Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

2 viewsAssignment AUT, A, B and MT Year 3, Level 7

Assignment AUT, A, B and MT Year 3, Level 7

Uploaded by

giftdamas350Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Honda Magna VF750C Wiring RC43 - 2023-10-11Document6 pagesHonda Magna VF750C Wiring RC43 - 2023-10-11rhys.aaron.sinclairNo ratings yet

- 3054 T & Ta Underground Mining Equipment: Caterpillar Engine SpecificationsDocument2 pages3054 T & Ta Underground Mining Equipment: Caterpillar Engine SpecificationsMas Inyeccion Electronica100% (2)

- SANY RSC45 Container Reach Stacker Maintenance Manual PDFDocument29 pagesSANY RSC45 Container Reach Stacker Maintenance Manual PDFejaz86% (7)

- MDSP Set 2Document9 pagesMDSP Set 2iaton77100% (2)

- Design of Electronic Semi - Automatic Clutch For Manual Actuation of Clutch in A CarDocument6 pagesDesign of Electronic Semi - Automatic Clutch For Manual Actuation of Clutch in A CarTamilarasanRpcg100% (2)

- Friction 2 Marks and Important ProblemsDocument2 pagesFriction 2 Marks and Important ProblemsSachi DhanandamNo ratings yet

- Power ScrewsDocument2 pagesPower ScrewsdvarsastryNo ratings yet

- Screw TutDocument2 pagesScrew TutEDISON OCHIENGNo ratings yet

- Pointers For ReviewDocument3 pagesPointers For ReviewAdriel JohnNo ratings yet

- Assignment No - 2 TE Div - BDocument2 pagesAssignment No - 2 TE Div - BSubhash KNo ratings yet

- Machine Design Fayoum University 2 Year - 2016-2017 Faculty of Engineering Sheet 2 Mechanical Engineering DepartmentDocument2 pagesMachine Design Fayoum University 2 Year - 2016-2017 Faculty of Engineering Sheet 2 Mechanical Engineering DepartmentAhmed Rabie Abd ElazeemNo ratings yet

- ME 311 Assignment Sheet No.3, 2016Document2 pagesME 311 Assignment Sheet No.3, 2016Aryan DCNo ratings yet

- DMM Question BankDocument2 pagesDMM Question Bankzubair ahmedNo ratings yet

- Department of Mechanical Engineering 18MD04-Kinematics of Machinery Module-3 Friction QuestionsDocument2 pagesDepartment of Mechanical Engineering 18MD04-Kinematics of Machinery Module-3 Friction QuestionsEmperor89No ratings yet

- Tutorial 6 (Kom)Document1 pageTutorial 6 (Kom)patelsandip1990No ratings yet

- FinallDocument175 pagesFinallremeceldo dagamac100% (1)

- Tom-Assignment 2Document2 pagesTom-Assignment 2jamunaa83No ratings yet

- Power Screw SheetDocument4 pagesPower Screw SheetMohamed GamalNo ratings yet

- Design of Machine Elements - IIDocument8 pagesDesign of Machine Elements - IIprasaad26No ratings yet

- MECH4914 Tutorial Sheet 3Document3 pagesMECH4914 Tutorial Sheet 3ahmedNo ratings yet

- Power Screw PrimeDocument6 pagesPower Screw PrimeFuture HazeNo ratings yet

- Design1 SheetsDocument9 pagesDesign1 SheetsYou channelNo ratings yet

- Dme Unit Ii (17.11.22)Document23 pagesDme Unit Ii (17.11.22)sathiaNo ratings yet

- ME-323 Threaded-Members 42423Document48 pagesME-323 Threaded-Members 42423Jam Maica TuboNo ratings yet

- EMD Question Bank II 2Document4 pagesEMD Question Bank II 2Soham MisalNo ratings yet

- UNIT 5 FullDocument8 pagesUNIT 5 FullNavinsithiNo ratings yet

- B Tech - 6 Sem (CBGS) Course Code: ME 602 Subject Name: Machine Component & Design Important Questions Unit - 1Document6 pagesB Tech - 6 Sem (CBGS) Course Code: ME 602 Subject Name: Machine Component & Design Important Questions Unit - 1suneel kumar rathoreNo ratings yet

- Imp Qoestions MDDocument3 pagesImp Qoestions MDvenuedNo ratings yet

- Tutorial No.6 DMEDocument1 pageTutorial No.6 DMEOnkarNo ratings yet

- Screw Friction-Tute - 2021 PDFDocument2 pagesScrew Friction-Tute - 2021 PDF凵又个已刀了七乙个入厂大No ratings yet

- DME Chapter Three: or (Summer 15)Document7 pagesDME Chapter Three: or (Summer 15)honeyfunnyNo ratings yet

- Assignment 3 TOM2 YBKDocument2 pagesAssignment 3 TOM2 YBKyogesh_b_kNo ratings yet

- Dme-II Mid QuestionsDocument6 pagesDme-II Mid QuestionsSree MurthyNo ratings yet

- Question Bank Numericals DMEDocument3 pagesQuestion Bank Numericals DMEVanessa SmithNo ratings yet

- Me8593 Iq R17Document4 pagesMe8593 Iq R17Vaideesh LJNo ratings yet

- Machine Design 2 P1 - Review of ShaftingDocument1 pageMachine Design 2 P1 - Review of Shafting裴瑞尼No ratings yet

- gupta PG - No:176) Exercise 9Document3 pagesgupta PG - No:176) Exercise 9mahendra babu mekalaNo ratings yet

- Cone Clutch Question BankDocument3 pagesCone Clutch Question BankSriram Nanjangud Subramanya100% (2)

- Assignment No. 3 &4 B.Tech Mechanical Engineering Third YearDocument4 pagesAssignment No. 3 &4 B.Tech Mechanical Engineering Third Yearharish_kumar201301No ratings yet

- Engine QBDocument4 pagesEngine QBSapari VelNo ratings yet

- Dom Assign MentDocument2 pagesDom Assign Mentjamunaa830% (2)

- Automobile Design Rev2015Document6 pagesAutomobile Design Rev2015Rithik Raj RanjuNo ratings yet

- MD-II Question BankDocument3 pagesMD-II Question BankAnonymous Pfi1bgrYNo ratings yet

- Our Official Android App - REJINPAUL NETWORK FromDocument3 pagesOur Official Android App - REJINPAUL NETWORK FromAjay KumarNo ratings yet

- Dme - Ii (17me64) : Assignement 01Document3 pagesDme - Ii (17me64) : Assignement 01NAVEEN H ENo ratings yet

- Design of Machine ElementsDocument10 pagesDesign of Machine ElementsMahalingam NanjappanNo ratings yet

- Macine Element I Worksheet For Final ExamDocument4 pagesMacine Element I Worksheet For Final Examdagimawgchew777No ratings yet

- Machine Design Exam PDFDocument6 pagesMachine Design Exam PDFLanz Cruzat100% (1)

- Tom I MT QB - 2022-23Document2 pagesTom I MT QB - 2022-23KirtanNo ratings yet

- Bolts and Power ScrewDocument1 pageBolts and Power Screwkim dianonNo ratings yet

- Dme Model Key 2019Document25 pagesDme Model Key 2019Siva RamanNo ratings yet

- Unit I - Shafts: Single ElementDocument7 pagesUnit I - Shafts: Single Elementchelam101100% (1)

- Dom Gtu ImpDocument8 pagesDom Gtu ImpSwastik PanchalNo ratings yet

- Elemen MesinDocument23 pagesElemen MesinMonika NikaNo ratings yet

- MD1 M3 Compiled Ot 1Document67 pagesMD1 M3 Compiled Ot 1Jiuan AndradaNo ratings yet

- Dom Unit I Imp QuestionsDocument1 pageDom Unit I Imp QuestionsSree MurthyNo ratings yet

- Machine Element-I WorksheetDocument4 pagesMachine Element-I WorksheetNahum MykingNo ratings yet

- Iii Me Ii Sem Q.bank 2016-17Document32 pagesIii Me Ii Sem Q.bank 2016-17Abhishek SakatNo ratings yet

- TE - 2019 - Design of Machine Elements PDFDocument4 pagesTE - 2019 - Design of Machine Elements PDFonkar nikamNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Prompting Science and Engineering Students in Practical TrigonometryFrom EverandPrompting Science and Engineering Students in Practical TrigonometryNo ratings yet

- Plano ElectricoDocument7 pagesPlano ElectricoCarlos FerreiraNo ratings yet

- 6 Cylinder: John Deere Engine Head Torque SequenceDocument1 page6 Cylinder: John Deere Engine Head Torque SequenceLieLiec CriStiantoNo ratings yet

- Instruction Sheet Is-Vr1501 Style Number: Vr1501Pn, Vr1501EsDocument4 pagesInstruction Sheet Is-Vr1501 Style Number: Vr1501Pn, Vr1501Esdayshift5No ratings yet

- Remove & Install CounterweightDocument2 pagesRemove & Install CounterweightchanlinNo ratings yet

- Springs NotesDocument9 pagesSprings NotesP DargopatilNo ratings yet

- Cat 3512B: Diesel Generator SetsDocument6 pagesCat 3512B: Diesel Generator SetsMohiuddin totulNo ratings yet

- AE Notes1 PDFDocument240 pagesAE Notes1 PDFchaitanya mudlapurNo ratings yet

- What Is Clean DieselDocument3 pagesWhat Is Clean DieselMeleștean MihaiNo ratings yet

- G-V-64C-D-XH: High Ow, Extreme High Head, Heavy Duty PumpDocument2 pagesG-V-64C-D-XH: High Ow, Extreme High Head, Heavy Duty Pumpjoanna joannaNo ratings yet

- Design of Machine Elements: Nivish GeorgeDocument25 pagesDesign of Machine Elements: Nivish GeorgeVishwa VardhanNo ratings yet

- I 3 SDocument13 pagesI 3 SSudhanshu PahadiaNo ratings yet

- Arctic Cat 2012 Prowler XT XTX XTZ Service ManualDocument20 pagesArctic Cat 2012 Prowler XT XTX XTZ Service Manualmark100% (57)

- Wip No 34664 4351AKDocument4 pagesWip No 34664 4351AKHari Hara SuthanNo ratings yet

- MAGATDocument1 pageMAGATReden LopezNo ratings yet

- Feed Pump Long TypeDocument20 pagesFeed Pump Long TypeSyam NairNo ratings yet

- X ( J / ËEÚŒ ( EÚ - EÚ Æ ( Æ "I HDocument8 pagesX ( J / ËEÚŒ ( EÚ - EÚ Æ ( Æ "I HTuna garadaNo ratings yet

- Diag Gen 3500BDocument2 pagesDiag Gen 3500BEdison ChicaizaNo ratings yet

- 2SB 1Document59 pages2SB 1Sukon SuNo ratings yet

- 794ac Plano LctriicoDocument16 pages794ac Plano LctriicoIvan De La Cruz GagoNo ratings yet

- Company Profile MetalindoDocument38 pagesCompany Profile MetalindoAngga PratamaNo ratings yet

- Parts - Equipment REMEXIM OÜDocument12 pagesParts - Equipment REMEXIM OÜBOCHORIDISMEUROPARTSNo ratings yet

- Dab Bombas Pag 5Document84 pagesDab Bombas Pag 5Evaldo Grasso NunesNo ratings yet

- FP3.0 INT TablerosDocument24 pagesFP3.0 INT TablerossueNo ratings yet

- Parts of A Robot, DOF, Classifying Robots PDFDocument71 pagesParts of A Robot, DOF, Classifying Robots PDFAswath SridharNo ratings yet

- Berlingo Mjenjač EgsDocument6 pagesBerlingo Mjenjač EgsSaša GojkovićNo ratings yet

- Protean ElectricDocument19 pagesProtean ElectricÁdám SzerbinNo ratings yet

Assignment AUT, A, B and MT Year 3, Level 7

Assignment AUT, A, B and MT Year 3, Level 7

Uploaded by

giftdamas3500 ratings0% found this document useful (0 votes)

2 views2 pagesOriginal Title

1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

2 views2 pagesAssignment AUT, A, B and MT Year 3, Level 7

Assignment AUT, A, B and MT Year 3, Level 7

Uploaded by

giftdamas350Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

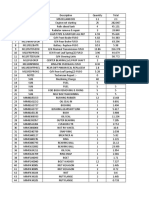

Assignment AUT, A,B and MT year 3, Level 7

1. A power screw having double start square threads of 25 mm

nominal diameter and 5 mm pitch is acted upon by an axial load of

10kN. The outer and inner diameters of screw collar are 50 mm and

20 mm respectively. The coefficient of thread friction and collar

friction may be assumed as 0.2 and 0.15 respectively. The screw

rotates at 12 r.p.m. Assuming uniform wear condition at the collar

and allowable thread bearing pressure of 5.8 N/mm2, find:

(i). the torque required to rotate the screw;

(ii). the stress in the screw;

and (iii). the number of threads of nut in engagement with screw.

2. The mean diameter of the square threaded screw having pitch of

10 mm is 50 mm. A load of 20kN is lifted through a distance of 170

mm. Find the work done in lifting the load and the efficiency of the

screw, when

1. The load rotates with the screw, and

2. The load rests on the loose head which does not rotate with the

screw.

The external and internal diameter of the bearing surface of the loose

head are 60 mm and 10 mm respectively. The coefficient of friction

for the screw and the bearing surface may be taken as 0.08.

3. A vertical two start square threaded screw of a 100 mm mean

diameter and20 mm pitch supports a vertical load of 18 KN. The axial

bearing of 250 mm outside diameter and 100 mm inside diameter.

Find the force required at the end of a lever which is 400 mm long in

order to lift and lower the load. The coefficient of friction for the

vertical screw and nut is 0.15 and that for collar bearing is 0.20.

4. The cutter of a broaching machine is pulled by square threaded

screw of 55 mm external diameter and 10 mm pitch. The operating

nut takes the axial load of 400 N on a flat surface of 60 mm and 90

mm internal and external diameters respectively. If the coefficient of

friction is 0.15 for all contact surfaces on the nut, determine the

power required to rotate the operating nut when the cutting speed is

6 m/min. Also find the efficiency of the screw.

5. An electric motor driven power screw moves a nut in a horizontal

plane against a force of 75 kN at a speed of 300 mm / min. The screw

has a single square thread of 6 mm pitch on a major diameter of 40

mm. The coefficient of friction at screw threads is 0.1. Estimate power

of the motor.

6. A vertical screw with single start square threads of 50 mm mean

diameter and 12.5 mm pitch is raised against a load of 10kN by

means of a hand wheel, the boss of which is threaded to act as a nut.

The axial load is taken up by a thrust collar which supports the wheel

boss and has a mean diameter of 60 mm. The coefficient of friction is

0.15 for the screw and 0.18 for the collar. If the tangential force

applied by each hand to the wheel is 100 N, find suitable diameter of

the hand wheel.

You might also like

- Honda Magna VF750C Wiring RC43 - 2023-10-11Document6 pagesHonda Magna VF750C Wiring RC43 - 2023-10-11rhys.aaron.sinclairNo ratings yet

- 3054 T & Ta Underground Mining Equipment: Caterpillar Engine SpecificationsDocument2 pages3054 T & Ta Underground Mining Equipment: Caterpillar Engine SpecificationsMas Inyeccion Electronica100% (2)

- SANY RSC45 Container Reach Stacker Maintenance Manual PDFDocument29 pagesSANY RSC45 Container Reach Stacker Maintenance Manual PDFejaz86% (7)

- MDSP Set 2Document9 pagesMDSP Set 2iaton77100% (2)

- Design of Electronic Semi - Automatic Clutch For Manual Actuation of Clutch in A CarDocument6 pagesDesign of Electronic Semi - Automatic Clutch For Manual Actuation of Clutch in A CarTamilarasanRpcg100% (2)

- Friction 2 Marks and Important ProblemsDocument2 pagesFriction 2 Marks and Important ProblemsSachi DhanandamNo ratings yet

- Power ScrewsDocument2 pagesPower ScrewsdvarsastryNo ratings yet

- Screw TutDocument2 pagesScrew TutEDISON OCHIENGNo ratings yet

- Pointers For ReviewDocument3 pagesPointers For ReviewAdriel JohnNo ratings yet

- Assignment No - 2 TE Div - BDocument2 pagesAssignment No - 2 TE Div - BSubhash KNo ratings yet

- Machine Design Fayoum University 2 Year - 2016-2017 Faculty of Engineering Sheet 2 Mechanical Engineering DepartmentDocument2 pagesMachine Design Fayoum University 2 Year - 2016-2017 Faculty of Engineering Sheet 2 Mechanical Engineering DepartmentAhmed Rabie Abd ElazeemNo ratings yet

- ME 311 Assignment Sheet No.3, 2016Document2 pagesME 311 Assignment Sheet No.3, 2016Aryan DCNo ratings yet

- DMM Question BankDocument2 pagesDMM Question Bankzubair ahmedNo ratings yet

- Department of Mechanical Engineering 18MD04-Kinematics of Machinery Module-3 Friction QuestionsDocument2 pagesDepartment of Mechanical Engineering 18MD04-Kinematics of Machinery Module-3 Friction QuestionsEmperor89No ratings yet

- Tutorial 6 (Kom)Document1 pageTutorial 6 (Kom)patelsandip1990No ratings yet

- FinallDocument175 pagesFinallremeceldo dagamac100% (1)

- Tom-Assignment 2Document2 pagesTom-Assignment 2jamunaa83No ratings yet

- Power Screw SheetDocument4 pagesPower Screw SheetMohamed GamalNo ratings yet

- Design of Machine Elements - IIDocument8 pagesDesign of Machine Elements - IIprasaad26No ratings yet

- MECH4914 Tutorial Sheet 3Document3 pagesMECH4914 Tutorial Sheet 3ahmedNo ratings yet

- Power Screw PrimeDocument6 pagesPower Screw PrimeFuture HazeNo ratings yet

- Design1 SheetsDocument9 pagesDesign1 SheetsYou channelNo ratings yet

- Dme Unit Ii (17.11.22)Document23 pagesDme Unit Ii (17.11.22)sathiaNo ratings yet

- ME-323 Threaded-Members 42423Document48 pagesME-323 Threaded-Members 42423Jam Maica TuboNo ratings yet

- EMD Question Bank II 2Document4 pagesEMD Question Bank II 2Soham MisalNo ratings yet

- UNIT 5 FullDocument8 pagesUNIT 5 FullNavinsithiNo ratings yet

- B Tech - 6 Sem (CBGS) Course Code: ME 602 Subject Name: Machine Component & Design Important Questions Unit - 1Document6 pagesB Tech - 6 Sem (CBGS) Course Code: ME 602 Subject Name: Machine Component & Design Important Questions Unit - 1suneel kumar rathoreNo ratings yet

- Imp Qoestions MDDocument3 pagesImp Qoestions MDvenuedNo ratings yet

- Tutorial No.6 DMEDocument1 pageTutorial No.6 DMEOnkarNo ratings yet

- Screw Friction-Tute - 2021 PDFDocument2 pagesScrew Friction-Tute - 2021 PDF凵又个已刀了七乙个入厂大No ratings yet

- DME Chapter Three: or (Summer 15)Document7 pagesDME Chapter Three: or (Summer 15)honeyfunnyNo ratings yet

- Assignment 3 TOM2 YBKDocument2 pagesAssignment 3 TOM2 YBKyogesh_b_kNo ratings yet

- Dme-II Mid QuestionsDocument6 pagesDme-II Mid QuestionsSree MurthyNo ratings yet

- Question Bank Numericals DMEDocument3 pagesQuestion Bank Numericals DMEVanessa SmithNo ratings yet

- Me8593 Iq R17Document4 pagesMe8593 Iq R17Vaideesh LJNo ratings yet

- Machine Design 2 P1 - Review of ShaftingDocument1 pageMachine Design 2 P1 - Review of Shafting裴瑞尼No ratings yet

- gupta PG - No:176) Exercise 9Document3 pagesgupta PG - No:176) Exercise 9mahendra babu mekalaNo ratings yet

- Cone Clutch Question BankDocument3 pagesCone Clutch Question BankSriram Nanjangud Subramanya100% (2)

- Assignment No. 3 &4 B.Tech Mechanical Engineering Third YearDocument4 pagesAssignment No. 3 &4 B.Tech Mechanical Engineering Third Yearharish_kumar201301No ratings yet

- Engine QBDocument4 pagesEngine QBSapari VelNo ratings yet

- Dom Assign MentDocument2 pagesDom Assign Mentjamunaa830% (2)

- Automobile Design Rev2015Document6 pagesAutomobile Design Rev2015Rithik Raj RanjuNo ratings yet

- MD-II Question BankDocument3 pagesMD-II Question BankAnonymous Pfi1bgrYNo ratings yet

- Our Official Android App - REJINPAUL NETWORK FromDocument3 pagesOur Official Android App - REJINPAUL NETWORK FromAjay KumarNo ratings yet

- Dme - Ii (17me64) : Assignement 01Document3 pagesDme - Ii (17me64) : Assignement 01NAVEEN H ENo ratings yet

- Design of Machine ElementsDocument10 pagesDesign of Machine ElementsMahalingam NanjappanNo ratings yet

- Macine Element I Worksheet For Final ExamDocument4 pagesMacine Element I Worksheet For Final Examdagimawgchew777No ratings yet

- Machine Design Exam PDFDocument6 pagesMachine Design Exam PDFLanz Cruzat100% (1)

- Tom I MT QB - 2022-23Document2 pagesTom I MT QB - 2022-23KirtanNo ratings yet

- Bolts and Power ScrewDocument1 pageBolts and Power Screwkim dianonNo ratings yet

- Dme Model Key 2019Document25 pagesDme Model Key 2019Siva RamanNo ratings yet

- Unit I - Shafts: Single ElementDocument7 pagesUnit I - Shafts: Single Elementchelam101100% (1)

- Dom Gtu ImpDocument8 pagesDom Gtu ImpSwastik PanchalNo ratings yet

- Elemen MesinDocument23 pagesElemen MesinMonika NikaNo ratings yet

- MD1 M3 Compiled Ot 1Document67 pagesMD1 M3 Compiled Ot 1Jiuan AndradaNo ratings yet

- Dom Unit I Imp QuestionsDocument1 pageDom Unit I Imp QuestionsSree MurthyNo ratings yet

- Machine Element-I WorksheetDocument4 pagesMachine Element-I WorksheetNahum MykingNo ratings yet

- Iii Me Ii Sem Q.bank 2016-17Document32 pagesIii Me Ii Sem Q.bank 2016-17Abhishek SakatNo ratings yet

- TE - 2019 - Design of Machine Elements PDFDocument4 pagesTE - 2019 - Design of Machine Elements PDFonkar nikamNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Prompting Science and Engineering Students in Practical TrigonometryFrom EverandPrompting Science and Engineering Students in Practical TrigonometryNo ratings yet

- Plano ElectricoDocument7 pagesPlano ElectricoCarlos FerreiraNo ratings yet

- 6 Cylinder: John Deere Engine Head Torque SequenceDocument1 page6 Cylinder: John Deere Engine Head Torque SequenceLieLiec CriStiantoNo ratings yet

- Instruction Sheet Is-Vr1501 Style Number: Vr1501Pn, Vr1501EsDocument4 pagesInstruction Sheet Is-Vr1501 Style Number: Vr1501Pn, Vr1501Esdayshift5No ratings yet

- Remove & Install CounterweightDocument2 pagesRemove & Install CounterweightchanlinNo ratings yet

- Springs NotesDocument9 pagesSprings NotesP DargopatilNo ratings yet

- Cat 3512B: Diesel Generator SetsDocument6 pagesCat 3512B: Diesel Generator SetsMohiuddin totulNo ratings yet

- AE Notes1 PDFDocument240 pagesAE Notes1 PDFchaitanya mudlapurNo ratings yet

- What Is Clean DieselDocument3 pagesWhat Is Clean DieselMeleștean MihaiNo ratings yet

- G-V-64C-D-XH: High Ow, Extreme High Head, Heavy Duty PumpDocument2 pagesG-V-64C-D-XH: High Ow, Extreme High Head, Heavy Duty Pumpjoanna joannaNo ratings yet

- Design of Machine Elements: Nivish GeorgeDocument25 pagesDesign of Machine Elements: Nivish GeorgeVishwa VardhanNo ratings yet

- I 3 SDocument13 pagesI 3 SSudhanshu PahadiaNo ratings yet

- Arctic Cat 2012 Prowler XT XTX XTZ Service ManualDocument20 pagesArctic Cat 2012 Prowler XT XTX XTZ Service Manualmark100% (57)

- Wip No 34664 4351AKDocument4 pagesWip No 34664 4351AKHari Hara SuthanNo ratings yet

- MAGATDocument1 pageMAGATReden LopezNo ratings yet

- Feed Pump Long TypeDocument20 pagesFeed Pump Long TypeSyam NairNo ratings yet

- X ( J / ËEÚŒ ( EÚ - EÚ Æ ( Æ "I HDocument8 pagesX ( J / ËEÚŒ ( EÚ - EÚ Æ ( Æ "I HTuna garadaNo ratings yet

- Diag Gen 3500BDocument2 pagesDiag Gen 3500BEdison ChicaizaNo ratings yet

- 2SB 1Document59 pages2SB 1Sukon SuNo ratings yet

- 794ac Plano LctriicoDocument16 pages794ac Plano LctriicoIvan De La Cruz GagoNo ratings yet

- Company Profile MetalindoDocument38 pagesCompany Profile MetalindoAngga PratamaNo ratings yet

- Parts - Equipment REMEXIM OÜDocument12 pagesParts - Equipment REMEXIM OÜBOCHORIDISMEUROPARTSNo ratings yet

- Dab Bombas Pag 5Document84 pagesDab Bombas Pag 5Evaldo Grasso NunesNo ratings yet

- FP3.0 INT TablerosDocument24 pagesFP3.0 INT TablerossueNo ratings yet

- Parts of A Robot, DOF, Classifying Robots PDFDocument71 pagesParts of A Robot, DOF, Classifying Robots PDFAswath SridharNo ratings yet

- Berlingo Mjenjač EgsDocument6 pagesBerlingo Mjenjač EgsSaša GojkovićNo ratings yet

- Protean ElectricDocument19 pagesProtean ElectricÁdám SzerbinNo ratings yet