Professional Documents

Culture Documents

Report (Repaired) REVISED

Report (Repaired) REVISED

Uploaded by

Soma Shekar. MOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Report (Repaired) REVISED

Report (Repaired) REVISED

Uploaded by

Soma Shekar. MCopyright:

Available Formats

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

ACKNOWLEDGEMENT

Through this project report I would like to thanks numerous people whose consistent

support and guidance has been the standing pillar in architecture of this project. To begin

with, my sincere thanks to the Management of SHREE SAI DEEKSHITH CREATION for

giving this opportunity to experience and learn the processes practiced in Garment/

Apparel Industry.

I would like to express my sincere thanks to the Management and staff of SHREE SAI

DEEKSHITH CREATION for their outstanding support and cooperation in my efforts to

gain knowledge about the practical aspects of Garment industries during the Internship.

I am thankful to Mr. Sai Somashekar (Sr. Manager), for the guidance and planning out

the schedule for the internship.

I would like to grab this opportunity to express my sincere gratitude to Ms. Partibha

Srinivas(Merchandiser), Ms. Shilpa (Merchandiser) for guiding me through all the

processes involved in the processing of the fabric and was patient enough to answer all

my doubts and queries.

I would specially like to thank all the staff members and workers for helping me

throughout the internship. Without their support, it would have been difficult job to

successfully complete the training.

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

PREFACE

I made this project on Garment Industry in order to know about that how

manufacturing process and management is done. This project is mainly centralized on

how various departments are working for management.

For a Commerce student the career of the student depends upon many things and one of

them is practical knowledge. Practical knowledge helps to implement the theoretical

aspects into the practical world.

For practical exposer I done this project. This project contains overall Management

Structure and Work Flow of the companies doing the textile products (like Suiting &

shirting).this project is basically for knowing how Garment Manufacturing concerns are

run their businesses and how they contributing to the Indian economy.

EXECUTIVE SUMMARY

In the past two decades, the Indian textile industry in terms of home textile, garments and

accessories have a witnessed a complete transformation in terms of quality, market and

product development as well as the expansion, In this scenario export house plays the

major role in the growth and conduct of exports. Looking from this perspective SHREE

SAI DEEKSHITH CREATIONS is a very good and important organization in its work.

Internship at SHREE SAI DEEKSHITH CREATIONS has been a great exposure for the

practical application of my learning. I gained knowledge about actual work culture of the

company and how to deal with the people at workplace.

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

GUIDE DECLERATION

This is to certify that the internship report entitled “ A Study on functions and Work

Flow in Garments Manufacturing Industry” , submitted by SOMASHEKAR M

(U03HW21C0072) is prepare under the guidance and supervision. This report is done in

partial fulfilment for the BCOM Course.

PLACE: BENGALURU Prof. SAVITHA V

DATE: Assistant Professor

RNS First Grade College

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

TABLE OF CONTENTS

ACKNOWLEGMENT

PREFERENCE

EXECUTIVE SUMMARY

CHAPTER 1

INTORDUCTION………………………………………………………………..…………….7-20

COMPANY PROFILE……………………………………………………...………………..20-22

VISION, MISSION, VALUES……………………………………………………………….22-23

SWOC ANALYSIS…………………………………….…………………………………….23-25

CHAPTER 2

OBJECTIVE OF STUDY………………………………………………………….…………….26

METHODOLOGY………………………………………………………………………………..26

LIMAITATION/ SCOPE OF STUDY…………………………………………………………...26

CHAPTER 3

WORK FLOW……………………………………………………………………………………29

LIST OF MACHINES………………………………………………………………………..30-31

PRODUCT DEPARTMENT…………………………………………………………………….31

MERCHANDISING DEPARTMENT……………………………………………………….32-33

PURCHASE ORDER………………………………………………………………………..33-36

QUALITY CONTROL DEPARTMENT…………………………………………………….36-37

SAMPLING DEPARTMENT………………………………………………………………..37-38

FABRRIC SOURCING DEPARTMENT…………………………………………………...38-42

TRIME STORE..…………………………………………………………………………………43

CAD DEPARTMENT.…….…………………………………………………………………43-45

SPREADING DEPARTMENT………………………………………………………………….46

CUTTING DEPARTMENT…………..……………………………………………………...47-49

SWEING DEPARTMENT……………………………………………………………………….49

PRODUCTION DEPARTMENT……………………………………………………………49-51

WASHING DEPARTMENT…………………………………………………………………52-53

FINISHING DEPARTMENT…………………………………………………………………….53

IRONING……………………………………………………………………………………..54-55

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

PACKING DEPARTMENT………………………………………………………………….55-56

SALES DEPARTMENT………………………………………………………………………....57

ACCOUNATING AND DOCUMENTATION………………………………………………58-59

CAPTER 4

CONCLUSION

SUGGESTIONS

LOG SHEET

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

CHAPTER- 1

1.1 Introduction

1.2 Indian MARKET Scenoria

1.3 Policy Incentive offered to Garments

1.4 Karnataka Market Scenoria

1.5 SNAPSHOT OF Investment under NUTHAN JAVALI NEETHI

(2013-18)

1.6 Karnataka vision, mission, strategy & road map on Textile &

Garment Industry

1.7 New Textile and Garment Industry 2018 - 2024

1.8 Profile of an Organisation

1.9 SWOC Analysis

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

Introduction

Tittle of the Study

“Study on Organizational Structure in SRI SAI DEEKSHITH CREATION (Garment

Manufacturing Industry)”.

ORGANIZATIONAL STRUCTURE:

What Is an Organizational Structure?

An organizational structure is a system that outlines how certain activities are directed in

order to achieve the goals of an organization. These activities can include rules, roles,

and responsibilities.

The organizational structure also determines how information flows between levels within

the company. For example, in a centralized structure, decisions flow from the top down,

while in a decentralized structure, decision-making power is distributed among various

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

levels of the organization. Having an organizational structure in place allows companies

to remain efficient and focused.

KEY TAKEAWAYS

• An organizational structure outlines how certain activities are directed to achieve

the goals of an organization.

• Successful organizational structures define each employee's job and how it fits

within the overall system.

• A centralized structure has a defined chain of command, while decentralized

structures give almost every employee receiving a high level of personal agency.

• Types of organizational structures include functional, divisional, flatarchy, and

matrix structures.

• Senior leaders should consider a variety of factors before deciding which type of

organization is best for their business, including the business goals, industry, and

culture of the company.

Understanding an Organizational Structure :

Businesses of all shapes and sizes use organizational structures heavily. They define a

specific hierarchy within an organization. A successful organizational structure defines

each employee's job and how it fits within the overall system. Put simply, the

organizational structure lays out who does what so the company can meet its objectives.

This structuring provides a company with a visual representation of how it is shaped and

how it can best move forward in achieving its goals. Organizational structures are

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

normally illustrated in some sort of chart or diagram like a pyramid, where the most

powerful members of the organization sit at the top, while those with the least amount of

power are at the bottom.

Not having a formal structure in place may prove difficult for certain organizations. For

instance, employees may have difficulty knowing to whom they should report. That can

lead to uncertainty as to who is responsible for what in the organization.

Having a structure in place can help with efficiency and provide clarity for everyone at

every level. That also means each and every department can be more productive, as

they are likely to be more focused on energy and time.

Centralized vs. Decentralized Organizational Structures

An organizational structure is either centralized or decentralized. Traditionally,

organizations have been structured with centralized leadership and a defined chain of

command. The military is an organization famous for its highly centralized structure, with

a long and specific hierarchy of superiors and subordinates. In a centralized

organizational system, there are very clear responsibilities for each role, with subordinate

roles defaulting to the guidance of their superiors.

There has been a rise in decentralized organizations, as is the case with many

technology startups. This allows companies to remain fast, agile, and adaptable, with

almost every employee receiving a high level of personal agency. For example, Johnson

& Johnson is a company that's known for its decentralized structure.

As a large company with over 200 business units and brands that function in sometimes

very different industries, each operates autonomously. Even in decentralized companies,

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

there are still usually built-in hierarchies (such as the chief operating officer operating at a

higher level than an entry-level associate). However, teams are empowered to make their

own decisions and come to the best conclusion without necessarily getting "approval"

from up top.

Types of Organizational Structures:

• Functional Structure

Four types of common organizational structures are implemented in the real world.

The first and most common is a functional structure. This is also referred to as a

bureaucratic organizational structure and breaks up a company based on the

specialization of its workforce. Most small-to-medium-sized businesses implement a

functional structure. Dividing the firm into departments consisting of marketing, sales,

and operations is the act of using a bureaucratic organizational structure.

• Divisional or Multidivisional Structure

The second type is common among large companies with many business units.

Called the divisional or multidivisional (M-Form) structure, a company that uses this

method structures its leadership team based on the products, projects, or subsidiaries

they operate. A good example of this structure is Johnson & Johnson. With thousands

of products and lines of business, the company structures itself so each business unit

operates as its own company with its own president.

Divisions may also be designated geographically in addition to specialization. For

instance, a global corporation may have a North American Division and a European

Division.

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

Similar to divisional or functional structures, team-based organizations segregate into

close-knit teams of employees that serve particular goals and functions, but where

each team is a unit that contains both leaders and workers.

• Flat (Flatarchy) Structure

Flatarchy, also known as a horizontal structure, is relatively newer, and is used

among many startups. As the name alludes, it flattens the hierarchy and chain of

command and gives its employees a lot of autonomy. Companies that use this

type of structure have a high speed of implementation.

• Matrix Structure

Firms can also have a matrix structure. It is also the most confusing and the least

used. This structure matrixes employees across different superiors, divisions, or

departments. An employee working for a matrixed company, for example, may

have duties in both sales and customer service.

• Circular Structure

Circular structures are hierarchical, but they are said to be circular as it places

higher-level employees and managers at the center of the organization with

concentric rings expanding outward, which contain lower-level employees and

staff. This way of organizing is intended to encourage open communication and

collaboration among the different ranks.

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

• Network Structure

The network structure organizes contractors and third-party vendors to carry out

certain key functions. It features a relatively small headquarters with

geographically-dispersed satellite offices, along with key functions outsourced to

other firms and consultants.

Benefits of Organizational Structures

Putting an organizational structure in place can be very beneficial to a company. The

structure not only defines a company's hierarchy but also allows the firm to lay out the

pay structure for its employees. By putting the organizational structure in place, the firm

can decide salary grades and ranges for each position.

The structure also makes operations more efficient and much more effective. By

separating employees and functions into different departments, the company can perform

different operations at once seamlessly.

In addition, a very clear organizational structure informs employees on how best to get

their jobs done. For example, in a hierarchical organization, employees will have to work

harder at buying favor or courting those with decision-making power. In a decentralized

organization, employees must take on more initiative and bring creative problem solving

to the table. This can also help set expectations for how employees can track their own

growth within a company and emphasize a certain set of skills—as well as for potential

employees to gauge if such a company would be a good fit with their own interests and

work styles.

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

What Are the Key Elements of an Organizational Structure?

Key elements of an organizational structure include how certain activities are directed in

order to achieve the goals of an organization, such as rules, roles, responsibilities, and

how information flows between levels within the company.

What Is the Best Organizational Structure?

There is no one best organizational structure, as it depends on the nature of the company

and the industry it operates in.

The Bottom Line

There are entire fields of study based on how to optimize and best structure organizations

to be the most effective and productive. Senior leaders should consider a variety of

factors before deciding which type of organization is best for their business, including the

business goals, industry, and culture of the company.

HISTORY

The textile industry in India traditionally, after agriculture, is the only industry that has

generated huge employment for both skilled and unskilled labour. The textile industry

continues to be the second-largest employment generating sector in India. It offers direct

employment to over 35 million people in the country. India is the world's second largest

exporter of textiles and clothing, and in the fiscal year 2022, the exports stood at US$

44.4 billion. According to the Ministry of Textiles, the share of textiles in total exports

during April–July 2010 was 11.04%. During 2009–2010, the Indian textile industry was

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

pegged at US$55 billion, 64% of which services domestic demand. In 2010, there were

2,500 textile weaving factories and 4,135 textile finishing factories in all of India.[3]

According to AT Kearney’s ‘Retail Apparel Index’, India was ranked as the fourth most

promising market for apparel retailers in 2009.

The textile industry is one of the oldest and most important industries in India. The Indian

textile industry is a key contributor to the country’s economy, with a current contribution of

around 1% of GDP. The sector employs over 45 million people directly and indirectly,

making it one of the largest employment generators in the country.

The industry is currently facing some challenges, including competition from cheaper

imports, high input costs, and declining exports. However, the government has taken

some steps to support the industry, such as providing financial assistance and creating

an export promotion scheme.

The textile industry is an important part of India’s economy and culture. It has a long

history and employs millions of people across the country. Despite some challenges, the

industry continues to play a vital role in India’s development.

The textile industry plays a significant role in the Indian economy, contributing to over

15% of the country’s total exports. It is also one of the largest employment generators in

India, providing direct and indirect employment to over 35 million people.

The sector has witnessed strong growth in recent years, driven by factors such as

increased domestic and foreign demand, government initiatives, and improved

infrastructure. The industry is expected to continue growing at a healthy pace in the

coming years, supported by positive macroeconomic indicators and growing consumer

spending.

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

The industry contributes to the country's GDP and provides employment to millions of

people. The sector is also an important source of foreign exchange earnings.

Importance of Textile and Garments industry:

The textile industry plays a vital role in the Indian economy. It is one of the largest

employers, providing employment to over 45 million people. The sector contributes

around 14% to the country's GDP and is also a major source of foreign exchange

earnings.

The textile industry is an important part of the Make in India initiative as it has a huge

potential for growth and job creation. The government has taken several steps to promote

the sector, including providing financial assistance and subsidies, setting up special

economic zones, and simplifying regulations.

The textile industry is critical for India's development as it generates vast amounts of

revenue and provides employment to millions of people. The sector holds great potential

for further growth and can play a significant role in achieving the government's

development goals.

1.2 Indian Market Scenario

India is the second largest producer of fibre. The country is the world's largest producer of

cotton and jute.[5][6] India is also the world's second largest producer of silk.[7] Other

fibres produced in India include wool, and man-made fibres. 100% FDI is allowed via

automatic route in textile sector. Rieter, Trutzschler, Saurer, Soktas, Zambiati, Bilsar,

Monti, CMT, E-land, Nisshinbo, Marks & Spencer, Zara, Promod, Benetton, and Levi’s

are some of the foreign textile companies invested or working in India.[8] Between

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

January and July 2021, India exported textile products worth Rs 1.77 lakh crore, which is

52.6% more than the same period last year.

India's textile and apparel sector has seen a wave of strong positive change and is

expected to export approximately USD 350 billion of textiles and apparel and attract

investments worth USD 180-200 billion by 2024. The textile sector is the largest industrial

employment provider in India, employing more than 100 million people directly and

indirectly. The sector contributes 5 per cent to India's GDP, 14 per cent to industrial

production, and 13 per cent to exports. The textiles sector has witnessed an increase in

investment during the last five years. The industry (including dyed and printed) attracted

foreign direct investment (FDI) worth USD 29.74 billion during April 2000 to June 2018,

as per Department of Industrial Policy and Promotion (DIPP) statistics.

India is the world's second largest exporter of textiles and clothing.

1.2 Karnataka Market Scenario:

Karnataka is one of the fastest growing State in India, propelling the country's growth to

greater heights. With a USD 189 billion globalized, market-based economy growing at 7.6

per annum the State has already taken a number of initiatives to enhance its stature as

one of the leading high-tech industrialized States

in the country. Karnataka has been at the forefront of development and is the fourth

largest economy of the country. The State has been a pioneer on many fronts, a leader

in many economic sectors and has consistently provided an environment that nurtures

the spirit of innovation and entrepreneurship. Karnataka has made a mark internationally

as a leading exporter and manufacturer of textiles and apparel globally.

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

Karnataka the Garment Capital of India has been one of the leading contributors in the

growth of textiles and apparel market in New Textile and Garment Policy 2019-24

The clothing industry is a broad system in the world consisting of merchandising,

producing, marketing, and distributing.

● The apparel industry is highly competitive global business.

● Both the manufacturers and retailers should serve their consumer markets, for the

industry to be successful.

● The management of this industry is a challenging task.

1.5.1 Karnataka Vision, Mission, Strategy & Roadmap on Textile and

Garments Industry:

1.5.1.1 Vision:

The State's New Textile and Garment Policy aims to position Karnataka as a

leading destination in the Textile and Apparel sector in the country and to make

textile value chain. into gold mine value chain. The Policy will provide a stimulus to

the textile industry in the State and aims to generate 5 lakh new employments in

the next 5 years and attract investments worth INR 10,000 crore.

1.5.1.2 Mission:

To retain Karnataka's position as the Garment Capital of India and to achieve

higher and sustainable growth in the entire textile value chain through capital

infusion, technology transfer, world class infrastructure and skill up-gradation.

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

1.5.1.3 Strategies:

a) To accelerate growth and increase manufacturing cost competitiveness in the

entire textile value chain from fibre to fashion products.

b) To give special focus on spinning, weaving (rapier loom, air jet looms and

electronic jacquard), integrated units, processing and technical textiles as thrust

sectors of the policy to create an internationally competitive textile industry in the

State.

c) To make Karnataka a skill rich State in each segment of the textile value chain

and develop high tech advanced skilling centers for skilling, re-skilling and up-

gradation of skills as per the needs of the industry,

d) To realise "Zero Effect; Zero Defect" at each level of the textile value chain by

attracting large scale investments for manufacturing world class facilities and

promoting ZLD Technology.

e) To increase the share of handloom exports and support designing, product

diversification, branding, marketing and distribution of handloom products to

distinct international markets.

f) To position Karnataka as a significant manufacturing hub and a net exporter of

Technical Textiles.

g) To become the retail destination and give a boost to the growth of buying

houses and international apparel retailers in Karnataka.

1.5.1.4 Roadmap:

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

The Department of Handlooms & Textiles shall implement the policy with

concentrated and synchronized efforts. To administer the policy, the Department of

Handlooms and Textiles would co-ordinate with various committees and

stakeholders of the industry from time-to-time for implementation of the policy.

Local associations in every district will also promote and create awareness of the

Policy within the district.

Macroeconomic Indicators of the Textile Industry

in Karnataka

Contribution to Garment Production in India 20%

Contribution to State GSDP 0.50%

Contribution to Mulberry Silk production in 49%

India

Contribution to Wool production in India 12%

Contribution to cotton production in India 6%

1.3 New Textile and Garment Policy 2019-24

According to the recent data published by Directorate General of Commercial Intelligence

and Statistics (DGCI&S) under the Union Ministry of Commerce, exports of textiles and

apparel from India have increased by 11 per cent in July2018 to INR 196.36 billion (USD

2.86 billion) compared to INR 176.92 billion (USD 2.74 billion) for the same month last

year. Also, total textiles exports witnessed a jump of 15 per cent to INR 108.79 billion

(USD 1.58 billion) for July 2018 as compared to INR 94.29 billion (INR 1.46 billion) during

July, 2017.

India has strengths in terms of raw material availability, manpower availability, large

domestic market, presence of complete manufacturing value chain and government

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

support. Abundant availability of raw material such as cotton, wool, silk and jute and

skilled workforce has made India a leading sourcing hub for the global market. The textile

sector is dominated by cotton, with a share of over 65 per cent of the total mill fibre

consumption in the country. India accounts for about 14 per cent of the global production

of textile fibre and yarns.

All the support extended by the Central Government, including INR 1,300 crore Samarth

scheme for skilling, INR 6000 crore package for Apparel & Made-ups along with various

State Incentives, is expected to create a strong turnaround in textiles and clothing sector.

# Zonal Classification is as under:

• Zone 1: Entire Kalyana Karnataka Region.

• Zone 2: All areas other than Municipal Corporations, District Headquarters

in Non Kalyana Karnataka region.

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

• Zone 3: All Municipal Corporations and District Headquarters in Non

Kalyana Karnataka region.

• Zone 4: Bangalore Urban.

1.4 Policy Incentives Offered for Garments

1.4.1 Credit Linked Capital Subsidy

a) Credit Linked Capital Subsidy for MSME Enterprises: New /Expansion

/Modernisation/Diversification Enterprises will be eligible for capital subsidy on the

eligible Fixed Assets as per the limits indicated below for Garmenting.

Capital subsidy for MSME Enterprise

Segments Zone 1 Zone 2 Zone 3 Zone 4

Garmenting 25% of Fixed 20% of Fixed 15% of Fixed -

Assets Assets Assets

Additional Additional 5% capital subsidy on the value of -

Subsidy Fixed Assets for SC / ST persons / Persons with

disabilities / Minority / Ex- servicemen / Women

b) Credit Linked Capital Subsidy for Large Enterprises: New /Expansion/

Modernisation/Diversification Enterprises will be eligible for capital subsidy on the

eligible Fixed Assets as per the limits indicated below for Garmenting.

Capital subsidy for Large Enterprises

Segments Zone 1 Zone 2 Zone 3 Zone 4

Garmenting 20% of Fixed 15% of Fixed 10% of Fixed -

Assets Assets Assets

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

Additional Additional 5% capital subsidy on the value of -

Subsidy Fixed Assets for SC / ST persons / Persons with

disabilities / Minority / Ex- servicemen / Women

1.4.2 Interest Subsidy

In order to facilitate the entrepreneurs, garment units for hassle free operations,

financial assistance will be provided to them in form of interest subsidy. Interest

subsidy will be provided for large units only at 5% per annum on term loans for the

first 5 years.

Interest Subsidy for Large Enterprises

Segments All Zones except Zone 4 Zone 4

Garmenting 5% per Interest Subsidy on -

Term loan for the first 5

years

1.4.3 Power Subsidy

Among the biggest issues of the textile industry today is the demand for energy

savings and the call for achieving lower energy consumption. Reimbursement of

cost of power paid by units for Garmenting. The subsidy will be valid for a period of

5 years from the date of commencement of commercial production.

Power Subsidy for Micro & Small Enterprises

Segments All Zones except Zone 4 Zone 4

Garmenting Reimbursement of cost of -

power paid at INR 1.0 for a

period of 5 years

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

1.4.4 Wage Subsidy

Karnataka has a strong garment industry since a long time. Garment

manufacturing industry is highly labour intensive and less capital intensive. This

industry has a woman-friendly employment orientation and provides employment

to large number of women. Since this sector has potential to create new

employment opportunities, the New Textile and Garment Policy 2019-2024 will be

giving monthly wage subsidy for garment enterprises generating new employment

for people of Karnataka domicile only for a period of five years where minimum

employment is 200 persons or above for Medium Enterprises and 500 persons or

above for Large Enterprises.

Wage Subsidy for Medium and Large Enterprise

Zone- 1 Zone- 2 Zone- 3 Zone- 4

INR 1500 per INR 1000 per employee -

employee

1.4.5 Stamp Duty Exemption and Concessional Registration Charges:

Stamp duty to be paid shall be exempted and concessional registration charges

rate of INR 1.00 per INR 1000 in respect of(i) Execution of Lease, Lease-cum sale

and Sale deeds in respect of industrial land / plots allotted; (ii) Execution of Lease

Deeds in case of industrial sheds / plots taken on Lease and (iii) Loan and credit

deeds, including security documents such as mortgage deed, pledge deed etc.,

executed for availing long term funds from banks/Fls and other agencies of

GoK/Gol.

Stamp Duty Exemption for MSME and Large Enterprise

Segments All Zones Except Zone 4 Zone- 4

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

Garmenting Stamp Duty Exemptions & -

concessional registration

charges rate of INR 1000

1.4.6 ESI & EPF Subsidy:

The Government will offer reimbursement of expenditure incurred on account of

employer's contribution towards Employees State Insurance (ESI) / Employees

Provident Fund (EPF) for a MSMEs. Reimbursement would be made on actual

payments made by the entrepreneurs as per the invoiced record, for the MSME

Project. The support would be available for a period of five years from the date of

commercial production.

EIS &EPF Subsidy for MSMEs

Segments All Zones Except Zone 4 Zone- 4

Garmenting 75% reimbursement of employers -

contribution of wage rate per employee

per month for the new units for a

period of 5 years as EPF and ESI

subsidy

# MEANING : MSME

Enterprise Textile Garments

MSME Ministry of Micro, Small and Ministry of Micro, Small and

Medium Manufacturing Medium Manufacturing

Enterprises, Govt of India Enterprises, Govt of India

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

notification dated 1.06.2020 notification dated 1.06.2020

• A Micro enterprise, where • A Micro enterprise, where

the investment in Plant the investment in Plant

and Machinery or and Machinery or

Equipment does not Equipment does not

exceed INR 5 crore. exceed INR 5 crore.

• A Small Enterprise, • A Small Enterprise,

where the investment in where the investment in

Plant and Machinery or Plant and Machinery or

Equipment does not Equipment does not

exceed NR 10 crore and exceed NR 10 crore and

Turnover not exceed INR Turnover not exceed INR

50 crore. 50 crore.

• A medium Enterprise, • A medium Enterprise,

where the investment in where the investment in

Plant and Machinery or Plant and Machinery or

Equipment does not Equipment does not

exceed INR 50 crore and exceed INR 50 crore and

turnover does not exceed turnover does not exceed

INR 250 crore. INR 250 crore.

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

Profile of an Organization :

SHREE SAI DEEKSHITH CREATIONS

We established the company in 2015 and combined fashion, textiles to provide

comprehensive design outcomes, rich with edgy originality, beauty and distinction. We

are Indian based designs of prints and fabric surface treatment specialists, whose

primary focus is to deliver original exclusive and bespoke designs for a wide range of

visual applications. We are committed to uncovering and servicing clients need while

promoting environmental sustainability and productions in an inspiring and creative way

that satisfies the clients.

We provide technical services in making production ready on the basis of clients needs.

We forecast trends, colors and pursue original concepts with stylistic diversity to produce

hand worked and computer generated designs. These includes for fabric and other

surfaces. We also do a lot of custom design development as well as our seasonal

collection.

In this company, the workers produce the high quality of goods at the right time is also

mainly because of goods infrastructure of an organization. With the installation of

machines at their manufacturing plant. The infrastructural building comprises different

units and are providing enough space and facilities according to the task being carried

out in the respective department.

PRODUCT RANGE :

They do some types of garments for their valuable clients. Their products covers casual

wear of gents and ladies and formal wear for men and women

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

The materials are purchased and processed step by step through the machineries to

ensure the best quality yarn . The efficient inventory management system ensures the

uninterrupted production processes of the company.

Company Profile :

Company Name SHREEI SAI DEEKSHITH CREATIONS

Company Status Active

Company category Non-Government company

Class of Company Private

Established in 2017

Age of company 7years

Activities Altering and Finishing

Company Founder Sai Somashekar

Managing Director Sai Somashekar

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

Total Employees 70

GSTIN 29AJKPC3875E1Z3

VISION

• To attain customer satisfaction by delivering nothing but the best, by means of

utilizing the highest quality of resources and systems.

• With well-defined quality objectives in mind to attain customer satisfaction, is at the

heart of our business policy and strategy.

• We are committed to manufacturing, source, supply, export and trade quality

textile products and services. We will always endeavor to satisfy our customers’

needs and exceed expectations through win-win relationships and delight them.

• Our vision is to serve our customers with dedication and offer specialized services

MISSION

• Committed to the consistent upliftment and improvement of both its products and

its responsibilities towards it’s employees.

• Striving hard to achieve highest levels of customer satisfaction through timely

deliveries along with enhanced quality and value of all our products.

• To empower our employees with the skills and knowledge.

• Committed for cleaner and greener environment.

• Encourage initiative, innovation and teamwork.

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

VALUES

We believe in living and practicing business ethics and norms Values – honesty, integrity

and human dignity, besides ethical approach in engagements with all connected

customers, suppliers, employees and others, remain close to our hearts resulting in out

hard earned repute.

SWOT ANALYSIS

SWOT analysis can be of special importance in the clothing industry when used for

designing a new article of clothing, i.e. collection.

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

Strength:

● Futuristic design

● Good image

● Reaction to a new fashion trend

● Quality of textile fabric and production

● The new ergonomic form of a model

● A short period of development of a model and a short period of duration

● Automation of production processes

● Industrial training conducted by specialist

● Ecological requirements.

Weakness:

● Very high price because of fast changes

● Small series with a large number of models (three to five articles in work

order)

● Manufacturing of only three sizes

● The bad covering of foreign market

● The high price of energy

● Condition and price rise of raw material because of introducing VAT

● Short time for optimization of products.

Opportunities:

● Consumers’ wish for new designs

● Marketing of products into a new market

● Market – Establishing “showroom” objects

● Making e-mail catalog – Value of labor

● Production of garments Made-to-Measure.

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

CHALLENGES:

● Import of similar articles of clothing at low price

● Competitors have a lower price

● Competitors have better distribution network with more sales places

● Quick obsolesce of technology.

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

CHAPTER 2

2.1 Objective of study

2.2 Methodology

2.3 Limitation / Scope of Study

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

Objectives of study

• To learn about the functions of various department.

• To develop and improve business skills.

• To build strength, teamwork, spirit and self confidence.

• To experience the business environment.

Origin of the report :

The report is a necessary requirement for the completion internship of my BCOM course.

Topic has been chosen by me as I put much thought into choosing best the possible

internship option to benefit my academic studies. As I am an interested in business field,

it has proved a good choice for me because it gave me an opportunity to learn some

business analytics in practice.

Objective of the study is to learn about the functioning of Garments Industry and Work

Flow of various departments, earning knowledge about different departments of the

company, their function and information flow during work.

DATA COLLECTION METHOD:

I collected this by following method-

• Personal interview from various departments.

• Close observation during work.

• Internal data from various departments.

• And secondary data was collected from the websites o.

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

CHAPTER 3

3.1 Work Flow Chart

3.2 List of Machines

3.3 Product Department

3.4 Merchandising Department

3.5 Purchase Order

3.6 Quality Control Department

3.7 Sampling Department

3.8 Fabric Sourcing Department

3.9 Trim Store

3.10 CAD Department

3.11 Spreading Department

3.12 Cutting Department

3.13 Sewing Department

3.14 Production Department

3.15 Washing Department

3.16 Finishing Department

3.17 Ironing

3.18 Packing Department

3.19 Sales Department

3.20 Accounts And Documentation Department

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

3.1 WORK FLOW

PRODUCT

BUYER MERCHANT

DEVELOPER

SAMPLING FABRIC TESTING

MARKER

SPEARDING CUTTING

PLANNING

RESEARCH &

BUNDLING PRODUCTION

DEVELOPMENT

FINISHING &

WASHING PRESSING PACKING

(IRONING)

ACCOUNTING AND

MARKETING SALES

DOCUMENTATION

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

3.2 LIST OF MACHINES

Sl.No Machine Name No. of

Machines

1 BROTHER SINGLE NEEDLE HIGH SPEED 24

LOCKSTITCH MACHINE

2 MACHINE BROTHER DOUBLE NEEDLE LOCKSTITCH 13

SPLIT FEED

3 BROTHER COMPUTERISED BARTECK MACHINE 3

4 BROTHER BUTTON HOLE MACHINE 4

6 WAIST BAND ATTACHMENT MACHINE 3

7 EASTMAN CUTTING MACHINE 2

8 BAND KNIFE CUTTING MACHINE WITH AIR 3

CUSHION TABLE

9 AUTOMATIC SNAP FASTNER WITH COMPRESSOR 4

10 FUSING PRESS (HASIMA-CONTINOUS FEED 1

11 ENZYME WASHERS – NGAI SHING 7

12 RAMSONS – 200 KG CAPACITY WASHER 3

13 DRYING TUMBLER – NGAI SHING 6

14 REECE KEY HOLE BUTTON HOLE MACHINE 1

15 FEED OF THE ARM 3

16 AUTOMATIC STICKERING MACHINE 4

17 CARTON STRAPPING AUTOMATIC MACHINE 4

18 PERC DRY CLEANING MACHINE 2

19 CINTEX & LOCK NEEDLE DETECTOR MACHINE 5

20 FOUR THREAD OVERLOCK MACHINE 2

21 COMPUTERIZED EMBROIDERY MACHINE 2

22 THREAD WINDING MACHINE 3

23 FLAT LOCK MACHINE 3

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

24 DOUBLE NEEDLE SMOCKING MACHINE 2

TOTAL NUMBER OF MACHINES : 104 MACINES

3.3 PRODUCT DEVELOPMENT

in the context of garment export business normally product development is handled by

design department. But where there is no design team, merchants are responsible for

whole production development process. In export houses sampling department is

considered as product development department.

CLASSIFICATION

PRODUCT

DEVELOPMENT

INTERNAL EXTERNAL

DESIDNING DESIGNING

OWN DESIGN

LINE TECH PARK

INSPIRATIONAL

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

3.4 MECHANDISING DEPARTMENT

Merchandising is a specialized management functions within the fashion industry. It is the

business that moves the world fashion from designers showroom to retail sales floor and

in to the hands of consumers. It is the internal planning that takes place within a retail

organization in order ensures adequate amount of merchandise are on hand to be sold at

prices that the consumers are willing to pay to profitable operation.

Following are the responsibilities of merchandisers which gives importance to

them:

• Internal& external communication.

• Sampling.

• Lab dips.

• Accessories& trims.

• Preparing internal order sheets.

• Preparing purchase orders.

• Advising and assisting production.

• Advising quality department about quality level.

• Mediating production and quality departments.

• Giving shipping instructions and following shipping.

• Helping documentation department.

• Taking responsibility for inspections and Following shipment.

PROCESS FLOW OF MERCHANDISING DEPARTMENT

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

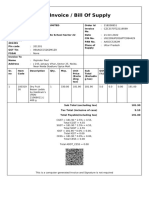

3.5 PURCHASE ORDER

PO is an external document which is issued by buyer in the name of SHREE SAI

DEEKSHITH CREATIONS it is an evidence as well as support of order confirmed in the

favour of company.

Po include the following information-

1. Delivery date.

2. FOB.

3. Ship cancel date.

4. Destination.

1. Ship mode.

6. Terms if sale.

7. Currency.

8. L/C.

9. Quantity.

10. Size break up / colour break up

SHREE ASI DEEKSHITH CREATION USE WFX ERP SOFTWARE -

In company employee work on WFX ERP software for making challan, purchase order,

indent etc. it's very simple and useful software.

Apparel export merchandising may be defined as 'all the planning & activities involved

right from the buyer communication & order receiving till the execution or shipment of the

order by fulfilling the following factors (Six Rights):

Right Merchandise: Retailers must fill their shelves with the merchandise that customer

wants.

Right Place: The location of the merchandise is of prime importance since it decides the

accessibility. Much merchandise is seasonal in nature and must be on hand when it is

most needed.

Right Time: Much merchandise is seasonal in nature and must be on hand when it is

most needed.

Right Quantity: A profitable balance between volume of sales and amount of inventory is

the desired goal.

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

Right Price: Merchandiser must arrive at a price that is high enough to give the store

profit and yet low enough to meet the competition and customers expectations.

Right Promotion: Right balance between the investment and the appeal created for the

customers.

The successful execution of any garment export order depends on the work performance

of a merchandiser. Merchandiser is the person who plans and coordinates all the

activities right from the order procuring and till the shipment order. A merchandiser should

have the comprehensive knowledge of his work procedures and responsibilities so that

he could perform his job efficiently and effectively. In the apparel export industry, a

merchandiser has to perform the following functions;

Communication: It is one of the foremost functions of merchandiser because the

merchandiser has to communicate with different levels of people in his day to day

activities.

Planning & Programming: A merchandiser has to check the order requirement,

planning for the given order, programming for various activities, proper allocation of work

to the assistants.

Follow ups: It includes sending of samples at various stages of order, buyer and buyer

house for sample and other approvals.

Decision making: A merchandiser has to make several decisions during the order

processing like giving approvals like fabrics, color, design, accessories, and packing,

selection of suppliers and vendors, selection of buyers, sometimes time extensions for

order shipment.

Sourcing & Purchasing: A merchandiser may have to do sourcing and purchasing for

raw materials and accessories, suppliers and vendors, new designs, new buyers.

Controlling: This is the crucial activities for any merchandiser. A merchandiser has to

make sure that all the activities are carried out as per the planning and even if there is

any deviation, he/she should make the alternatives measures.

Coordination: Merchandiser has to coordinate in such way to reduce the uncertainties

and difficulties and if there is a problem arises, the merchandiser has to support and lend

helping hand in order to complete the task successfully in the given period. Both the

controlling and coordinating activities complement each other and a merchandiser has to

adopt the both accordingly,

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

Negotiation: It is the activity of convincing, compromising and cooperation which would

benefit the both parties involved in the negotiation.

Costing: It is the process of estimating the expenditure of a given product and the

subsequent price. It is another crucial function because mostly order conformation

depends on the price offered to the buyers. The merchandiser should know the current

prices and rates of various products and processes to do the accurate costing.

Meeting: There are two types of meeting a merchandiser has to be involved. First type, a

merchandiser has to conduct the meeting with the concern department in charges to

discuss about the proceedings and the status of the running order. In second type, a

merchandiser has to attend the meeting with the superiors or buyers or business people

in giving reporting or participation or discussion.

Forecasting: Forecasting is the activity of predicting the future happenings or problems.

A merchandiser has to predict the future uncertainties in the current order or industry so

that alternative actions or corrective measures can be taken in advance this also includes

giving suggestion or ideas about new technologies or new products or latest industry

trends.

3.6 QUALITY CONTROL DEPARTMENT

While raw materials are converted into garments, there are possibilities to make errors,

like making defective garment components and defective garment. Making defective

garment is a cost to the company. So to make sure garments are made as per customer

requirement and whatever raw materials are sourced must meet the factory standards,

factory establish Quality Control Department.

Function of the quality control department can vary widely. But most common function of

quality control depart are as follows

Quality Inspection of Internal Processes and Outsourced work

Inspection of raw material: Checking of raw materials to ensure there is no defective or

abnormal goods.

Testing of of raw material: Quality control department does not conduct testing of raw

materials but they send sample to testing lab for testing physical and chemical test. Once

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

factory receive test report, quality control team get assurance whether raw material to

accept or not.

Inspection of Sample: Visual inspection and measurement checking is done prior to

sending sample to respective buyers.

Cutting room inspection: Quality department is also inspects work done by cutting

room. Like, layering of fabrics on cutting table, cut layer inspection, cut component

inspection, Bundle inspection etc.

Preparatory work inspection: In high fashion garment, lot preparatory work are

outsourced like, printing, machine embroidery, bead work, special decoration on

garments etc. Before feeding this outsourced goods, quality department checks and

approve for further process (sewing process).

Sewing process: In sewing there are multiple checking process is practiced by

exporters, like, Inline inspection, end of line inspection, stitching quality audit etc.

Finishing Process: Finally quality personnel checks finished and packed goods and do

auditing prior to handover shipment to external inspector.

Quality System Development

To make quality product throughout the garment manufacturing process, factories need

to develop quality system. Quality Control Department is responsible for setting quality

system for the factory.

Quality Awareness development

They are also responsible to bring quality awareness among the workers and all

employees.

3.7 SAMPLING DEPARTMENT

A sample is a proto type of a product to be manufactured in future course of production. It

is also called mock up of a product and is made to check the design effectiveness and fit

of the garment. Sampling is a set of the procedure follow to produce various sample style.

It contains activities like making of the pattern for proto type according to measurement of

the sample with the help of machinery and getting buyers approvals for sample produce.

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

In an export house, the sampling department play vital role in the up- lifting of a unit. This

department directly coordinates with the merchandising dept, and production dept.

sampling is done to see how the product will look when produce in bulk and to check

discrepancies in the pattern are.

STEPS OF SAMPLING

3.8 FABRIC SOURCING DEPARTMENT

SOURCING DEALS with getting information about material form different sources then

selecting the best material which suits over budget and buyer's specification.

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

Fabric sourcing means souring the right kind of fabric which fulfils the specification.

Fabric sourcing department is quite important as more than 90% of garment is fabric and

approximately 70% cost of garment is due to the fabric cost.

Selecting the right quality of the fabric as per the buyer's specification otherwise it may

lead to cancellation or rejection of the whole order given by the buyer. The fabric sourcing

department gets the fabric sample from the vendor. These samples are tested before

sending to buyer for approval. After the buyer approves the sample, the fabric is order for

bulk production.

TYPE OF FABRIC

Predominantly woven fabrics solids & printed voiles, cambric, poplin, yarn dyed (mainly

auto-loom & mill-made), complete range of polyester fabrics, viscose, mill made twill,

canvas, denims.

We are also doing woven knit combo wherein top is mainly woven and bottom leggings in

s/l ctnlycra + poly s/j linings for see through dresses & tops in polyester.

Step followed for fabric purchasing:

1. Market trends enquiry.

2. Vendor-folders in-house swatches.

3. Display to buyer.

4. After approval from the buyer swatch is send for the sampling (5-10 meter of fabric)

FABRIC STORE

Fabric storehouse actual are where the fabric for production is receive or dispatched for

processing. Beside storage the fabric store department is also responsible for the

inspection of good receives by it.

PROCESS FLOW OF FABRIC STORE

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

STORAGE

Rack system of storage is followed i.e. packages are stored in two areas:

1. Check fabric.

2. Unchecked fabric.

They are further segregated on the basic of style no. and lot wise. The fabric rolls are put

in rack manual way. Such systematic maintenance of the store makes it easy to make the

fabric whenever needed in future.

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

ORDER PROCESSING AND FABRIC IN-HOUSE:

The merchant receives the purchase order from the buyer. On the basis of this purchase

order, the fabric source prepares a requisition for fabric as per the demand of the buyer

and raises it to the fabric vendors in the market. The best deal and the vendor are

finalized and the order is placed. The factory may send the yarn from the store to the

fabricator for fabric production, buy greige for dyeing or directly order processed fabric to

the vendors. Once the fabrics development receives the approval for the fabric, the

vendor send it from of lot within the specified the time period and the fabric is made in

house in the fabric store. About 5% extra goods are supplied by the vendor.

The fabric via transport trucks comes in various packages like rolls, book fold etc. each

consignment comes in with an invoice having details like quantity, color, GSM, and

weight. The goods are weighted and other detailed are reconfirmed before they store.

FABRIC INSPECTION

The fabric being the main contribution to development of our final product i.e. the

garment, it is very important to control its quality indicated by the no. of faults and various

present in it. Identification of these objectionable variations and faults right at the initial

stage to reduce the production time. So once the fabric is in- house it is immediately sent

on a pilot and trolley assembly to inspection.

4 POINT SYSTEM:

4 Point system for fabric inspection is widely used in apparel industry for fabric quality

inspection.

1. Fabric inspection method or preparation.

2. Criteria of giving penalty points based on defects and defect length.

3. Calculation method of total penalty points for total defects found in a fabric roll.

4. A Check sheet or format for recording data.

Criteria for giving penalty points

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

The penalty evaluation points have been given for different length of fabric defect and

dimension of holes.

FORMULA TO CALCULATE TOTAL POINT PER YARD

In 4 point system fabrioc quality is evaluated by point by unit point/100sq.yds.

Points/100sq.yds = total point in roll*3937

Fabric length in MTR*fabric width in inch

3.9 TRIMS STORE

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

Trims store as the name suggests is a department, which acts as a storehouse for

accessories. It is the place where all the accessories required in an export house, are

stored. Right from sewing thread, needles to packaging material mike poly bags and taps

etc. all are stored in the accessories store.

The merchandiser as per buyer specifications order the purchase dept. to buy the

accessories that are used in a particular style of that buyer. Merchandiser prepares a

swatch card containing all the accessories and their quantity in a cycle. These

accessories used in the swatch card are as per the quality and color mentioned and

approve by the buyer. The purchase dept. with help of swatch card prepared by the

merchandiser purchase the required quantity of accessories. The accessories are

purchased 10-15% extra then the required, as the wastage in case of accessories is

more. The receiving dept. then receives these accessories from the vendor and then

checking and testing of these accessories are done. They are checked quality and color.

The accessories like buttons are tested with help of button snap tester. After all

accessories are checked and tested as per the buyer's specification then an accessories

approval card is prepared.

After the accessories are received they are stored in the accessory store. The

accessories are stored in different racks. The accessories of a single buyer are stored in

one rack but the different accessories are stored separately from each other in the same

rack. The accessories store also houses the stationary required in export house.

Now, whenever the production starts the accessories required in production are issued to

the production dept. through an internal channel. A stock register is used for maintaining

records. Thus an accessory store function as a store house for accessories where all

accessories are assembled and kept and also issued to sampling and production dept.

for the garment manufacture.

3.10 CAD DEPARTMENT:

Computer Aided Design (CAD) becomes an essential tool for pattern making and related

jobs in garment industry. In apparel industry CAD Software is used for pattern making,

Grading of pattern, marker making and digitizing manual patterns.

MARKER MAKING

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

A marker is a diagram of precise arrangement of pattern pieces for size of specific style

that are to be cut from a single spread.

Marker making is a process of developing a diagram which is superimposed on the top of

a ground of superimposed piles as a guide for cutting these plies.

It determines the most efficient layout of pattern pieces for a specific style fabric and

distribution sizes.

Cut order planning determines:

• How many markers are needed?

• How many of each size should be in each marker and the number of plies that will

be cut from each marker?

WAYS TO MAKE MARKER MOST EFFICIENT:

• PATTERN ENGINEERING

An examination of the seam location to ensure the possible placement of pattern in

marker

• HEM ALTERATION ALLOWANCES

Means dividing a large panel awkwardly shaped pattern into two pieces to better

accommodation in the marker.

• THE SELECTION OF FABRIC WIDTH

The best width depends among other factor on the cost of various fabric width

square meter, the typical number of size in a marker, the potential pattern

engineering changes at various width and the marker efficiency achieve.

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

3.11 SPREASING DEPARTMENT

Spreading department is the process of smooth layering of fabrics in superimposed

layers of specific length, After fabric is received it is issued to spreading department for

future processing. Spreading is done with the type of fabric, print of fabric and maker

issued by CAD dept.

PROCESS FLOW OF SPREADING.

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

3.12 CUTTING DEPARTMENT:

Cutting means to separate out different garment process from the lay of fabric with the

help of cutting template and devices. It is done to get required shape in different no. or as

a whole to make a complete product. The first stage in the manufacture if garment is the

cutting of material into the necessary pattern shapes. These patterns are joined to form a

garment when large amount of garment style has to be cut, a lay is created, which consist

of many piles of fabric spread one above the other. Now all the pattern pieces for all sizes

are from this lay. The main objective of the cutting dept. is the cutting of garment parts

accurately and economically and in sufficient value to keep the sewing room supplied

with work.

Objective:

• To maintain the quality of the cut components.

• To cut the raw material in required shape and quality.

• Availability of cut components on time.

Cutting department receives the order for cutting a garment style from the production

manager. Cutting order is an authorization by the production manager to cut a given

amount of styles, from the spreads. It comes in from of a package file that carries the

following details:

• Sampling average, weight of garment (base fabric consumption only) and other

trims averages.

• Measurement sheet

• Design worksheet of the garment

• Purchase order

• Fabric requisition sheet

• CAD mini marker

• Marker planning length of lay etc. size ratio and colours in which the patterns are

to be cut.

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

CUTTING SUB DEPARTMENT:

1. Layering and spreading

2. Cutting

3. Bundling and ticketing

4. Fusing area

5. QA department

TICKETING

Once the pattern pieces are cut by the cutting machine, they are then ticketed. Cut

components are group together as per their sizes and taken to the checking table. Here

the cut components are inspected for any error. It is very important to take care that

pieces cut from two different bolts of fabric are not mixed up. This is because within lot

there bolt to bolt variation in colour shade.

FUSING

Fusing is also carried out in the cutting room itself. The parts to be fused are separated

from the bundle. The fusing material (like interlining) is cut according to size of the

component to be fused. The component along with the cut fusing material are kept

between to paper sheets and the pack is passed through the fusing machine by means of

temperature and pressure fusing takes place at particular speed and for a particular time.

The pack comes out at the other end on conveyors and the pieces are removed and re-

bundled.

Parameters affecting the fusing process:

❖ Pressure - Pressure applied to the fabric should be adequate so that even contact

between the interlining and cloth takes place and uniform heat is supplied to the

adhesive. Pressure should be adequate for the correct penetration of resin among

the fibres of fabric.

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

❖ Temperature - Itis another important parameter. It depends upon the type of resin

used in fusing process. It should be high enough to change the dry thermoplastic

resin into a molten state so that it can flow properly between the fabrics. If

temperature is low it gives proper low of resin and if is high it gives to much flow of

resin and the resin will come out.

❖ Time - Time should also be adequate along with temperature and pressure. It

should be long enough so that melting and penetration of resin among the fibres of

fabric can takes place.

3.13 SEWING DEPARTMENT

❖ The basic aim of an export house is to deliver value satisfaction of the customer at

the profit level.

❖ Production is an act of producing i.e. quantity obtained by multiplying two

quantities to gather by making use available resources.

❖ To deliver quality with the quantity the ratio between input resources or material &

output good and service is known as productivity are reciprocally related to each

other. Therefore an increase in production leads to fall in the cost per unit & rise in

profit.

❖ The production department is spread in two floors, ground floor and first floor is for

jacket, blazer and basic garment. Both floors have common cutting dept. so all the

sizes of bundles are received from there only.

3.14 PRODUCTION DEPARTMENT:

Production floor follows assembly line system. Following are steps to start a

production line.

• To study the production file.

• To study operation bulletin and set line accordingly.

• Manpower operators, checkers, quality controller and helper.

• Load and feeding line.

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

• To arrange buffer or work-in-progress.

• Manufacturing.

• To make daily production and to achieve target accordingly.

• To understand bottlenecks stage of production.

Working steps of production department:

• Shrinkage production pattern is issued to production floor from CAD dept.

• Ready pattern are made as per the requirement of production room.

• Cutting received from cutting dept.

• Cross checking of cut panels with patterns.

• Bundling of cut panels is done.

• Operation wise feeding of cut angels into the line.

• Inline checkpoint

• Output of line

• Final checkpoints.

• Auditing of checked pieces.

Some important production points:

• Ratio between worker and machinery

• Bottleneck area to be considered

• In most of machine, guide is there

• They are using cartons to moving bundles

• They generate report for broken needle

PRODUCTION CAN BE CARRIED OUT IN ONE WAY

1. ASSEMBLY LINE PRODUCTION SYSTEM:

In this production system a garment is being by no. of workers, therefore one part is

stitched by one worker and then passed on to other, due to which line gets setup. In the

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

end assembly of the parts is done, in modern industries conveyor belts are used as a

medium of transportation of garment part from one worker to another. This system is very

commonly used in industry as it reduces the manufacturing cost increase the production.

3.15 WASHING DEPARTMENT:

Garments pass through various handling processes, which may render them dirty and

stain, thereby reducing their aesthetic appeal. To restore this aesthetic value, they are

subjected to cleansing process like washing and dry cleaning. Garments are sent for

washing by the production department as per the buyer's requirement. Normally the

fabrics are not asked to go for wash by the buyer. Whether the fabric department may

internally sent it a number of other reasons.

1. To control uneven shrinkage

2. To remove bowing

3. To lighten colour shade

4. To improve hand

5. To even out colour shade variations

6. To remove printing smell

7. To execute a dyeing program

WASHING FACILITIES:

• ENZYME,

• STONE WASHING,

• OVERDYEING ETC...

3.16 FINISHING DEPARTMENT:

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

After assembly, the garments now come for finishing – a key stage of garments

manufacturing process. Finishing is done to prepare the garment according to the quality

standared of the buyer before packing it for shipment.

PROCESS FLOW OF FINISHING:

BASIC WORK FLOW

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

• WASHING, PERC- according to the buyer's demand or as per the buyer specifies

recipes and the method to be employed. The pieces are count and sent with the

asg or PERC program.

• Thread trimming - pieces received from the washing department or from the

assembly line now come for thread trimming where trails of thread are cut off from

the seams, buttons etc. manually with the help of trimming scissor.

• Spotting- during the assembly, the garment may acquire stain and other

objectionable marks which must be removed. This is done either in washing

department or they are locally 'sported off. Objectionable stains like that of chalk

are spotted by means of spotting guns containing mild solvent. Harder and

stubborn stain(like that of tobacco, rust, dye, kerosene etc) are sent to the spotting

room where they are cleansed under the spotting machine in a protective

environment. If the spots still don't go then they are sent for perc or dry cleaning.

• General checking - now the garment comes for general checking relating to

overall stitching. Here, first the general visual appearance is studied which

includes shape of the garments; balancing of the parts; color variations etc. then

any seaming defects are recognized for example unmade seams, missed stitches

etc. as per requirement the checked pieces are send for mending to assemble line.

The production manager gives a top sample to checkers as a visual aid.

• Final thread cutting- minute thread like those of labels, bar tack etc. are trimmed

off to give the neat look. Thread loosely sticking to the garments is also shed off,

both in and out by jerking the garment before it goes for pressing.

• Pressing- pressing in general is shaping the assemble material with pressure,

with/without heat and moisture, for further processing. In case of knits, this is

important but not as significant as in the case of woven because of their property

of excellent recovery and fit.

• Measurement and final checking - this is the final and most stringent done for

garment measurement, appearance, labels, trim etc to study the final look and

shape the final look and shape of the product produced. Measurements are done

according to the specification sheets and recording are made for any variations in

the measurement chart. This gives an overall idea about the quality of the garment

being produced.

3.17 IRONING:

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

Ironing is the most important finishing process in the readymade garment sector which is

done by subjecting a cloth to heat and pressure with or without steam to remove

unwanted creases and to impart a flat appearence to the garments. Pressing or ironing is

also done to introduce creases in the apparel.

Objectives of ironning are:

● Removal of unwanted creases and crinkles.

● Shaping,

● To apply creases where necessary,

● Under pressing.

● Final presing.

3.18 PACKAGING DEPARTMENT:

Packing is the LAST STAGE WHERE THE FINISHED GARMENT ARE PRIMED,

Organized, geared up for the shipment to the buyer, the entire process from the way a

garment will be folded to the final labeling of the cartons is dictated by buyer’s

specifications. These instructions are standardized for a particular type of garment and

sent to the merchandiser in from of a packing manual. The merchandiser forwards it to

the packing in charge along with a top of production sample i.e. packed with dimension

approved by the buyer. This is kept as a visual reference for the packers.

PROCESS FLOW OF PACKING

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

3.19 SALES DEPARTMENT:

In this sales department the basis are dispatched from the mill with the delivery rate and

Perform invoice to the dealer.

In the administrative office. The final invoice is prepared for the extract value of per sales

in confirmation with gate pass, when the Perform is shown at the check post, the goods

delivered after the lay freight in collect from the concerned parties. The dealer remix the

full value as per the invoice. The yam a sold to Calcutta and in kolatha also. The

company produces minimum spindles of 1000 per day.

A) Sale of finished good.

● Local depot sale.

● Consignment sale.

3.20 FINANCE AND DOCUMENTATION DEPARTMENT:

3.20.1.FINANCE

In this company all the accounts will be maintained by the senior accountant of the

company. They maintain bills receivable and bills payable records. All the money

transaction will be done only under this department. Weekly wages will be given in such

labours and monthly salary will be given to the senior employees either in cash or in

cheque. As to motivate the employees the company will give them in the mode of cash.

FUNCTIONS

BOOK KEEPING - This is the most basic function of the finance department. It involves

the day-two-day recording, analysis and interpretation of a company's financial

transactions. This will include the tracking of all expenses (purchases, payments etc.) and

sales of finished products.

MANAGEMENT OF COMPANY'S CASH FLOW - It is the duty of the finance department

to manage all cash flows into and out of a company and ensure that there are enough

funds available to meet the day-tun-day running of the company.

SRI SAI DEEKSHITH CREATION RNSFGC

ORGANISATIONAL STRUCUTRE IN GARMENT INDUSTRY

BUDGETS AND FORECASTING - In this function, the finance department works with

managers to prepare the company's budgets and forecasts and also give feedback with

regards to the financial standing of the company. This information can be used to fulfil the

cash needs of each department, plan company staffing levels, plan asset purchase and