect before failure?

Detection (D)

Rating Detectability Description

10 Impossible Impossible to detect, or no inspection Example:

9 Very rare Phone

8 Rare update

7 Possible Some chance of detecting, or 50% inspection causing

6 Quite possible random

5 Somewhat likely restarts

4 Likely Quite likely to detect, or 75% inspection every 2-4

3 Quite likely hours

2 Almost certain

1 Certain Will be detected, or 100% inspection D~6

ENG 1430 | 2024

13

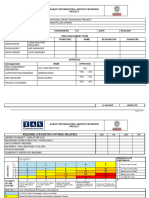

FMEA Table (often in engineering design reports)

Severity (S) Occurrence (O) Detection (D)

S O controls D Recommended

Failure mode Effects Rating Causes Rating tests Rating RPN Action

Random restart 3 10 6 180 Mitigate risk:

revert to the

previous

software

version.

Reduce

severity:

Factory reset.

ENG 1430 | 2024

14

FMEA Steps

1. Identify failure modes (how can things fail?)

2. Evaluate the effects on the system

3. Define and prioritize actions to correct the

problems

• Prioritize the problem items (RPN = SOD)

• Define action items

4. Track corrective actions (mitigation strategies)

and their effects – did the changes work?

• Assign responsibility and monitor

5. Document the entire decision process

ENG 1430 | 2024

15

General Guidelines for Safe Products & Systems

• Perform appropriate analyses (FMEA, fault tree,

risk score, etc.)

• Comply with published standards

• Use state-of-the-art technology

• Include reasonable safety features or devices

• Consider how the user might misuse the

product

• Consider hidden dangers that might surprise

the user

ENG 1430 | 2024

16

General Guidelines for Safe Products & Systems (cont’d)

• Consider variations in materials or manufacturing

processes, or effects of wear

• Carry out appropriate testing and interpret

results correctly

• Provide adequate warnings

• Implement superior quality control

• Document everything

ENG 1430 | 2024

17

Safety Definitions

• Fail-Safe Design: to ensure that a product failure will not

result in damage to people, the product itself, or the

environment

ENG 1430 | 2024

18

Safety Definitions – Fail-Safe Types

• Fail-Passive Design: reduces the product to its lowest

level of energy so product cannot operate until

corrective action is taken

• Fail-Active Design: the product remains energized

but in a safe mode until corrective action is taken

• Fail-Operational Design: product continues to

operate with reasonable safety until corrective action

is possible

ENG 1430 | 2024

21

Safety Definitions

• Emergency Shut-Off Devices: allows the

immediate stopping of a machine once a person,

or other foreign objects, becomes caught by the

machine

• Engineering Controls: passive measures designed

into the work environment to prevent contact

with potential hazards.

• Administrative Controls: attempt to minimize

exposure, implement proper housekeeping

practices, and devise appropriate worker training.

ENG 1430 | 2024

22

Take-Away

Make it easier to do

the RIGHT thing (the SAFE thing)

than to do the WRONG thing.

ENG 1430 | 2024

23

Safety in Project 2

ENG 1430 | 2024

24

Reliability - Rubric

• “Reliability: The system functions consistently

without breakdown or errors. Consideration of

fail-safe mechanisms was given in the case of

technical issues.”

ENG 1430 | 2024

25

What are some potential failure points in your system?

• Hardware errors

• Sensor failure?

• Loose wire?

• Environmental factors

• Clog in the line?

• Displaced hardware?

• Leak?

ENG 1430 | 2024

26

How might you design for reliability in your project?

• Failure Minimization: minimize the consequences

of failure using four methods:

• Monitoring devices

If you cannot build

• Warning devices your safety

• Safety factors and margins mechanism, what

recommendations

• Failure rate reduction can you make?

ENG 1430 | 2024

27

Engineering Failures

ENG 1430 | 2024

28

Engineering Failures

• Protecting the public is an engineer’s primary

responsibility.

• Learning from past failures ensures we do not

make the same mistakes twice.

• System of checks and balances exists in the

profession to reduce risk of catastrophic failures

• Standards, codes, bylaws, multi-level review

process

ENG 1430 | 2024

29

Quebec Bridge Collapse (1907, 1916)

ENG 1430 | 2024

30

Quebec Bridge Collapse

• August 29, 1907

• Quebec City, Canada

• Cause:

• Misalignment in fastener locations –

forced into place, causing

deformation (bending)

• Calculation errors and overlooked

onsite concerns

• Result: 75 worker fatalities, 11 injured

ENG 1430 | 2024

31

Quebec Bridge Collapse – Episode 2

• September 11, 1916

• Quebec City, Canada

• Cause:

• Material failure

• Chief engineer alerted of the

issue 6 weeks before the

incident but no action taken.

• Result: 13 worker fatalities

ENG 1430 | 2024

32

Quebec Bridge Today

• August 1919 completed and remains today – major

access car/pedestrian/cyclist access across St.

Lawrence River

ENG 1430 | 2024

33

Greater Winnipeg Water District Aqueduct

(1913 – Present)

ENG 1430 | 2024

34

GWWD

• Winnipeg in need of clean drinking water

• Previously, water taken from Assiniboine river

(river contamination & Typhoid outbreaks)

• Then artesian wells were constructed (mineral-

heavy water & inconsistent yield)

• 1912: Engineers identified Shoal Lake for its soft

water and elevated position from Winnipeg (91 m

higher)

ENG 1430 | 2024

35

Aqueduct Facts

• Aqueduct construction

began: 1914

• 154 km from Shoal Lake

to Deacon Reservoir

• Original Ojibwa village

of Shoal Lake 40 First

Nation was displaced

and moved to a man-

made island

ENG 1430 | 2024

36

Results

• For much of the 20th century, this project was seen as an

engineering “success”

• Good water quality, structural integrity, economic

consideration for Winnipeg residents, work done in 3 years

• In reality: Shoal Lake 40 First Nation and the nearby

Iskatewizaagegan #39 Independent First Nation suffered:

• Cultural, spiritual, and financial damage

ENG 1430 | 2024

37

Results

• Furthermore:

• Shoal Lake 40 under boil water advisory from 1997 – 2017

• No road to community: this restricted access to move supplies

and build water treatment facility locally, on top of daily

challenges of transport

• Engineering failure – design decisions made in violation of human

rights

ENG 1430 | 2024

38

Today

• 2017 (almost 100 years since aqueduct built): Freedom road

constructed to ease community access to mainland

ENG 1430 | 2024

39

The Legend of the Iron Ring

• When you complete an engineering degree in

Canada, you are awarded an Iron Ring at an

official ceremony

• Worn on the little finger of your dominant

hand Serves as a

• Symbol of a Canadian accredited engineer reminder of our

• Legend has it that the iron used in the rings was ethical

forged from the steel of the collapsed Quebec responsibility

bridge to signify the weight and responsibility of in the

the profession. profession

ENG 1430 | 2024

41

Take-Away

An Engineer’s responsibility is to protect the public.

Prioritize public safety and ethical responsibility in

engineering design.

ENG 1430 | 2024

42

43

References and Further Reading

GWWD:

• https://www.cbc.ca/news/canada/manitoba/win

nipeg-aqueduct-shoal-lake-100-years-1.5152678

• https://www.frontiersin.org/articles/10.3389/fed

uc.2023.1177035/full

Quebec Bridge Collapse

• https://www.youtube.com/watch?v=e4DTMe0hu

XM

You might also like

- MCQ CAG StandardsDocument11 pagesMCQ CAG StandardsAjay Singh PhogatNo ratings yet

- Failure Modes and Effect Analysis of Electro-Pneumatics SystemDocument9 pagesFailure Modes and Effect Analysis of Electro-Pneumatics SystemmutluNo ratings yet

- Koh Kiar Sing Wpa (Paper 4)Document32 pagesKoh Kiar Sing Wpa (Paper 4)Muhamad HarizNo ratings yet

- Medicinal PlantsDocument10 pagesMedicinal PlantsAnurag GoelNo ratings yet

- Failure Mode and Effects Analysis of Hotwell System Motor Operated Butterfly ValveDocument19 pagesFailure Mode and Effects Analysis of Hotwell System Motor Operated Butterfly ValveBalan SelvanNo ratings yet

- Eggert - Ch10Document31 pagesEggert - Ch10GeorgeNo ratings yet

- Hirarc of Soil Investigation at Gadang Construction SiteDocument21 pagesHirarc of Soil Investigation at Gadang Construction Sitesyafiq ishakNo ratings yet

- Anirudh Acharya FA Exp 1Document5 pagesAnirudh Acharya FA Exp 1Anirudh AcharyaNo ratings yet

- 13 Fmea 1Document36 pages13 Fmea 1hello2er.ajayNo ratings yet

- Failure Mode and Effects Analysis of PCB For Quality Control ProcessDocument10 pagesFailure Mode and Effects Analysis of PCB For Quality Control Processapurav_27No ratings yet

- FMEADocument3 pagesFMEAyadiNo ratings yet

- FmeaDocument6 pagesFmeaUmerNo ratings yet

- Prediction and Assessment of LHD Machine Breakdowns Using Failure Mode Effect Analysis (Fmea)Document8 pagesPrediction and Assessment of LHD Machine Breakdowns Using Failure Mode Effect Analysis (Fmea)julio beniscelliNo ratings yet

- Software Risk ManagementDocument20 pagesSoftware Risk ManagementAye CleofasNo ratings yet

- FMEA Failure Mode Effect AnalysisDocument61 pagesFMEA Failure Mode Effect AnalysisAbhijeet RandhirNo ratings yet

- 3 FmeaDocument24 pages3 FmeaSiddhant TemghareNo ratings yet

- Design and Process Failure Mode and Effect Analysis (Dfmea & Pfmea)Document19 pagesDesign and Process Failure Mode and Effect Analysis (Dfmea & Pfmea)Mohammed KassemNo ratings yet

- Hydro Static Test: Risk AssessmentDocument10 pagesHydro Static Test: Risk Assessmentmohammed a hseNo ratings yet

- Safety at OffshoreDocument51 pagesSafety at OffshoreRavi Kant TripathiNo ratings yet

- FEMEA Ranking TablesDocument3 pagesFEMEA Ranking TablesAhmed KsibiNo ratings yet

- Support Your Business Goals With SKF Maintenance Strategy ReviewDocument4 pagesSupport Your Business Goals With SKF Maintenance Strategy ReviewAndresNo ratings yet

- E P R I 4.0 E: Valuation of Rocess Isks in Ndustry NvironmentDocument10 pagesE P R I 4.0 E: Valuation of Rocess Isks in Ndustry NvironmentxxxxxNo ratings yet

- Cost Based Process Failure Mode Effect Analysis of Blanking, Forming and Piercing of Hinge L NovaDocument6 pagesCost Based Process Failure Mode Effect Analysis of Blanking, Forming and Piercing of Hinge L NovaRahul MishraNo ratings yet

- "Fmea & Case Study": Kelompok: Rohmat Setiawan Titin NuryawatiDocument41 pages"Fmea & Case Study": Kelompok: Rohmat Setiawan Titin Nuryawatirohmat_setiawan77No ratings yet

- SF 011 Hazard Risk AseessmentDocument3 pagesSF 011 Hazard Risk AseessmentShahid RazaNo ratings yet

- Fmea Notes-1Document6 pagesFmea Notes-1sagarvadhel78No ratings yet

- Failure Management in Distribution Logistics Applying FMEA ApproachDocument7 pagesFailure Management in Distribution Logistics Applying FMEA ApproachKamal RajNo ratings yet

- Topic 4 Relevant Notes Part 2 - FireExtinguisherDocument18 pagesTopic 4 Relevant Notes Part 2 - FireExtinguisherNazrina RinaNo ratings yet

- Risk ManagementDocument5 pagesRisk ManagementmominNo ratings yet

- Generic RA FSDocument5 pagesGeneric RA FSStephenNo ratings yet

- STM KPI Contractor 2023 DraftDocument32 pagesSTM KPI Contractor 2023 Draftsafety.acm.askimahciwimandiriNo ratings yet

- 20040616-Zero Human Errors (112pag)Document112 pages20040616-Zero Human Errors (112pag)gonzaloNo ratings yet

- Risk Assessment For Blinding Concrete - 01Document6 pagesRisk Assessment For Blinding Concrete - 01Bulent Ak100% (1)

- Evaluation Chart For Ranking Equipment Edge MillingDocument6 pagesEvaluation Chart For Ranking Equipment Edge MillingParesh ValaNo ratings yet

- Fmea Failure Mode and Effects Analysis: Adapted From Presentation by Dr. StamperDocument23 pagesFmea Failure Mode and Effects Analysis: Adapted From Presentation by Dr. Stamperhasan_taşkınNo ratings yet

- 8-8 Nail-Risk Management Report PDFDocument12 pages8-8 Nail-Risk Management Report PDFDiana Rodriguez ParodiNo ratings yet

- Dfmea TemplateDocument5 pagesDfmea TemplateHerbert WeigeltNo ratings yet

- Risk Assessment For CONCRETE WORKS - SUBSTRUCTURE - 01Document6 pagesRisk Assessment For CONCRETE WORKS - SUBSTRUCTURE - 01Bulent AkNo ratings yet

- Irjet V8i4373Document5 pagesIrjet V8i4373gadhang dewanggaNo ratings yet

- WS4 - Risk Estimation & EvaluationDocument6 pagesWS4 - Risk Estimation & EvaluationKaren Bangibang WalayNo ratings yet

- WS4 - Risk Estimation & EvaluationDocument6 pagesWS4 - Risk Estimation & EvaluationKaren Bangibang WalayNo ratings yet

- 80DA0AAAd01 PDFDocument19 pages80DA0AAAd01 PDFdelviyolandaNo ratings yet

- Risk Assessment For Excavation and BackfillingDocument5 pagesRisk Assessment For Excavation and BackfillingBulent AkNo ratings yet

- A19-Article 1673103804Document11 pagesA19-Article 1673103804Safiye SencerNo ratings yet

- AMEF Entrenamiento 1st StageDocument41 pagesAMEF Entrenamiento 1st StagevictorvillegasNo ratings yet

- Lecture 11 - Six Sigma 1 - FMEADocument67 pagesLecture 11 - Six Sigma 1 - FMEAMenadžment Vusb100% (1)

- SFSDFDocument6 pagesSFSDFali shahNo ratings yet

- SeverityDocument10 pagesSeverityVijayamalar AmruthalingamNo ratings yet

- HIRARC Table Dosh OfficeDocument4 pagesHIRARC Table Dosh OfficeeimanmunirahNo ratings yet

- Risk Assessment / Job Hazard Analysis (Jha) FormDocument7 pagesRisk Assessment / Job Hazard Analysis (Jha) FormZameel KhanNo ratings yet

- RGU MEng Risk Presentation 2910017Document28 pagesRGU MEng Risk Presentation 2910017iJordanScribdNo ratings yet

- 31.0.11 ALR - Temporary Electrical InstallationDocument3 pages31.0.11 ALR - Temporary Electrical InstallationGerritNo ratings yet

- All+Rating+Guidelines ServiceDocument4 pagesAll+Rating+Guidelines ServiceSegu PratheekNo ratings yet

- Aea 1305 WC El MS 0002Document14 pagesAea 1305 WC El MS 0002Adil HasanovNo ratings yet

- T05 Fault Tree IntroductionDocument149 pagesT05 Fault Tree IntroductionEkky BudiyantoNo ratings yet

- Patient Records System 2Document12 pagesPatient Records System 2bhargaviNo ratings yet

- 203 LSS Gbo - FmeaDocument47 pages203 LSS Gbo - FmeaRocker byNo ratings yet

- 333 - Element 5.02.78 Working On Gantries and Heights (EPCM)Document8 pages333 - Element 5.02.78 Working On Gantries and Heights (EPCM)contrax8No ratings yet

- Risk AnalysisDocument5 pagesRisk AnalysisZack ANo ratings yet

- Gas Cylinders Risk AssessmentDocument3 pagesGas Cylinders Risk AssessmentMAB AliNo ratings yet

- Equipment Criticality White PaperDocument6 pagesEquipment Criticality White Papercderin2000No ratings yet

- Introduction to Enterprise Risk Management: A Guide to Risk Analysis and Control for Small and Medium EnterprisesFrom EverandIntroduction to Enterprise Risk Management: A Guide to Risk Analysis and Control for Small and Medium EnterprisesNo ratings yet

- Concept of C ProgrammingDocument74 pagesConcept of C ProgrammingAbhishek KumarNo ratings yet

- BSC 6600Document11 pagesBSC 6600Naldo Baskara ArmandNo ratings yet

- Flat Iron BuildingDocument17 pagesFlat Iron BuildingGargi KoulNo ratings yet

- ADIS - COURSE Information SheetDocument1 pageADIS - COURSE Information SheetPriteshJangamNo ratings yet

- Aerospace Power System For A 1U Cubesat Built by SSU StudentsDocument1 pageAerospace Power System For A 1U Cubesat Built by SSU StudentsWes WatsonNo ratings yet

- Imagist Poems - Class of 2021 1.: PetrichorDocument3 pagesImagist Poems - Class of 2021 1.: PetrichorPaulaNo ratings yet

- Water Pollution SEDocument4 pagesWater Pollution SEaveri0% (1)

- 1438 The Development of Sociology As A DisciplineDocument3 pages1438 The Development of Sociology As A Disciplinejeneille belfonNo ratings yet

- Membrane Potential Summary - FinalDocument6 pagesMembrane Potential Summary - FinalAlfred BajarNo ratings yet

- 12 Speed Gear BoxDocument19 pages12 Speed Gear BoxMurugesan Ramesh100% (1)

- Tashni-Ann Dubroy Professional ResumeDocument5 pagesTashni-Ann Dubroy Professional ResumeKeshaNo ratings yet

- SDL1909 Monstrous Pages - Genius Loci (2019)Document21 pagesSDL1909 Monstrous Pages - Genius Loci (2019)Aqua Yang0% (1)

- Microsoft Access 2016 - Stewart MelartDocument74 pagesMicrosoft Access 2016 - Stewart Melartmaidanez_ro324133% (3)

- Olompia UnderpassDocument60 pagesOlompia UnderpassEngineeri TadiyosNo ratings yet

- Q4 ICT CSS 7 - 8 Week1Document4 pagesQ4 ICT CSS 7 - 8 Week1melanieNo ratings yet

- Chapter9 PDFDocument28 pagesChapter9 PDFSayantan RoyChowdhuryNo ratings yet

- Boss FDR-1 Fender '65 Deluxe Reverb - Ranked #49 in Multi Effects Pedals EquipboardDocument1 pageBoss FDR-1 Fender '65 Deluxe Reverb - Ranked #49 in Multi Effects Pedals EquipboardPietro RainoneNo ratings yet

- Resistance Welding Applications and ControlsDocument65 pagesResistance Welding Applications and ControlssunhuynhNo ratings yet

- Consultant: Project: Designed By: Case: Date: Design of Masonry Retaining WallDocument4 pagesConsultant: Project: Designed By: Case: Date: Design of Masonry Retaining WallSamuel Gezahegn100% (1)

- Ozone Layer Depletion & Greenhouse EffectDocument34 pagesOzone Layer Depletion & Greenhouse EffectAhad Kanak ProttoyNo ratings yet

- Handling Missing ValueDocument12 pagesHandling Missing ValueNarendra SinghNo ratings yet

- Packing Slip Template ExcelDocument15 pagesPacking Slip Template ExcelAlan Isai Valdez CastrejónNo ratings yet

- Metrosils For High Impedance RelaysDocument4 pagesMetrosils For High Impedance RelaysPramod B.WankhadeNo ratings yet

- Python-Cluster Documentation: Release 1.4.2Document26 pagesPython-Cluster Documentation: Release 1.4.2César Anderson HNNo ratings yet

- 32-Bit Power Architecture MCU For Automotive General Purpose Applications - Chorus FamilyDocument139 pages32-Bit Power Architecture MCU For Automotive General Purpose Applications - Chorus FamilyEcus ElectronicsNo ratings yet

- Aco 08 DS 2020 08 31 en A4Document2 pagesAco 08 DS 2020 08 31 en A4omarrg7No ratings yet

- Exercise 2Document19 pagesExercise 2Jenn AguilarNo ratings yet