Professional Documents

Culture Documents

Dynamic Positioning Systems: Offshore Drilling Vessels (Drilling Ships and Semi

Dynamic Positioning Systems: Offshore Drilling Vessels (Drilling Ships and Semi

Uploaded by

mohamed0 ratings0% found this document useful (0 votes)

3 views5 pagesOriginal Title

DP2

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

3 views5 pagesDynamic Positioning Systems: Offshore Drilling Vessels (Drilling Ships and Semi

Dynamic Positioning Systems: Offshore Drilling Vessels (Drilling Ships and Semi

Uploaded by

mohamedCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 5

Dynamic Positioning Systems

For many offshore operations it is necessary to keep a vessel at a

fix position and heading. Traditionally this has been done using an

anchor spread. Nowadays, Dynamic Positioning (DP) systems are

replacing anchors.

A Dynamic Positioning system is able to control the position and

heading of a vessel by using thrusters that are constantly active

and automatically balance the environmental forces (wind, waves,

current etc.). Environmental forces tend to move the vessel off the

desired position while the automatically controlled thrust

balances those forces and keeps the vessel in position.

The main components of any DP system are the positioning

system, the DP computer and the thrusters. The positioning

system, usually a GPS, monitors the position of the vessel. When

the vessel moves off the intended position the DP computer will

calculate the required thrust which will then be applying by the

thrusters in order to maintain the position of the vessel.

The use of DP systems

Dynamic positioning systems are typically used by offshore

vessels for accurate maneuvering, for maintaining a fixed position

or for track keeping (pipe/cable laying). We usually find DP

systems on:

Offshore drilling vessels (Drilling ships and Semi-

submersibles). A Drilling vessel will use DP to remain in a fix

location while drilling in deep water.

Offshore support vessels: Platform supply vessels

(PSVs), Well intervention vessels, Diving Support Vessels.

Support vessel use DP to stay in a safe distance from

offshore platforms and drilling rigs.

Pipe-laying and offshore construction vessels. Pipe-laying

vessels use DP for position keeping and track keeping.

Dredging vessels. Suction Hopper dredgers, Rock-dumping

vessels, Trenching vessels

Shuttle Tankers. Shuttle tankers during offloading of FPSOs.

Pros and Cons of using Dynamic Positioning

Dynamic Positioning is not always the best of the most

economical option. Mooring lines are usually a better option for

shallow water or for operation that do not require frequent

relocation of the vessel (e.g. drilling at shallow water, diving

operations in shallow waters). On the other hand DP is the best

option for deep water operations, for congested seabeds and in

situations where to vessel needs to relocated frequently

Pros

Quick and easy positioning and maneuverability of the

vessel. No need for mooring lines, tugs boats and time

consuming anchor handling operations.

Offshore operations can take place in ultra-deep waters were

mooring lines are difficult to installed.

Easy to change location or weather vane in order to avoid

the effects of bad weather. Quick disconnect and sail away in

case of emergency.

Very safe when working in congested seabeds with many

pipelines, mooring lines from other vessels or subsea

structures such as manifolds, wellheads, risers etc.

Cons:

High Capital expenditure for designing and installing a DP

systems. High CAPEX.

High fuel consumption and increased maintenance cost.

High OPEX.

It poses limitations in very swallow waters and situations

were diving operations must take place close to the thrusters

Potentially severe consequences in case of equipment failure

during pipe-laying or during operations near fixed platforms.

The components of a DP systems

There are 5 main component in a DP systems:

1. Control Systems. The DP control system calculates the

offets between the measured values of position and heading

and the required values (setpoint values). Based on the

calculated offsets the control system calculated the forces

that the thrusters must generate in order to reduce the

errors to zero.

2. Power generation

3. Thrusters and propulsion

4. Environmental reference

5. Position and Heading reference

A taut wire

Hipap

دول بتوع ال

keep a distance from ship

FMEA

Failure Modes and Effect Analysis (FMEA) A systematic analysis to

determine whether the redundant equipment groups in a DP

system are independent of each other and fail to a safe condition.

ده بيكون موجود في المراكب وبيحسب الفلير وكيفية معالجته

Open pass / close pass

DP Advantages

Vessel Heading

Vessel Position

Support close proximities

What is the difference between DP1,

DP2, and DP3 vessels?

DP1 has no redundancy. Loss of position may occur in the event

of a single fault.

DP2 has redundancy so that no single fault in an active system will

cause the system to fail. Loss of position should not occur from a

single fault of an active component or system such as generators,

thruster, switchboards, remote controlled valves etc., but may

occur after failure of a static component such as cables, pipes,

manual valves etc.

DP 3 also has to withstand fire or flood in any single compartment

without affecting the system. Loss of position should not occur

from any single failure including a completely burnt fire sub

division or flooded watertight compartment.

You might also like

- Chapter 15-Basics of Electrical Systems: True/FalseDocument190 pagesChapter 15-Basics of Electrical Systems: True/FalsewesamNo ratings yet

- Jack-Up Rigs Operational Aspects (Offshore Drilling)Document22 pagesJack-Up Rigs Operational Aspects (Offshore Drilling)myusuf_engineer100% (9)

- PETRONAS Fuel Oil 80: Safety Data SheetDocument10 pagesPETRONAS Fuel Oil 80: Safety Data SheetJaharudin JuhanNo ratings yet

- Miter Bend CalculationDocument4 pagesMiter Bend CalculationRavindra S. Jivani100% (4)

- Questionario de DP #1Document14 pagesQuestionario de DP #1Tathiana Dantas100% (3)

- Treleborg MS-OIM Offshore BrochureDocument8 pagesTreleborg MS-OIM Offshore BrochureAdrianBuzamatNo ratings yet

- Module 1 Safety Induction 1Document90 pagesModule 1 Safety Induction 1Sandhy Subhash100% (1)

- SPM (Single Point Mooring) or SBM OperationsDocument9 pagesSPM (Single Point Mooring) or SBM OperationsGiorgi Kandelaki100% (2)

- Aops PDFDocument3 pagesAops PDFHaryNo ratings yet

- Basic Principle of OperationDocument9 pagesBasic Principle of OperationMohammed MizbauddinNo ratings yet

- Mooring Systems For Floaters - FPSO Mooring System 1Document24 pagesMooring Systems For Floaters - FPSO Mooring System 1apis14No ratings yet

- 3 Operating The DP VesselDocument20 pages3 Operating The DP Vessela.sakha1982No ratings yet

- Dynamic PositionDocument16 pagesDynamic Positionnavalandy802No ratings yet

- AnswersDocument9 pagesAnswersVictor Ose MosesNo ratings yet

- Dynamic PositioningDocument31 pagesDynamic PositioningU Zaw Aung100% (3)

- WO0114 Shell HalliburtonDocument4 pagesWO0114 Shell HalliburtonLoganBohannonNo ratings yet

- A Savelyev Dynamic Positioning SystemDocument119 pagesA Savelyev Dynamic Positioning SystemPurposeful KentavrNo ratings yet

- Activity Operational PlanningDocument8 pagesActivity Operational PlanningKrammer KodelNo ratings yet

- Observation RovsDocument4 pagesObservation Rovscharles IkeNo ratings yet

- Advanced Offshore Engineering Notes For Petrochem BranchDocument91 pagesAdvanced Offshore Engineering Notes For Petrochem BranchVikas Katiyar100% (1)

- Maritime University of Constanta Faculty of Naval Electromechanics Specialization: Advanced Engineering in The Oil and Gas Offshore IndustryDocument14 pagesMaritime University of Constanta Faculty of Naval Electromechanics Specialization: Advanced Engineering in The Oil and Gas Offshore IndustryTempest_LNo ratings yet

- An Overview of DP OperationDocument7 pagesAn Overview of DP OperationAquiles SaburoNo ratings yet

- DP Operations Part 2 Paper NIDocument4 pagesDP Operations Part 2 Paper NIparareceberspamsNo ratings yet

- Anchor Handling EquipmentDocument33 pagesAnchor Handling EquipmentJayvee Bongon Galos89% (9)

- AnchorsDocument4 pagesAnchorsRajeevNo ratings yet

- DP Operations Guidelines - SEACORDocument7 pagesDP Operations Guidelines - SEACORRoyNo ratings yet

- DP SystemDocument31 pagesDP SystemShashank MishraNo ratings yet

- FPSO Mooring SystemDocument11 pagesFPSO Mooring SystemsyamsulNo ratings yet

- POWER DISTRIBUTION and THRUSTER SYSTEMSDocument23 pagesPOWER DISTRIBUTION and THRUSTER SYSTEMSRoyNo ratings yet

- Assignment 2Document4 pagesAssignment 2oconnorr81No ratings yet

- Mooring SystemsDocument6 pagesMooring SystemsVinicius PessottiNo ratings yet

- Dynamic PositioningDocument3 pagesDynamic PositioningultrapopeyeNo ratings yet

- Deepwater DrillingDocument52 pagesDeepwater DrillingErdin Ali100% (1)

- DP Operator Manual: Section 6 Environmental Reference SystemsDocument3 pagesDP Operator Manual: Section 6 Environmental Reference SystemsKunal SinghNo ratings yet

- MasterDocument17 pagesMasterCelal Bozdogan100% (1)

- Dynamic PositioningDocument74 pagesDynamic PositioningMarc AlfredNo ratings yet

- Newapps ShiDocument12 pagesNewapps ShiLegend AnbuNo ratings yet

- Predator ROV Spec v3Document2 pagesPredator ROV Spec v3malikscribdNo ratings yet

- What Is ROVDocument2 pagesWhat Is ROVFhrenz Niño MagonciaNo ratings yet

- SHIP SIMULATOR PRACTICE NotesDocument9 pagesSHIP SIMULATOR PRACTICE NotesapendavyomlembaNo ratings yet

- FPSO Mooring SystemDocument11 pagesFPSO Mooring SystemAbam JoshuaNo ratings yet

- Thruster EffectivityDocument190 pagesThruster Effectivityronny-su100% (2)

- Drillship SystemsDocument14 pagesDrillship SystemssanyuktaNo ratings yet

- 6 - Special ApplicationsDocument18 pages6 - Special ApplicationsandreyengNo ratings yet

- DP system-MarineVessels-LRDocument2 pagesDP system-MarineVessels-LRDhamodaran RNo ratings yet

- Dynamic Positioning and Wrovs: A Productive Union Richard GrossDocument11 pagesDynamic Positioning and Wrovs: A Productive Union Richard Grossharry_1981No ratings yet

- Dynamic Positioning c10Document57 pagesDynamic Positioning c10S DNo ratings yet

- Chapter-11 Off-Shore DrillingDocument22 pagesChapter-11 Off-Shore Drillingzimbazimba75No ratings yet

- DP Drilling PDF ManualDocument97 pagesDP Drilling PDF ManualFábio GonçalvesNo ratings yet

- Msre - Anchoring Procedure Letter PDFDocument5 pagesMsre - Anchoring Procedure Letter PDFanhlh100% (1)

- Anchor Handling ManualDocument15 pagesAnchor Handling ManualBrian Smith100% (3)

- ???14?? ?°??????????Document63 pages???14?? ?°??????????rqkkvvkzs7No ratings yet

- Jackup Rig Whitepape FINAL LoRes SpreadsDocument5 pagesJackup Rig Whitepape FINAL LoRes SpreadsRicky Ocktavi RizkyNo ratings yet

- Master'S Bridge Standing Orders: MT LadonDocument5 pagesMaster'S Bridge Standing Orders: MT LadonopytnymoryakNo ratings yet

- S5.1 IntroductionDocument7 pagesS5.1 IntroductionzikriNo ratings yet

- LNG Journal2004Document3 pagesLNG Journal2004Isma VSNo ratings yet

- ResumoDocument78 pagesResumoMarco Antonio Toscano100% (2)

- Buoyed Up: Proven in The Past, Prepared For The FutureDocument10 pagesBuoyed Up: Proven in The Past, Prepared For The FutureantidemosNo ratings yet

- Design of Well CompletionDocument10 pagesDesign of Well Completionscorpionking888No ratings yet

- Ppt:-Deck MachineryDocument35 pagesPpt:-Deck Machineryaimri_cochin81% (32)

- The Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerFrom EverandThe Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerRating: 5 out of 5 stars5/5 (1)

- Bottom ConstructionDocument6 pagesBottom ConstructionmohamedNo ratings yet

- Ship Types and FeaturesDocument6 pagesShip Types and FeaturesmohamedNo ratings yet

- How Read Pump CurvesDocument5 pagesHow Read Pump CurvesmohamedNo ratings yet

- The Level Measurement: Sachin MewaraDocument32 pagesThe Level Measurement: Sachin MewaramohamedNo ratings yet

- Shantilal Shah Engineering College BhavnagarDocument49 pagesShantilal Shah Engineering College BhavnagarmohamedNo ratings yet

- Level Measuring DevicesDocument18 pagesLevel Measuring DevicesmohamedNo ratings yet

- 06-076-080 Ring Joints RTJDocument5 pages06-076-080 Ring Joints RTJmohamedNo ratings yet

- UR Z23 Rev2 pdf1040Document30 pagesUR Z23 Rev2 pdf1040mohamedNo ratings yet

- Instrumentation & Process Control: Topic: Liquid Level MeasurementDocument8 pagesInstrumentation & Process Control: Topic: Liquid Level MeasurementmohamedNo ratings yet

- Norsk Standard NS 2520: Sjøteknikk Låsfeste For Dører Og Luker Av StålDocument8 pagesNorsk Standard NS 2520: Sjøteknikk Låsfeste For Dører Og Luker Av StålmohamedNo ratings yet

- Sea Cort Jan Dix Seal Ring GasketsDocument5 pagesSea Cort Jan Dix Seal Ring GasketsmohamedNo ratings yet

- Form 2 Notice of Expected Implementation Date in The Rules and Practices As at June 2008Document9 pagesForm 2 Notice of Expected Implementation Date in The Rules and Practices As at June 2008mohamedNo ratings yet

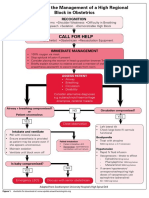

- Algorithm For The Management of A High Regional Block in ObstetricsDocument5 pagesAlgorithm For The Management of A High Regional Block in ObstetricsRaditya DidotNo ratings yet

- 1104A-44TG2 ElectropaK PN1784Document2 pages1104A-44TG2 ElectropaK PN1784NedhoNerimo TroyaNo ratings yet

- 12 Production and Purification of Recombinant Glargine Insulin From Escherichia Coli BL-21 StrainDocument12 pages12 Production and Purification of Recombinant Glargine Insulin From Escherichia Coli BL-21 StrainAnand KumarNo ratings yet

- Chemistry ProjectDocument22 pagesChemistry ProjectkishoreNo ratings yet

- (Download PDF) The Monstrous Feminine in Contemporary Japanese Popular Culture Raechel Dumas Online Ebook All Chapter PDFDocument42 pages(Download PDF) The Monstrous Feminine in Contemporary Japanese Popular Culture Raechel Dumas Online Ebook All Chapter PDFdavid.messer693100% (15)

- 03b Van Parijs 20141996 Two Dilemmas of The Welfare StateDocument6 pages03b Van Parijs 20141996 Two Dilemmas of The Welfare StateNela PetrováNo ratings yet

- H. P. Lovecraft - PolarisDocument3 pagesH. P. Lovecraft - PolarisBárbara AlvesNo ratings yet

- Alternatives To Shifting Cultivation-248Document9 pagesAlternatives To Shifting Cultivation-248Chandrashekhar KhobragadeNo ratings yet

- Effects of Experimental Parameters On NF3 Decomposition Fraction in An Oxygen-Based 2004Document7 pagesEffects of Experimental Parameters On NF3 Decomposition Fraction in An Oxygen-Based 2004Регина ШаяхметоваNo ratings yet

- ESCVS ProgramDocument122 pagesESCVS ProgramNaser Hamdi ZalloumNo ratings yet

- Iso TS 19036 Amd 1 - 2009Document12 pagesIso TS 19036 Amd 1 - 2009oscarosorto100% (1)

- Sebi GuidelinesDocument16 pagesSebi GuidelinesJerome P100% (1)

- Mounted On Rails or Rubber Tyres and Is Able To Straddle Several Rows of ContainersDocument2 pagesMounted On Rails or Rubber Tyres and Is Able To Straddle Several Rows of ContainersIcha AfNo ratings yet

- Homemade Parallettes: What Is A Parallette?Document58 pagesHomemade Parallettes: What Is A Parallette?Athos VianaNo ratings yet

- Sacral ChakraDocument8 pagesSacral ChakraEbyug AkhilNo ratings yet

- Ominous Octet For PharmacistsDocument16 pagesOminous Octet For PharmaciststreeshadowNo ratings yet

- Attachment 15 The Silent Genocide of The Boer Nation in South Africa IndexDocument3 pagesAttachment 15 The Silent Genocide of The Boer Nation in South Africa Indexapi-232649836No ratings yet

- HSE Monitoring and Measurement Procedure: Suez Oil CompanyDocument6 pagesHSE Monitoring and Measurement Procedure: Suez Oil CompanyzakalyNo ratings yet

- Cylinder Safety Poster (ID 801089) 042019 B2 500x700mmDocument1 pageCylinder Safety Poster (ID 801089) 042019 B2 500x700mmChris TeohNo ratings yet

- (NCRP Report No. 174 - ) - Preconception and Prenatal Radiation Exposure - Health Effects and Protective Guidance-National Council On Radiation (2014) PDFDocument386 pages(NCRP Report No. 174 - ) - Preconception and Prenatal Radiation Exposure - Health Effects and Protective Guidance-National Council On Radiation (2014) PDFIulia ChiriacNo ratings yet

- Interpretation of The Maha Dasha of KetuDocument25 pagesInterpretation of The Maha Dasha of Ketuktpadmanabhan9202100% (1)

- Manure Fiber Separation Drying - Rickland Dairy - Case Study - Prf3Document4 pagesManure Fiber Separation Drying - Rickland Dairy - Case Study - Prf3Héctor Magaña SuelvesNo ratings yet

- Nauli-The Key To ConfidenceDocument4 pagesNauli-The Key To ConfidencekailashchsabatNo ratings yet

- Infection Control Webinar 16022010Document88 pagesInfection Control Webinar 16022010shyamchepurNo ratings yet

- FamiliesDocument26 pagesFamiliesChaoukiNo ratings yet

- Requiem Bloodlines & PowersDocument16 pagesRequiem Bloodlines & PowersLuiz Henrique Matias MarcondesNo ratings yet

- Flanges Table: ANSI B16.5 #150Document17 pagesFlanges Table: ANSI B16.5 #150Gaurav SalujaNo ratings yet