Professional Documents

Culture Documents

Magnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%

Magnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%

Uploaded by

fogok72408Copyright:

Available Formats

You might also like

- BS 8297 2017Document64 pagesBS 8297 2017MOHAMMAD100% (4)

- TE32+MANUAL (FZ Transm) (041-060)Document20 pagesTE32+MANUAL (FZ Transm) (041-060)Marco Guachun100% (1)

- Dwyer 2000Document4 pagesDwyer 2000Saravana KumarNo ratings yet

- Magnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%Document4 pagesMagnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%RyanNo ratings yet

- Magnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%Document4 pagesMagnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%Johan VBNo ratings yet

- Magnehelic Differential Pressure Gages: SolutionsDocument2 pagesMagnehelic Differential Pressure Gages: Solutionsdaniel GasperinNo ratings yet

- Series 2000 - Magnahelic Differential Pressure GaugeDocument2 pagesSeries 2000 - Magnahelic Differential Pressure GaugeKoteswara RaoNo ratings yet

- 004 005 D PDFDocument2 pages004 005 D PDFRangga Prasetya BaitullahNo ratings yet

- Serie 2000Document2 pagesSerie 2000Fredy MurilloNo ratings yet

- MAGNEHELICDocument2 pagesMAGNEHELICCésar Arturo TorresNo ratings yet

- Magnehelic-Gage Series 2000Document2 pagesMagnehelic-Gage Series 2000Jonathan GanNo ratings yet

- Purafil Side Access BulletinDocument5 pagesPurafil Side Access BulletinPablo TorresNo ratings yet

- Dwyer 2300 250pa Pressure Gauge DatasheetDocument2 pagesDwyer 2300 250pa Pressure Gauge DatasheetGorch Marroko100% (1)

- Fr. No.: +-+ - All Angles All Decimal Dimensions Standard Tolerances Unless Noted: 1 .005Document1 pageFr. No.: +-+ - All Angles All Decimal Dimensions Standard Tolerances Unless Noted: 1 .005César Arturo TorresNo ratings yet

- Digihelic 3 Differential Pressure Controllers: Digihelic Controller in Photohelic Gage, Square Root Output For FlowDocument1 pageDigihelic 3 Differential Pressure Controllers: Digihelic Controller in Photohelic Gage, Square Root Output For FlowAdriana Zarahi Velez HernandezNo ratings yet

- Dwyer - PG - M - Iom Rev 10 2014 HebDocument2 pagesDwyer - PG - M - Iom Rev 10 2014 HebDeffous AbdelhadiNo ratings yet

- Series 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsDocument4 pagesSeries 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsAlberto Angel Mora ZavalaNo ratings yet

- Magnehelic Differential Pressure Indicating TransmitterDocument1 pageMagnehelic Differential Pressure Indicating Transmitterfogok72408No ratings yet

- Magnehelic Series 2000 - CatDocument2 pagesMagnehelic Series 2000 - CatFerdian AriestaNo ratings yet

- Magnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 2%Document2 pagesMagnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 2%SlametKhoerudinNo ratings yet

- Series 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsDocument4 pagesSeries 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsKrissthian EspitiaNo ratings yet

- Explosion-Proof Differential Pressure SwitchDocument1 pageExplosion-Proof Differential Pressure SwitchTadau EnergyNo ratings yet

- 1910 00 ManualDocument4 pages1910 00 ManualRusty AllenNo ratings yet

- CO Component Description: Discharge DelaysDocument1 pageCO Component Description: Discharge DelayskiuNo ratings yet

- Dwyer B - 30Document20 pagesDwyer B - 30Alex MeadowsNo ratings yet

- Continuous Level Transmitter: Customize To Fit Application, 316 SS or Buna-N FloatsDocument1 pageContinuous Level Transmitter: Customize To Fit Application, 316 SS or Buna-N FloatsMohamed HammamNo ratings yet

- Dwyer - 1630-Presostato SwitchDocument2 pagesDwyer - 1630-Presostato Switchomorales.cyvsaNo ratings yet

- Series DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDocument2 pagesSeries DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsJuan Carlos Chara VelazcoNo ratings yet

- DA-DS CatDocument2 pagesDA-DS Catsorin sorinNo ratings yet

- Dweyer Pressure SwitchDocument1 pageDweyer Pressure SwitchMuhamad PriyatnaNo ratings yet

- Anemometro Dwyer VT-200Document1 pageAnemometro Dwyer VT-200Israel Hernandez GomezNo ratings yet

- 616kd 11 DatasheetDocument1 page616kd 11 Datasheetramalho12andyNo ratings yet

- PL5 PMC365 CVR 20-25Document6 pagesPL5 PMC365 CVR 20-25Dwiki RamadhaniNo ratings yet

- Series DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDocument2 pagesSeries DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsJorge Renato Chirinos QuiñonezNo ratings yet

- DWYER Serie 3000 Photohelic - Pressure Switch-GageDocument12 pagesDWYER Serie 3000 Photohelic - Pressure Switch-Gageraphael31No ratings yet

- Ametek Nautilair 150560 150561 150562 150563 150564 150565 Tech SheetDocument2 pagesAmetek Nautilair 150560 150561 150562 150563 150564 150565 Tech SheetAlejandroNo ratings yet

- Ansul Design #007 Kidde Booth SystemDocument8 pagesAnsul Design #007 Kidde Booth SystemJhoNo ratings yet

- Differential Pressure Transmitter: Same Size As Standard Magnehelic Differential Pressure GageDocument1 pageDifferential Pressure Transmitter: Same Size As Standard Magnehelic Differential Pressure GageJose Antonio Yupa MedinaNo ratings yet

- 18.20 (59'-9") Client Drawing Title: Car Parking-1Document1 page18.20 (59'-9") Client Drawing Title: Car Parking-1KeerthivasanNo ratings yet

- Photohelic Pressure Switch/Gages: 3-In-One Indicating Gage, Lo-Limit and Hi-Limit ControlDocument2 pagesPhotohelic Pressure Switch/Gages: 3-In-One Indicating Gage, Lo-Limit and Hi-Limit ControlAnonymous u0wETydFNo ratings yet

- Dwyer 4000 SeriesDocument1 pageDwyer 4000 SeriesMuh RenandaNo ratings yet

- As Sea20007e Ew 121 128 B As Ew 129Document1 pageAs Sea20007e Ew 121 128 B As Ew 129Juan RuizNo ratings yet

- Kidde 81-871403-000Document1 pageKidde 81-871403-000pedrocardososNo ratings yet

- Dwyer-1910-1-Product OverviewDocument1 pageDwyer-1910-1-Product OverviewRusty AllenNo ratings yet

- Ficha Tecnica Mod 2-5002Document2 pagesFicha Tecnica Mod 2-5002Nestor Augusto Duran SanchezNo ratings yet

- WLNA9CE Outline DrawingDocument1 pageWLNA9CE Outline Drawingsclaveau20No ratings yet

- Cooling People-45166Document1 pageCooling People-45166Rifai IndraswariNo ratings yet

- Magnehelic Differential Pressure Gage: Bulletin A-27Document2 pagesMagnehelic Differential Pressure Gage: Bulletin A-27Marco Antonio Rivera DoteroNo ratings yet

- Diaphragm Seal For DA Series Pressure Switch: PVC and FEP Construction For Corrosive ApplicationsDocument1 pageDiaphragm Seal For DA Series Pressure Switch: PVC and FEP Construction For Corrosive Applicationsluat1983No ratings yet

- Master Plan Alameda Chabuca GrandaDocument1 pageMaster Plan Alameda Chabuca GrandaSusana EstefannyNo ratings yet

- Esp Calculation Exhaust Air-TaDocument4 pagesEsp Calculation Exhaust Air-TaAshiq NishmaNo ratings yet

- Astral: 3/4" MANUAL Air Vent 16" Ø ManwayDocument1 pageAstral: 3/4" MANUAL Air Vent 16" Ø Manwayalquiler pisosNo ratings yet

- JETTA 96 Tierras A BateríaDocument7 pagesJETTA 96 Tierras A BateríajcarlosahuatltNo ratings yet

- Photo Helic Ps PDFDocument4 pagesPhoto Helic Ps PDFSoumen PaulNo ratings yet

- Fi-103 Agitator PDFDocument18 pagesFi-103 Agitator PDFuttam prabhuNo ratings yet

- 23 Ridge-Hip (Floating) DetailDocument1 page23 Ridge-Hip (Floating) DetailAhmed Saber NassarNo ratings yet

- Dwyer MagnehelicmanualDocument2 pagesDwyer MagnehelicmanualAndres GonzalesNo ratings yet

- Ametek Windjammer 117637 117643 117636 117642 117635 117641 Spec SheetDocument2 pagesAmetek Windjammer 117637 117643 117636 117642 117635 117641 Spec SheetGonzalo Jesus Ccahuin FernandezNo ratings yet

- Series 647 Wet/Wet Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDocument2 pagesSeries 647 Wet/Wet Differential Pressure Transmitter: Specifications - Installation and Operating Instructionsindra_onevisionNo ratings yet

- Datasheet: RS Pro Pre-Printed Adhesive Label. Quantity: 180 445-3773Document2 pagesDatasheet: RS Pro Pre-Printed Adhesive Label. Quantity: 180 445-3773fogok72408No ratings yet

- Fit Families: Positive LockingDocument2 pagesFit Families: Positive Lockingfogok72408No ratings yet

- Product Specification: Mini-Fit JRDocument10 pagesProduct Specification: Mini-Fit JRfogok72408No ratings yet

- General: Part Number: Status: Overview: DescriptionDocument3 pagesGeneral: Part Number: Status: Overview: Descriptionfogok72408No ratings yet

- Part Number: Status: Overview: Description:: DocumentsDocument2 pagesPart Number: Status: Overview: Description:: Documentsfogok72408No ratings yet

- CX 01 J8F: Part NumberDocument2 pagesCX 01 J8F: Part Numberfogok72408No ratings yet

- PLR Series - Planar Transformer: Features ApplicationsDocument4 pagesPLR Series - Planar Transformer: Features Applicationsfogok72408No ratings yet

- Female Cordset V1-G-5M-PUR: DimensionsDocument3 pagesFemale Cordset V1-G-5M-PUR: Dimensionsfogok72408No ratings yet

- Ressure Auges P GDocument3 pagesRessure Auges P Gfogok72408No ratings yet

- Connection Cable V1-G-10M-PUR-V1-W: DimensionsDocument3 pagesConnection Cable V1-G-10M-PUR-V1-W: Dimensionsfogok72408No ratings yet

- Female Cordset V1-W-E2-5M-PUR: DimensionsDocument3 pagesFemale Cordset V1-W-E2-5M-PUR: Dimensionsfogok72408No ratings yet

- 4130-C Parker Check Valves, August 2005Document8 pages4130-C Parker Check Valves, August 2005jbjb2000No ratings yet

- Alloy Guide 2011Document12 pagesAlloy Guide 2011bbmoksh100% (1)

- Corrosion ControlDocument41 pagesCorrosion ControldigecaNo ratings yet

- 200 Questions AnswersDocument150 pages200 Questions AnswersvempadareddyNo ratings yet

- 487 SpecDocument2 pages487 SpecEriks GrazulisNo ratings yet

- Technical Sheet: Home Meat Mincer and Grater TG ModelsDocument1 pageTechnical Sheet: Home Meat Mincer and Grater TG ModelslucaNo ratings yet

- Citric Acid Passivation of Stainless SteelDocument41 pagesCitric Acid Passivation of Stainless Steelnqh2009100% (2)

- Selective Hardening MethodsDocument47 pagesSelective Hardening MethodsvishnuNo ratings yet

- Tubing Data-Engineered Combinations MS-06-117Document7 pagesTubing Data-Engineered Combinations MS-06-117kirlaniano@gmail.comNo ratings yet

- SSC 6MO Steel Spec SheetDocument2 pagesSSC 6MO Steel Spec SheetDouglas BooyensNo ratings yet

- BS 970 Chemical Composition Table: Grade Chemical Composition (% by Mass - Max Unless Stated) Ferritic SteelsDocument18 pagesBS 970 Chemical Composition Table: Grade Chemical Composition (% by Mass - Max Unless Stated) Ferritic Steelspm Starkeon100% (1)

- Sa 961 PDFDocument10 pagesSa 961 PDFaruntpeNo ratings yet

- 304H Buttweld FittingsDocument4 pages304H Buttweld FittingsPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- Datasheet Sandvik Saf 2507 en PDFDocument15 pagesDatasheet Sandvik Saf 2507 en PDFShesharam Chouhan100% (1)

- Stainless Steel: Tables of Technical Properties: Materials and Applications Series, Volume 5Document24 pagesStainless Steel: Tables of Technical Properties: Materials and Applications Series, Volume 5process processNo ratings yet

- Refsheet Doha Pedestrian Bridge CH enDocument1 pageRefsheet Doha Pedestrian Bridge CH enviv99844No ratings yet

- Nitrogen Purging For Stainless SteelDocument4 pagesNitrogen Purging For Stainless Steelmahmoud_allam3No ratings yet

- Blueshield La 23 SawDocument1 pageBlueshield La 23 SawSungJun ParkNo ratings yet

- CRP PaintSprayDocument36 pagesCRP PaintSpraytosanda.putraNo ratings yet

- ISO Update - May08Document20 pagesISO Update - May08evang.pmsiNo ratings yet

- Pleuger Electrical Submersible Pumps and Water-Filled MotorsDocument12 pagesPleuger Electrical Submersible Pumps and Water-Filled MotorsGabrielMachado100% (1)

- Brakes CaeDocument4 pagesBrakes CaeRishav MittalNo ratings yet

- J Matpr 2019 10 018Document4 pagesJ Matpr 2019 10 018Alagar SamyNo ratings yet

- European Steel and Alloy Grades: X6Crnicus18-9-2 (1.4570)Document2 pagesEuropean Steel and Alloy Grades: X6Crnicus18-9-2 (1.4570)farshid KarpasandNo ratings yet

- Chrome MigrationDocument3 pagesChrome Migrationdk24991No ratings yet

- KVC (UK) LTD Brochure PDFDocument32 pagesKVC (UK) LTD Brochure PDFasitdeyNo ratings yet

- BAKS 2015 - 16 (1) CatalogueDocument681 pagesBAKS 2015 - 16 (1) Catalogueelena_ciriNo ratings yet

- CA6NMDocument2 pagesCA6NMJoshua WalkerNo ratings yet

- 1415712636wpdm - Stainless Steel Grade AISI 409Document2 pages1415712636wpdm - Stainless Steel Grade AISI 409Anurag SarkarNo ratings yet

Magnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%

Magnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%

Uploaded by

fogok72408Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Magnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%

Magnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%

Uploaded by

fogok72408Copyright:

Available Formats

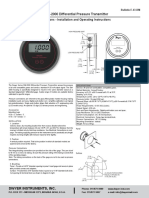

PRESSURE

SERIES 2000

MAGNEHELIC® DIFFERENTIAL PRESSURE GAGES

Indicate Positive, Negative or Differential, Accurate within 1% YEAR LIMITED

WARRANTY

CALIBRATION SERVICES AVAILABLE

RUBBER PRESSURE RELIEF PLUG

WILL UNSEAT ITSELF WHEN GAGE [3] 6-32 X 3/16 [4.76] DEEP

IS OVERPRESSURIZED HOLES EQUALLY SPACED ON

.025 [.64] SPACE CREATED BY 3 SPACER A Ø4-1/8 [104.78] BOLT CIRCLE

PADS WHEN SURFACE MOUNTED. FOR PANEL MOUNTING

DO NOT OBSTRUCT. PROVIDES PATH 17/32

FOR RELIEF OF OVERPRESSURE. [13.49] 1/8 FEMALE NPT

1/8 FEMALE HIGH PRESSURE

NPT HIGH CONNECTION

PRESSURE 1-3/4

1-1/4 [31.75] CONNECTION [44.45]

Ø4-1/2 1/8 FEMALE

[114.3] NPT LOW

PRESSURE 1/2

CONNECTION [12.70]

Ø4-3/4 15/32 [11.91]

[120.65] 1/8 FEMALE NPT LOW

1-11/16 [42.86] 7/16 [11.11] 11/16

[17.46] PRESSURE CONNECTION

17/32

Standard Magnehelic® gage [13.49] ø4-3/4 [120.65] 1/8 FEMALE NPT

1-1/4 PANEL CUTOUT HIGH PRESSURE

[31.75] CONNECTION

ø5

[127] 1-3/4

ø4-47/64 [44.45]

ø4-1/2 [120.27]

[114.3] 1/2

[12.70]

VIDEO ON ø5-1/2 15/32 11/16 1/8 FEMALE

High Accuracy Magnehelic® gage [139.70] [11.91] 2-17/32 3/16 [17.46] NPT LOW

LI

MOUNTING RING PRESSURE

NE

Shown with optional -SS bezel [64.29] [4.76]

CONNECTION

Select the Series 2000 Magnehelic® Differential Pressure Gages for a versatile low SPECIFICATIONS

differential pressure gage with a wide choice of 81 models and 27 options to choose Service: Air and non-combustible, compatible gases (natural gas option available).

from. Using Dwyer’s simple, frictionless Magnehelic® gage movement, it quickly Note: May be used with hydrogen. Order a Buna-N diaphragm. Pressures must be

indicates air or non-corrosive gas pressures--either positive, negative (vacuum) or

Differential Pressure Gages

less than 35 psi.

differential. The design resists shock, vibration, over-pressures and is weatherproof Wetted Materials: Consult factory.

to IP67. Housing: Die cast aluminum case and bezel, with acrylic cover. Exterior finish is

Select the –HA High Accuracy Magnehelic® gage option for an accuracy within 1% coated gray to withstand 168 hour salt spray corrosion test.

of full-scale. Also included with the –HA option at no extra cost are a mirrored scale Accuracy: ±2% (-HA model ±1) of FS (±3% (-HA ±1.5%) on -0, -100PA, -125PA,

overlay and a 6 point calibration certificate. -10MM and ±4% (-HA ±2%) on -00, -60PA, -6MM ranges), throughout range at 70°F

(21.1°C).

BENEFITS/FEATURES Pressure Limits: -20 in Hg to 15 psig (-0.677 to 1.034 bar); MP option: 35 psig

• Easy to read gage through undistorted plastic face permits viewing from far away (2.41 bar); HP option: 80 psig (5.52 bar).

• Patented design provides quick response to pressure changes means no delay in Enclosure Rating: IP67.

assessing critical situations Overpressure: Relief plug opens at approximately 25 psig (1.72 bar), standard

• Durable and rugged housing and high-quality components combine to provide long- gages only.u

service life and minimized down-time Temperature Limits: 20 to 140°F* (-6.67 to 60°C). -20°F (-28°C) with low

• High accuracy option is twice as accurate as the standard Magnehelic® gage temperature option.

Size: 4˝ (101.6 mm) diameter dial face.

APPLICATIONS Mounting Orientation: Diaphragm in vertical position. Consult factory for other

• Filter monitoring position orientations.

• Air velocity with Dwyer® pitot tube Process Connections: 1/8˝ female NPT duplicate high and low pressure taps - one

• Blower vacuum monitoring pair side and one pair back.

• Fan pressure indication Weight: 1 lb 2 oz (510 g), MP & HP 2 lb 2 oz (963 g).

• Duct, room or building pressures Standard Accessories: Two 1/8˝ NPT plugs for duplicate pressure taps, two

• Clean room positive pressure indication 1/8˝ pipe thread to rubber tubing adaptor, and three flush mounting adapters with

screws. (Mounting and snap ring retainer substituted for three adapters in MP & HP

ACCESSORIES gage accessories.)

Model Description Compliance: Meets the technical requirements of EU Directive 2011/65/EU (RoHS

II). Note: -SP models not RoHS approved.

A-432 Portable kit; combine carrying case with any Magnehelic® gage of

standard range, except high pressure connection. Includes 9 ft (2.7 m) of *Low temperature models available as special options.

3/16˝ ID rubber tubing, standhang bracket and terminal tube with holder Note: For applications with high cycle rate within gage total pressure rating, next

A-605 Air filter gage accessory kit; adapts any standard Magnehelic® gage for higher rating is recommended. See Medium and High pressure options.

use as an air filter gage. Includes aluminum surface mounting bracket

with screws, two 5 ft (1.5 m) lengths of 1/4˝ aluminum tubing, two static

pressure tips and two molded plastic vent valves, integral compression

fittings on both tips and valves

A-605B Air filter gage accessory kit; air filter kit with two plastic open/close valves,

two 4˝ steel static tips, plastic tubing and mounting flange

A-605C Air filter gage accessory kit; air filter kit with two plastic open/close valves,

two plastic static tips, plastic tubing and mounting flange

USA: California Proposition 65

WARNING: This product can expose you to chemicals including Lead, which is known to the State

of California to cause cancer and birth defects or other reproductive harm. For more information go

to www.P65Warnings.ca.gov.

A-432 A-605

uOver Protection Note: See page 21 (Series 2000)

20 DWYER INSTRUMENTS, LLC | dwyer-inst.com

PRESSURE

SERIES 2000

MAGNEHELIC® DIFFERENTIAL PRESSURE GAGES

Indicate Positive, Negative or Differential, Accurate within 1% YEAR LIMITED

WARRANTY

CALIBRATION SERVICES AVAILABLE

Bezel provides flange for flush mounting in panel. O-ring seal for cover assures pressure integrity of case.

Clear plastic face is highly resistant to breakage. Provides OVERPRESSURE PROTECTION

undistorted viewing of pointer and scale. Blowout plug is comprised of a rubber plug on the rear which

functions as a relief valve by unseating and venting the gage

Precision litho-printed scale is accurate and easy to read. interior when over pressure reaches approximately 25 psig

(1.7 bar). To provide a free path for pressure relief, there are

Calibrated range spring is flat spring steel. Small amplitude of four spacer pads which maintain 0.023˝ clearance when gage

motion assures consistency and long life. It reacts to pressure is surface mounted. Do not obstruct the gap created by these

on diaphragm. Live length adjustable for calibration. pads.

The blowout plug is not used on models above 180˝ of water

Red tipped pointer of heat treated aluminum tubing is easy to pressure, medium or high pressure models, or on gages which

see. It is rigidly mounted on the helix shaft. require an elastomer other than silicone for the diaphragm.

The blowout plug should not be used as a system overpressure

Pointer stops of molded rubber prevent pointer over-travel control. High supply pressures may still cause the gage to fail

without damage. due to over pressurization, resulting in property damage or

serious injury. Good engineering practices should be utilized

“Wishbone” assembly provides mounting for helix, helix to prevent your system from exceeding the ratings of any

bearings and pointer shaft. component.

Jeweled bearings are shock-resistant mounted; provide Die cast aluminum case is precision made and iridite-dipped

virtually friction-free motion for helix. Motion damped with high to withstand 168 hour salt spray corrosion test. Exterior

viscosity silicone fluid. finished in baked dark gray hammerloid. One case size is used

for all standard pressure options, and for both surface and flush

Helix is precision made from an alloy of high magnetic mounting.

permeability. Mounted in jeweled bearings, it turns freely,

following the magnetic field to move the pointer across the Silicone rubber diaphragm with integrally molded O-ring

scale. is supported by front and rear plates. It is locked and sealed

in position with a sealing plate and retaining ring. Diaphragm

Zero adjustment screw is conveniently located in the plastic motion is restricted to prevent damage due to overpressures.

cover, and is accessible without removing cover. O-ring seal

provides pressure tightness. Samarium Cobalt magnet mounted at one end of range

spring rotates helix without mechanical linkages.

MODEL CHART

Range, Range,

Inches of Range, MM of Range, Dual Scale Air Velocity Units

Model Water Model PSI Model Water Model kPa For use with pitot tube

2000-00N†•• .05-0-.2 2201 0-1 2000-6MM†•• 0-6 2000-0.5KPA 0-0.5 Range, in w.c./

2000-00†•• 0-.25 2202 0-2 2000-10MM†• 0-10 2000-1KPA 0-1 Model Velocity F.P.M.

2000-0†• 0-.50 2203 0-3 2000-15MM 0-15 2000-1.5KPA 0-1.5 2000-00AV†•• 0-.25/300-2000

2001 0-1.0 2204 0-4 2000-25MM 0-25 2000-2KPA 0-2 2000-0AV†• 0-.50/500-2800

Differential Pressure Gages

2002 0-2.0 2205 0-5 2000-30MM 0-30 2000-2.5KPA 0-2.5 2001AV 0-1.0/500-4000

2003 0-3.0 2210* 0-10 2000-50MM 0-50 2000-3KPA 0-3 2002AV 0-2.0/1000-5600

2004 0-4.0 2215* 0-15 2000-80MM 0-80 2000-4KPA 0-4 2005AV 0-5.0/2000-8800

2005 0-5.0 2220* 0-20 2000-100MM 0-100 2000-5KPA 0-5 2010AV 0-10/2000-12500

2006 0-6.0 2230** 0-30 2000-125MM 0-125 2000-8KPA 0-8

2008 0-8.0 Range, 2000-150MM 0-150 2000-10KPA 0-10

2010 0-10 CM of 2000-200MM 0-200 2000-15KPA 0-15

2012 0-12 Model Water 2000-250MM 0-250 2000-20KPA 0-20

2015 0-15 2000-15CM 0-15 2000-300MM 0-300 2000-25KPA 0-25

2020 0-20 2000-20CM 0-20 2000-30KPA 0-30

2025 0-25 2000-25CM 0-25

2030 0-30 2000-50CM 0-50

2040 0-40 2000-80CM 0-80 Zero Center Ranges Zero Center Ranges

2050 0-50 2000-100CM 0-100 2300-6MM†•• 3-0-3 2300-1KPA .5-0-.5

2060 0-60 2000-150CM 0-150 2300-10MM†• 5-0-5 2300-2KPA 1-0-1

2080 0-80 2000-200CM 0-200 2300-20MM†• 10-0-10 2300-2.5KPA 1.25-0-1.25

2100 0-100 2000-250CM 0-250 2300-3KPA 1.5-0-1.5

2120 0-120 2000-300CM 0-300 Model Range, Pa

2150 0-150 2000-60NPA†•• 10-0-50

2160 0-160 Zero Center Ranges 2000-30PA†•• 0-30 Dual Scale English/Metric Models

2180* 0-180 2300-4CM 2-0-2 2000-60PA†•• 0-60

2250* 0-250 2300-10CM 5-0-5 2000-100PA†• 0-100 Range, Range,

Model in w.c. Pa or kPa VELOCITY AND

2300-30CM 15-0-15 2000-125PA†• 0-125 VOLUMETRIC FLOW UNITS

Zero Center Ranges 2000-250PA 0-250 2000-00D†•• 0-.25 0-62 Pa

2000-300PA 0-300 2000-0D†• 0-0.5 0-125 Pa Scales are available on the

2300-00†•• 0.125-0-0.125 Magnehelic ® gage that read

2300-0†• .25-0-.25 2000-500PA 0-500 2001D 0-1.0 0-250 Pa

2000-750PA 0-750 2002D 0-2.0 0-500 Pa in velocity units (FPM, m/s) or

2301 .5-0-.5 volumetric flow units (SCFM,

2302 1-0-1 2000-1000PA 0-1000 2003D 0-3.0 0-750 Pa

2004D 0-4.0 0-1.0 kPa m3/s, m3/h).

2304 2-0-2 Zero Center Ranges Stocked velocity units with dual

2310 5-0-5 Model Range, Pa 2005D 0-5.0 0-1.25 kPa

2006D 0-6.0 0-1.5 kPa range scales in inches w.c.

2320 10-0-10 2300-60PA†•• 30-0-30 and feet per minute are shown

2330 15-0-15 2300-100PA†• 50-0-50 2008D 0-8.0 0-2.0 kPa

2010D 0-10 0-2.5 kPa above. For other ranges contact

2300-120PA 60-0-60 the factory.

2300-200PA 100-0-100 2015D 0-15 0-3.7 kPa

When ordering volumetric

2300-250PA 125-0-125 2020D 0-20 0-5 kPa

flow scales please specify

2300-300PA 150-0-150 2025D 0-25 0-6.2 kPa

the maximum flow rate and its

2300-500PA 250-0-250 2050D 0-50 0-12.4 kPa

corresponding pressure.

2300-1000PA 500-0-500 2060D 0-60 0-15 kPa

Example: 0.5 in w.c. = 16,000

†These ranges calibrated for vertical scale position. • Accuracy ±3%. •• Accuracy ±4%. *MP option standard. **HP option standard. CFM.

ACCESSORIES

Model Description

A-135 Rubber gasket for panel mounting

A-310A 3-way vent valves. In applications where pressure is continuous and the Magnehelic® gage is A-310A

connected by metal or plastic tubing which cannot be easily removed, we suggest using Dwyer

A-310A vent valves to connect gage. Pressure can then be removed to check or re-zero the gage USA: California Proposition 65

WARNING: This product can expose you to chemicals

A-321 Safety relief valve including Lead, which is known to the State of California to

A-401 Plastic carry case cause cancer and birth defects or other reproductive harm.

A-448 3-piece magnet kit for mounting Magnehelic gage directly to magnetic surface

®

For more information go to www.P65Warnings.ca.gov.

DWYER INSTRUMENTS, LLC | dwyer-inst.com 21

PRESSURE

HIGH ACCURACY MAGNEHELIC® DIFFERENTIAL PRESSURE GAGE YEAR LIMITED

CALIBRATION SERVICES AVAILABLE WARRANTY

OPTIONS - HIGH ACCURACY MAGNEHELIC®

Twice as accurate as the GAGE

standard Magnehelic ® gage To order

add suffix: Description

Mirrored scale overlay -HA High accuracy Magnehelic® gage.

eliminates parallax error Accuracy within 1% and weatherproof.

Also includes mirrored scale overlay and

a six point calibration certificate

-SS Corrosion resistant brushed 304 stainless

IP67 weatherproof housing steel bezel

VIDEO ON

6-point calibration

LI

NE

certificate included

Optional brushed SS bezel Accuracy Specifications: See page 20 (Series 2000)

ADDITIONAL GAGE OPTIONS

OPTIONS - OTHER OPTIONAL BEZELS

To order add suffix: Description

-CB Chrome bezel option: A chrome plated aluminum bezel for

an aesthetically pleasing finish when mounting on metal

surfaces such as control panels.

-SB Stainless steel bezel option: 304 stainless steel electro

polished Ra 16 finished bezel.

-SS Corrosion resistant brushed 304 stainless steel bezel

OPTIONS - LED SET POINT INDICATOR

To order add suffix: Description

-SP Bright red LED on right scale shows when set point is

reached. Field adjustable from gage face, unit operates on

12-24 VDC. Set point indicator option comes with medium

pressure (MP) bezel.

Note: 4-13/16˝ hole for flush mounting.

OPTIONS - ADJUSTABLE SIGNAL FLAG

Differential Pressure Gages

To order add suffix: Description

LED set point indicator Adjustable signal flag -ASF Integral with plastic gage cover. Available for most models

except those with medium or high pressure construction.

Can be ordered with gage or separate.

OPTIONS - TRANSPARENT OVERLAYS

To order add suffix: Description

-G Green (to highlight and emphasize critical pressures)

-R Red (to highlight and emphasize critical pressures)

-Y Yellow (to highlight and emphasize critical pressures)

OPTIONS - MIRRORED SCALE OVERLAY

To order add suffix: Description

Transparent overlay Mirrored scale overlay -M A mirrored scale overlay is also available to assist in reduc-

ing parallax error.

OPTIONS - INTEGRATED MOUNTING PLATE

To order add suffix: Description

-AHU1 Furnished with attached surface mounting plate

-AHU2 Furnished with attached surface mounting plate and including

A-481 installer kit (2 plastic static pressure tips and 7´of

PVC tubing)

Integrated mounting plate

OPTIONS - FOR HIGH STATE PRESSURE APPLICATIONS

To order add suffix: Description

-HP High pressure option: for pressures to 80 psig

-MP Medium pressure option: for pressures to 35 psig

OPTIONS

To order add suffix: Description

-FC Factory calibration certificate

-LT Low temperatures to -20°F (-28°C)

-NIST NIST traceable calibration certificate

USA: California Proposition 65

WARNING: This product can expose you to chemicals including Lead, which is known to the State

of California to cause cancer and birth defects or other reproductive harm. For more information go

to www.P65Warnings.ca.gov.

22 DWYER INSTRUMENTS, LLC | dwyer-inst.com

PRESSURE

MAGNEHELIC® GAGE MOUNTING ACCESSORIES

Pressure

reference

port

A-610 A-369 A-464 A-464-SS A-299

VIDEO ON

LI

NE

A-286 A-300 A-368 A-371

A single case size is used for most models of Magnehelic® gages. They can be ACCESSORIES

flush or surface mounted with standard hardware supplied. Complete mounting and Model Description

connection fittings plus instructions are furnished with each instrument. A 4-9/16˝ hole A-286 Magnehelic® gage panel mounting flange

is required for flush panel mounting. A-299 Mounting bracket, flush mount for Magnehelic® gage, bracket is then

Flush mounting is easily accomplished with the new A-300 Flush Mounting bracket. surface mounted, steel with gray hammerloid epoxy finish

This bracket provides a solution to quickly and conveniently flush mount the A-300 Flush mounting bracket

Magnehelic® gage. The A-300 is ideal for mounting the Magnehelic® gage on control A-368 Surface mounting plate, aluminum, for Magnehelic® gage

panel doors. A-369 Stand-hang bracket, aluminum, for Magnehelic® gage

The A-368 is a simple bracket for quickly surface mounting the Magnehelic® gage. A-371 Surface mounting bracket, use with medium pressure (-MP) or high

After securing the Magnehelic® gage to the A-368 bracket, mount the bracket on any pressure (-HP) models only

flat surface. A-464-SS Stainless steel flush mount kit for Magnehelic® gage

The A-369 allows the Magnehelic® gage to be easily carried to locations where A-464 Flush mount kit for Magnehelic® gage

pressure readings need to be taken. The A-369 can stand on its own or hang on a A-610 Pipe mounting kit for installing on 1-1/4˝ to 2˝ horizontal or vertical pipe

nail or hook.

Differential Pressure Gages

SERIES A-320

INSTRUMENT ENCLOSURES

Protects Various Instruments

VIDEO ON

LI

NE

A-320-A1 A-320-B1 A-320-BC A-320-A-SS A-320-B-SS

The Series A-320 Instrument Enclosures protect instruments in all applications. The SPECIFICATIONS

enclosures, available in plastic and stainless steel, fit a variety of gages including the Housing Material: ABS plastic or 304 SS.

Series 605 transmitter, DM-2000, 3000MR/MRS and DH3. All models include silicone Process Connection: 1/8˝ female NPT (-SS models: 1/8˝ BSPT).

tubing, Banjo fittings, and threaded pressure connections pre-installed. The threaded Enclosure Rating: Plastic models: IP66.

pressure connections allow the user to easily change the connection type through the Weight: A-320-A1: 1.1 lb (0.5 kg); A-320-B1: 1.4 lb (0.65 kg); A-320-BC: 1.4 lb

use of fittings or adapters. This modification can be implemented to allow connection (0.65 kg); A-320-A-SS: 2.3 lb (1.05kg); A-320-B-SS: 3.0 lb (1.35 kg).

to a wide variety of plastic or metal tubing.

MODEL CHART

Model Description

A-320-A1 2000 Magnehelic® gage

A-320-B1* 3000MR/MRS Photohelic® switch/gage, Series 605 Magnehelic®

differential pressure transmitter, DH3 Digihelic® pressure controller,

2000 Magnehelic® gage with medium and high pressure options

A-320-BC 2000 Magnehelic® gage, DM-1000 DigiMag® digital differential

pressure gage, DM-2000 differential pressure transmitter, instruments

with backwards compatible bezel option

A-320-A-SS 2000 Magnehelic® gage ACCESSORIES

A-320-B-SS 2000 Magnehelic® gage, DM-2000 differential pressure transmitter Model Description

*For DH3 to fit on A-320-B1 the casing on the electrical plug must be removed. A-339-SS 1/8˝ male BSPT to 3/16˝ hose barb

DWYER INSTRUMENTS, LLC | dwyer-inst.com 23

You might also like

- BS 8297 2017Document64 pagesBS 8297 2017MOHAMMAD100% (4)

- TE32+MANUAL (FZ Transm) (041-060)Document20 pagesTE32+MANUAL (FZ Transm) (041-060)Marco Guachun100% (1)

- Dwyer 2000Document4 pagesDwyer 2000Saravana KumarNo ratings yet

- Magnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%Document4 pagesMagnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%RyanNo ratings yet

- Magnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%Document4 pagesMagnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%Johan VBNo ratings yet

- Magnehelic Differential Pressure Gages: SolutionsDocument2 pagesMagnehelic Differential Pressure Gages: Solutionsdaniel GasperinNo ratings yet

- Series 2000 - Magnahelic Differential Pressure GaugeDocument2 pagesSeries 2000 - Magnahelic Differential Pressure GaugeKoteswara RaoNo ratings yet

- 004 005 D PDFDocument2 pages004 005 D PDFRangga Prasetya BaitullahNo ratings yet

- Serie 2000Document2 pagesSerie 2000Fredy MurilloNo ratings yet

- MAGNEHELICDocument2 pagesMAGNEHELICCésar Arturo TorresNo ratings yet

- Magnehelic-Gage Series 2000Document2 pagesMagnehelic-Gage Series 2000Jonathan GanNo ratings yet

- Purafil Side Access BulletinDocument5 pagesPurafil Side Access BulletinPablo TorresNo ratings yet

- Dwyer 2300 250pa Pressure Gauge DatasheetDocument2 pagesDwyer 2300 250pa Pressure Gauge DatasheetGorch Marroko100% (1)

- Fr. No.: +-+ - All Angles All Decimal Dimensions Standard Tolerances Unless Noted: 1 .005Document1 pageFr. No.: +-+ - All Angles All Decimal Dimensions Standard Tolerances Unless Noted: 1 .005César Arturo TorresNo ratings yet

- Digihelic 3 Differential Pressure Controllers: Digihelic Controller in Photohelic Gage, Square Root Output For FlowDocument1 pageDigihelic 3 Differential Pressure Controllers: Digihelic Controller in Photohelic Gage, Square Root Output For FlowAdriana Zarahi Velez HernandezNo ratings yet

- Dwyer - PG - M - Iom Rev 10 2014 HebDocument2 pagesDwyer - PG - M - Iom Rev 10 2014 HebDeffous AbdelhadiNo ratings yet

- Series 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsDocument4 pagesSeries 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsAlberto Angel Mora ZavalaNo ratings yet

- Magnehelic Differential Pressure Indicating TransmitterDocument1 pageMagnehelic Differential Pressure Indicating Transmitterfogok72408No ratings yet

- Magnehelic Series 2000 - CatDocument2 pagesMagnehelic Series 2000 - CatFerdian AriestaNo ratings yet

- Magnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 2%Document2 pagesMagnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 2%SlametKhoerudinNo ratings yet

- Series 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsDocument4 pagesSeries 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsKrissthian EspitiaNo ratings yet

- Explosion-Proof Differential Pressure SwitchDocument1 pageExplosion-Proof Differential Pressure SwitchTadau EnergyNo ratings yet

- 1910 00 ManualDocument4 pages1910 00 ManualRusty AllenNo ratings yet

- CO Component Description: Discharge DelaysDocument1 pageCO Component Description: Discharge DelayskiuNo ratings yet

- Dwyer B - 30Document20 pagesDwyer B - 30Alex MeadowsNo ratings yet

- Continuous Level Transmitter: Customize To Fit Application, 316 SS or Buna-N FloatsDocument1 pageContinuous Level Transmitter: Customize To Fit Application, 316 SS or Buna-N FloatsMohamed HammamNo ratings yet

- Dwyer - 1630-Presostato SwitchDocument2 pagesDwyer - 1630-Presostato Switchomorales.cyvsaNo ratings yet

- Series DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDocument2 pagesSeries DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsJuan Carlos Chara VelazcoNo ratings yet

- DA-DS CatDocument2 pagesDA-DS Catsorin sorinNo ratings yet

- Dweyer Pressure SwitchDocument1 pageDweyer Pressure SwitchMuhamad PriyatnaNo ratings yet

- Anemometro Dwyer VT-200Document1 pageAnemometro Dwyer VT-200Israel Hernandez GomezNo ratings yet

- 616kd 11 DatasheetDocument1 page616kd 11 Datasheetramalho12andyNo ratings yet

- PL5 PMC365 CVR 20-25Document6 pagesPL5 PMC365 CVR 20-25Dwiki RamadhaniNo ratings yet

- Series DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDocument2 pagesSeries DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsJorge Renato Chirinos QuiñonezNo ratings yet

- DWYER Serie 3000 Photohelic - Pressure Switch-GageDocument12 pagesDWYER Serie 3000 Photohelic - Pressure Switch-Gageraphael31No ratings yet

- Ametek Nautilair 150560 150561 150562 150563 150564 150565 Tech SheetDocument2 pagesAmetek Nautilair 150560 150561 150562 150563 150564 150565 Tech SheetAlejandroNo ratings yet

- Ansul Design #007 Kidde Booth SystemDocument8 pagesAnsul Design #007 Kidde Booth SystemJhoNo ratings yet

- Differential Pressure Transmitter: Same Size As Standard Magnehelic Differential Pressure GageDocument1 pageDifferential Pressure Transmitter: Same Size As Standard Magnehelic Differential Pressure GageJose Antonio Yupa MedinaNo ratings yet

- 18.20 (59'-9") Client Drawing Title: Car Parking-1Document1 page18.20 (59'-9") Client Drawing Title: Car Parking-1KeerthivasanNo ratings yet

- Photohelic Pressure Switch/Gages: 3-In-One Indicating Gage, Lo-Limit and Hi-Limit ControlDocument2 pagesPhotohelic Pressure Switch/Gages: 3-In-One Indicating Gage, Lo-Limit and Hi-Limit ControlAnonymous u0wETydFNo ratings yet

- Dwyer 4000 SeriesDocument1 pageDwyer 4000 SeriesMuh RenandaNo ratings yet

- As Sea20007e Ew 121 128 B As Ew 129Document1 pageAs Sea20007e Ew 121 128 B As Ew 129Juan RuizNo ratings yet

- Kidde 81-871403-000Document1 pageKidde 81-871403-000pedrocardososNo ratings yet

- Dwyer-1910-1-Product OverviewDocument1 pageDwyer-1910-1-Product OverviewRusty AllenNo ratings yet

- Ficha Tecnica Mod 2-5002Document2 pagesFicha Tecnica Mod 2-5002Nestor Augusto Duran SanchezNo ratings yet

- WLNA9CE Outline DrawingDocument1 pageWLNA9CE Outline Drawingsclaveau20No ratings yet

- Cooling People-45166Document1 pageCooling People-45166Rifai IndraswariNo ratings yet

- Magnehelic Differential Pressure Gage: Bulletin A-27Document2 pagesMagnehelic Differential Pressure Gage: Bulletin A-27Marco Antonio Rivera DoteroNo ratings yet

- Diaphragm Seal For DA Series Pressure Switch: PVC and FEP Construction For Corrosive ApplicationsDocument1 pageDiaphragm Seal For DA Series Pressure Switch: PVC and FEP Construction For Corrosive Applicationsluat1983No ratings yet

- Master Plan Alameda Chabuca GrandaDocument1 pageMaster Plan Alameda Chabuca GrandaSusana EstefannyNo ratings yet

- Esp Calculation Exhaust Air-TaDocument4 pagesEsp Calculation Exhaust Air-TaAshiq NishmaNo ratings yet

- Astral: 3/4" MANUAL Air Vent 16" Ø ManwayDocument1 pageAstral: 3/4" MANUAL Air Vent 16" Ø Manwayalquiler pisosNo ratings yet

- JETTA 96 Tierras A BateríaDocument7 pagesJETTA 96 Tierras A BateríajcarlosahuatltNo ratings yet

- Photo Helic Ps PDFDocument4 pagesPhoto Helic Ps PDFSoumen PaulNo ratings yet

- Fi-103 Agitator PDFDocument18 pagesFi-103 Agitator PDFuttam prabhuNo ratings yet

- 23 Ridge-Hip (Floating) DetailDocument1 page23 Ridge-Hip (Floating) DetailAhmed Saber NassarNo ratings yet

- Dwyer MagnehelicmanualDocument2 pagesDwyer MagnehelicmanualAndres GonzalesNo ratings yet

- Ametek Windjammer 117637 117643 117636 117642 117635 117641 Spec SheetDocument2 pagesAmetek Windjammer 117637 117643 117636 117642 117635 117641 Spec SheetGonzalo Jesus Ccahuin FernandezNo ratings yet

- Series 647 Wet/Wet Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDocument2 pagesSeries 647 Wet/Wet Differential Pressure Transmitter: Specifications - Installation and Operating Instructionsindra_onevisionNo ratings yet

- Datasheet: RS Pro Pre-Printed Adhesive Label. Quantity: 180 445-3773Document2 pagesDatasheet: RS Pro Pre-Printed Adhesive Label. Quantity: 180 445-3773fogok72408No ratings yet

- Fit Families: Positive LockingDocument2 pagesFit Families: Positive Lockingfogok72408No ratings yet

- Product Specification: Mini-Fit JRDocument10 pagesProduct Specification: Mini-Fit JRfogok72408No ratings yet

- General: Part Number: Status: Overview: DescriptionDocument3 pagesGeneral: Part Number: Status: Overview: Descriptionfogok72408No ratings yet

- Part Number: Status: Overview: Description:: DocumentsDocument2 pagesPart Number: Status: Overview: Description:: Documentsfogok72408No ratings yet

- CX 01 J8F: Part NumberDocument2 pagesCX 01 J8F: Part Numberfogok72408No ratings yet

- PLR Series - Planar Transformer: Features ApplicationsDocument4 pagesPLR Series - Planar Transformer: Features Applicationsfogok72408No ratings yet

- Female Cordset V1-G-5M-PUR: DimensionsDocument3 pagesFemale Cordset V1-G-5M-PUR: Dimensionsfogok72408No ratings yet

- Ressure Auges P GDocument3 pagesRessure Auges P Gfogok72408No ratings yet

- Connection Cable V1-G-10M-PUR-V1-W: DimensionsDocument3 pagesConnection Cable V1-G-10M-PUR-V1-W: Dimensionsfogok72408No ratings yet

- Female Cordset V1-W-E2-5M-PUR: DimensionsDocument3 pagesFemale Cordset V1-W-E2-5M-PUR: Dimensionsfogok72408No ratings yet

- 4130-C Parker Check Valves, August 2005Document8 pages4130-C Parker Check Valves, August 2005jbjb2000No ratings yet

- Alloy Guide 2011Document12 pagesAlloy Guide 2011bbmoksh100% (1)

- Corrosion ControlDocument41 pagesCorrosion ControldigecaNo ratings yet

- 200 Questions AnswersDocument150 pages200 Questions AnswersvempadareddyNo ratings yet

- 487 SpecDocument2 pages487 SpecEriks GrazulisNo ratings yet

- Technical Sheet: Home Meat Mincer and Grater TG ModelsDocument1 pageTechnical Sheet: Home Meat Mincer and Grater TG ModelslucaNo ratings yet

- Citric Acid Passivation of Stainless SteelDocument41 pagesCitric Acid Passivation of Stainless Steelnqh2009100% (2)

- Selective Hardening MethodsDocument47 pagesSelective Hardening MethodsvishnuNo ratings yet

- Tubing Data-Engineered Combinations MS-06-117Document7 pagesTubing Data-Engineered Combinations MS-06-117kirlaniano@gmail.comNo ratings yet

- SSC 6MO Steel Spec SheetDocument2 pagesSSC 6MO Steel Spec SheetDouglas BooyensNo ratings yet

- BS 970 Chemical Composition Table: Grade Chemical Composition (% by Mass - Max Unless Stated) Ferritic SteelsDocument18 pagesBS 970 Chemical Composition Table: Grade Chemical Composition (% by Mass - Max Unless Stated) Ferritic Steelspm Starkeon100% (1)

- Sa 961 PDFDocument10 pagesSa 961 PDFaruntpeNo ratings yet

- 304H Buttweld FittingsDocument4 pages304H Buttweld FittingsPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- Datasheet Sandvik Saf 2507 en PDFDocument15 pagesDatasheet Sandvik Saf 2507 en PDFShesharam Chouhan100% (1)

- Stainless Steel: Tables of Technical Properties: Materials and Applications Series, Volume 5Document24 pagesStainless Steel: Tables of Technical Properties: Materials and Applications Series, Volume 5process processNo ratings yet

- Refsheet Doha Pedestrian Bridge CH enDocument1 pageRefsheet Doha Pedestrian Bridge CH enviv99844No ratings yet

- Nitrogen Purging For Stainless SteelDocument4 pagesNitrogen Purging For Stainless Steelmahmoud_allam3No ratings yet

- Blueshield La 23 SawDocument1 pageBlueshield La 23 SawSungJun ParkNo ratings yet

- CRP PaintSprayDocument36 pagesCRP PaintSpraytosanda.putraNo ratings yet

- ISO Update - May08Document20 pagesISO Update - May08evang.pmsiNo ratings yet

- Pleuger Electrical Submersible Pumps and Water-Filled MotorsDocument12 pagesPleuger Electrical Submersible Pumps and Water-Filled MotorsGabrielMachado100% (1)

- Brakes CaeDocument4 pagesBrakes CaeRishav MittalNo ratings yet

- J Matpr 2019 10 018Document4 pagesJ Matpr 2019 10 018Alagar SamyNo ratings yet

- European Steel and Alloy Grades: X6Crnicus18-9-2 (1.4570)Document2 pagesEuropean Steel and Alloy Grades: X6Crnicus18-9-2 (1.4570)farshid KarpasandNo ratings yet

- Chrome MigrationDocument3 pagesChrome Migrationdk24991No ratings yet

- KVC (UK) LTD Brochure PDFDocument32 pagesKVC (UK) LTD Brochure PDFasitdeyNo ratings yet

- BAKS 2015 - 16 (1) CatalogueDocument681 pagesBAKS 2015 - 16 (1) Catalogueelena_ciriNo ratings yet

- CA6NMDocument2 pagesCA6NMJoshua WalkerNo ratings yet

- 1415712636wpdm - Stainless Steel Grade AISI 409Document2 pages1415712636wpdm - Stainless Steel Grade AISI 409Anurag SarkarNo ratings yet