Professional Documents

Culture Documents

QSGF Demo Board E

QSGF Demo Board E

Uploaded by

CleytonBronoskiCopyright:

Available Formats

You might also like

- Ford Falcon Workshop Manual 2008 - 2014 FG Free Factory Service ManualDocument3 pagesFord Falcon Workshop Manual 2008 - 2014 FG Free Factory Service ManualEddie Mamudoski17% (6)

- EV PDI PDS Sheet - v2Document2 pagesEV PDI PDS Sheet - v2yonatan solomon100% (3)

- PC 3.3 With QSK45 and 60Document432 pagesPC 3.3 With QSK45 and 60Sajid Hanif92% (12)

- Vermeer D100x120 Series II NavigatorDocument608 pagesVermeer D100x120 Series II NavigatorHector DiazNo ratings yet

- 4TEC3F60B1000ADocument21 pages4TEC3F60B1000ABlackdragon86No ratings yet

- Ba CFD - RLM - 9 8 10 2018 - en PDFDocument18 pagesBa CFD - RLM - 9 8 10 2018 - en PDFAngga HardiyantomoNo ratings yet

- 02 A4-A3-e PDFDocument177 pages02 A4-A3-e PDFAttila KolesNo ratings yet

- BD Compressors 04-2007 pk100c802Document32 pagesBD Compressors 04-2007 pk100c802georgedragosNo ratings yet

- Pioneer X-EM11 Manual enDocument27 pagesPioneer X-EM11 Manual enDragan CavicNo ratings yet

- Vma DP 00697 D s01Document56 pagesVma DP 00697 D s01Pasc Claudiu100% (1)

- Manual Service Tektronix 2712Document692 pagesManual Service Tektronix 2712TECSISCOM100% (1)

- Pioneer vsx-524-k vsx-5241 Av Receiver rrv4533 Parts SMDocument4 pagesPioneer vsx-524-k vsx-5241 Av Receiver rrv4533 Parts SMImraan Ramdjan50% (2)

- PJ500MDocument92 pagesPJ500Mvasilikot100% (2)

- Rockwell T 221 T 223 Transfer Case Parts ManualDocument47 pagesRockwell T 221 T 223 Transfer Case Parts ManualMauricio Exequiel Chavez100% (1)

- 5600 Single Phase Circuit DiagramDocument11 pages5600 Single Phase Circuit DiagramPaulmankeNo ratings yet

- SBM Technology: Cooling / Air Recovery ValveDocument8 pagesSBM Technology: Cooling / Air Recovery ValveEricsson BotchweyNo ratings yet

- Ariston LL64 - B-S-W - MANUALDocument31 pagesAriston LL64 - B-S-W - MANUALSebastianNo ratings yet

- GEZE Installation Instructions en 740565Document32 pagesGEZE Installation Instructions en 740565PiotrNo ratings yet

- 05 4 ServomotorsDocument118 pages05 4 ServomotorsJosé Carlos Macavilca RománNo ratings yet

- Manual Ur82 VivancoDocument35 pagesManual Ur82 Vivancorotzkop0% (1)

- Customs Poster For ODSDocument1 pageCustoms Poster For ODSkashifbutty2k0% (1)

- Lead-Free Repairing SystemDocument14 pagesLead-Free Repairing SystemRoy Muy GolfoNo ratings yet

- Ak VSG260Document14 pagesAk VSG260bartholomuszNo ratings yet

- Hoval+Thermalia+ Technical+ INM-en+ 2017 PDFDocument94 pagesHoval+Thermalia+ Technical+ INM-en+ 2017 PDFTunadcoNo ratings yet

- Deh 2350ubDocument62 pagesDeh 2350ubLuis XoocNo ratings yet

- OM070 Halton M.a.R.v.E.L. Demand Control VentilationDocument31 pagesOM070 Halton M.a.R.v.E.L. Demand Control VentilationRaul Jaime Flores GuardiaNo ratings yet

- AVH-X5880TV: CRT5881 DVD Rds Av ReceiverDocument2 pagesAVH-X5880TV: CRT5881 DVD Rds Av ReceiverRogerio BuenoNo ratings yet

- Bluesky, TV Beko 12.7 Chassis, SMDocument5 pagesBluesky, TV Beko 12.7 Chassis, SMkilol0No ratings yet

- Manual Home Theater HTS3520Document20 pagesManual Home Theater HTS3520José CardozoNo ratings yet

- Rocktron Patchmate Loop FloorDocument32 pagesRocktron Patchmate Loop FloorrazvskarbuNo ratings yet

- FP92E C501 Service Manual 9J.L2V72.000 9J.L2V72.000-C501-001 9J.L2V72.001 NA Q9C5Document49 pagesFP92E C501 Service Manual 9J.L2V72.000 9J.L2V72.000-C501-001 9J.L2V72.001 NA Q9C5Iliescu CristianNo ratings yet

- Service Manual: 27" Color TelevisionDocument54 pagesService Manual: 27" Color TelevisionEnriqueNo ratings yet

- Catalogo Botoes EatonDocument348 pagesCatalogo Botoes EatonxixiaucamruNo ratings yet

- LG FloorStanding - Service Manual P05AH (AP-Z488TC0)Document56 pagesLG FloorStanding - Service Manual P05AH (AP-Z488TC0)abcdefNo ratings yet

- Toshiba 42WP56 Plasma TV Service ManualDocument94 pagesToshiba 42WP56 Plasma TV Service ManualrogermbNo ratings yet

- LG LCS500UN Manual Servicio PDFDocument47 pagesLG LCS500UN Manual Servicio PDFaldo0% (1)

- Philips Hts5520Document68 pagesPhilips Hts5520miroljubNo ratings yet

- PanasonicDocument26 pagesPanasonicmecatronic22No ratings yet

- Hoh Singh VP 70 Manual English 1Document32 pagesHoh Singh VP 70 Manual English 1David Zoracá HNo ratings yet

- Part 1. Introduction: A Brief HistoryDocument9 pagesPart 1. Introduction: A Brief HistoryJean RisquezNo ratings yet

- CFD F17CPDocument58 pagesCFD F17CPEmmanuel VargasNo ratings yet

- Pioneer Pdp-lx5090 Arp3480Document185 pagesPioneer Pdp-lx5090 Arp3480dasho1No ratings yet

- PT4 Pressure Transmitters: Technical DataDocument4 pagesPT4 Pressure Transmitters: Technical DataMamdooh AbdallahNo ratings yet

- AD INTERNATIONAL Model 950Document21 pagesAD INTERNATIONAL Model 950Zoeloe_2No ratings yet

- Dell Inspiron E1505 - 6400 Service ManualDocument57 pagesDell Inspiron E1505 - 6400 Service Manualankurb.iimbNo ratings yet

- Pioneer-GMX542 642 CarampDocument26 pagesPioneer-GMX542 642 Carampccris13No ratings yet

- DVD Toshiba Sd-3990su, Sd-3990sc Service ManualDocument30 pagesDVD Toshiba Sd-3990su, Sd-3990sc Service Manualmaldo7No ratings yet

- Physiomed Physioson Expert Operating Instructions Manual 34Document34 pagesPhysiomed Physioson Expert Operating Instructions Manual 34nhatnam06dt1No ratings yet

- Lavavajillas Whirlpool ADP6600WH Ver 8542 660 53950 Service ManualDocument15 pagesLavavajillas Whirlpool ADP6600WH Ver 8542 660 53950 Service ManualMarcelo Sergio HamerNo ratings yet

- Codigos de Diodos Zener PDFDocument6 pagesCodigos de Diodos Zener PDFEduardo Perez100% (1)

- Service Manual: HCD-BX2/DX2/DX2BDocument72 pagesService Manual: HCD-BX2/DX2/DX2BDanielNo ratings yet

- Nad C375bee PDFDocument59 pagesNad C375bee PDFAnonymous rFnwsvNo ratings yet

- CERAVAC Transmitter: Operating Manual 17200257 - 002 - 02Document32 pagesCERAVAC Transmitter: Operating Manual 17200257 - 002 - 02mayito12093120No ratings yet

- Samsung Ua32eh50x0r 40eh50x0r Ua42eh5000r Ua46eh50x0r-50eh50x0r Ua22es500xr Chassis U73a 74pagesDocument74 pagesSamsung Ua32eh50x0r 40eh50x0r Ua42eh5000r Ua46eh50x0r-50eh50x0r Ua22es500xr Chassis U73a 74pagesWilinton PissoNo ratings yet

- Icom UT-109 UT-110 Instruction ManualDocument13 pagesIcom UT-109 UT-110 Instruction Manualmusan15No ratings yet

- Candy Auto Test Za Cld135Document5 pagesCandy Auto Test Za Cld135Zoran KovacevicNo ratings yet

- Manual Inglês AI-010 Transdutor 3-15-PSI Série-G7Document5 pagesManual Inglês AI-010 Transdutor 3-15-PSI Série-G7davinmotion051No ratings yet

- ASD533 TD T140287en BDocument111 pagesASD533 TD T140287en Btame7478No ratings yet

- Service Information: GeneralDocument3 pagesService Information: GeneralghilesNo ratings yet

- Industrial Heat Flux SensorDocument27 pagesIndustrial Heat Flux Sensorسامح الجاسمNo ratings yet

- ASD531 TD T140416enDocument105 pagesASD531 TD T140416enishaangreavesNo ratings yet

- Instruction Manual Feel FDP - Eng 4Document8 pagesInstruction Manual Feel FDP - Eng 4Bui TAN HIEPNo ratings yet

- FP0ThermocoupleUnit ARCT1F366V10EN PDFDocument31 pagesFP0ThermocoupleUnit ARCT1F366V10EN PDFHuuThienNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Needle Valve With Reverse Flow Check ZW-SDR06: Sandwich Plate TypeDocument2 pagesNeedle Valve With Reverse Flow Check ZW-SDR06: Sandwich Plate TypeCleytonBronoskiNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2003/0222067 A1Document24 pagesPatent Application Publication (10) Pub. No.: US 2003/0222067 A1CleytonBronoskiNo ratings yet

- EC500 User Manual V2Document24 pagesEC500 User Manual V2CleytonBronoskiNo ratings yet

- Automotive Diagnostic System GT90 User's Manual v120180622Document84 pagesAutomotive Diagnostic System GT90 User's Manual v120180622CleytonBronoskiNo ratings yet

- FTF 40 Food Grade Centrifugal Feeder Installation Maintenance ManualDocument48 pagesFTF 40 Food Grade Centrifugal Feeder Installation Maintenance ManualCleytonBronoskiNo ratings yet

- DS LEADER-Volt Catalog USAR ZCL08.264.US .4Document2 pagesDS LEADER-Volt Catalog USAR ZCL08.264.US .4Zouhir kéniNo ratings yet

- Seated Valves: Type WV700Document14 pagesSeated Valves: Type WV700John EvansNo ratings yet

- Getrag En1 PDFDocument6 pagesGetrag En1 PDFJeremías EspinozaNo ratings yet

- IEC Catalog PDFDocument36 pagesIEC Catalog PDFPeter RhoadsNo ratings yet

- SF395Document1 pageSF395EduRoiNo ratings yet

- Technical Details: Complementary Metal-Oxide-Semiconductor (CMOS)Document4 pagesTechnical Details: Complementary Metal-Oxide-Semiconductor (CMOS)Testing toolsNo ratings yet

- GRT200 Brochure - 16001-G2A-1.1Document37 pagesGRT200 Brochure - 16001-G2A-1.1krishna mohanNo ratings yet

- M E S C: Power / Control CableDocument2 pagesM E S C: Power / Control CablerajuNo ratings yet

- Technical Data Sheet Arcapro Positioner Type 827A TD - 827ADocument15 pagesTechnical Data Sheet Arcapro Positioner Type 827A TD - 827AMakshoof GulNo ratings yet

- John Deere Tractor Parts Manual JD P Pc1539Document33 pagesJohn Deere Tractor Parts Manual JD P Pc1539jose marfullNo ratings yet

- Crane Systems: Greer Company Greer Company Greer Company Greer CompanyDocument14 pagesCrane Systems: Greer Company Greer Company Greer Company Greer Companyduongpndng100% (1)

- Hirschmann HC3901 Operation Manual ZCC1100H 20140804 PDFDocument29 pagesHirschmann HC3901 Operation Manual ZCC1100H 20140804 PDFPAULO100% (1)

- Arc Protection Instruction Manual EN1.1Document65 pagesArc Protection Instruction Manual EN1.1Alexandre MorenoNo ratings yet

- 3516B Generator Set Engine Fuel Injector Adjustment SIS CATERPILLAR PDFDocument5 pages3516B Generator Set Engine Fuel Injector Adjustment SIS CATERPILLAR PDFayman akrabNo ratings yet

- IND5Document14 pagesIND5ExperimentonomenNo ratings yet

- Infinte Peripherals Infinea Tab 2 User GuideDocument23 pagesInfinte Peripherals Infinea Tab 2 User GuidearrowheadcorpNo ratings yet

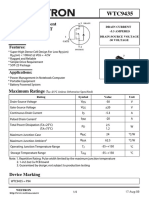

- P-Channel Enhancement Mode Power MOSFET: FeaturesDocument4 pagesP-Channel Enhancement Mode Power MOSFET: FeaturesMarco MoralesNo ratings yet

- Hyosung PlanetDocument8 pagesHyosung PlanetErcan BAYRAKCINo ratings yet

- Impact Valve Block (COPROD) : Qds-A QDS-J Pilot ValveDocument11 pagesImpact Valve Block (COPROD) : Qds-A QDS-J Pilot ValveFrancisco Alvarado HuenquiaoNo ratings yet

- DSE7310 MKII DSE7320 MKII Configuration Suite PC Software Manual PDFDocument232 pagesDSE7310 MKII DSE7320 MKII Configuration Suite PC Software Manual PDFEdson Da Rosa MachadoNo ratings yet

- C. AppendixDocument20 pagesC. AppendixgechnetNo ratings yet

- Compliance 34Document4 pagesCompliance 34midhunvarNo ratings yet

- Auger CabinDocument442 pagesAuger CabinOsw GalatiNo ratings yet

- 74 HC 4060Document13 pages74 HC 4060anyenkts2No ratings yet

QSGF Demo Board E

QSGF Demo Board E

Uploaded by

CleytonBronoskiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QSGF Demo Board E

QSGF Demo Board E

Uploaded by

CleytonBronoskiCopyright:

Available Formats

Quick Start Guide

Flow Demo Board

FS5/FS7, OOL

Front side of Flow Demo Board:

Back side of Flow Demo Board:

A = 3.5 mm

W = 31 mm

L = 80 mm

How to connect PCB:

▪ For OOL sensor move switch to “OOL” position, for FS5 or FS7 sensor to “FS5/7” position.

▪ Connect the sensor to CON2 terminals according to the diagram on back of PCB: Heater to terminals “H”,

temperature sensor to terminals “S” (screw or solder them directly to pads). For FS5 or FS7 sensor please

connect sensor’s common wire to one of the middle terminals of CON2.

▪ Select desired difference of temperatures between heater and temperature sensor using ΔT switch and the

table on back of the PCB.

▪ Connect power supply to CON1: positive to “VCC”, negative to “GND”. For OOL sensor no more than +15 V,

for FS5/7 no more than +9 V.

▪ Connect voltmeter to CON1: positive to “OUT” or “OUTZ”, negative to “GND”.

▪ Switch on power supply.

▪ For zero flow press “ZERO” button in order to subtract zero flow offset from LED bar and “OUTZ” output, note

that “OUT” output will remain unaffected.

▪ The OOL sensor is directional, flow’s direction should be: from temperature sensor to heater.

QSGF_Demo_Board_E2.3.2 | Flow | Demo Board 1/4

Wiring for OOL Sensor:

temperature sensor

FLOW

heater

Wiring for FS5/FS7 Sensor:

heater

common

temperature

sensor

QSGF_Demo_Board_E2.3.2 | Flow | Demo Board 2/4

How the PCB works:

▪ The PCB measures flow using the Constant Temperature Anemometer (CTA) principle.

▪ During normal operation CTA will always keep the temperature of the heater (TH) above the temperature of the

sensor (TS) by a constant, predefined value ΔT = TH – TS.

▪ The CTA is made using an analog Wheatstone Bridge with simplified diagram:

▪ PCB’s output voltage “OUT” is connected to the bridge.

▪ Additionally, the PCB has the “OUTZ” output allowing the user to measure flow without zero flow offset (zero

flow = zero volts).

▪ Maximum power dissipated in the sensor / maximum “OUT” voltage can be limited using supply voltage:

UOUT(max) = VCC – 2V. Maximum VCC current should not exceed 0.4 A.

▪ The PCB is protected using 0.5 A fuse F1, if PCB does not respond please check the fuse.

▪ The total value of R14..16 sensors is 21 Ω, for OOL sensor R17 = 420 Ω while for FS5/7 sensor R17 = 560 Ω.

▪ Please note that the Flow Demo Board ist not temperature-compensated.

Typical characteristics

FS7 Sensor:

QSGF_Demo_Board_E2.3.2 | Flow | Demo Board 3/4

OOL Sensor:

Order Information

Order Code / Former order code:

108327 Board without sensor

104018 / 160.00023 Board with FS7 sensor (with housing)

104019 / 160.00024 Board with 6 mm Out of Liquid sensor

104021 / 160.00026 Board with 4 mm Out of Liquid sensor

104022 / 160.00027 Board with Real Probe sensors

Additional Documents

Document name:

Data Sheet: DFFS5_E

DFFS7_E

DFOOL_E

DF_Demo_Board_E

Application Note: AFFS5_E

AFFS7_E

Innovative Sensor Technology IST AG, Stegrütistrasse 14, 9642 Ebnat-Kappel, Switzerland

Phone: +41 71 992 01 00 | Fax: +41 71 992 01 99 | Email: info@ist-ag.com | www.ist-ag.com

All mechanical dimensions are valid at 25 °C ambient temperature, if not differently indicated • All data except the mechanical dimensions only have information purposes and are not to be understood as assured characteristics • Technical

changes without previous announcement as well as mistakes reserved • The information on this data sheet was examined carefully and will be accepted as correct; No liability in case of mistakes • Load with extreme values during a longer

period can affect the reliability • The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner • Typing errors and mistakes reserved • Product

specifications are subject to change without notice • All rights reserved

QSGF_Demo_Board_E2.3.2 | Flow | Demo Board 4/4

You might also like

- Ford Falcon Workshop Manual 2008 - 2014 FG Free Factory Service ManualDocument3 pagesFord Falcon Workshop Manual 2008 - 2014 FG Free Factory Service ManualEddie Mamudoski17% (6)

- EV PDI PDS Sheet - v2Document2 pagesEV PDI PDS Sheet - v2yonatan solomon100% (3)

- PC 3.3 With QSK45 and 60Document432 pagesPC 3.3 With QSK45 and 60Sajid Hanif92% (12)

- Vermeer D100x120 Series II NavigatorDocument608 pagesVermeer D100x120 Series II NavigatorHector DiazNo ratings yet

- 4TEC3F60B1000ADocument21 pages4TEC3F60B1000ABlackdragon86No ratings yet

- Ba CFD - RLM - 9 8 10 2018 - en PDFDocument18 pagesBa CFD - RLM - 9 8 10 2018 - en PDFAngga HardiyantomoNo ratings yet

- 02 A4-A3-e PDFDocument177 pages02 A4-A3-e PDFAttila KolesNo ratings yet

- BD Compressors 04-2007 pk100c802Document32 pagesBD Compressors 04-2007 pk100c802georgedragosNo ratings yet

- Pioneer X-EM11 Manual enDocument27 pagesPioneer X-EM11 Manual enDragan CavicNo ratings yet

- Vma DP 00697 D s01Document56 pagesVma DP 00697 D s01Pasc Claudiu100% (1)

- Manual Service Tektronix 2712Document692 pagesManual Service Tektronix 2712TECSISCOM100% (1)

- Pioneer vsx-524-k vsx-5241 Av Receiver rrv4533 Parts SMDocument4 pagesPioneer vsx-524-k vsx-5241 Av Receiver rrv4533 Parts SMImraan Ramdjan50% (2)

- PJ500MDocument92 pagesPJ500Mvasilikot100% (2)

- Rockwell T 221 T 223 Transfer Case Parts ManualDocument47 pagesRockwell T 221 T 223 Transfer Case Parts ManualMauricio Exequiel Chavez100% (1)

- 5600 Single Phase Circuit DiagramDocument11 pages5600 Single Phase Circuit DiagramPaulmankeNo ratings yet

- SBM Technology: Cooling / Air Recovery ValveDocument8 pagesSBM Technology: Cooling / Air Recovery ValveEricsson BotchweyNo ratings yet

- Ariston LL64 - B-S-W - MANUALDocument31 pagesAriston LL64 - B-S-W - MANUALSebastianNo ratings yet

- GEZE Installation Instructions en 740565Document32 pagesGEZE Installation Instructions en 740565PiotrNo ratings yet

- 05 4 ServomotorsDocument118 pages05 4 ServomotorsJosé Carlos Macavilca RománNo ratings yet

- Manual Ur82 VivancoDocument35 pagesManual Ur82 Vivancorotzkop0% (1)

- Customs Poster For ODSDocument1 pageCustoms Poster For ODSkashifbutty2k0% (1)

- Lead-Free Repairing SystemDocument14 pagesLead-Free Repairing SystemRoy Muy GolfoNo ratings yet

- Ak VSG260Document14 pagesAk VSG260bartholomuszNo ratings yet

- Hoval+Thermalia+ Technical+ INM-en+ 2017 PDFDocument94 pagesHoval+Thermalia+ Technical+ INM-en+ 2017 PDFTunadcoNo ratings yet

- Deh 2350ubDocument62 pagesDeh 2350ubLuis XoocNo ratings yet

- OM070 Halton M.a.R.v.E.L. Demand Control VentilationDocument31 pagesOM070 Halton M.a.R.v.E.L. Demand Control VentilationRaul Jaime Flores GuardiaNo ratings yet

- AVH-X5880TV: CRT5881 DVD Rds Av ReceiverDocument2 pagesAVH-X5880TV: CRT5881 DVD Rds Av ReceiverRogerio BuenoNo ratings yet

- Bluesky, TV Beko 12.7 Chassis, SMDocument5 pagesBluesky, TV Beko 12.7 Chassis, SMkilol0No ratings yet

- Manual Home Theater HTS3520Document20 pagesManual Home Theater HTS3520José CardozoNo ratings yet

- Rocktron Patchmate Loop FloorDocument32 pagesRocktron Patchmate Loop FloorrazvskarbuNo ratings yet

- FP92E C501 Service Manual 9J.L2V72.000 9J.L2V72.000-C501-001 9J.L2V72.001 NA Q9C5Document49 pagesFP92E C501 Service Manual 9J.L2V72.000 9J.L2V72.000-C501-001 9J.L2V72.001 NA Q9C5Iliescu CristianNo ratings yet

- Service Manual: 27" Color TelevisionDocument54 pagesService Manual: 27" Color TelevisionEnriqueNo ratings yet

- Catalogo Botoes EatonDocument348 pagesCatalogo Botoes EatonxixiaucamruNo ratings yet

- LG FloorStanding - Service Manual P05AH (AP-Z488TC0)Document56 pagesLG FloorStanding - Service Manual P05AH (AP-Z488TC0)abcdefNo ratings yet

- Toshiba 42WP56 Plasma TV Service ManualDocument94 pagesToshiba 42WP56 Plasma TV Service ManualrogermbNo ratings yet

- LG LCS500UN Manual Servicio PDFDocument47 pagesLG LCS500UN Manual Servicio PDFaldo0% (1)

- Philips Hts5520Document68 pagesPhilips Hts5520miroljubNo ratings yet

- PanasonicDocument26 pagesPanasonicmecatronic22No ratings yet

- Hoh Singh VP 70 Manual English 1Document32 pagesHoh Singh VP 70 Manual English 1David Zoracá HNo ratings yet

- Part 1. Introduction: A Brief HistoryDocument9 pagesPart 1. Introduction: A Brief HistoryJean RisquezNo ratings yet

- CFD F17CPDocument58 pagesCFD F17CPEmmanuel VargasNo ratings yet

- Pioneer Pdp-lx5090 Arp3480Document185 pagesPioneer Pdp-lx5090 Arp3480dasho1No ratings yet

- PT4 Pressure Transmitters: Technical DataDocument4 pagesPT4 Pressure Transmitters: Technical DataMamdooh AbdallahNo ratings yet

- AD INTERNATIONAL Model 950Document21 pagesAD INTERNATIONAL Model 950Zoeloe_2No ratings yet

- Dell Inspiron E1505 - 6400 Service ManualDocument57 pagesDell Inspiron E1505 - 6400 Service Manualankurb.iimbNo ratings yet

- Pioneer-GMX542 642 CarampDocument26 pagesPioneer-GMX542 642 Carampccris13No ratings yet

- DVD Toshiba Sd-3990su, Sd-3990sc Service ManualDocument30 pagesDVD Toshiba Sd-3990su, Sd-3990sc Service Manualmaldo7No ratings yet

- Physiomed Physioson Expert Operating Instructions Manual 34Document34 pagesPhysiomed Physioson Expert Operating Instructions Manual 34nhatnam06dt1No ratings yet

- Lavavajillas Whirlpool ADP6600WH Ver 8542 660 53950 Service ManualDocument15 pagesLavavajillas Whirlpool ADP6600WH Ver 8542 660 53950 Service ManualMarcelo Sergio HamerNo ratings yet

- Codigos de Diodos Zener PDFDocument6 pagesCodigos de Diodos Zener PDFEduardo Perez100% (1)

- Service Manual: HCD-BX2/DX2/DX2BDocument72 pagesService Manual: HCD-BX2/DX2/DX2BDanielNo ratings yet

- Nad C375bee PDFDocument59 pagesNad C375bee PDFAnonymous rFnwsvNo ratings yet

- CERAVAC Transmitter: Operating Manual 17200257 - 002 - 02Document32 pagesCERAVAC Transmitter: Operating Manual 17200257 - 002 - 02mayito12093120No ratings yet

- Samsung Ua32eh50x0r 40eh50x0r Ua42eh5000r Ua46eh50x0r-50eh50x0r Ua22es500xr Chassis U73a 74pagesDocument74 pagesSamsung Ua32eh50x0r 40eh50x0r Ua42eh5000r Ua46eh50x0r-50eh50x0r Ua22es500xr Chassis U73a 74pagesWilinton PissoNo ratings yet

- Icom UT-109 UT-110 Instruction ManualDocument13 pagesIcom UT-109 UT-110 Instruction Manualmusan15No ratings yet

- Candy Auto Test Za Cld135Document5 pagesCandy Auto Test Za Cld135Zoran KovacevicNo ratings yet

- Manual Inglês AI-010 Transdutor 3-15-PSI Série-G7Document5 pagesManual Inglês AI-010 Transdutor 3-15-PSI Série-G7davinmotion051No ratings yet

- ASD533 TD T140287en BDocument111 pagesASD533 TD T140287en Btame7478No ratings yet

- Service Information: GeneralDocument3 pagesService Information: GeneralghilesNo ratings yet

- Industrial Heat Flux SensorDocument27 pagesIndustrial Heat Flux Sensorسامح الجاسمNo ratings yet

- ASD531 TD T140416enDocument105 pagesASD531 TD T140416enishaangreavesNo ratings yet

- Instruction Manual Feel FDP - Eng 4Document8 pagesInstruction Manual Feel FDP - Eng 4Bui TAN HIEPNo ratings yet

- FP0ThermocoupleUnit ARCT1F366V10EN PDFDocument31 pagesFP0ThermocoupleUnit ARCT1F366V10EN PDFHuuThienNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Needle Valve With Reverse Flow Check ZW-SDR06: Sandwich Plate TypeDocument2 pagesNeedle Valve With Reverse Flow Check ZW-SDR06: Sandwich Plate TypeCleytonBronoskiNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2003/0222067 A1Document24 pagesPatent Application Publication (10) Pub. No.: US 2003/0222067 A1CleytonBronoskiNo ratings yet

- EC500 User Manual V2Document24 pagesEC500 User Manual V2CleytonBronoskiNo ratings yet

- Automotive Diagnostic System GT90 User's Manual v120180622Document84 pagesAutomotive Diagnostic System GT90 User's Manual v120180622CleytonBronoskiNo ratings yet

- FTF 40 Food Grade Centrifugal Feeder Installation Maintenance ManualDocument48 pagesFTF 40 Food Grade Centrifugal Feeder Installation Maintenance ManualCleytonBronoskiNo ratings yet

- DS LEADER-Volt Catalog USAR ZCL08.264.US .4Document2 pagesDS LEADER-Volt Catalog USAR ZCL08.264.US .4Zouhir kéniNo ratings yet

- Seated Valves: Type WV700Document14 pagesSeated Valves: Type WV700John EvansNo ratings yet

- Getrag En1 PDFDocument6 pagesGetrag En1 PDFJeremías EspinozaNo ratings yet

- IEC Catalog PDFDocument36 pagesIEC Catalog PDFPeter RhoadsNo ratings yet

- SF395Document1 pageSF395EduRoiNo ratings yet

- Technical Details: Complementary Metal-Oxide-Semiconductor (CMOS)Document4 pagesTechnical Details: Complementary Metal-Oxide-Semiconductor (CMOS)Testing toolsNo ratings yet

- GRT200 Brochure - 16001-G2A-1.1Document37 pagesGRT200 Brochure - 16001-G2A-1.1krishna mohanNo ratings yet

- M E S C: Power / Control CableDocument2 pagesM E S C: Power / Control CablerajuNo ratings yet

- Technical Data Sheet Arcapro Positioner Type 827A TD - 827ADocument15 pagesTechnical Data Sheet Arcapro Positioner Type 827A TD - 827AMakshoof GulNo ratings yet

- John Deere Tractor Parts Manual JD P Pc1539Document33 pagesJohn Deere Tractor Parts Manual JD P Pc1539jose marfullNo ratings yet

- Crane Systems: Greer Company Greer Company Greer Company Greer CompanyDocument14 pagesCrane Systems: Greer Company Greer Company Greer Company Greer Companyduongpndng100% (1)

- Hirschmann HC3901 Operation Manual ZCC1100H 20140804 PDFDocument29 pagesHirschmann HC3901 Operation Manual ZCC1100H 20140804 PDFPAULO100% (1)

- Arc Protection Instruction Manual EN1.1Document65 pagesArc Protection Instruction Manual EN1.1Alexandre MorenoNo ratings yet

- 3516B Generator Set Engine Fuel Injector Adjustment SIS CATERPILLAR PDFDocument5 pages3516B Generator Set Engine Fuel Injector Adjustment SIS CATERPILLAR PDFayman akrabNo ratings yet

- IND5Document14 pagesIND5ExperimentonomenNo ratings yet

- Infinte Peripherals Infinea Tab 2 User GuideDocument23 pagesInfinte Peripherals Infinea Tab 2 User GuidearrowheadcorpNo ratings yet

- P-Channel Enhancement Mode Power MOSFET: FeaturesDocument4 pagesP-Channel Enhancement Mode Power MOSFET: FeaturesMarco MoralesNo ratings yet

- Hyosung PlanetDocument8 pagesHyosung PlanetErcan BAYRAKCINo ratings yet

- Impact Valve Block (COPROD) : Qds-A QDS-J Pilot ValveDocument11 pagesImpact Valve Block (COPROD) : Qds-A QDS-J Pilot ValveFrancisco Alvarado HuenquiaoNo ratings yet

- DSE7310 MKII DSE7320 MKII Configuration Suite PC Software Manual PDFDocument232 pagesDSE7310 MKII DSE7320 MKII Configuration Suite PC Software Manual PDFEdson Da Rosa MachadoNo ratings yet

- C. AppendixDocument20 pagesC. AppendixgechnetNo ratings yet

- Compliance 34Document4 pagesCompliance 34midhunvarNo ratings yet

- Auger CabinDocument442 pagesAuger CabinOsw GalatiNo ratings yet

- 74 HC 4060Document13 pages74 HC 4060anyenkts2No ratings yet