Professional Documents

Culture Documents

ADF - EAM - Activity Maintenance BOM Routing Schedule GS

ADF - EAM - Activity Maintenance BOM Routing Schedule GS

Uploaded by

Daniel andersonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ADF - EAM - Activity Maintenance BOM Routing Schedule GS

ADF - EAM - Activity Maintenance BOM Routing Schedule GS

Uploaded by

Daniel andersonCopyright:

Available Formats

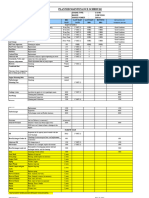

ORGANIZATIONACTIVITY_NAME ITEM DESCRIPTION DEPARTMENT FREQUENCY FREQ UNIT TYPE_ACTIVITY

161 Service Besar 161 3 Days Preventive Maintenance

161 Service Kecil 161 6 Hours Preventive Maintenance

161 Service Berkala 161 1 Days Preventive Maintenance

161 Service AC 161 1 Days Preventive Maintenance

161 Service Dinamo 161 1 Days Preventive Maintenance

161 Service Kopling 161 1 Days Preventive Maintenance

161 Ganti Ban 161 2 Hours Preventive Maintenance

161 Ganti Accu 161 1 Hours Preventive Maintenance

161 Ganti Oli 161 1 Hours Preventive Maintenance

ACTIVITY ASSET_TYPE ASSET_GROUP

Service Besar AG.KDR.0000003TON.HPL

Service Kecil AG.KDR.000002.5TON.HPL

Service Berkala AG.KDR.00000200CC.SPM

Service AC AG.KDR.00001300CC.MBS

Service Dinamo AG.KDR.00001500CC.PKU

Service Kopling AG.KDR.00001500CC.SDN

Ganti Ban AG.KDR.00001800CC.MBS

Ganti Accu AG.KDR.00001800CC.SDN

Ganti Oli AG.KDR.00002000CC.JEP

AG.KDR.00002000CC.MBS

AG.KDR.00002400CC.JEP

AG.KDR.00002500CC.AMB

AG.KDR.00002500CC.JEP

AG.KDR.00002500CC.MBS

AG.KDR.00002800CC.MCS

AG.KDR.00003500CC.TRK

ACTIVITY ITEM SEQ OPERATION SEQ ITEM_CODE

Service Besar 1 Blm Ada di Master item

Service Kecil 1 Blm Ada di Master item

Service Berkala 1 Blm Ada di Master item

Service AC 1 Blm Ada di Master item

Service Dinamo 1 Blm Ada di Master item

Service Kopling 1 Blm Ada di Master item

Ganti Ban 1 Blm Ada di Master item

Ganti Accu 1 Blm Ada di Master item

Ganti Oli 1 Blm Ada di Master item

DESCRIPTION

COMPONENT QUANTITY UOM

Seher

Lubricant

Busi, Oli Mesin, Sil

Freon, Filter Kabin, Evaporator

Magnet, Spull

Kanvas Kopling, Laher

Ban

Air Accu, Accu

Oli

ACTIVITY SEQ DEPARTMENT SHUTDOWN TYPE

Service Besar GS YES

Service Kecil GS YES

Service Berkala GS YES

Service AC GS YES

Service Dinamo GS YES

Service Kopling GS YES

Ganti Ban GS YES

Ganti Accu GS YES

Ganti Oli GS YES

DESCRIPTION RESOURCE SEQ RESOURCE USAGE UOM UNIT

3 Days

6 Hours

1 Days

1 Days

1 Days

1 Days

2 Hours

1 Hours

1 Hours

SCHEDULE_NAME DEFAULT AUTOMATIC INSTANTIATION

Preventive Maintenance Kendaraan Yes Yes

Preventive Maintenance AC Yes Yes

RESCHEDULE MANUAL WORK ORDER RUN TO FAILURE SET NAME ASSET TYPE ASSET GROUP

No No MAIN Capital AG.KDR.0000002500.MB

No No MAIN Capital AG.AC0.0000002500.CST

SCHEDULE TYPE SCHEDULING OPTION US TO SUGGEST NEXT SERVIC WORK ORDER STATUS

Rule Based Actual End Date Start Date Released

Rule Based Actual End Date Start Date Released

USE DATE THAT COMESGENERATE NEXT WOACTIVITY BASE INTERVAL IN DAYSBASE INTERVAL METER

First No Service Kendaraan 2000

First No Service AC 30

LIST DATES

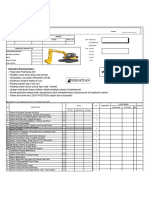

Preventive Maintenance

Corrective Maintenance

UP PLAT : periksa up plat lumasi dengan menggunakan grase

20

CONECTING : periksa conecting rod, lumasi dengan menggunakan grase

30

MAIN SHOFT : periksa main shoft dan pastikan lubang conecting tdk haus, bila

haus segera ganti 30

ROLLER : periksa roller depan belakang dan dicoba diputar. Bila macet segera

ganti bearing 10

STROKE ADJUSTING : periksa stroke adjusting, dicoba setting hadel diputar. Bila

berat segera lumasi 10

CYLINDER : periksa cylinder dan pastikan tidak ada yg bocor, bila ada ganti

10

MOTOR : periksa motor dengan meggunakan tang ampere dan ganti bearing. Bila

sudah rusak 30

POMPA OLI : pastikan tekanan masih normal dan ganti seal bila ada yg bocor

30

COPLING : periksa rumah copling dan copling PVC, bila rusak segera ganti

30

SELENOID : periksa selenoid, pastikan dlm kondisi baik dan dicoba manual

30

TUBING ONE TOUCH : periksa tubing dan one touch, bila bocor segera ganti

30

FLEXIBLE : periksa semua flexible dan pastikan tdk ada yg bocor. Kencangkan

semua sambungan 15

OLI : ganti oli bila kepekatannya sudah hilang 30

PLAT HAMMER : periksa kemiringan plat hammer, bila miring segera di set

30

CONTACTOR + NFB : periksa contactor dan NFB, bila rusak ganti coil

30

You might also like

- Data Mine TutorialDocument23 pagesData Mine TutorialDhabith100% (4)

- Above Ground Storage TanksDocument3 pagesAbove Ground Storage TanksAugusto Manuel Inga Sánchez0% (1)

- Gear Failure AnalysisDocument110 pagesGear Failure AnalysisMuhammad afzal100% (5)

- Service Manual Picanto Ion G3HGDocument12 pagesService Manual Picanto Ion G3HGrectificamosNo ratings yet

- Manual Ato 7227 FX 2019 IngDocument10 pagesManual Ato 7227 FX 2019 IngAlvaro PadillaNo ratings yet

- IBM MMS For Cisco FLYER-IBMTSS-MMSFORCISCO PDFDocument2 pagesIBM MMS For Cisco FLYER-IBMTSS-MMSFORCISCO PDFMaarten FolmerNo ratings yet

- RECON-BRX-2017-Breaking CRP On NXP LPC Microcontrollers SlidesDocument57 pagesRECON-BRX-2017-Breaking CRP On NXP LPC Microcontrollers SlidespaulNo ratings yet

- Evo Ipmvp Core Adherence-Criteria 2016Document4 pagesEvo Ipmvp Core Adherence-Criteria 2016rpercorNo ratings yet

- Manutenção Programada WP CrownDocument8 pagesManutenção Programada WP CrownVinicio HenriqueNo ratings yet

- File Pms Engine Tug Boat Maju Daya 53Document14 pagesFile Pms Engine Tug Boat Maju Daya 53k684ryjm8vNo ratings yet

- Service Routines HV2-210Document1 pageService Routines HV2-210Suraj SinghNo ratings yet

- Dwifarid Alifandi d85Document28 pagesDwifarid Alifandi d85gemabasilius53No ratings yet

- Shop Manual: Hydraulic BreakerDocument37 pagesShop Manual: Hydraulic BreakerFernando Chinchazo CamposNo ratings yet

- Daily Activity Report Day14Document3 pagesDaily Activity Report Day14Muhammad ZakiNo ratings yet

- Cat C18 Maintenance.Document1 pageCat C18 Maintenance.ChiefNo ratings yet

- Installation and Operation Manual: KP1 and KP2 Vehicle Mounted Fire PumpDocument42 pagesInstallation and Operation Manual: KP1 and KP2 Vehicle Mounted Fire PumpZacke EsmaNo ratings yet

- 1a. PS1000 PC200-8MO Adi WDocument28 pages1a. PS1000 PC200-8MO Adi WDeni SetiawanNo ratings yet

- 7 - Training Registration SystemDocument198 pages7 - Training Registration SystemПавел ПогребнойNo ratings yet

- PMS PER WAKTUDocument57 pagesPMS PER WAKTUAbdul BasitNo ratings yet

- Maintenance Manual Recommended Guidelines (FIRST EDITION)Document38 pagesMaintenance Manual Recommended Guidelines (FIRST EDITION)ErwinNo ratings yet

- Service Sheet ScaniaDocument2 pagesService Sheet Scaniamiswansabani86No ratings yet

- Maintenance Schedule: M/S Saranya Spinning Mills (P) LTDDocument3 pagesMaintenance Schedule: M/S Saranya Spinning Mills (P) LTDVenkatesh BabuNo ratings yet

- Pm. Dozer d85ssDocument20 pagesPm. Dozer d85ssIqmal WahabNo ratings yet

- 2.5t-3.5t ICB Maintenance GuideDocument17 pages2.5t-3.5t ICB Maintenance GuideKaran AroraNo ratings yet

- Cópia de AC SupervisoresDocument5 pagesCópia de AC Supervisoresdangelo silveiraNo ratings yet

- SXP-D Maintenance ScheduleDocument2 pagesSXP-D Maintenance ScheduleGerardo Sanchez LopezNo ratings yet

- Maintenance: Right Maintenance and Inspection MethodsDocument13 pagesMaintenance: Right Maintenance and Inspection MethodsPreett Rajin MenabungNo ratings yet

- Preventive Maintenance Check and Lubrication Frequency (YEAR)Document18 pagesPreventive Maintenance Check and Lubrication Frequency (YEAR)Anonymous h0yutV8No ratings yet

- Me MaintenanceDocument3 pagesMe MaintenanceVin DieselNo ratings yet

- Cat 325F L Operators ManualDocument4 pagesCat 325F L Operators ManualСергій БоженкоNo ratings yet

- Lisensi LVDocument1 pageLisensi LVpuryono941No ratings yet

- Tap Changing PositionDocument12 pagesTap Changing PositionAbdulyunus AmirNo ratings yet

- Pump Lubrication PlanDocument1 pagePump Lubrication PlanSiraj AhmedNo ratings yet

- Presentasi UtDocument31 pagesPresentasi UtRiyan DwiNo ratings yet

- Jadwal Weekly MaintanaceDocument8 pagesJadwal Weekly Maintanaceardy ansyahNo ratings yet

- SL-E Air End Service Manual Compressor ScrollDocument35 pagesSL-E Air End Service Manual Compressor ScrollLucky Karunia Setyawan PratamaNo ratings yet

- 90 160kW PM GuideDocument1 page90 160kW PM GuideNikolay VelchevNo ratings yet

- Chklist HEXDocument3 pagesChklist HEXluisNo ratings yet

- Orden de Mantenimiento Maquina 1Document1 pageOrden de Mantenimiento Maquina 1AgamizRNo ratings yet

- Owner'S ManualDocument36 pagesOwner'S ManualEric LaqueilleNo ratings yet

- TM 1000 1500 (PV03)Document18 pagesTM 1000 1500 (PV03)FrancoNo ratings yet

- Maintenance & Troubleshooting Guide: Sprocket & Gear, IncDocument12 pagesMaintenance & Troubleshooting Guide: Sprocket & Gear, IncGarry Yan DiazNo ratings yet

- Zenoah G230RC - G260RCDocument20 pagesZenoah G230RC - G260RCsousou0033No ratings yet

- 02-Engine Mechanical SystemDocument150 pages02-Engine Mechanical SystemDavid VillamarinNo ratings yet

- Huaming OLTC BrochureDocument6 pagesHuaming OLTC BrochureAn AccountNo ratings yet

- Customer Service Report: Parameters Actuals ResponseDocument2 pagesCustomer Service Report: Parameters Actuals ResponseMASU BRAKE PADS QANo ratings yet

- Toyota Vitz Preventive Maintenance ScheduleDocument8 pagesToyota Vitz Preventive Maintenance Schedulealexberhane3No ratings yet

- Service Manual PDFDocument93 pagesService Manual PDFJorge MartinezNo ratings yet

- Causes of Generator Breakdown.Document7 pagesCauses of Generator Breakdown.Service CoatechNo ratings yet

- Overhauling of Ray Roll 33Kv Circuit Breaker: Presented By: Asset Management - Transformer & Work Shop StaffDocument26 pagesOverhauling of Ray Roll 33Kv Circuit Breaker: Presented By: Asset Management - Transformer & Work Shop Staffమాచర్ల రవీంద్ర నాథ్No ratings yet

- Ntpc-Sail Power Co. Pvt. LTD Ntpc-Sail Power Co - LTD.: 2X250Mw Bhilai ExpansionDocument28 pagesNtpc-Sail Power Co. Pvt. LTD Ntpc-Sail Power Co - LTD.: 2X250Mw Bhilai Expansionइंजी. महेन्द्र प्रताप सिंहNo ratings yet

- PM PC1250SP-8Document25 pagesPM PC1250SP-8Teguh Imam AdriNo ratings yet

- Ag 1500Document37 pagesAg 1500the70767% (3)

- 2021 - Chennai MMDDocument11 pages2021 - Chennai MMDsenthilkumar rNo ratings yet

- Laporan Pms Engine Tug BoatDocument14 pagesLaporan Pms Engine Tug Boatk684ryjm8vNo ratings yet

- Periodical Service Scania P380: Maintenance SheetDocument2 pagesPeriodical Service Scania P380: Maintenance SheetWanda Panggih KurniawanNo ratings yet

- 02 - Engine Mechanical SystemDocument136 pages02 - Engine Mechanical SystemWimpie KeyterNo ratings yet

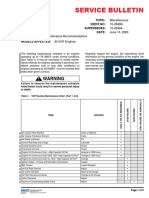

- Service Bulletin: WarningDocument2 pagesService Bulletin: WarningJuly E. Maldonado M.No ratings yet

- Jack-Luber: Installation InstructionsDocument4 pagesJack-Luber: Installation InstructionsAlexander Aristizábal PeñalozaNo ratings yet

- Level 2 - TR100 SA Hydraulic System Complete 020710Document118 pagesLevel 2 - TR100 SA Hydraulic System Complete 020710Anonymous 340A7vnwV1100% (2)

- Toyota Platz Preventive Maintenance ScheduleDocument8 pagesToyota Platz Preventive Maintenance Schedulealexberhane3No ratings yet

- SCH Training A9000Document162 pagesSCH Training A9000Sugeng AriyadiNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Rician DetailDocument4 pagesRician DetailDaniel andersonNo ratings yet

- Key User FormDocument2 pagesKey User FormDaniel andersonNo ratings yet

- Template Asset NumberDocument8 pagesTemplate Asset NumberDaniel andersonNo ratings yet

- Stationary 2012Document6 pagesStationary 2012Daniel andersonNo ratings yet

- Continous Form and Stampel 2012Document5 pagesContinous Form and Stampel 2012Daniel andersonNo ratings yet

- Atk Juni 2012Document1 pageAtk Juni 2012Daniel andersonNo ratings yet

- Pemakaian Stensilan 20121Document5 pagesPemakaian Stensilan 20121Daniel andersonNo ratings yet

- Plan Budget Opex Jan 2014 - ChemicalDocument3 pagesPlan Budget Opex Jan 2014 - ChemicalDaniel andersonNo ratings yet

- Pemakain Toner N Catridge (Dept)Document4 pagesPemakain Toner N Catridge (Dept)Daniel andersonNo ratings yet

- Rekap BudgetDocument1 pageRekap BudgetDaniel andersonNo ratings yet

- Lexmark X642eDocument192 pagesLexmark X642eNdrianina RasoamananaNo ratings yet

- IkegamiDocument2 pagesIkegamiRaul Balderrama DNo ratings yet

- To Cleaning & Degreasing Within The Industrial ManufacturingDocument8 pagesTo Cleaning & Degreasing Within The Industrial ManufacturingukalNo ratings yet

- Steripleat Vent: Sterile Tank Vent FiltrationDocument3 pagesSteripleat Vent: Sterile Tank Vent FiltrationPraful IngleNo ratings yet

- Manual HPVFV ModbusDocument16 pagesManual HPVFV ModbusZohra ElNo ratings yet

- Annexure I List of Govt & Govt. Aided Polytechnic Colleges and Diploma ProgrammesDocument12 pagesAnnexure I List of Govt & Govt. Aided Polytechnic Colleges and Diploma ProgrammesSarath ChandranNo ratings yet

- Kyron Channelling John Magnetics Part 1Document1 pageKyron Channelling John Magnetics Part 1john100% (1)

- 15 KW Net Metering System 3997 Ace Solar Energy Honorable Admiral Naeem SarwarDocument5 pages15 KW Net Metering System 3997 Ace Solar Energy Honorable Admiral Naeem SarwarTaimur KhattakNo ratings yet

- 11 KV 200 Amp 3 Pole AB Switch Technical Specification: ScopeDocument4 pages11 KV 200 Amp 3 Pole AB Switch Technical Specification: ScopeVIKRAM DESAINo ratings yet

- Invervesor Growatt 75kwDocument38 pagesInvervesor Growatt 75kwStênio PimentelNo ratings yet

- Case Tool BenefitsDocument2 pagesCase Tool Benefitsmutha123No ratings yet

- Moisture CorrectionDocument34 pagesMoisture CorrectionShitanshu SinghNo ratings yet

- Thread Inspection MethodsDocument2 pagesThread Inspection MethodsMohamed AshfaqNo ratings yet

- Technical Guide MLCDocument80 pagesTechnical Guide MLCCraciun DanielNo ratings yet

- Tilt Angle OA OBDocument16 pagesTilt Angle OA OBaliradicalNo ratings yet

- Distance Amplitude Correction Curve (Dac) : 2.4mmø SDH 80% FSH 1 PositionDocument2 pagesDistance Amplitude Correction Curve (Dac) : 2.4mmø SDH 80% FSH 1 PositionAnonymous StO1rpYNo ratings yet

- Wheel Set: Dealer's ManualDocument31 pagesWheel Set: Dealer's ManualHeather ColeNo ratings yet

- Case 1Document19 pagesCase 1JonathanNo ratings yet

- Object Oriented Programming: in PythonDocument29 pagesObject Oriented Programming: in PythonJohn mari CadNo ratings yet

- Baxter Colleague - Service ManualDocument422 pagesBaxter Colleague - Service ManualErik Van HalenNo ratings yet

- Power System Analysis: Fundamentals of Power Systems (EEL 3216)Document29 pagesPower System Analysis: Fundamentals of Power Systems (EEL 3216)subaidahNo ratings yet

- MasoneilanDocument24 pagesMasoneilan62719No ratings yet

- ASSL Product ListDocument1 pageASSL Product Listmmrashid1904No ratings yet

- Zoning Ordinance 2Document89 pagesZoning Ordinance 2jao daquiganNo ratings yet

- GSM Radio Network PlanningDocument121 pagesGSM Radio Network PlanningFarhad DanaeiNo ratings yet