Professional Documents

Culture Documents

Technical Data Sheet SSG4800J 2018

Technical Data Sheet SSG4800J 2018

Uploaded by

Jhon DewantoCopyright:

Available Formats

You might also like

- Assessment 3 - HIT172 - 2023Document5 pagesAssessment 3 - HIT172 - 2023F&B ManagerNo ratings yet

- Technical Data Sheet: Product DescriptionDocument1 pageTechnical Data Sheet: Product DescriptionkhuelvNo ratings yet

- Ficha Tecnica Um180821 Tds Tough Pla RB v11Document3 pagesFicha Tecnica Um180821 Tds Tough Pla RB v11Servirol CiaNo ratings yet

- Cast Nylon PDFDocument2 pagesCast Nylon PDFrohitdakngNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- SSG4000AC Data SheetDocument8 pagesSSG4000AC Data SheetThiagoAgNo ratings yet

- Proglaze SSG Data SheetDocument2 pagesProglaze SSG Data SheetDavid LuongNo ratings yet

- Ninjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrintersDocument1 pageNinjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrinterssrikanthNo ratings yet

- ACRYLITE® Satinice df21 8NDocument3 pagesACRYLITE® Satinice df21 8NEnriqueNo ratings yet

- Dural Fast Epoxy Gel EuclidDocument3 pagesDural Fast Epoxy Gel Euclidpayaso1973No ratings yet

- 3D-Systems DuraForm GF DATASHEET USEN 2017.06.08 WEBDocument1 page3D-Systems DuraForm GF DATASHEET USEN 2017.06.08 WEBsdhgwdNo ratings yet

- Hdi0653u1 Enus AstmDocument1 pageHdi0653u1 Enus AstmJonathan GuadarramaNo ratings yet

- Duraform Pa Plastic: General Properties FeaturesDocument2 pagesDuraform Pa Plastic: General Properties FeaturesMarouane MbarkiNo ratings yet

- PP PP9074MED DatasheetDocument1 pagePP PP9074MED DatasheetDiogo SouzaNo ratings yet

- Product Comparison - GE SSG4400 UltraGlaze Vs SSG4600 UltraGlaze Vs DC98...Document8 pagesProduct Comparison - GE SSG4400 UltraGlaze Vs SSG4600 UltraGlaze Vs DC98...Nguyễn SơnNo ratings yet

- SCGC LSP L2420J Technical Datasheet ProvisionalDocument3 pagesSCGC LSP L2420J Technical Datasheet Provisionalakankshas06No ratings yet

- Bitumastic 300 M PDSDocument2 pagesBitumastic 300 M PDSrekstromNo ratings yet

- Specialty 6 1-Pager Glass ClothDocument2 pagesSpecialty 6 1-Pager Glass ClothjjonasNo ratings yet

- ALLEN 8300FR Technical Data SheetDocument2 pagesALLEN 8300FR Technical Data SheetRachit RanjanNo ratings yet

- TDS - Acrylic V825 - From PolyOneDocument2 pagesTDS - Acrylic V825 - From PolyOneVio Amariei0% (1)

- Manta Canusa - GTS65 - en InglesDocument2 pagesManta Canusa - GTS65 - en IngleserwinvillarNo ratings yet

- GPH-060 110Document3 pagesGPH-060 110Ben KeeNo ratings yet

- Pmma Plexigals Hfi7-101Document4 pagesPmma Plexigals Hfi7-101countzeroaslNo ratings yet

- Onyx - MarkforgedDocument2 pagesOnyx - MarkforgedalkhalidibaiderNo ratings yet

- 3812 ExceedDocument2 pages3812 ExceedJimmys GothiqueNo ratings yet

- CANUSA Wrapid TapeDocument2 pagesCANUSA Wrapid TapeHalimNo ratings yet

- TDS Pla 3D870 enDocument1 pageTDS Pla 3D870 encristianNo ratings yet

- ABS Sabic Cycolac MG94 Cust.cDocument5 pagesABS Sabic Cycolac MG94 Cust.cMurillo AraujoNo ratings yet

- LS Nylon 11 DatasheetDocument1 pageLS Nylon 11 DatasheetkeeblerkhanNo ratings yet

- Futong Ism Tds SCG Hdpe h2001wc 20jul20Document3 pagesFutong Ism Tds SCG Hdpe h2001wc 20jul20Aung Thein OoNo ratings yet

- Exceed™ XP 8346CB: Performance PolymerDocument2 pagesExceed™ XP 8346CB: Performance PolymerMaram YasserNo ratings yet

- RX 102 BLACK GREY 9141: Linear Low Density Polyethylene: ColourDocument1 pageRX 102 BLACK GREY 9141: Linear Low Density Polyethylene: ColourEetu SatosalmiNo ratings yet

- Special Characteristics:: Innoplus Ll7420DDocument1 pageSpecial Characteristics:: Innoplus Ll7420DFahad MohamedNo ratings yet

- Protective & Marine Coatings: Galvite™ HsDocument4 pagesProtective & Marine Coatings: Galvite™ HsAna CabreraNo ratings yet

- Armadillo TDSDocument1 pageArmadillo TDSPIETRO DAVID DE LUCANo ratings yet

- 3M Structural Glazing TapeDocument4 pages3M Structural Glazing TapeChristian Dominic Dela CruzNo ratings yet

- LLDPE-218BJ EditDocument3 pagesLLDPE-218BJ EditChu ChuNo ratings yet

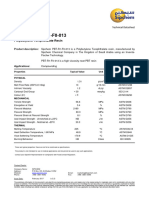

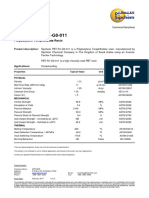

- Sipchem PBT-R1-F0-013: Polybutylene Terephthalate ResinDocument1 pageSipchem PBT-R1-F0-013: Polybutylene Terephthalate ResinTahir IqbalNo ratings yet

- Product Datasheet: BU Powder CoatingsDocument1 pageProduct Datasheet: BU Powder CoatingsVasudev BhanajiNo ratings yet

- Sipchem PBT-R1-G0-011: Polybutylene Terephthalate ResinDocument1 pageSipchem PBT-R1-G0-011: Polybutylene Terephthalate ResinTahir IqbalNo ratings yet

- Sabic - Sabic® Hdpe CC453 PDFDocument4 pagesSabic - Sabic® Hdpe CC453 PDFquangga10091986No ratings yet

- Lexan 925u ResinDocument2 pagesLexan 925u ResinAndrNo ratings yet

- TGS TDS NBR Dia 6165Document1 pageTGS TDS NBR Dia 6165Chang MikeNo ratings yet

- LL7410D1Document1 pageLL7410D1Nitin MaheshwariNo ratings yet

- 3 Property R3450 EngDocument1 page3 Property R3450 EngMohit MohataNo ratings yet

- Technical Data Sheet (ABS) - SmithsDocument1 pageTechnical Data Sheet (ABS) - SmithsKelvin Tai Wei LimNo ratings yet

- Manufacturing Processes and Materials ExercisesDocument2 pagesManufacturing Processes and Materials ExercisesMedSparkNo ratings yet

- SABIC® LLDPE - 324CNJ - Global - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 324CNJ - Global - Technical - Data - Sheettechnical kmiNo ratings yet

- HD M5306 PDFDocument2 pagesHD M5306 PDFmohamed1303No ratings yet

- Datasheet - r680s - Randompp - e 3Document2 pagesDatasheet - r680s - Randompp - e 3Gulzar HossainNo ratings yet

- Estane 58887Document2 pagesEstane 58887M J VoraNo ratings yet

- Exceed™ XP 6056ML: Performance PolymerDocument2 pagesExceed™ XP 6056ML: Performance PolymerkjmontilNo ratings yet

- SABIC® PP - 5271K - Global - Technical - Data - SheetDocument1 pageSABIC® PP - 5271K - Global - Technical - Data - SheetjituniNo ratings yet

- Hollow Sections Catalogue PDFDocument56 pagesHollow Sections Catalogue PDFDaniel Alvarado LizanaNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetLeductoan LeNo ratings yet

- TDS LC670 Eng 220216Document1 pageTDS LC670 Eng 220216AthonioMourinhoNo ratings yet

- Welding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesFrom EverandWelding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesRating: 1 out of 5 stars1/5 (1)

- UNIT-11-JUST-SUPPOSEDocument13 pagesUNIT-11-JUST-SUPPOSECesar RodriguezNo ratings yet

- RElatório Global Teacher 2018 PDFDocument105 pagesRElatório Global Teacher 2018 PDFKimbellyNo ratings yet

- Tie Back Liner RunDocument3 pagesTie Back Liner RunkangrassNo ratings yet

- Understanding Feyerabend On GalileoDocument5 pagesUnderstanding Feyerabend On Galileorustycarmelina108No ratings yet

- Air Entrainment - 02Document16 pagesAir Entrainment - 02ThejaswiniNo ratings yet

- Critical Path MethodDocument13 pagesCritical Path MethodNymisa RavuriNo ratings yet

- 13.4 Electrical Diagram: 9 - 9461 02 E Service Manual Screw Compressor SK Sigma Control 2Document17 pages13.4 Electrical Diagram: 9 - 9461 02 E Service Manual Screw Compressor SK Sigma Control 2Mehedi HasanNo ratings yet

- Acyfar1 Syllabus t3 Ay 1920Document8 pagesAcyfar1 Syllabus t3 Ay 1920Kim TolosaNo ratings yet

- Strategic Marketing 10th Edition Cravens Test BankDocument9 pagesStrategic Marketing 10th Edition Cravens Test Bankdanielxavia55fok100% (17)

- Grade 6 - Q1 - W3 - BDocument2 pagesGrade 6 - Q1 - W3 - BMary Joy G TornoNo ratings yet

- Project 4Document6 pagesProject 4Trai TranNo ratings yet

- TV Productor Service Manual: Approved SignaturesDocument61 pagesTV Productor Service Manual: Approved SignaturesJCNo ratings yet

- E-Proceedings - ICCRET-2023Document30 pagesE-Proceedings - ICCRET-2023RAGHIB R SHARIFNo ratings yet

- Petroleum Geomechanics Assignment 3Document6 pagesPetroleum Geomechanics Assignment 3Binish KhanNo ratings yet

- Brochure Bb3102 Eva Pur-C Pur-NDocument2 pagesBrochure Bb3102 Eva Pur-C Pur-NĐinh ThuậnNo ratings yet

- Proposal MathDocument18 pagesProposal MathKarrel Joy Dela CruzNo ratings yet

- TH 10 012Document10 pagesTH 10 012IAS CrackNo ratings yet

- Ficha Tecnica Inverter Mini SplitDocument1 pageFicha Tecnica Inverter Mini SplitpabloabelgilsotoNo ratings yet

- Cot Eng6q3Document6 pagesCot Eng6q3Arlyn Borbe BordeosNo ratings yet

- Holiday HomeworkDocument2 pagesHoliday Homeworkapi-245176244No ratings yet

- DAR - STS Reflection PaperDocument3 pagesDAR - STS Reflection Papernikko darNo ratings yet

- Name: Period: DateDocument3 pagesName: Period: DateCarolina RozoNo ratings yet

- Towards A Social Theory of Rhythm - Nelson PDFDocument10 pagesTowards A Social Theory of Rhythm - Nelson PDFugubroNo ratings yet

- Buku Keamanan InformasiDocument156 pagesBuku Keamanan InformasiBadruzZamanNo ratings yet

- Z:/windchill/codebase Z:/windchill/codebaseDocument3 pagesZ:/windchill/codebase Z:/windchill/codebaseamalNo ratings yet

- Green Façades: Marwa Hisham Salem El-ZoklahDocument16 pagesGreen Façades: Marwa Hisham Salem El-ZoklahEphremZelekeNo ratings yet

- Lab 4 - SQLStatementsDocument3 pagesLab 4 - SQLStatementsDoan Hoang Dung QP2775No ratings yet

- Science 5Document6 pagesScience 5Edlyn KayNo ratings yet

- YOSHITAKE SL-1S 1F Sight GlassDocument1 pageYOSHITAKE SL-1S 1F Sight GlassJohn Marvin ValenzuelaNo ratings yet

Technical Data Sheet SSG4800J 2018

Technical Data Sheet SSG4800J 2018

Uploaded by

Jhon DewantoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Data Sheet SSG4800J 2018

Technical Data Sheet SSG4800J 2018

Uploaded by

Jhon DewantoCopyright:

Available Formats

GE Silicones Technical Data Sheet

SSG4800J UltraGlaze*

Silicone Structural Glazing Adhesive

Product Description

UltraGlaze SSG4800J structural glazing adhesive is a one-component, high-strength neutral cure

silicone elastomeric adhesive with accelerated cure characteristics providing for enhanced early hour

cure properties. SSG4800J is useful in structurally glazed curtain wall applications. The material is

moisture.

• Compatible

SCS2000N, SCS2700, SCS9000, SCS2800, SCS2900 series.

• Silicone Durability—Exhibits excellent long term resistance to • Compatible with these GE sealants SSG products: SSG4000AC

ultraviolet radiation, high and low temperatures, rain, snow and structural glazing adhesive and SSG4600, SSG4400 series.

natural weathering with negligible change in elasticity.

• Non-corrosive cure byproduct with low odor.

• Stable Consistency (uncured state)—Supplied as a lightweight

paste the consistency of which remains relatively unchanged

over a wide temperature range. The material will extrude easily Packaging

from the cartridge or container and remains workable under

almost any practical temperature without requiring heating (other UltraGlaze SSG4800J structural glazing adhesive is available in 20

fl.oz.(591 ml) foil sausage packs.

require heating in order to dispense and work the material).

• Thermal Stability (cured state)—Once cured, the material

Potential Applications

250°F (121°C).

• UltraGlaze SSG4800J structural glazing adhesive may be

• Primerless Adhesion—Bonds to most conventional substrates an excellent material of choice for use in structural glazing

applications such as factory glazing of unitized curtainwall

• Low Sag or Slump—Which may be used for application to • UltraGlaze SSG4800J structural glazing adhesive can also be

horizontal, vertical or overhead surfaces. used as a weatherseal product, when movement expected in the

• Accelerated Cure—Faster early hour cure properties to facilitate joint does not exceed its movement capability (±25%).

handling of assembled units. • UltraGlaze SSG4800J structural glazing adhesive has been

• High Tensile Strength—Increases safety factors in SSG designs. validated in designs as an appropriate candidate for consideration

for use in protective glazing applications.

• High Tear Strength—Useful in Protective Glazing applications.

• UltraGlaze SSG4800J structural glazing adhesive is useful in

• Compatible with these GE sealants insulating glass products:

IGS3703, IGS3713-D1, IGS3729, IGS3723, IGS3733.

*UltraGlaze is a trademark of Momentive Performance Materials Inc. Page 1 of 8

SSG4800J UltraGlaze* Technical Data Sheet

Silicone Structural Glazing Adhesive

Colors Typical Properties – Cured

Property Value Test Method

Weight

Grade Color Container Hardness, Durometer

(kgs) 45 ASTM D2240

(Type A Indentor)

Ultimate Tensile Strength 2.3 MPa ASTM D412

SSG 4800J Black Sausage 0.858

Ultimate Elongation 400% ASTM D412

SSG 4800J.09 Gray Sausage 0.858 Tensile at 50% Elongation 0.59 MPa ASTM C1184

Ultimate Tensile Strength 0.89 MPa ASTM C1135

Ultimate Elongation 160% ASTM C1135

Tear Strength; die B 65.7 ppi ASTM D624

Shear Strength

Black Gray 0.80 MPa ASTM C961

(@ 1/4” thickness)

Peel Strength (average);

aluminum, glass (21-day cure 50 ppi ASTM C794

Typical Physical Properties @ 75°F (21°C) 50% RH)

Joint Movement Capability ±25% ASTM C719

Typical property values of SSG4800J UltraGlaze adhesive as Service Temperature Range -48°C to +149°C

supplied and cured are set forth in the tables below. Assistance (after cure)

with specifications is available by contacting Momentive Weathering and U.V. Resistance Excellent GE 20 yr. study

Cure Time (1/4” or 6 mm deep

Performance Materials at 800 820 0202. section) @ 75°F (24°C) 50% RH 3-4 days

Full Cure 10-14 days

Typical Properties – Uncured (most common bead sizes)

Typical properties are average data and are not to be used as or to develop

Property Value Test Method specifications.

Color Black, Grey

Polymer 100% Silicone

Consistency Paste Installation

Specific Gravity 1.45

Work Life (tooling time) 10-20 minutes

Surface Preparation

Tack Free Time 60-90 minutes ASTM C679 Sealants may not adhere or maintain long-term adhesion to

Application Rate 2 seconds ASTM C603 substrates if the surface is not prepared and cleaned properly

Sag/Slump 1mm max ASTM D2202 before sealant application. Using proper materials and following

Typical properties are average data and are not to be used as or to develop prescribed surface preparation and cleaning procedures is vital for

specifications.

sealant adhesion. Momentive Performance Materials can provide

quality control information and suggestions to user upon request.

Materials

• Use clean, fresh solvent as recommended by the sealant

manufacturer’s test report. When handling solvents, refer to

manufacturer’s MSDS for information on handling, safety and

personal protective equipment. Isopropyl Alcohol (IPA) is

commonly used and has proven useful for most substrates

encountered in SSG systems. Xylene and Toluene have also

been found useful on many substrates.

• Use clean, white cloths free of lint or other lint-free wiping

materials.

• Use a clean, narrow-blade putty knife when tooling structural

silicone into the cavity.

• Use primer when required.

*UltraGlaze is a trademark of Momentive Performance Materials Inc. Page 2 of 8

SSG4800J UltraGlaze* Technical Data Sheet

Silicone Structural Glazing Adhesive

Installation—continued Primers

UltraGlaze SSG4800J structural glazing adhesive will

Cleaning Procedures

bond to many clean surfaces without the aid of a primer. For

• Remove all loose material (such as dirt and dust), plus any oil,

frost or other contaminants from the substrates to which the preparation should be evaluated. An evaluation should be made for

structural silicone will be adhered.

• Do not use detergent to clean the substrate as residue may be When properly used, primers help assure strong and consistent

left on the surface.

primers are a blend of organic and inorganic chemicals, resins and

• Clean the substrates receiving the sealant as follows: Using a

solvents. NEVER APPLY PRIMER TO GLASS SURFACES. Obtaining the

two-rag wipe technique. Wet one rag with solvent and wipe the

proper materials, as well as following the prescribed procedures, is

surface with it, then use the second rag to wipe the wet solvent

vital to ensure the successful use of primers. PRIMER APPLICATION

from the surface BEFORE it evaporates. Allowing solvent to dry

IS NOT A SUBSTITUTE FOR SURFACE PREPARATION. Consult

on the surface without wiping with a second cloth can negate

the entire cleaning procedure because the contaminants may be

for use.

re-deposited as the solvent dries.

CAUTION

• Change the cleaning rags frequently, as they become soiled. It is

Primers may contain solvents. When handling solvents, refer to

easier to see the soiling if white rags are used. Do not dip used

manufacturer’s MSDS for information on handling, safety and

wipe cloths into solvent as this can contaminate the solvent.

personal protective equipment.

Cleaning with contaminated solvent can result in sealant

adhesion issues. Always use clean containers for solvent use Masking

and for solvent storage. • To simplify clean up of excess sealant, use easy to release,

• When cleaning deep, narrow joints, wrap the cleaning cloth pressure sensitive tape to mask adjacent surfaces before applying

around a clean, narrow-blade putty knife. This permits force to the structural silicone sealant.

be applied to the cleaned surface. • Start from the top down and overlap the runs. Tool in direction of

• Clean only as much area as can be sealed in one hour. If cleaned over-lap so that masking is not disturbed during tooling.

areas are again exposed to rain or contaminants, the surface must • Remove masking immediately after application of silicone or as

be cleaned again. soon as possible or practical.

• Drop cloths can be used to cover any surfaces likely to collect

excess sealant removed during tooling operations.

*UltraGlaze is a trademark of Momentive Performance Materials Inc. Page 3 of 8

SSG4800J UltraGlaze* Technical Data Sheet

Silicone Structural Glazing Adhesive

Joint Designs and Dimensions • Short-term compatibility test results on gaskets, spacers and

setting blocks and other accessories per ASTM C1087 or

Silicone contact width and thickness (see Figure 1) will vary by

GE sealants test method for compatibility.

project with the design wind load and glass size. Contact width

can be calculated using the following formula: [Design Wind Load • Information regarding suggested primers, when required.

(PSF) x Longest Short Span of Glass or Panel (Ft.)] divided by 480.

A minimum sealant thickness of 1/4” (7mm) between substrates is Figure 1

required to accommodate thermal expansion and contraction

(see Figure 2) of most systems and should be used in order to

assure that sealant can be injected into the structural cavity

DEPTH

obtaining full contact with both the glass and metal surfaces while

THICKNESS

remaining free of air voids. Greater joint thickness may be required

to accommodate movement in some larger-sized SSG systems. STRUCTURAL

SILICONE

Momentive Performance Materials can be contacted to assist in

determination of proper joint thickness to accommodate expected CONTACT

movement in structurally glazed applications. WIDTH

The following materials are required to be submitted to

Momentive Performance Materials to receive suggestions for

the use of UltraGlaze SSG4800J structural glazing adhesive. HORIZONTAL

SECTION

• Architectural and shop drawings for review and comment.

• Design wind load requirement(s) for project.

• Glass or panel sizes.

• Production samples of metal, glass, gaskets, spacers and setting

Figure 2: Movement from thermal expansion

and contraction and/or glass rotation

•

UltraGlaze SSG4800J structural glazing adhesive is intended

to adhere (i.e.,

system and ID#).

Momentive Performance Materials will provide the following,

after reviewing the materials above:

• Determination as to whether the submitted joint dimensions

meet the minimum design criteria necessary for the use of

UltraGlaze SSG4800J structural glazing adhesive.

• Short-term adhesion data using (typically) the ASTM C794 and/or

ASTM C1135 test method. Other test methods may be employed.

*UltraGlaze is a trademark of Momentive Performance Materials Inc. Page 4 of 8

SSG4800J UltraGlaze* Technical Data Sheet

Silicone Structural Glazing Adhesive

Joint Designs and Dimensions—continued • The cure rate of this product is dependent upon temperature

and the availability of atmospheric moisture. Under Standard

Momentive Performance Materials will not:

Conditions (relative humidity of 50 ±5% at an air temperature of

• Design sealant joints.

73.4 ±2°F [23 of ±1°C]) this material can attain a cured thickness

• Provide comments on the structural integrity of overall framing of 3-4 mm per 24 hours (assuming ample access to atmospheric

system(s). moisture). As temperature decreases, the cure rate slows down

• Provide long-term performance data. (and vice versa). Low moisture environments will also reduce

access to atmospheric moisture will cure only from that surface

determination of structural sealant joint dimensions based on

which has access to the atmosphere. Colder temperatures can

project conditions, design wind load(s), glass or panel sizes,

anticipated thermal, seismic or other movement of the system.

sealant irregularities if joint movement occurs while sealant

The ASTM C1401 Standard Guide for Structural Sealant Glazing is not fully cured. The following reference provides additional

provides a thorough overview of design topics and information for information on Movement-During-Cure of sealant joints:

use in SSG systems. ASTM C1193 – Standard Guide for Use of Joint Sealants;

section 12.5.

Structural Glazing

Sealant Application Method of Application

• Apply the sealant by pushing the bead ahead of the nozzle and

UltraGlaze SSG4800J structural glazing adhesive can be

dispensed directly from cartridges and foil sausage packs Consult

neatly, forcing the sealant into contact with the sides of the joint, Momentive Performance Materials regarding suggested pumping

thus helping to eliminate any internal voids and assuring good equipment and information.

substrate contact. AIR POCKETS OR VOIDS WITHIN THE

STRUCTURAL CAVITY ARE NOT ACCEPTABLE.

• Due to the smooth consistency of UltraGlaze SSG4800J

structural glazing adhesive, tooling agents such as water, soap

or detergent solutions are not necessary or recommended.

Dry tooling is recommended.

• Sealant application is not recommended when the temperature is

below 40°F (4°C) or if frost or moisture is present on the

surfaces to be sealed.

• UltraGlaze SSG4800J structural glazing adhesive works best

when applied to surfaces below 122°F (50°C).

• UltraGlaze SSG4800J structural glazing adhesive should

requires atmospheric moisture from the air and release of cure

by-products to cure properly and develop typical properties. In a

typical SSG cavity, cure depths up to 3/4” from an air interface will

generally cure satisfactorily and reach maximum properties within

several days. Cure depths > 3/4

to cure and when applied in a single application may not cure

satisfactorily. Please consult Momentive Performance Materials

technical services for additional information on depth of cure for

this product.

*UltraGlaze is a trademark of Momentive Performance Materials Inc. Page 5 of 8

SSG4800J UltraGlaze* Technical Data Sheet

Silicone Structural Glazing Adhesive

Structural Glazing—continued Technical Services

For additional technical resources, please contact your local

Storage Conditions and Warranty Period customer service center. (See Customer Service Centers section

The warranty period is 12 months from date of shipment from herein for contact information.) Any technical advice furnished

Momentive Performance Materials1 if stored in the original by MPM or any representative of MPM concerning any use or

unopened container at 80°F (27°C) or lower. All users of this application of any MPM product is believed to be reliable, but

material are recommended to obtain and retain any invoices or MPM makes no warranty, expressed or implied, of suitability for

other documentation relating to delivery and to manage their use in any application for which such advice is furnished.

inventory on a FIFO (FIRST IN / FIRST OUT) basis.

Limitations

Availability Customers must evaluate MPM products and make their own

Information on ordering can be obtained from Momentive

Performance Materials,1 or an authorized GE sealants’ product applications.

distributor. For information regarding cost, contact your local

distributor or territory manager.

Government Requirement

Prior to considering use of a GE sealants

government requirement, please contact the Government and

Applicable Standards

UltraGlaze SSG4800J structural glazing adhesive meets or

one-part sealants.

• C1184, Type S, Use G and O

• C920; Type S, Grade NS, Class 25, Use NT, A, G, O

China National Specification

GB16776

*UltraGlaze is a trademark of Momentive Performance Materials Inc. Page 6 of 8

SSG4800J UltraGlaze* Technical Data Sheet

Silicone Structural Glazing Adhesive

Patent Status Product Safety, Handling, and Storage

Nothing contained herein shall be construed to imply the Customers considering the use of this product should review the

nonexistence of any relevant patents or to constitute the latest Safety Data Sheet and label for product safety information,

permission, inducement, or recommendation to practice any handling instructions, personal protective equipment if necessary,

invention covered by any patent, without authority from the and any special storage conditions required. Material Safety Data

owner of the patent. Sheets are available at www.siliconeforbuilding.com or, upon

request, from any MPM representative. Use of other materials in

conjunction with MPM products (for example, primers) may require

additional precautions. Please review and follow the safety

information provided by the manufacturer of such other materials.

Customer Service Centers

Americas +1 800 295 2392

+1 704 805 6946

Email: commercial.services@momentive.com

Europe, Middle East, Africa, and India +00 800 4321 1000

+40 212 044229

Email: 4information.eu@momentive.com

Japan

+0120 975 400

+81 276 20 6182

China

+800 820 0202

+86 21 3860 4892

All APAC

+60 3 9206 1543

Email: 4information.ap@momentive.com

www.siliconeforbuilding.com

THE MATERIALS, PRODUCTS, AND SERVICES OF MOMENTIVE PERFORMANCE MATERIALS INC. AND ITS SUBSIDIARIES AND AFFILIATES (COLLECTIVELY

“SUPPLIER”), ARE SOLD SUBJECT TO SUPPLIER’S STANDARD CONDITIONS OF SALE, WHICH ARE INCLUDED IN THE APPLICABLE DISTRIBUTOR OR

OTHER SALES AGREEMENT, PRINTED ON THE BACK OF ORDER ACKNOWLEDGMENTS AND INVOICES, AND AVAILABLE UPON REQUEST. ALTHOUGH

ANY INFORMATION, RECOMMENDATIONS, OR ADVICE CONTAINED HEREIN IS GIVEN IN GOOD FAITH, SUPPLIER MAKES NO WARRANTY OR

GUARANTEE, EXPRESS OR IMPLIED, (i) THAT THE RESULTS DESCRIBED HEREIN WILL BE OBTAINED UNDER END-USE CONDITIONS, OR (ii) AS TO THE

EFFECTIVENESS OR SAFETY OF ANY DESIGN INCORPORATING ITS PRODUCTS, MATERIALS, SERVICES, RECOMMENDATIONS, OR ADVICE. EXCEPT AS

PROVIDED IN SUPPLIER’S STANDARD CONDITIONS OF SALE, SUPPLIER AND ITS REPRESENTATIVES SHALL IN NO EVENT BE RESPONSIBLE FOR ANY

LOSS RESULTING FROM ANY USE OF ITS MATERIALS, PRODUCTS, OR SERVICES DESCRIBED HEREIN. Each user bears full responsibility for making its

own determination as to the suitability of Supplier’s materials, services, recommendations, or advice for its own particular use. Each user must identify

in a writing signed by Supplier. No statement contained herein concerning a possible or suggested use of any material, product, service, or design is

intended, or should be construed, to grant any license under any patent or other intellectual property right of Supplier covering such use or design, or as

a recommendation for the use of such material, product, service, or design in the infringement of any patent or other intellectual property right.

GE is a registered trademark of General Electric Company and is used under license by Momentive Performance Materials Inc.

*UltraGlaze is trademark of Momentive Performance Materials Inc.

Copyright 2018 Momentive Performance Materials Inc. All rights reserved.

CDS: DataUltraGlaze4800J(8/18) Page 7 of 8

Page 8 of 8

You might also like

- Assessment 3 - HIT172 - 2023Document5 pagesAssessment 3 - HIT172 - 2023F&B ManagerNo ratings yet

- Technical Data Sheet: Product DescriptionDocument1 pageTechnical Data Sheet: Product DescriptionkhuelvNo ratings yet

- Ficha Tecnica Um180821 Tds Tough Pla RB v11Document3 pagesFicha Tecnica Um180821 Tds Tough Pla RB v11Servirol CiaNo ratings yet

- Cast Nylon PDFDocument2 pagesCast Nylon PDFrohitdakngNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- SSG4000AC Data SheetDocument8 pagesSSG4000AC Data SheetThiagoAgNo ratings yet

- Proglaze SSG Data SheetDocument2 pagesProglaze SSG Data SheetDavid LuongNo ratings yet

- Ninjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrintersDocument1 pageNinjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrinterssrikanthNo ratings yet

- ACRYLITE® Satinice df21 8NDocument3 pagesACRYLITE® Satinice df21 8NEnriqueNo ratings yet

- Dural Fast Epoxy Gel EuclidDocument3 pagesDural Fast Epoxy Gel Euclidpayaso1973No ratings yet

- 3D-Systems DuraForm GF DATASHEET USEN 2017.06.08 WEBDocument1 page3D-Systems DuraForm GF DATASHEET USEN 2017.06.08 WEBsdhgwdNo ratings yet

- Hdi0653u1 Enus AstmDocument1 pageHdi0653u1 Enus AstmJonathan GuadarramaNo ratings yet

- Duraform Pa Plastic: General Properties FeaturesDocument2 pagesDuraform Pa Plastic: General Properties FeaturesMarouane MbarkiNo ratings yet

- PP PP9074MED DatasheetDocument1 pagePP PP9074MED DatasheetDiogo SouzaNo ratings yet

- Product Comparison - GE SSG4400 UltraGlaze Vs SSG4600 UltraGlaze Vs DC98...Document8 pagesProduct Comparison - GE SSG4400 UltraGlaze Vs SSG4600 UltraGlaze Vs DC98...Nguyễn SơnNo ratings yet

- SCGC LSP L2420J Technical Datasheet ProvisionalDocument3 pagesSCGC LSP L2420J Technical Datasheet Provisionalakankshas06No ratings yet

- Bitumastic 300 M PDSDocument2 pagesBitumastic 300 M PDSrekstromNo ratings yet

- Specialty 6 1-Pager Glass ClothDocument2 pagesSpecialty 6 1-Pager Glass ClothjjonasNo ratings yet

- ALLEN 8300FR Technical Data SheetDocument2 pagesALLEN 8300FR Technical Data SheetRachit RanjanNo ratings yet

- TDS - Acrylic V825 - From PolyOneDocument2 pagesTDS - Acrylic V825 - From PolyOneVio Amariei0% (1)

- Manta Canusa - GTS65 - en InglesDocument2 pagesManta Canusa - GTS65 - en IngleserwinvillarNo ratings yet

- GPH-060 110Document3 pagesGPH-060 110Ben KeeNo ratings yet

- Pmma Plexigals Hfi7-101Document4 pagesPmma Plexigals Hfi7-101countzeroaslNo ratings yet

- Onyx - MarkforgedDocument2 pagesOnyx - MarkforgedalkhalidibaiderNo ratings yet

- 3812 ExceedDocument2 pages3812 ExceedJimmys GothiqueNo ratings yet

- CANUSA Wrapid TapeDocument2 pagesCANUSA Wrapid TapeHalimNo ratings yet

- TDS Pla 3D870 enDocument1 pageTDS Pla 3D870 encristianNo ratings yet

- ABS Sabic Cycolac MG94 Cust.cDocument5 pagesABS Sabic Cycolac MG94 Cust.cMurillo AraujoNo ratings yet

- LS Nylon 11 DatasheetDocument1 pageLS Nylon 11 DatasheetkeeblerkhanNo ratings yet

- Futong Ism Tds SCG Hdpe h2001wc 20jul20Document3 pagesFutong Ism Tds SCG Hdpe h2001wc 20jul20Aung Thein OoNo ratings yet

- Exceed™ XP 8346CB: Performance PolymerDocument2 pagesExceed™ XP 8346CB: Performance PolymerMaram YasserNo ratings yet

- RX 102 BLACK GREY 9141: Linear Low Density Polyethylene: ColourDocument1 pageRX 102 BLACK GREY 9141: Linear Low Density Polyethylene: ColourEetu SatosalmiNo ratings yet

- Special Characteristics:: Innoplus Ll7420DDocument1 pageSpecial Characteristics:: Innoplus Ll7420DFahad MohamedNo ratings yet

- Protective & Marine Coatings: Galvite™ HsDocument4 pagesProtective & Marine Coatings: Galvite™ HsAna CabreraNo ratings yet

- Armadillo TDSDocument1 pageArmadillo TDSPIETRO DAVID DE LUCANo ratings yet

- 3M Structural Glazing TapeDocument4 pages3M Structural Glazing TapeChristian Dominic Dela CruzNo ratings yet

- LLDPE-218BJ EditDocument3 pagesLLDPE-218BJ EditChu ChuNo ratings yet

- Sipchem PBT-R1-F0-013: Polybutylene Terephthalate ResinDocument1 pageSipchem PBT-R1-F0-013: Polybutylene Terephthalate ResinTahir IqbalNo ratings yet

- Product Datasheet: BU Powder CoatingsDocument1 pageProduct Datasheet: BU Powder CoatingsVasudev BhanajiNo ratings yet

- Sipchem PBT-R1-G0-011: Polybutylene Terephthalate ResinDocument1 pageSipchem PBT-R1-G0-011: Polybutylene Terephthalate ResinTahir IqbalNo ratings yet

- Sabic - Sabic® Hdpe CC453 PDFDocument4 pagesSabic - Sabic® Hdpe CC453 PDFquangga10091986No ratings yet

- Lexan 925u ResinDocument2 pagesLexan 925u ResinAndrNo ratings yet

- TGS TDS NBR Dia 6165Document1 pageTGS TDS NBR Dia 6165Chang MikeNo ratings yet

- LL7410D1Document1 pageLL7410D1Nitin MaheshwariNo ratings yet

- 3 Property R3450 EngDocument1 page3 Property R3450 EngMohit MohataNo ratings yet

- Technical Data Sheet (ABS) - SmithsDocument1 pageTechnical Data Sheet (ABS) - SmithsKelvin Tai Wei LimNo ratings yet

- Manufacturing Processes and Materials ExercisesDocument2 pagesManufacturing Processes and Materials ExercisesMedSparkNo ratings yet

- SABIC® LLDPE - 324CNJ - Global - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 324CNJ - Global - Technical - Data - Sheettechnical kmiNo ratings yet

- HD M5306 PDFDocument2 pagesHD M5306 PDFmohamed1303No ratings yet

- Datasheet - r680s - Randompp - e 3Document2 pagesDatasheet - r680s - Randompp - e 3Gulzar HossainNo ratings yet

- Estane 58887Document2 pagesEstane 58887M J VoraNo ratings yet

- Exceed™ XP 6056ML: Performance PolymerDocument2 pagesExceed™ XP 6056ML: Performance PolymerkjmontilNo ratings yet

- SABIC® PP - 5271K - Global - Technical - Data - SheetDocument1 pageSABIC® PP - 5271K - Global - Technical - Data - SheetjituniNo ratings yet

- Hollow Sections Catalogue PDFDocument56 pagesHollow Sections Catalogue PDFDaniel Alvarado LizanaNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetLeductoan LeNo ratings yet

- TDS LC670 Eng 220216Document1 pageTDS LC670 Eng 220216AthonioMourinhoNo ratings yet

- Welding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesFrom EverandWelding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesRating: 1 out of 5 stars1/5 (1)

- UNIT-11-JUST-SUPPOSEDocument13 pagesUNIT-11-JUST-SUPPOSECesar RodriguezNo ratings yet

- RElatório Global Teacher 2018 PDFDocument105 pagesRElatório Global Teacher 2018 PDFKimbellyNo ratings yet

- Tie Back Liner RunDocument3 pagesTie Back Liner RunkangrassNo ratings yet

- Understanding Feyerabend On GalileoDocument5 pagesUnderstanding Feyerabend On Galileorustycarmelina108No ratings yet

- Air Entrainment - 02Document16 pagesAir Entrainment - 02ThejaswiniNo ratings yet

- Critical Path MethodDocument13 pagesCritical Path MethodNymisa RavuriNo ratings yet

- 13.4 Electrical Diagram: 9 - 9461 02 E Service Manual Screw Compressor SK Sigma Control 2Document17 pages13.4 Electrical Diagram: 9 - 9461 02 E Service Manual Screw Compressor SK Sigma Control 2Mehedi HasanNo ratings yet

- Acyfar1 Syllabus t3 Ay 1920Document8 pagesAcyfar1 Syllabus t3 Ay 1920Kim TolosaNo ratings yet

- Strategic Marketing 10th Edition Cravens Test BankDocument9 pagesStrategic Marketing 10th Edition Cravens Test Bankdanielxavia55fok100% (17)

- Grade 6 - Q1 - W3 - BDocument2 pagesGrade 6 - Q1 - W3 - BMary Joy G TornoNo ratings yet

- Project 4Document6 pagesProject 4Trai TranNo ratings yet

- TV Productor Service Manual: Approved SignaturesDocument61 pagesTV Productor Service Manual: Approved SignaturesJCNo ratings yet

- E-Proceedings - ICCRET-2023Document30 pagesE-Proceedings - ICCRET-2023RAGHIB R SHARIFNo ratings yet

- Petroleum Geomechanics Assignment 3Document6 pagesPetroleum Geomechanics Assignment 3Binish KhanNo ratings yet

- Brochure Bb3102 Eva Pur-C Pur-NDocument2 pagesBrochure Bb3102 Eva Pur-C Pur-NĐinh ThuậnNo ratings yet

- Proposal MathDocument18 pagesProposal MathKarrel Joy Dela CruzNo ratings yet

- TH 10 012Document10 pagesTH 10 012IAS CrackNo ratings yet

- Ficha Tecnica Inverter Mini SplitDocument1 pageFicha Tecnica Inverter Mini SplitpabloabelgilsotoNo ratings yet

- Cot Eng6q3Document6 pagesCot Eng6q3Arlyn Borbe BordeosNo ratings yet

- Holiday HomeworkDocument2 pagesHoliday Homeworkapi-245176244No ratings yet

- DAR - STS Reflection PaperDocument3 pagesDAR - STS Reflection Papernikko darNo ratings yet

- Name: Period: DateDocument3 pagesName: Period: DateCarolina RozoNo ratings yet

- Towards A Social Theory of Rhythm - Nelson PDFDocument10 pagesTowards A Social Theory of Rhythm - Nelson PDFugubroNo ratings yet

- Buku Keamanan InformasiDocument156 pagesBuku Keamanan InformasiBadruzZamanNo ratings yet

- Z:/windchill/codebase Z:/windchill/codebaseDocument3 pagesZ:/windchill/codebase Z:/windchill/codebaseamalNo ratings yet

- Green Façades: Marwa Hisham Salem El-ZoklahDocument16 pagesGreen Façades: Marwa Hisham Salem El-ZoklahEphremZelekeNo ratings yet

- Lab 4 - SQLStatementsDocument3 pagesLab 4 - SQLStatementsDoan Hoang Dung QP2775No ratings yet

- Science 5Document6 pagesScience 5Edlyn KayNo ratings yet

- YOSHITAKE SL-1S 1F Sight GlassDocument1 pageYOSHITAKE SL-1S 1F Sight GlassJohn Marvin ValenzuelaNo ratings yet