Professional Documents

Culture Documents

Highways Department: Guidance Notes Approval of Private Laboratories To Perform Design Testing of Bituminous Mixes

Highways Department: Guidance Notes Approval of Private Laboratories To Perform Design Testing of Bituminous Mixes

Uploaded by

kelvinyucwOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Highways Department: Guidance Notes Approval of Private Laboratories To Perform Design Testing of Bituminous Mixes

Highways Department: Guidance Notes Approval of Private Laboratories To Perform Design Testing of Bituminous Mixes

Uploaded by

kelvinyucwCopyright:

Available Formats

HIGHWAYS DEPARTMENT

GUIDANCE NOTES

Approval of Private Laboratories

to Perform Design Testing of Bituminous Mixes

Research & Development Division RD/GN/006B

January 1997

Guidance Note RD/GN/006B

Approval of Private Laboratories

to Perform Design Testing of Bituminous Mixes

In April 1989, Highways Department implemented a centralised mix design vetting

system. The procedures of the system were promulgated under Highways Department

Technical Circular 4/89.

The General Specification requires the Contractor to carry out the design of

bituminous materials at a laboratory approved by the Engineer. The purpose of this Guidance

Note is to set down the minimum standards required for a laboratory to be approved for the

performance of design testing of bituminous mixes, in accordance with the Specification and

the above described Technical Circular.

The laboratory staff, operating systems and environment etc. should be of acceptable

standard. Since the whole ( or at least most ) of the mix design will be witnessed by

PWL/R&D staff under the above system, checking will be concentrated on the suitability and

calibration of equipment, and records of such calibrations initially. This Guidance Note lists

out details of such requirements. It should be noted that:

approval under this Guidance Note does not

constitute general approval of the laboratory to

perform compliance or other testing.

The Laboratory concerned shall satisfy the Research and Development Division that

the laboratory staff are conversant with the mix design procedures, competent in performing

them and the equipment used, is in a suitable condition and complies fully with the

requirements of this Guidance Note. Calibration certificates issued either by a laboratory

accredited by HOKLAS or in-house calibrations permitted by HOKLAS for the relevant test

(or a laboratory recognised by HOKLAS under mutual recognition agreement), shall be sent

to the Research and Development Division for examination every six months. The date of

calibration, the type of calibration device used and identification number of the devices shall be

given where relevant. Reports shall be properly signed by an authorized signatory, with the

name and post clearly printed. For administrative convenience, calibration certificates together

with a summary on the calibration of laboratory equipment shall be forwarded to the Research

and Development Division by 1st January and 1st July respectively each year.

Calibration results should be presented formally, accompanied by a letter from the

design testing laboratory, on paper bearing the company's address and logo.

RD/GN/006B Approval of Private Laboratories P 1 of 4

to perform Design Testing of Bituminous Mixes

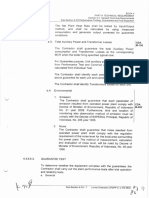

Calibration Requirements

Type of equipment Recommended period Calibration/Checking procedure and

between successive equipment requirement

calibrations/checking

Balances and scales Three years By a HOKLAS accredited calibration

authority

or

Three years calibrate using certified masses in

accordance with CSIRO Division of

Applied Physics paper 'Calibration of

Balances' by D.B. Prowse (1985)

Either alternative

accompanied by

(i) Each weighing (i) Zero check

(ii) One month (ii) One-point check using a known

mass near balance capacity

(iii) Six months (iii) Repeatability check

Dial gauges Two years BS 907

Length measuring Rules and vernier calipers from

devices : reputable manufacturers may be used

without calibration except that in the

Working rules and case of callipers, a zero point check

vernier calipers shall be performed before each use

Drying ovens Five years Temperature variation in accordance

with AS2853 (1986)

One year Check the temperature at the centre of

usable oven space with a thermocouple

and compare with the setting

temperature for the working

temperature range of the oven.

Linear variable Two years (complete Check against length standard such as a

differential transducers calibration) micrometer

(LVDT)

RD/GN/006B Approval of Private Laboratories P 2 of 4

to perform Design Testing of Bituminous Mixes

Type of equipment Recommended period Calibration/Checking procedure and

between successive equipment requirement

calibrations/checking

Marshall equipment BS 598 : Part 107 : 1990

a. Hammer

Mass, dimensions, One year

height of drop

b. Testing machine

Rate of strain One year

c. Testing head

Dimensions Six months

d. Mould

Dimensions Six months

General condition Before each mix design

Pressure and Six months BS 1780:Part 2:1985

vacuum gauges

Proving rings One year By a dead weight tester in conjunction

with a calibration rig in accordance

with manufacturers' instructions. The

grading of the proving ring shall be

based on NAMAS Publication B0415

Sieves Before each test Visual checking for damage and

clogging

One year Check the apertures of perforated plate

test sieves in accordance with appendix

F of BS410 : 1986.

Six months Check the performance of woven wire

cloth test sieves against a set of master

sieves in accordance with BS 812: Part

100 : 1990.

(Sieves may be used without initial

calibration if from a reputable

manufacturer and supplied with a

manufacturer's calibration certificate

confirming compliance with

BS410:1986 )

RD/GN/006B Approval of Private Laboratories P 3 of 4

to perform Design Testing of Bituminous Mixes

Type of equipment Recommended period Calibration/Checking procedure and

between successive equipment requirement

calibrations/checking

Masses

Reference masses of Five years initial; Ten By a HOKLAS accredited calibration

integral construction, years subsequent authority or equivalent

stainless steel or nickel

chromium alloy

Reference thermometers Ten years By a HOKLAS accredited calibration

(Liquid-in-glass) authority or equivalent

Six months TELARC Technical Note No.6

Ice point or one-point check

Working thermometers Initial Check TELARC Technical Note No.6

(Liquid-in-glass) Check against a calibrated reference

thermometer at sufficient points to

cover expected working range

Six months TELARC Technical Note No. 6

One point check, e.g. ice point or the

temperature at which the thermometer

is most frequently used.

Thermocouples

a. Reference Three years (complete BS 1041:Part 4; BS4937;

calibration) ASTM E200; ASTME230

b. Working Six months One point check against a reference

thermometer

Timers Three months Check against time signal given by

(Stopwatches and (RTHK) for at least half an hour.

timing devices) (Timers shall be accurate to 1 second

within 5 minutes)

Water baths Six months Relate temperature of water and setting

using a reference thermometer.

RD/GN/006B Approval of Private Laboratories P 4 of 4

to perform Design Testing of Bituminous Mixes

You might also like

- LASR07 Appendix A Equipment Calibration IntervalDocument7 pagesLASR07 Appendix A Equipment Calibration IntervalLorenzo-Aubrey FabroNo ratings yet

- Meat Inspection in The Abattoir in CameroonDocument122 pagesMeat Inspection in The Abattoir in CameroonKevine Kenmoe MocheNo ratings yet

- Director of Fundraising Competency FrameworkDocument4 pagesDirector of Fundraising Competency FrameworkRobert BrownNo ratings yet

- 8.inspection CalculationDocument38 pages8.inspection CalculationAMAL VISHNUNo ratings yet

- Cleanroom Performance Testing Specifications - Bio-Medical PharmaceuticalDocument18 pagesCleanroom Performance Testing Specifications - Bio-Medical PharmaceuticalginnaNo ratings yet

- Astm C 1064Document3 pagesAstm C 1064Juan Jesus Garcia ReyesNo ratings yet

- Astm C 1069 - 86 R04 PDFDocument2 pagesAstm C 1069 - 86 R04 PDFo_l_0No ratings yet

- Manual of YFD300 Ultrasonic Flaw DetectorDocument72 pagesManual of YFD300 Ultrasonic Flaw DetectorHenry CruzNo ratings yet

- UKAS Calibration IntervalDocument18 pagesUKAS Calibration IntervalRudolf100% (1)

- Calibration Procedure: 1-PurposeDocument5 pagesCalibration Procedure: 1-PurposeHassan SleemNo ratings yet

- Technical Notes MECH 001: Specific Requirements For Mechanical Testing LaboratoriesDocument11 pagesTechnical Notes MECH 001: Specific Requirements For Mechanical Testing LaboratoriessandeepNo ratings yet

- 3455 1971 Reff2020Document17 pages3455 1971 Reff2020Ashish DubeyNo ratings yet

- Temperature of Freshly Mixed Hydraulic-Cement Concrete: Standard Test Method ForDocument3 pagesTemperature of Freshly Mixed Hydraulic-Cement Concrete: Standard Test Method ForCory BradleyNo ratings yet

- PR RFR P07-31 How To Perform TrialsDocument3 pagesPR RFR P07-31 How To Perform TrialsJuan Nacimba NacimbaNo ratings yet

- Testing Concrete: BS 1881: Part 115: 1986Document11 pagesTesting Concrete: BS 1881: Part 115: 1986Mohamed AnasNo ratings yet

- Is 2086 StiDocument6 pagesIs 2086 StiAnuj PandeyNo ratings yet

- Doc:STI/3575/3 April, 1994Document4 pagesDoc:STI/3575/3 April, 1994Venkatesh VardhantiNo ratings yet

- C1064 Temperatura PDFDocument3 pagesC1064 Temperatura PDFJohnny Ccatamayo BNo ratings yet

- Astm C 1064-2017Document3 pagesAstm C 1064-2017Mohammed AliNo ratings yet

- Corretion ListDocument5 pagesCorretion ListAkhmad SyukrieNo ratings yet

- BS 1881-Part 115-86Document11 pagesBS 1881-Part 115-86jaafar abdullahNo ratings yet

- Temperature of Freshly Mixed Hydraulic-Cement Concrete: Standard Test Method ForDocument3 pagesTemperature of Freshly Mixed Hydraulic-Cement Concrete: Standard Test Method ForMario UzuriagaNo ratings yet

- Resistance To Deformation and Cohesion of Bituminous Mixtures by Means of Hveem ApparatusDocument7 pagesResistance To Deformation and Cohesion of Bituminous Mixtures by Means of Hveem ApparatusROHITNo ratings yet

- C1064C1064M 33838Document3 pagesC1064C1064M 33838René Nicolas Valenzuela RosasNo ratings yet

- C1064 Temperature of Freshly Mixed Hydraulic-Cement ConcreteDocument3 pagesC1064 Temperature of Freshly Mixed Hydraulic-Cement ConcreteLuis AlvarezNo ratings yet

- IS 15490 Second Revision Sep 2021Document12 pagesIS 15490 Second Revision Sep 2021surender kumarNo ratings yet

- Resistance To Deformation and Cohesion of Bituminous Mixtures by Means of Hveem ApparatusDocument7 pagesResistance To Deformation and Cohesion of Bituminous Mixtures by Means of Hveem ApparatusFanny SiregarNo ratings yet

- SACIC-Q-1026 Rev.01 Precast Concrete Compressive Strenght Insp.Document2 pagesSACIC-Q-1026 Rev.01 Precast Concrete Compressive Strenght Insp.Muhammad AbrarNo ratings yet

- Calibration of Bitumen Sprayers Part 0: General Introduction, List of Methods and Calibration Test CertificateDocument6 pagesCalibration of Bitumen Sprayers Part 0: General Introduction, List of Methods and Calibration Test Certificateतिप्लोकाची तिरुनचिपल्ली केरकेट्टाNo ratings yet

- Astm 2196Document5 pagesAstm 2196Alexandre LiraNo ratings yet

- 13 - Exhibit D Hydro. Test. Cross Country PLDocument12 pages13 - Exhibit D Hydro. Test. Cross Country PLMoaatazz NouisriNo ratings yet

- Astm C1064.2104017 1Document3 pagesAstm C1064.2104017 1elmer portilloNo ratings yet

- Batch Test CertificateDocument3 pagesBatch Test Certificatekarthikeyan1003No ratings yet

- Ministry of Defence Defence Procurement Agency, ADRP2 Abbey Wood Bristol BS34 8JHDocument3 pagesMinistry of Defence Defence Procurement Agency, ADRP2 Abbey Wood Bristol BS34 8JHgotspatelNo ratings yet

- 5 CQM Manual Appendix IRC SP 47 1998 (Page 46to79)Document29 pages5 CQM Manual Appendix IRC SP 47 1998 (Page 46to79)Rupesh KumarNo ratings yet

- Checklist-Testing Equpt Lab-StoreDocument4 pagesChecklist-Testing Equpt Lab-StoreRomar BalangaoNo ratings yet

- D 2168 - 02 Rdixnjgtukve PDFDocument7 pagesD 2168 - 02 Rdixnjgtukve PDFLupita CarelyNo ratings yet

- ASTM C113 Standard Test Method For Reheat Change of Refractory BrickDocument3 pagesASTM C113 Standard Test Method For Reheat Change of Refractory Brickjoshua johnNo ratings yet

- ASTM D88-68 - Saybolt ViscosityDocument9 pagesASTM D88-68 - Saybolt ViscosityKamruzaman MiahNo ratings yet

- ASTM D2228 Rubber Prop-Abrasion Resistance TestingDocument9 pagesASTM D2228 Rubber Prop-Abrasion Resistance TestingJesse KrebsNo ratings yet

- Astm C704-C704M (2012)Document11 pagesAstm C704-C704M (2012)Shiburaj SomarajanNo ratings yet

- Resistance To Deformation and Cohesion of Bituminous Mixtures by Means of Hveem ApparatusDocument7 pagesResistance To Deformation and Cohesion of Bituminous Mixtures by Means of Hveem Apparatusgrats_singcoNo ratings yet

- L4-UAE-046E (Rev 4) Densitometer Calibration ProcedureDocument4 pagesL4-UAE-046E (Rev 4) Densitometer Calibration ProcedureRahul DubeyNo ratings yet

- Is Code:2026 Power Transformers: PreliminariesDocument7 pagesIs Code:2026 Power Transformers: PreliminariesShailesh SinghNo ratings yet

- Vacuum Cleaner Hose-Durability and Reliability (Plastic) : Standard Test Methods ForDocument7 pagesVacuum Cleaner Hose-Durability and Reliability (Plastic) : Standard Test Methods Forbdr85No ratings yet

- AnnexureDocument3 pagesAnnexureqamarNo ratings yet

- Tandard Perating Rocedure: Authorised by Number Effective Date Pages AuthorDocument5 pagesTandard Perating Rocedure: Authorised by Number Effective Date Pages Authoryousaf_zai_khan81995No ratings yet

- Astm D5444-15Document3 pagesAstm D5444-15UNUSED MUSIC MIRANDANo ratings yet

- Evaluating and Qualifying Oil Field and Refinery Corrosion Inhibitors Using Rotating CageDocument6 pagesEvaluating and Qualifying Oil Field and Refinery Corrosion Inhibitors Using Rotating CageNav Talukdar100% (1)

- 3832 - 4-Chain Pulley BlockDocument8 pages3832 - 4-Chain Pulley BlockAshish PattanaikNo ratings yet

- G-TE-001-00 Work Instruction Guidline For ShacklesDocument3 pagesG-TE-001-00 Work Instruction Guidline For ShacklesbeshoyNo ratings yet

- QAPtanks 27453 345417Document1 pageQAPtanks 27453 345417wasim akramNo ratings yet

- Appendix Ⅰ: ・ Quality control table ・ Check List for performed workDocument69 pagesAppendix Ⅰ: ・ Quality control table ・ Check List for performed workShohel RanaNo ratings yet

- Saudi Aramco Test Report: SATR-B-6105 10-Jun-19 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestDocument2 pagesSaudi Aramco Test Report: SATR-B-6105 10-Jun-19 Inst Fire Alarm System - Manual Pull Station - Pre-Commissioning TestSino hydroNo ratings yet

- STR1 T080 8Document1 pageSTR1 T080 8Suntech Testing Limited STLNo ratings yet

- NATA Calibration Reference Equipment TableDocument25 pagesNATA Calibration Reference Equipment TableAdmer Rey C. DablioNo ratings yet

- 40-SDMS-02A CT TestingDocument14 pages40-SDMS-02A CT TestingMaktoob M Knif100% (1)

- Annexure - A General Technical Specifications For CS Pipe FittingsDocument3 pagesAnnexure - A General Technical Specifications For CS Pipe FittingslalababeNo ratings yet

- SR 2406 Supplemental Requirements - NACLA Recognized 17025 Construction Materials Testing-13027-7Document8 pagesSR 2406 Supplemental Requirements - NACLA Recognized 17025 Construction Materials Testing-13027-7Sreenath KooliyattuNo ratings yet

- That HousesDocument9 pagesThat HousesAri BinukoNo ratings yet

- Testing UMTS: Assuring Conformance and Quality of UMTS User EquipmentFrom EverandTesting UMTS: Assuring Conformance and Quality of UMTS User EquipmentNo ratings yet

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Ravi LE ROCHUS - ResumeDocument1 pageRavi LE ROCHUS - ResumeRavi Le RochusNo ratings yet

- 0650-EDW-00009-02 - Seaking DST Parts List - Customer Parts ListDocument11 pages0650-EDW-00009-02 - Seaking DST Parts List - Customer Parts ListJosianeMacielNo ratings yet

- Napul ResumeDocument2 pagesNapul ResumeNp LbNo ratings yet

- National Insurance Company Ltd. Policy No: 57150031216760012077 1 Year Liability Only From 00:00:01 Hours On 28-Jan-2022 To Midnight of 27/01/2023Document2 pagesNational Insurance Company Ltd. Policy No: 57150031216760012077 1 Year Liability Only From 00:00:01 Hours On 28-Jan-2022 To Midnight of 27/01/2023Benson BennyNo ratings yet

- Procedure For HORCM and RAIDCOMDocument4 pagesProcedure For HORCM and RAIDCOMdennisNo ratings yet

- Treatment of Gestational Hypertension With Oral Labetalol and Methyldopa in Iraqi Pregnant WomenDocument9 pagesTreatment of Gestational Hypertension With Oral Labetalol and Methyldopa in Iraqi Pregnant WomenOmar Nassir MoftahNo ratings yet

- Product And/or Service Positioning: Baju Melayu, Kurta, Baju KurungDocument2 pagesProduct And/or Service Positioning: Baju Melayu, Kurta, Baju KurungAeliza100% (1)

- Section Capacity Section Capacity: AbutmentDocument4 pagesSection Capacity Section Capacity: AbutmentGajendra SNo ratings yet

- JEE 2024 RoadmapDocument42 pagesJEE 2024 Roadmaplilop27557No ratings yet

- Setting Outlook RulesDocument2 pagesSetting Outlook Ruleswijaya_dny0% (1)

- Math NCF 268-293Document26 pagesMath NCF 268-293natureyt4No ratings yet

- Legend of The Galactic Heroes, Vol. 10 Sunset by Yoshiki Tanaka (Tanaka, Yoshiki)Document245 pagesLegend of The Galactic Heroes, Vol. 10 Sunset by Yoshiki Tanaka (Tanaka, Yoshiki)StafarneNo ratings yet

- Test Bank For Psychology 9th Edition BernsteinDocument45 pagesTest Bank For Psychology 9th Edition BernsteinRamona Fretwell100% (33)

- How To Complete StudentVisa Online Application InternationalDocument37 pagesHow To Complete StudentVisa Online Application InternationalAdeyinka AkinlawonNo ratings yet

- BBRC4103 Kaedah Penyelidikan September Semester 2020Document12 pagesBBRC4103 Kaedah Penyelidikan September Semester 2020SARIPAH NOOR FARAH AIN BINTI P.AFDZAL SHAH STUDENTNo ratings yet

- CH PDFDocument43 pagesCH PDFBobVonCatNo ratings yet

- Core Java InterviewDocument251 pagesCore Java InterviewLalitNo ratings yet

- 1 The Building Blocks of JapanDocument26 pages1 The Building Blocks of JapanschelleslarsNo ratings yet

- The Language of Legal DocumentsDocument15 pagesThe Language of Legal DocumentsAldo CokaNo ratings yet

- Cate 825 6M33 WPG825 7 12M26Document3 pagesCate 825 6M33 WPG825 7 12M26Nicolas DodoricoNo ratings yet

- MT6227 SchematicsDocument7 pagesMT6227 SchematicsRenan Birck PinheiroNo ratings yet

- Tectonic Evolution of Mogok Metamorphic BeltDocument21 pagesTectonic Evolution of Mogok Metamorphic BeltOak KarNo ratings yet

- Peripheral Blood Smear Pathologist ToolDocument3 pagesPeripheral Blood Smear Pathologist ToolSimon HafeniNo ratings yet

- SF15 XCM DS RL 29 80,100Document1 pageSF15 XCM DS RL 29 80,100Vagner PaludoNo ratings yet

- Institute of Food Security (Food Corporation of India) Gurgaon Management Trainee Batch:V/2010 Objective Test:Commercial (Sales&Export)Document2 pagesInstitute of Food Security (Food Corporation of India) Gurgaon Management Trainee Batch:V/2010 Objective Test:Commercial (Sales&Export)Swarup MukherjeeNo ratings yet

- UntitledDocument23 pagesUntitledPravinNo ratings yet

- Assignment 4 Inplant TrainingDocument14 pagesAssignment 4 Inplant TrainingRajas BiliyeNo ratings yet