Professional Documents

Culture Documents

Emergency Spill Control Drill Aug 2022

Emergency Spill Control Drill Aug 2022

Uploaded by

Subbu AbuCopyright:

Available Formats

You might also like

- Emergency Drill ReportDocument6 pagesEmergency Drill ReportDirga Delonix Regia100% (4)

- On Site Emergency Response Plan: Creative Textile Mills Privae LimitedDocument28 pagesOn Site Emergency Response Plan: Creative Textile Mills Privae LimitedMuntaj Ansari75% (4)

- 1.3.8.8. Action-Reflection-Action-Session-ARAS (BSN2H)Document1 page1.3.8.8. Action-Reflection-Action-Session-ARAS (BSN2H)Kristil ChavezNo ratings yet

- Standard Operating Procedure - Liquid Nitrogen - Storage, Use & Transportation Guidance & Code of PracticeDocument9 pagesStandard Operating Procedure - Liquid Nitrogen - Storage, Use & Transportation Guidance & Code of PracticejrodNo ratings yet

- Emergency ResponseDocument32 pagesEmergency ResponseMizerNo ratings yet

- 675 2013 TRIUMPH ServiceManual T3856909Document697 pages675 2013 TRIUMPH ServiceManual T3856909张连杉No ratings yet

- Method Statement For MpsDocument14 pagesMethod Statement For MpsAhmed NasserNo ratings yet

- Ip-22 Emergency Preparedness & ResponseDocument11 pagesIp-22 Emergency Preparedness & ResponseScha AffinNo ratings yet

- Emergency Response Plan ProcedureDocument28 pagesEmergency Response Plan Procedureகண்ணன் ரவிச்சந்திரன்No ratings yet

- VMC-QMS-HSE-PRO-013-Spill Response PlanDocument12 pagesVMC-QMS-HSE-PRO-013-Spill Response PlanAnar HajiyevNo ratings yet

- Inbound 5425125211198410005Document3 pagesInbound 5425125211198410005Rabeh BàtenNo ratings yet

- Volume 1 Focus PDFDocument47 pagesVolume 1 Focus PDFAjay Kumar GuptaNo ratings yet

- Demobilasation Plan: Should Be Done by A Third Party Approved Contractors. Isolate The Dismantling AreaDocument3 pagesDemobilasation Plan: Should Be Done by A Third Party Approved Contractors. Isolate The Dismantling ArearadeepNo ratings yet

- CryogenicDocument9 pagesCryogenicShoaib JadoonNo ratings yet

- R.A 6969: Toxic Substances and Hazardous Waste and Nuclear Wastes Control ACT OF 1990Document31 pagesR.A 6969: Toxic Substances and Hazardous Waste and Nuclear Wastes Control ACT OF 1990Erlyn Bacoy QuizoNo ratings yet

- Guidelines For The Performance, Location, Use and Care of Emergency Escape Breathing Devices (Eebds)Document4 pagesGuidelines For The Performance, Location, Use and Care of Emergency Escape Breathing Devices (Eebds)joroma58No ratings yet

- Steam Turbine StartupDocument17 pagesSteam Turbine StartupRahul ChoubeyNo ratings yet

- Vessel Survey ReportDocument8 pagesVessel Survey Reportdivan semestaNo ratings yet

- Safe WorkingDocument142 pagesSafe Workingrizonico0% (1)

- GAP.1.07.0.1.a Page 06 Suggested Flood ChecklistDocument1 pageGAP.1.07.0.1.a Page 06 Suggested Flood ChecklistAndres JimenezNo ratings yet

- CK0602 2014Document10 pagesCK0602 2014anishavanloggerenbergNo ratings yet

- Dropped Objects Prevention SchemeDocument17 pagesDropped Objects Prevention SchemekhurramNo ratings yet

- Comprehensive Contingency Plan-Used Oil PDFDocument6 pagesComprehensive Contingency Plan-Used Oil PDFNeil John Lequigan100% (2)

- Personal Protective Equipment (PPE) : Safe Operational Procedure: Fuel Handling & StorageDocument2 pagesPersonal Protective Equipment (PPE) : Safe Operational Procedure: Fuel Handling & StorageJamesNo ratings yet

- Chemical Exposed and Medivac KOIN Warehouse ReviewedDocument1 pageChemical Exposed and Medivac KOIN Warehouse ReviewedUD. Gunung JatiNo ratings yet

- Proweld Pickling Paste 20121019Document17 pagesProweld Pickling Paste 20121019felipekillerNo ratings yet

- Product InfoDocument13 pagesProduct Inforizki hidayatNo ratings yet

- Safety Awareness Training ProgramDocument143 pagesSafety Awareness Training ProgramAnjaana PrashantNo ratings yet

- Code of Conduct: Quality Manual Services in Water SurveyDocument17 pagesCode of Conduct: Quality Manual Services in Water Surveyaidilmuhamad210No ratings yet

- Heat Stress Awareness Drill June 2022Document18 pagesHeat Stress Awareness Drill June 2022Subbu AbuNo ratings yet

- 2023 Decon SOPsDocument47 pages2023 Decon SOPsBV GutzNo ratings yet

- BO0001 - Kixx Lubo 150N - EngDocument9 pagesBO0001 - Kixx Lubo 150N - EngkokoNo ratings yet

- BO0003 - Kixx LUBO 600N - EngDocument9 pagesBO0003 - Kixx LUBO 600N - EngkokoNo ratings yet

- Famirlirisatio Card s3.14f PDFDocument2 pagesFamirlirisatio Card s3.14f PDFNaNNo ratings yet

- Let ColregsDocument33 pagesLet Colregsswapnil ChaturvediNo ratings yet

- Part 4 ExcavationDocument6 pagesPart 4 ExcavationHana Seiadi100% (1)

- Sustainable Safety in Cemeteries - Andre Van Den BergDocument45 pagesSustainable Safety in Cemeteries - Andre Van Den BergMackoy MarasiganNo ratings yet

- MEMO - Disaster Vulcanic EruptionDocument2 pagesMEMO - Disaster Vulcanic EruptionAlbertJohnOliveraNo ratings yet

- Appendix 1b2 Fj9097.33-160a Msdsnew2Document6 pagesAppendix 1b2 Fj9097.33-160a Msdsnew2RUDDY ALFAN SUBAKTINo ratings yet

- 202.014d - Water Rescue OperationsDocument10 pages202.014d - Water Rescue OperationsDan HalloranNo ratings yet

- BO0005 - Kixx LUBO 4cst - EngDocument9 pagesBO0005 - Kixx LUBO 4cst - EngkokoNo ratings yet

- Ipc-1.67-2e CSSD Health ChallengesDocument4 pagesIpc-1.67-2e CSSD Health ChallengesFalak KhanNo ratings yet

- Emergency Responce Plan For Gulf CryoDocument22 pagesEmergency Responce Plan For Gulf CryoHabib ur rahman0% (1)

- Health and Hyginc Audit ReportDocument8 pagesHealth and Hyginc Audit ReportAhmad SaeedNo ratings yet

- National Energy Group of Companies: Project HSE PlanDocument4 pagesNational Energy Group of Companies: Project HSE PlanalinkarrnyaNo ratings yet

- Checklist As Per BOCWADocument4 pagesChecklist As Per BOCWAAkhilSRzNo ratings yet

- Cargill Palm Products SDN BHD Emergency Action PlanDocument69 pagesCargill Palm Products SDN BHD Emergency Action Planheikal hajazieNo ratings yet

- Bremen ManualDocument120 pagesBremen Manual4ddy23100% (1)

- PHN Industry Sdn. BHD.: 1.0 Objective 1.1 1.2 2.0 SCOPE 2.1 2.2Document7 pagesPHN Industry Sdn. BHD.: 1.0 Objective 1.1 1.2 2.0 SCOPE 2.1 2.2Zack MalikNo ratings yet

- BO0006 Kixx LUBO 6cst EngDocument9 pagesBO0006 Kixx LUBO 6cst EngkokoNo ratings yet

- Waste Management ProcedureDocument7 pagesWaste Management Procedureaone mothupiNo ratings yet

- Evaluation of Camp OHS Risks AssessmentDocument3 pagesEvaluation of Camp OHS Risks Assessmenthasanhse640100% (1)

- 3 5 3 2 Water RescueDocument5 pages3 5 3 2 Water Rescuewyma01No ratings yet

- SGP26903Document28 pagesSGP26903ezgiNo ratings yet

- Health and Safety at SeaDocument5 pagesHealth and Safety at SeaSwapnil SheteNo ratings yet

- 09042015274N4LEKFINALDISMGMTPLANDocument33 pages09042015274N4LEKFINALDISMGMTPLANRahul mishraNo ratings yet

- GAP.1.07.0.1.a Page 09 Suggested Hurricane ChecklistDocument1 pageGAP.1.07.0.1.a Page 09 Suggested Hurricane ChecklistAndres JimenezNo ratings yet

- Emergency Preparedness and ResponseDocument7 pagesEmergency Preparedness and Responseusq venture100% (1)

- Drop Cover HoldOn PublicAdministratorsDocument69 pagesDrop Cover HoldOn PublicAdministratorsVanessa Grace Peradilla HainoNo ratings yet

- 9 QRA Chapter 7Document8 pages9 QRA Chapter 7Manan ChadhaNo ratings yet

- Disaster Recovery for Archives, Libraries and Records Management Systems in Australia and New ZealandFrom EverandDisaster Recovery for Archives, Libraries and Records Management Systems in Australia and New ZealandNo ratings yet

- Partial Evacuation Drill ReportDocument18 pagesPartial Evacuation Drill ReportSubbu AbuNo ratings yet

- Excavator ChecklistsDocument1 pageExcavator ChecklistsSubbu AbuNo ratings yet

- Emergency Drill (Electrocution) April 2023 (HSEM Reviewed)Document3 pagesEmergency Drill (Electrocution) April 2023 (HSEM Reviewed)Subbu AbuNo ratings yet

- Track RegisterDocument1 pageTrack RegisterSubbu AbuNo ratings yet

- JD Hse OfficerDocument2 pagesJD Hse OfficerSubbu AbuNo ratings yet

- Scaffolding JSADocument10 pagesScaffolding JSASubbu AbuNo ratings yet

- Heat Index ChartDocument1 pageHeat Index ChartSubbu AbuNo ratings yet

- Jack Hammer Machine Inpection Checklist-2Document2 pagesJack Hammer Machine Inpection Checklist-2Subbu AbuNo ratings yet

- JD TechnicianDocument1 pageJD TechnicianSubbu AbuNo ratings yet

- Risk Assessment For Runway Beams 1Document10 pagesRisk Assessment For Runway Beams 1Subbu AbuNo ratings yet

- Electrical SafetyDocument1 pageElectrical SafetySubbu AbuNo ratings yet

- GRINDING Machine Inpection Checklist-3Document2 pagesGRINDING Machine Inpection Checklist-3Subbu AbuNo ratings yet

- Drilling Machine Inpection Checklist - 1Document1 pageDrilling Machine Inpection Checklist - 1Subbu AbuNo ratings yet

- JD HelperDocument1 pageJD HelperSubbu AbuNo ratings yet

- List of ProceduresDocument1 pageList of ProceduresSubbu AbuNo ratings yet

- Home SafetyDocument1 pageHome SafetySubbu AbuNo ratings yet

- Ammonia HandlingDocument1 pageAmmonia HandlingSubbu AbuNo ratings yet

- Carbon MonoxideDocument1 pageCarbon MonoxideSubbu AbuNo ratings yet

- Sleep DeprivationDocument1 pageSleep DeprivationSubbu AbuNo ratings yet

- Chemical Storage Safety MomentDocument1 pageChemical Storage Safety MomentSubbu AbuNo ratings yet

- Material Purchase RequestDocument1 pageMaterial Purchase RequestSubbu AbuNo ratings yet

- JHA GasesDocument2 pagesJHA GasesSubbu AbuNo ratings yet

- Multimeter ChecklistDocument1 pageMultimeter ChecklistSubbu AbuNo ratings yet

- Hse Induction ChecklistDocument1 pageHse Induction ChecklistSubbu AbuNo ratings yet

- Risk MatrixDocument1 pageRisk MatrixSubbu AbuNo ratings yet

- Lesson LearntDocument1 pageLesson LearntSubbu AbuNo ratings yet

- Hse Risk Register OffshoreDocument1 pageHse Risk Register OffshoreSubbu AbuNo ratings yet

- Eye ExcersiseDocument1 pageEye ExcersiseSubbu AbuNo ratings yet

- Emergency PlanDocument39 pagesEmergency PlanSubbu Abu100% (2)

- Heat Index Card (Pocket Size)Document2 pagesHeat Index Card (Pocket Size)Subbu AbuNo ratings yet

- Business Plan: Presented by Lesley ClaffeyDocument77 pagesBusiness Plan: Presented by Lesley ClaffeyLesleyNo ratings yet

- Persuasive Speech Topics 8cDocument2 pagesPersuasive Speech Topics 8cIsaid OrtegaNo ratings yet

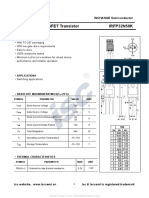

- Isc N-Channel MOSFET Transistor IRFP32N50K: INCHANGE SemiconductorDocument2 pagesIsc N-Channel MOSFET Transistor IRFP32N50K: INCHANGE SemiconductorWilson Yecit OrtizNo ratings yet

- Executive Director Operations Administrations in Portland OR Resume Christina TubbDocument3 pagesExecutive Director Operations Administrations in Portland OR Resume Christina TubbChristina Tubb100% (1)

- Fissell Patient's NarrativeDocument9 pagesFissell Patient's NarrativeQue SabNo ratings yet

- Summary of Findings and Outcome of The HAZOP StudyDocument4 pagesSummary of Findings and Outcome of The HAZOP Studydhanu_lagwankarNo ratings yet

- Nurse Patient Interact OnDocument9 pagesNurse Patient Interact OnHyeji KwonNo ratings yet

- Volleyball Skill PeriodizationDocument13 pagesVolleyball Skill PeriodizationScott_PTNo ratings yet

- 5s Pillars of The Visual WorkplaceDocument35 pages5s Pillars of The Visual WorkplaceSaravana kumar NagarajanNo ratings yet

- Themax N1 - TDS Issue A0Document5 pagesThemax N1 - TDS Issue A0Saif KhanNo ratings yet

- Luis Marcelo TavaresDocument24 pagesLuis Marcelo Tavaresrichard gutierrezNo ratings yet

- Road To RMPDocument9 pagesRoad To RMPMay Ann GarciaNo ratings yet

- Night-Lite Pro II Parts Manual (2021-110292 Rev E)Document514 pagesNight-Lite Pro II Parts Manual (2021-110292 Rev E)nursultanNo ratings yet

- English Stories For KidsDocument11 pagesEnglish Stories For Kidsngoctoankhtnhn2886100% (2)

- KP Rules 4Document33 pagesKP Rules 4Karanbir Singh75% (4)

- Trenchless TechnologyDocument29 pagesTrenchless Technologyraps5_priya100% (1)

- Coffee Pests and Their ManagementDocument38 pagesCoffee Pests and Their ManagementFaiz IsmailNo ratings yet

- Deborah Hellyer AsthmaDocument86 pagesDeborah Hellyer AsthmaGiorgi PopiashviliNo ratings yet

- Curriculum Vitae: Name: Aisha Sitwat Title: Assistant ProfessorDocument20 pagesCurriculum Vitae: Name: Aisha Sitwat Title: Assistant ProfessorSaad KhanNo ratings yet

- Ebook Manual of Critical Care Nursing Nursing Interventions and Collaborative Management PDF Full Chapter PDFDocument67 pagesEbook Manual of Critical Care Nursing Nursing Interventions and Collaborative Management PDF Full Chapter PDFbrian.williams904100% (31)

- In House Welding Inspector ONGCDocument1 pageIn House Welding Inspector ONGCGaurang PandyaNo ratings yet

- Escherichia Coli Plasmid Production in FermenterDocument8 pagesEscherichia Coli Plasmid Production in Fermenterdary.podoliak03No ratings yet

- T NG H P Writing Task 1 SampleDocument50 pagesT NG H P Writing Task 1 Samplengân nguyễnNo ratings yet

- ON DRYING OF SOLIDS Final FixedDocument18 pagesON DRYING OF SOLIDS Final Fixedvaskur royNo ratings yet

- FNoL 15060$06$2021 RE VII$SlNo47 (NeFMS 4) - OTHDocument2 pagesFNoL 15060$06$2021 RE VII$SlNo47 (NeFMS 4) - OTHABCDNo ratings yet

- Bioradiations: High-Resolution Melt AnalysisDocument36 pagesBioradiations: High-Resolution Melt AnalysisDr-Dalya ShakirNo ratings yet

- Self EsteemDocument3 pagesSelf EsteemMary Rose NaboaNo ratings yet

- Web Panel ClinicDocument41 pagesWeb Panel ClinickhairuliqrammazlanNo ratings yet

Emergency Spill Control Drill Aug 2022

Emergency Spill Control Drill Aug 2022

Uploaded by

Subbu AbuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Emergency Spill Control Drill Aug 2022

Emergency Spill Control Drill Aug 2022

Uploaded by

Subbu AbuCopyright:

Available Formats

EMERGENCY DRILL REPORT

Drill Report No.: 57 Cost Center Name: Al Aweer Power Plant

Location: DEWA Exisiting Plant Cost Center Number: 5001

Date: 8th, 9th and 10th/08/2022

Time: 7:30 AM

Drill Scenario observation: ESC has initiated massive awareness campaign about incident/ lessons learnt based

Environmental Incident No. 04 dated 14th July 2022- 'Minor Chemical Spill during chemical cleaning at Fuel gas

piping loop-02 chemical cleaning'. Emergency Response Team has performed spill control simulation drill as part of

Emergency Spill Control Plan and to enhance Awareness Sessions in other to maintain the high level awareness

among the Subcontractors. In addition, it was intended that participants will learn about chemical waste disposal,

principles of emergency response and basic first aid during chemical spillage incidents.

S.N. Drill Sequence Planning Planned time

IDENTIFY THE SUBSTANCE & DETERMINE THE RISK

The ERT in charge should identify (to the extent possible) all hazardous substances,

1 the conditions present, handling procedures, amount of liquid and potential dangers. Aug-22

The most important thing to consider here is if the spill is life threatening.

PROTECT YOURSELF

Once the ERT has determined that the spill is not life threatening and is manageable,

2 protect the clean up team by properly outfitting them in Personal Protective Equipment Aug-22

(PPE). This includes PPE suits (choose the correct level of suit that can be found on

the liquids MSDS sheet), respirators (SCBA recommended), boots, gloves and

goggles.

STOP THE SPILL

3 ERT Lead will gave the instruction to stop the spill at its source. This can be done by Aug-22

turning a valve, rolling a drum over or using a leak stopper.

CONTAIN THE SPILL

Limit the spread and exposure of the spill by properly containing the liquid. This can be

done by utilizing the correct equipment like SPILL KITS and proper sorbents like

4 Aug-22

SORBENT SOCKS. These products can all be used to dam, dike or divert the spill for

easy, manageable clean up. If properly planned, many spills can be self contained by

using the proper SECONDARY CONTAINMENT like DRY SAND.

MINIMIZE THE RISK

5 Acids and Bases will need to be neutralized (CEP NEUTRALIZERS) and at times oil Aug-22

and their by products can be emulsified using DEGREASERS and MICROBLAZE.

CLEAN UP THE SPILL

Emergency response team will immediately start to control the spillage encircle by

6 using spill kit absorberts to remove the chemical water. Often these clean up products Aug-22

will be stored and ready to use in one of our OVERPACK SPILL KITS which can then

be used for proper disposal.

DECONTAMINATE

7 Contaminated soil, garnels, cotton rugs and sponge put in a Polythene cover and Aug-22

secured for removal (to be disposed in Harzardous Waste Skip).

DECONTAMINATE

Cleaning a spill means properly cleaning both the clean up crew and their equipment

8 Aug-22

afterwards. Remove and dispose of used PPE the same manner as spilled liquid or

Solid waste.

TOOL BOX TALK

ESC HSE and ERT Lead to conducting a Tool Box Talk on the Drill highlighting the

9 Clean-up preparedness/ requirements: (1) prior training in clean-up procedures; Aug-22

(2)immediate availability of clean-up (spill kit) materials and; (3) prompt notification to

the ESC HSE Management.

PO‐3761800008 / HSEP / Att.103 Rev. L, 20/05/2020 1 of 8

EMERGENCY DRILL REPORT

Resources:

Personnel Involved: ESC HSE Staff, EMH Site Supervisors,HSE and Workers, DFO Subcontractors

S.N. Name Position Mobile Role

1 Ibukun Abiodun ERT Lead 052‐9211074 Lead and supervise all of the rescue activities

4 Bharat Magar Firefighter 056 969 4461 Performed Spill Clean‐up Activities

5 Omar Khan FTO 054 576 5116 Operated Emergency Vehicle

Mahmmoud & Ahmed

6 Firefighters 056 226 2427 Performed rescue activities and decontamination

Mahsoub ERT

Dealt with the victim, provide first aid and medical

7 Ram Kumar and Varsha Paramedics 052 734 4218

assistance

9 M.Iqbar Ambulance Driver 055 941 2633 Operated Ambulance/Emergency Vehicles

10 Ifthikar Ali‐Sha Firefighter 056 969 4461 Performed rescue activities

Required Equipment:

S.N. Equipment Quantity Location

1 Hazardous Waste Bin and 1

2 Foam Fire Extinguisher 1 DEWA Existing Plant: Assembly Point and Gas Line

3 Spill Kit and Eye Wash 1 each Area.

4 N95 Mask 1

Communication Tools

S.N. Type Quantity

1 Project Emergency Hotline 1

2 Radio 3

3 Hand phone 1

Drill Scenario observation

S.N. Steps Response time

7:30AM TO 8:00AM ON 8TH,

A planned Emergency Spill Control Drill (Control of Substances Hazardous to Health)

1 9TH AND 10TH OF AUGUST

commenced.

2022

7:30AM TO 8:00AM ON 8TH,

The ERT Lead called the Emergency Response Team using Mobile Radio, mentioning the type of

2 9TH AND 10TH OF AUGUST

Emergency, the location and equipments to come along with.

2022

ERT and Paramedic team arrived the scene, evacuated workers from the area and secured the 7:30AM TO 8:00AM ON 8TH,

3 area using warning tapes. The ERT Lead read‐out SDS of the Spilled Chemical; less corrosive 9TH AND 10TH OF AUGUST

and non inflamable (cleaning agent). 2022

7:30AM TO 8:00AM ON 8TH,

4 ERT commenced demonstration for spill control of hazardous chemical and clean‐up exercise. 9TH AND 10TH OF AUGUST

2022

PO‐3761800008 / HSEP / Att.103 Rev. L, 20/05/2020 2 of 8

EMERGENCY DRILL REPORT

7:30AM TO 8:00AM ON 8TH,

ERT and Paramedic team demonstrated First Aid for Incident Person with chemical contact to

5 9TH AND 10TH OF AUGUST

eyes. Using eyewash to rinse the eyes and immediate medical attention.

2022

7:30AM TO 8:00AM ON 8TH,

ERT Lead and HSE briefed the workforce about Hazards of chemicals, Safe handling, chemical

6 9TH AND 10TH OF AUGUST

storages, PPE, MSDS, use of Spill Kit and Monthly Inspection of Emergency Kits.

2022

The ERT asked questions regarding Drip Tray and one Supervisor responded, citing the 7:30AM TO 8:00AM ON 8TH,

7 importance of chemicals must be stored inside a drip tray and the use of a drip during leakage 9TH AND 10TH OF AUGUST

control. 2022

7:30AM TO 8:00AM ON 8TH,

8 Attendance was taken and positive observations noted by EDF and HSE. 9TH AND 10TH OF AUGUST

2022

7:30AM TO 8:00AM ON 8TH,

After the TBT, ERT lead gave all clear signal for workers to return back to work area and

9 9TH AND 10TH OF AUGUST

resume their work activities.

2022

SUMMARY

Planning for an oil spill emergency helps to minimize potential danger to human health and the environment by

ensuring a timely and coordinated response. Well designed local contingency plans can assist response personnel in their efforts to

contain and clean up oil spills by providing information that the response teams will need before, during, and after

spills occur. Developing and exercising the plan provides opportunities for the response community to work together as a team and

develop the interpersonal relationships that can mean so much to the smooth functioning of a response.

Drill Evaluation:

Effectiveness Deficiencies

Implementation of Emergency Preparedness Protocols as per

dealing with hazardous material, chemical spillage and use of

eyewash station.

Supervisor Responsibilities :

1. Call for Assistance.

2. Stop all work, make area safe.

No Deficiency (The drill was planned and executed with precision).

3. Arrange First Aiders to assist IP.

Using Water as corrosive chemical, no immediate danger and mass

4. Ensure the Access is Clear.

gathering followed covid19 protocol. Chemical cleaning of fuel gas

5. Control the Crowd.

line, essential spill control measures and prepardeness based on the

6. Identify and note Witnesses.

recent environemntal incident lesson learnt was effectively

7. Make himself known to Emergency Response Team.

communciated to the crew to enhance their awareness.

Because the approaches and methods for responding to oil

spills are constantly evolving and each oil spill provides an

opportunity to learn how to better prepare for future

incidents, contingency plans are also constantly evolving

and improving—ensuring increased protection for human

health and the environment from these accidents.

PO‐3761800008 / HSEP / Att.103 Rev. L, 20/05/2020 3 of 8

EMERGENCY DRILL REPORT

Recommendations:

Contractor must enhance the site monitoring specifically at the pipeline joint area during the chemical cleaning operation, so that early

detection of such leakage can be identified before overflowing from the drip tray and before contaminating the soil (routine inspection

check, with proper record). Othe incident lesson learnt recommendations shall be practiced during regular Tool Box Talks and pre‐work

briefing sessions.

Drill Pictures

Abiodun Ibukun

ERT Lead

Prepared by

Laxmikanth Pandit (ESC HSE Manager)

Reviewed/ Approved by

Ahmed Hassan (Consortium Site Manager)

Noted by

Closed Out

During the briefing, workers got adequate awareness about Handling Hazardous Material, MSDS and control measures . Also the workers

were informed about the procedures to follow in case of emergencies like harmful gas exposure and hazardous chemical spill.

PO‐3761800008 / HSEP / Att.103 Rev. L, 20/05/2020 4 of 8

DEWA EXISTING PLANT (GAS PIPE

LINE AREA)

DEWA EXISTING PLANT (GAS PIPE

LINE AREA)

DEWA EXISTING PLANT (GAS PIPE

LINE AREA)

DEWA EXISTING PLANT (DFO AREA)

DEWA EXISTING PLANT (DFO AREA)

You might also like

- Emergency Drill ReportDocument6 pagesEmergency Drill ReportDirga Delonix Regia100% (4)

- On Site Emergency Response Plan: Creative Textile Mills Privae LimitedDocument28 pagesOn Site Emergency Response Plan: Creative Textile Mills Privae LimitedMuntaj Ansari75% (4)

- 1.3.8.8. Action-Reflection-Action-Session-ARAS (BSN2H)Document1 page1.3.8.8. Action-Reflection-Action-Session-ARAS (BSN2H)Kristil ChavezNo ratings yet

- Standard Operating Procedure - Liquid Nitrogen - Storage, Use & Transportation Guidance & Code of PracticeDocument9 pagesStandard Operating Procedure - Liquid Nitrogen - Storage, Use & Transportation Guidance & Code of PracticejrodNo ratings yet

- Emergency ResponseDocument32 pagesEmergency ResponseMizerNo ratings yet

- 675 2013 TRIUMPH ServiceManual T3856909Document697 pages675 2013 TRIUMPH ServiceManual T3856909张连杉No ratings yet

- Method Statement For MpsDocument14 pagesMethod Statement For MpsAhmed NasserNo ratings yet

- Ip-22 Emergency Preparedness & ResponseDocument11 pagesIp-22 Emergency Preparedness & ResponseScha AffinNo ratings yet

- Emergency Response Plan ProcedureDocument28 pagesEmergency Response Plan Procedureகண்ணன் ரவிச்சந்திரன்No ratings yet

- VMC-QMS-HSE-PRO-013-Spill Response PlanDocument12 pagesVMC-QMS-HSE-PRO-013-Spill Response PlanAnar HajiyevNo ratings yet

- Inbound 5425125211198410005Document3 pagesInbound 5425125211198410005Rabeh BàtenNo ratings yet

- Volume 1 Focus PDFDocument47 pagesVolume 1 Focus PDFAjay Kumar GuptaNo ratings yet

- Demobilasation Plan: Should Be Done by A Third Party Approved Contractors. Isolate The Dismantling AreaDocument3 pagesDemobilasation Plan: Should Be Done by A Third Party Approved Contractors. Isolate The Dismantling ArearadeepNo ratings yet

- CryogenicDocument9 pagesCryogenicShoaib JadoonNo ratings yet

- R.A 6969: Toxic Substances and Hazardous Waste and Nuclear Wastes Control ACT OF 1990Document31 pagesR.A 6969: Toxic Substances and Hazardous Waste and Nuclear Wastes Control ACT OF 1990Erlyn Bacoy QuizoNo ratings yet

- Guidelines For The Performance, Location, Use and Care of Emergency Escape Breathing Devices (Eebds)Document4 pagesGuidelines For The Performance, Location, Use and Care of Emergency Escape Breathing Devices (Eebds)joroma58No ratings yet

- Steam Turbine StartupDocument17 pagesSteam Turbine StartupRahul ChoubeyNo ratings yet

- Vessel Survey ReportDocument8 pagesVessel Survey Reportdivan semestaNo ratings yet

- Safe WorkingDocument142 pagesSafe Workingrizonico0% (1)

- GAP.1.07.0.1.a Page 06 Suggested Flood ChecklistDocument1 pageGAP.1.07.0.1.a Page 06 Suggested Flood ChecklistAndres JimenezNo ratings yet

- CK0602 2014Document10 pagesCK0602 2014anishavanloggerenbergNo ratings yet

- Dropped Objects Prevention SchemeDocument17 pagesDropped Objects Prevention SchemekhurramNo ratings yet

- Comprehensive Contingency Plan-Used Oil PDFDocument6 pagesComprehensive Contingency Plan-Used Oil PDFNeil John Lequigan100% (2)

- Personal Protective Equipment (PPE) : Safe Operational Procedure: Fuel Handling & StorageDocument2 pagesPersonal Protective Equipment (PPE) : Safe Operational Procedure: Fuel Handling & StorageJamesNo ratings yet

- Chemical Exposed and Medivac KOIN Warehouse ReviewedDocument1 pageChemical Exposed and Medivac KOIN Warehouse ReviewedUD. Gunung JatiNo ratings yet

- Proweld Pickling Paste 20121019Document17 pagesProweld Pickling Paste 20121019felipekillerNo ratings yet

- Product InfoDocument13 pagesProduct Inforizki hidayatNo ratings yet

- Safety Awareness Training ProgramDocument143 pagesSafety Awareness Training ProgramAnjaana PrashantNo ratings yet

- Code of Conduct: Quality Manual Services in Water SurveyDocument17 pagesCode of Conduct: Quality Manual Services in Water Surveyaidilmuhamad210No ratings yet

- Heat Stress Awareness Drill June 2022Document18 pagesHeat Stress Awareness Drill June 2022Subbu AbuNo ratings yet

- 2023 Decon SOPsDocument47 pages2023 Decon SOPsBV GutzNo ratings yet

- BO0001 - Kixx Lubo 150N - EngDocument9 pagesBO0001 - Kixx Lubo 150N - EngkokoNo ratings yet

- BO0003 - Kixx LUBO 600N - EngDocument9 pagesBO0003 - Kixx LUBO 600N - EngkokoNo ratings yet

- Famirlirisatio Card s3.14f PDFDocument2 pagesFamirlirisatio Card s3.14f PDFNaNNo ratings yet

- Let ColregsDocument33 pagesLet Colregsswapnil ChaturvediNo ratings yet

- Part 4 ExcavationDocument6 pagesPart 4 ExcavationHana Seiadi100% (1)

- Sustainable Safety in Cemeteries - Andre Van Den BergDocument45 pagesSustainable Safety in Cemeteries - Andre Van Den BergMackoy MarasiganNo ratings yet

- MEMO - Disaster Vulcanic EruptionDocument2 pagesMEMO - Disaster Vulcanic EruptionAlbertJohnOliveraNo ratings yet

- Appendix 1b2 Fj9097.33-160a Msdsnew2Document6 pagesAppendix 1b2 Fj9097.33-160a Msdsnew2RUDDY ALFAN SUBAKTINo ratings yet

- 202.014d - Water Rescue OperationsDocument10 pages202.014d - Water Rescue OperationsDan HalloranNo ratings yet

- BO0005 - Kixx LUBO 4cst - EngDocument9 pagesBO0005 - Kixx LUBO 4cst - EngkokoNo ratings yet

- Ipc-1.67-2e CSSD Health ChallengesDocument4 pagesIpc-1.67-2e CSSD Health ChallengesFalak KhanNo ratings yet

- Emergency Responce Plan For Gulf CryoDocument22 pagesEmergency Responce Plan For Gulf CryoHabib ur rahman0% (1)

- Health and Hyginc Audit ReportDocument8 pagesHealth and Hyginc Audit ReportAhmad SaeedNo ratings yet

- National Energy Group of Companies: Project HSE PlanDocument4 pagesNational Energy Group of Companies: Project HSE PlanalinkarrnyaNo ratings yet

- Checklist As Per BOCWADocument4 pagesChecklist As Per BOCWAAkhilSRzNo ratings yet

- Cargill Palm Products SDN BHD Emergency Action PlanDocument69 pagesCargill Palm Products SDN BHD Emergency Action Planheikal hajazieNo ratings yet

- Bremen ManualDocument120 pagesBremen Manual4ddy23100% (1)

- PHN Industry Sdn. BHD.: 1.0 Objective 1.1 1.2 2.0 SCOPE 2.1 2.2Document7 pagesPHN Industry Sdn. BHD.: 1.0 Objective 1.1 1.2 2.0 SCOPE 2.1 2.2Zack MalikNo ratings yet

- BO0006 Kixx LUBO 6cst EngDocument9 pagesBO0006 Kixx LUBO 6cst EngkokoNo ratings yet

- Waste Management ProcedureDocument7 pagesWaste Management Procedureaone mothupiNo ratings yet

- Evaluation of Camp OHS Risks AssessmentDocument3 pagesEvaluation of Camp OHS Risks Assessmenthasanhse640100% (1)

- 3 5 3 2 Water RescueDocument5 pages3 5 3 2 Water Rescuewyma01No ratings yet

- SGP26903Document28 pagesSGP26903ezgiNo ratings yet

- Health and Safety at SeaDocument5 pagesHealth and Safety at SeaSwapnil SheteNo ratings yet

- 09042015274N4LEKFINALDISMGMTPLANDocument33 pages09042015274N4LEKFINALDISMGMTPLANRahul mishraNo ratings yet

- GAP.1.07.0.1.a Page 09 Suggested Hurricane ChecklistDocument1 pageGAP.1.07.0.1.a Page 09 Suggested Hurricane ChecklistAndres JimenezNo ratings yet

- Emergency Preparedness and ResponseDocument7 pagesEmergency Preparedness and Responseusq venture100% (1)

- Drop Cover HoldOn PublicAdministratorsDocument69 pagesDrop Cover HoldOn PublicAdministratorsVanessa Grace Peradilla HainoNo ratings yet

- 9 QRA Chapter 7Document8 pages9 QRA Chapter 7Manan ChadhaNo ratings yet

- Disaster Recovery for Archives, Libraries and Records Management Systems in Australia and New ZealandFrom EverandDisaster Recovery for Archives, Libraries and Records Management Systems in Australia and New ZealandNo ratings yet

- Partial Evacuation Drill ReportDocument18 pagesPartial Evacuation Drill ReportSubbu AbuNo ratings yet

- Excavator ChecklistsDocument1 pageExcavator ChecklistsSubbu AbuNo ratings yet

- Emergency Drill (Electrocution) April 2023 (HSEM Reviewed)Document3 pagesEmergency Drill (Electrocution) April 2023 (HSEM Reviewed)Subbu AbuNo ratings yet

- Track RegisterDocument1 pageTrack RegisterSubbu AbuNo ratings yet

- JD Hse OfficerDocument2 pagesJD Hse OfficerSubbu AbuNo ratings yet

- Scaffolding JSADocument10 pagesScaffolding JSASubbu AbuNo ratings yet

- Heat Index ChartDocument1 pageHeat Index ChartSubbu AbuNo ratings yet

- Jack Hammer Machine Inpection Checklist-2Document2 pagesJack Hammer Machine Inpection Checklist-2Subbu AbuNo ratings yet

- JD TechnicianDocument1 pageJD TechnicianSubbu AbuNo ratings yet

- Risk Assessment For Runway Beams 1Document10 pagesRisk Assessment For Runway Beams 1Subbu AbuNo ratings yet

- Electrical SafetyDocument1 pageElectrical SafetySubbu AbuNo ratings yet

- GRINDING Machine Inpection Checklist-3Document2 pagesGRINDING Machine Inpection Checklist-3Subbu AbuNo ratings yet

- Drilling Machine Inpection Checklist - 1Document1 pageDrilling Machine Inpection Checklist - 1Subbu AbuNo ratings yet

- JD HelperDocument1 pageJD HelperSubbu AbuNo ratings yet

- List of ProceduresDocument1 pageList of ProceduresSubbu AbuNo ratings yet

- Home SafetyDocument1 pageHome SafetySubbu AbuNo ratings yet

- Ammonia HandlingDocument1 pageAmmonia HandlingSubbu AbuNo ratings yet

- Carbon MonoxideDocument1 pageCarbon MonoxideSubbu AbuNo ratings yet

- Sleep DeprivationDocument1 pageSleep DeprivationSubbu AbuNo ratings yet

- Chemical Storage Safety MomentDocument1 pageChemical Storage Safety MomentSubbu AbuNo ratings yet

- Material Purchase RequestDocument1 pageMaterial Purchase RequestSubbu AbuNo ratings yet

- JHA GasesDocument2 pagesJHA GasesSubbu AbuNo ratings yet

- Multimeter ChecklistDocument1 pageMultimeter ChecklistSubbu AbuNo ratings yet

- Hse Induction ChecklistDocument1 pageHse Induction ChecklistSubbu AbuNo ratings yet

- Risk MatrixDocument1 pageRisk MatrixSubbu AbuNo ratings yet

- Lesson LearntDocument1 pageLesson LearntSubbu AbuNo ratings yet

- Hse Risk Register OffshoreDocument1 pageHse Risk Register OffshoreSubbu AbuNo ratings yet

- Eye ExcersiseDocument1 pageEye ExcersiseSubbu AbuNo ratings yet

- Emergency PlanDocument39 pagesEmergency PlanSubbu Abu100% (2)

- Heat Index Card (Pocket Size)Document2 pagesHeat Index Card (Pocket Size)Subbu AbuNo ratings yet

- Business Plan: Presented by Lesley ClaffeyDocument77 pagesBusiness Plan: Presented by Lesley ClaffeyLesleyNo ratings yet

- Persuasive Speech Topics 8cDocument2 pagesPersuasive Speech Topics 8cIsaid OrtegaNo ratings yet

- Isc N-Channel MOSFET Transistor IRFP32N50K: INCHANGE SemiconductorDocument2 pagesIsc N-Channel MOSFET Transistor IRFP32N50K: INCHANGE SemiconductorWilson Yecit OrtizNo ratings yet

- Executive Director Operations Administrations in Portland OR Resume Christina TubbDocument3 pagesExecutive Director Operations Administrations in Portland OR Resume Christina TubbChristina Tubb100% (1)

- Fissell Patient's NarrativeDocument9 pagesFissell Patient's NarrativeQue SabNo ratings yet

- Summary of Findings and Outcome of The HAZOP StudyDocument4 pagesSummary of Findings and Outcome of The HAZOP Studydhanu_lagwankarNo ratings yet

- Nurse Patient Interact OnDocument9 pagesNurse Patient Interact OnHyeji KwonNo ratings yet

- Volleyball Skill PeriodizationDocument13 pagesVolleyball Skill PeriodizationScott_PTNo ratings yet

- 5s Pillars of The Visual WorkplaceDocument35 pages5s Pillars of The Visual WorkplaceSaravana kumar NagarajanNo ratings yet

- Themax N1 - TDS Issue A0Document5 pagesThemax N1 - TDS Issue A0Saif KhanNo ratings yet

- Luis Marcelo TavaresDocument24 pagesLuis Marcelo Tavaresrichard gutierrezNo ratings yet

- Road To RMPDocument9 pagesRoad To RMPMay Ann GarciaNo ratings yet

- Night-Lite Pro II Parts Manual (2021-110292 Rev E)Document514 pagesNight-Lite Pro II Parts Manual (2021-110292 Rev E)nursultanNo ratings yet

- English Stories For KidsDocument11 pagesEnglish Stories For Kidsngoctoankhtnhn2886100% (2)

- KP Rules 4Document33 pagesKP Rules 4Karanbir Singh75% (4)

- Trenchless TechnologyDocument29 pagesTrenchless Technologyraps5_priya100% (1)

- Coffee Pests and Their ManagementDocument38 pagesCoffee Pests and Their ManagementFaiz IsmailNo ratings yet

- Deborah Hellyer AsthmaDocument86 pagesDeborah Hellyer AsthmaGiorgi PopiashviliNo ratings yet

- Curriculum Vitae: Name: Aisha Sitwat Title: Assistant ProfessorDocument20 pagesCurriculum Vitae: Name: Aisha Sitwat Title: Assistant ProfessorSaad KhanNo ratings yet

- Ebook Manual of Critical Care Nursing Nursing Interventions and Collaborative Management PDF Full Chapter PDFDocument67 pagesEbook Manual of Critical Care Nursing Nursing Interventions and Collaborative Management PDF Full Chapter PDFbrian.williams904100% (31)

- In House Welding Inspector ONGCDocument1 pageIn House Welding Inspector ONGCGaurang PandyaNo ratings yet

- Escherichia Coli Plasmid Production in FermenterDocument8 pagesEscherichia Coli Plasmid Production in Fermenterdary.podoliak03No ratings yet

- T NG H P Writing Task 1 SampleDocument50 pagesT NG H P Writing Task 1 Samplengân nguyễnNo ratings yet

- ON DRYING OF SOLIDS Final FixedDocument18 pagesON DRYING OF SOLIDS Final Fixedvaskur royNo ratings yet

- FNoL 15060$06$2021 RE VII$SlNo47 (NeFMS 4) - OTHDocument2 pagesFNoL 15060$06$2021 RE VII$SlNo47 (NeFMS 4) - OTHABCDNo ratings yet

- Bioradiations: High-Resolution Melt AnalysisDocument36 pagesBioradiations: High-Resolution Melt AnalysisDr-Dalya ShakirNo ratings yet

- Self EsteemDocument3 pagesSelf EsteemMary Rose NaboaNo ratings yet

- Web Panel ClinicDocument41 pagesWeb Panel ClinickhairuliqrammazlanNo ratings yet