Professional Documents

Culture Documents

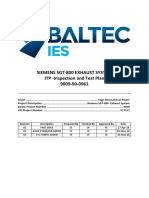

Itp Stainless Steel Coating

Itp Stainless Steel Coating

Uploaded by

ibrahim hegazyCopyright:

Available Formats

You might also like

- Charm Parts ListDocument7 pagesCharm Parts ListThomas O'brien-bardenNo ratings yet

- Quality Assurance Plan: High Frequency Electric Resistance Welded PipeDocument15 pagesQuality Assurance Plan: High Frequency Electric Resistance Welded PipeSachin KumarNo ratings yet

- Itp 001 PipelineDocument2 pagesItp 001 PipelineMohd Effiezool YaserNo ratings yet

- Modulation Techniques MATLAB CodeDocument14 pagesModulation Techniques MATLAB CodeAbdallah E. AbdallahNo ratings yet

- Peugeot 404 Workshop ManualDocument99 pagesPeugeot 404 Workshop ManualDiego Hernan Piñeiro100% (6)

- Cement Mill-1 Girth Gear Alignment Readings Summary Report Girth Gear Axial Runout Girth Gear Radial RunoutDocument4 pagesCement Mill-1 Girth Gear Alignment Readings Summary Report Girth Gear Axial Runout Girth Gear Radial Runoutkaka100% (2)

- 2020B CNC Machine ManualDocument33 pages2020B CNC Machine ManualFelipeAndrésLondoñoGrandaNo ratings yet

- 2.1 Inspection Test PlanDocument26 pages2.1 Inspection Test PlanDeven Patle50% (2)

- 2.8.2. Indicative QAP - ColumnsDocument12 pages2.8.2. Indicative QAP - ColumnsAshish Dhok0% (1)

- 9-Material Treacibility PDFDocument64 pages9-Material Treacibility PDFmamounsdNo ratings yet

- Staircases & HandrailsDocument2 pagesStaircases & HandrailsPavul RajNo ratings yet

- Heat Exchanger QAPDocument3 pagesHeat Exchanger QAPRajnikant PatelNo ratings yet

- Ac Oqa 2014Document1 pageAc Oqa 2014pm9286vNo ratings yet

- Issue B Exhibit No. 4-6 Dated - 18-11-2011 Cir SeamDocument1 pageIssue B Exhibit No. 4-6 Dated - 18-11-2011 Cir SeamGanesh YadavNo ratings yet

- ETP - Reinforcement Concrete WorksDocument7 pagesETP - Reinforcement Concrete WorksjiniNo ratings yet

- AEPCOM-QAP-3281-58548 Rev 1Document3 pagesAEPCOM-QAP-3281-58548 Rev 1VIVEK TIWARINo ratings yet

- Process Inspection ExampleDocument6 pagesProcess Inspection ExampleJayant Kumar JhaNo ratings yet

- GroutingDocument1 pageGroutingAlif Rahmat FebriantoNo ratings yet

- Test Sertifikasi: Kiraç Galvaniz Telekom Metal Mak - İnş.El - San.Ve Tic.A.ŞDocument3 pagesTest Sertifikasi: Kiraç Galvaniz Telekom Metal Mak - İnş.El - San.Ve Tic.A.ŞBeytullah KurnalıNo ratings yet

- Safety ClampDocument3 pagesSafety ClampMuhammed AthaullahNo ratings yet

- M/S. Larsen & Toubro Limited Qap & Itp For Piling WorksDocument2 pagesM/S. Larsen & Toubro Limited Qap & Itp For Piling WorksAkash GiriNo ratings yet

- Report UT CS From 21Document112 pagesReport UT CS From 21daemsalNo ratings yet

- 3795-210-S10-E99-0002-Rev.3 PLC Io Mapping List Including Time Synchronize SDocument7 pages3795-210-S10-E99-0002-Rev.3 PLC Io Mapping List Including Time Synchronize SFomaa ElsayedNo ratings yet

- Report 1 Paut Sts 409Document12 pagesReport 1 Paut Sts 409DEBJYOTI SENGUPTA100% (2)

- Inspection Report For Masonry WallsDocument2 pagesInspection Report For Masonry WallsAndile CeleNo ratings yet

- Side Door ElevatorDocument3 pagesSide Door ElevatorMuhammed AthaullahNo ratings yet

- FORM004 Inspection Report For PlasteringDocument2 pagesFORM004 Inspection Report For PlasteringAndile CeleNo ratings yet

- Insulation QAPDocument2 pagesInsulation QAPPavul RajNo ratings yet

- Itp Transfer Tower - Xls (Bvi Comment)Document52 pagesItp Transfer Tower - Xls (Bvi Comment)Alif Rahmat FebriantoNo ratings yet

- PIPING R04 101022 DraftDocument2 pagesPIPING R04 101022 DraftPavul RajNo ratings yet

- SUPPORT (Scaph, Ducting) QAP R02 080822Document2 pagesSUPPORT (Scaph, Ducting) QAP R02 080822Pavul RajNo ratings yet

- ITP For Handrail WeldingDocument2 pagesITP For Handrail WeldingKumar AbhishekNo ratings yet

- Condensate Collection Tank Qap 290722Document3 pagesCondensate Collection Tank Qap 290722Pavul RajNo ratings yet

- Prds & Piping QapDocument2 pagesPrds & Piping QapPavul RajNo ratings yet

- 1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureDocument6 pages1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureprasongNo ratings yet

- Piping Qap R03 250822Document2 pagesPiping Qap R03 250822Pavul RajNo ratings yet

- Wo Add PK - LHM Di BTHDocument3 pagesWo Add PK - LHM Di BTHrockmansatuNo ratings yet

- QAP Check ListDocument1 pageQAP Check Listbed passNo ratings yet

- Elevator LinkDocument2 pagesElevator LinkMuhammed AthaullahNo ratings yet

- Itp Tank-29jan 07Document3 pagesItp Tank-29jan 07Anonymous lv8SNRyNo ratings yet

- QAP For Ducting V1 R0Document1 pageQAP For Ducting V1 R0Hema NandhNo ratings yet

- 4-ITP For Installation & Testing of Lighting Fixtures.Document9 pages4-ITP For Installation & Testing of Lighting Fixtures.Haggag AbouelkhairNo ratings yet

- Ducting QAP R02 080822Document2 pagesDucting QAP R02 080822Pavul RajNo ratings yet

- Inspection Testing Plan (ITP)Document1 pageInspection Testing Plan (ITP)Kdown 99100% (1)

- FORM005 Inspection Report For PaintingDocument2 pagesFORM005 Inspection Report For PaintingAndile CeleNo ratings yet

- Itp STR Slpg-Q-0000-24001-032-001-4-ADocument11 pagesItp STR Slpg-Q-0000-24001-032-001-4-AsivagnanamNo ratings yet

- 03 V-3125-001-A-702 (Site Inspection and Test Plan) ITP - 0Document4 pages03 V-3125-001-A-702 (Site Inspection and Test Plan) ITP - 0AlfaNo ratings yet

- TS-PTX-QUA-049-E-R03 Rotary Bushing Cat IIIDocument3 pagesTS-PTX-QUA-049-E-R03 Rotary Bushing Cat IIIict petrexNo ratings yet

- Sil FQP - STRUDocument19 pagesSil FQP - STRUPrasanta ParidaNo ratings yet

- Updated Standard Qap 14.07.22Document6 pagesUpdated Standard Qap 14.07.22Karna Satish KumarNo ratings yet

- Acc Fqap Rev 1 - DundigalDocument2 pagesAcc Fqap Rev 1 - DundigalHema NandhNo ratings yet

- Rekomendasi Vibrasi BC-02 072023Document2 pagesRekomendasi Vibrasi BC-02 072023putel_ajaNo ratings yet

- Asa-146 NSH Apco Ir 040Document10 pagesAsa-146 NSH Apco Ir 040Fahad AhmadNo ratings yet

- F-Qac-20 Sample Layout Inspection ReportDocument10 pagesF-Qac-20 Sample Layout Inspection Reportcer.qualityNo ratings yet

- Form10 Shipment Report - Nov 2020Document1 pageForm10 Shipment Report - Nov 2020darithNo ratings yet

- 7-Itp For Ups Installation and Testing.Document7 pages7-Itp For Ups Installation and Testing.Haggag AbouelkhairNo ratings yet

- Engineering Work Order: Turbo Aviation PVT LTDDocument2 pagesEngineering Work Order: Turbo Aviation PVT LTDsivaNo ratings yet

- R03 C03B01 Mag MTS Ci 0006 - 01Document26 pagesR03 C03B01 Mag MTS Ci 0006 - 01Syed AliNo ratings yet

- TMK - Insp of Fuel Filter.342Document2 pagesTMK - Insp of Fuel Filter.342sivaNo ratings yet

- Oksb-Itp-Cr2610-2022 1 Rev 00 OnshoreDocument4 pagesOksb-Itp-Cr2610-2022 1 Rev 00 OnshoreMohd Ayman YazidNo ratings yet

- Slip Type Elevator Cat. IVDocument2 pagesSlip Type Elevator Cat. IVRanjithNo ratings yet

- QAP1Document2 pagesQAP1akshaymehra2354No ratings yet

- Transformer: Quality Assurance PlanDocument9 pagesTransformer: Quality Assurance PlanRadhakrishnan VNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet

- Investment Performance Measurement: Evaluating and Presenting ResultsFrom EverandInvestment Performance Measurement: Evaluating and Presenting ResultsPhilip Lawton, CIPMRating: 1 out of 5 stars1/5 (1)

- 2018 Publications Catalog FinalDocument29 pages2018 Publications Catalog Finalibrahim hegazyNo ratings yet

- 977 - Painting Procedure Rev.02Document19 pages977 - Painting Procedure Rev.02ibrahim hegazyNo ratings yet

- MN4 Log-Sheets 24-03-2024Document1 pageMN4 Log-Sheets 24-03-2024ibrahim hegazyNo ratings yet

- MN4 Log-Sheets 24-03-2024-5Document1 pageMN4 Log-Sheets 24-03-2024-5ibrahim hegazyNo ratings yet

- Paintng ReportDocument1 pagePaintng Reportibrahim hegazyNo ratings yet

- Fit UpDocument1 pageFit Upibrahim hegazyNo ratings yet

- Inspection ReportDocument7 pagesInspection Reportibrahim hegazyNo ratings yet

- Welding Visual Inspection ReportDocument1 pageWelding Visual Inspection Reportibrahim hegazyNo ratings yet

- Lab Report MN4Document1 pageLab Report MN4ibrahim hegazyNo ratings yet

- Tighting Torque MethodDocument6 pagesTighting Torque Methodibrahim hegazyNo ratings yet

- Report # 016-220127-PDocument1 pageReport # 016-220127-Pibrahim hegazyNo ratings yet

- Cub Test ReportDocument1 pageCub Test Reportibrahim hegazyNo ratings yet

- Tweak Build - PropDocument3 pagesTweak Build - PropBang mipNo ratings yet

- Accropode IIDocument4 pagesAccropode IIAhmad Balah100% (1)

- Assessment of Air Preheater Effects On Power Plant EfficiencyDocument38 pagesAssessment of Air Preheater Effects On Power Plant Efficiencysugianto barusNo ratings yet

- Wartsila 20 TR - 2004Document16 pagesWartsila 20 TR - 2004Jage100% (1)

- PhysicsDocument142 pagesPhysicsairbuk doeingNo ratings yet

- Rammed EarthDocument3 pagesRammed EarthLeonardoGarza100% (3)

- Engine Ajh Awc Mechanics Eng PDFDocument290 pagesEngine Ajh Awc Mechanics Eng PDFNPNo ratings yet

- Cf34-8 CMM Index PDFDocument12 pagesCf34-8 CMM Index PDFHaithem BrebishNo ratings yet

- Pulsed Discharge Detector Models D-3-I-HP and D-3-I-7890 Instruction ManualDocument25 pagesPulsed Discharge Detector Models D-3-I-HP and D-3-I-7890 Instruction ManualTrinh Đình VũNo ratings yet

- K220 Accessories BrochureDocument6 pagesK220 Accessories Brochurehh8g9y6ggcNo ratings yet

- DS 1147 SS CMCDT2100LTC ADocument3 pagesDS 1147 SS CMCDT2100LTC ANightcrawlerNo ratings yet

- Slides On Drawing Lecture-2: Demonstration On Complete Drawing of An Architectural StructureDocument11 pagesSlides On Drawing Lecture-2: Demonstration On Complete Drawing of An Architectural StructureReal NazihNo ratings yet

- Adiabatic FBR DesignDocument10 pagesAdiabatic FBR DesignRana UzairNo ratings yet

- Gaskets: Standard Definitions of Terms Relating ToDocument2 pagesGaskets: Standard Definitions of Terms Relating ToAhmad Zubair RasulyNo ratings yet

- Stability and Control Iit KanpurDocument844 pagesStability and Control Iit KanpursankalpNo ratings yet

- Single Replacement Reactions LabDocument3 pagesSingle Replacement Reactions Labapi-241225667No ratings yet

- Seismic Earth Pressures Against Structures With Restrained DisplaDocument9 pagesSeismic Earth Pressures Against Structures With Restrained DisplavttrlcNo ratings yet

- SM 15 PDFDocument357 pagesSM 15 PDFEnrique Arevalo LeyvaNo ratings yet

- Otech Analysis of Carsington Dam PDFDocument9 pagesOtech Analysis of Carsington Dam PDF0808276kNo ratings yet

- Errores y Alarmas Servo-Drivers (INGLES)Document36 pagesErrores y Alarmas Servo-Drivers (INGLES)ernesto.conde.navarroNo ratings yet

- Maintenance Schedule 6R183 - M050525 - 02EDocument4 pagesMaintenance Schedule 6R183 - M050525 - 02EdattienNo ratings yet

- Integral Plant Maintenance: Maximum Performance From Your AssetsDocument12 pagesIntegral Plant Maintenance: Maximum Performance From Your AssetsWALDO MOLINA PINTONo ratings yet

- MSDS MethanolDocument6 pagesMSDS Methanolcrni rokoNo ratings yet

- Ac Parts CatalogDocument98 pagesAc Parts CatalogLoïka Manuela DjomgouéNo ratings yet

- FT Aeroterme Systemair PDFDocument20 pagesFT Aeroterme Systemair PDFCrisTimNo ratings yet

Itp Stainless Steel Coating

Itp Stainless Steel Coating

Uploaded by

ibrahim hegazyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Itp Stainless Steel Coating

Itp Stainless Steel Coating

Uploaded by

ibrahim hegazyCopyright:

Available Formats

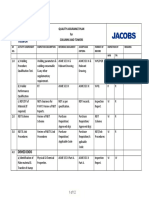

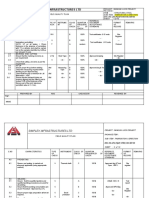

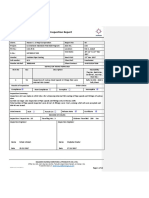

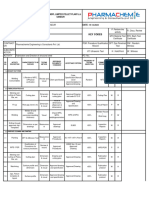

INSPECTION AND TEST PLAN (ITP)

CORROSION REPAIR AND DESCRIPTION : ITP # A

PROTECTION WORK REV # 0

COATING OF STAINLESS STEEL RAILING AT AL‐FANATIR SHORELINE STRUCTURE

560 ‐ S28 PAGE # 001

UNIT / AREA / LOCATION DISCIPLINE EQUIPMENT DESCRIPTION / TAG NUMBER

COATING FOR STAINLESS STEEL CIVIL

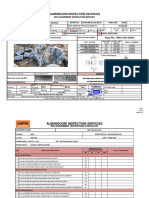

METHOD OF VERIFICATION (see

INSPECTION / TEST REQUIREMENTS REFERENCE DOCUMENTS

legend below) INSPECTION REPORT HOLD POINT

ACTIVITY # ACTIVITY DESCRIPTION

TEST OR INSPECTION ACCEPTANCE CONTR. RELEASE REFERENCE

STAGE/ FREQUENCY CODE, SPEC,Etc. R/C OTHERS

PERFORMED CRITERIA QC

1.0 CLEANING COATING SURFACE REMOVAL OF DUST, DIRT BY RINSING PER LOCATION RC IFC 560‐801‐20TY‐CE‐038 IT IH DAILY REPORT, MS

OR SURFACE PERAPARATION WITH CLEANING AGENT

DRY THE SURFACE

2.0 COATING

1ST COAT APPLICATION BY ORIFICE NOZZLE OR COVERAGE 35 SQ.M PER RC IFC 560‐801‐20TY‐CE‐038

2.1 SPRAY HIGH DENSITY COATING FOAM ROLLER LITER PER COAT ‐> 0.013" to 0.014" Nozzle 80 MICRON DFT IR R

HPR, DAILY REPORT, METHOD STATEMENT

2DN COAT APPLICATION BY ORIFICE NOZZLE OR COVERAGE 35 SQ.M PER ‐> 90 to 100 bar pressure PER COAT

2.2 SPRAY HIGH DENSITY COATING FOAM ROLLER LITER PER COAT ‐> 16 Hours Min. Dry Time per Coat 160 DFT TOTAL IR IH

2.3 COATING THICKNESS IR IW T DAILY REPORT, METHOD STATEMENT

QC MANAGER (Date & Signature/Stamp No. RC REPRESENTATIVE (Date & Signature)

LEGEND : I ‐ INSPECTION ; R ‐ DOCUMENT REVIEW ; T ‐ TEST ; W ‐ WITNESS POINT ; H ‐ HOLD POINT

You might also like

- Charm Parts ListDocument7 pagesCharm Parts ListThomas O'brien-bardenNo ratings yet

- Quality Assurance Plan: High Frequency Electric Resistance Welded PipeDocument15 pagesQuality Assurance Plan: High Frequency Electric Resistance Welded PipeSachin KumarNo ratings yet

- Itp 001 PipelineDocument2 pagesItp 001 PipelineMohd Effiezool YaserNo ratings yet

- Modulation Techniques MATLAB CodeDocument14 pagesModulation Techniques MATLAB CodeAbdallah E. AbdallahNo ratings yet

- Peugeot 404 Workshop ManualDocument99 pagesPeugeot 404 Workshop ManualDiego Hernan Piñeiro100% (6)

- Cement Mill-1 Girth Gear Alignment Readings Summary Report Girth Gear Axial Runout Girth Gear Radial RunoutDocument4 pagesCement Mill-1 Girth Gear Alignment Readings Summary Report Girth Gear Axial Runout Girth Gear Radial Runoutkaka100% (2)

- 2020B CNC Machine ManualDocument33 pages2020B CNC Machine ManualFelipeAndrésLondoñoGrandaNo ratings yet

- 2.1 Inspection Test PlanDocument26 pages2.1 Inspection Test PlanDeven Patle50% (2)

- 2.8.2. Indicative QAP - ColumnsDocument12 pages2.8.2. Indicative QAP - ColumnsAshish Dhok0% (1)

- 9-Material Treacibility PDFDocument64 pages9-Material Treacibility PDFmamounsdNo ratings yet

- Staircases & HandrailsDocument2 pagesStaircases & HandrailsPavul RajNo ratings yet

- Heat Exchanger QAPDocument3 pagesHeat Exchanger QAPRajnikant PatelNo ratings yet

- Ac Oqa 2014Document1 pageAc Oqa 2014pm9286vNo ratings yet

- Issue B Exhibit No. 4-6 Dated - 18-11-2011 Cir SeamDocument1 pageIssue B Exhibit No. 4-6 Dated - 18-11-2011 Cir SeamGanesh YadavNo ratings yet

- ETP - Reinforcement Concrete WorksDocument7 pagesETP - Reinforcement Concrete WorksjiniNo ratings yet

- AEPCOM-QAP-3281-58548 Rev 1Document3 pagesAEPCOM-QAP-3281-58548 Rev 1VIVEK TIWARINo ratings yet

- Process Inspection ExampleDocument6 pagesProcess Inspection ExampleJayant Kumar JhaNo ratings yet

- GroutingDocument1 pageGroutingAlif Rahmat FebriantoNo ratings yet

- Test Sertifikasi: Kiraç Galvaniz Telekom Metal Mak - İnş.El - San.Ve Tic.A.ŞDocument3 pagesTest Sertifikasi: Kiraç Galvaniz Telekom Metal Mak - İnş.El - San.Ve Tic.A.ŞBeytullah KurnalıNo ratings yet

- Safety ClampDocument3 pagesSafety ClampMuhammed AthaullahNo ratings yet

- M/S. Larsen & Toubro Limited Qap & Itp For Piling WorksDocument2 pagesM/S. Larsen & Toubro Limited Qap & Itp For Piling WorksAkash GiriNo ratings yet

- Report UT CS From 21Document112 pagesReport UT CS From 21daemsalNo ratings yet

- 3795-210-S10-E99-0002-Rev.3 PLC Io Mapping List Including Time Synchronize SDocument7 pages3795-210-S10-E99-0002-Rev.3 PLC Io Mapping List Including Time Synchronize SFomaa ElsayedNo ratings yet

- Report 1 Paut Sts 409Document12 pagesReport 1 Paut Sts 409DEBJYOTI SENGUPTA100% (2)

- Inspection Report For Masonry WallsDocument2 pagesInspection Report For Masonry WallsAndile CeleNo ratings yet

- Side Door ElevatorDocument3 pagesSide Door ElevatorMuhammed AthaullahNo ratings yet

- FORM004 Inspection Report For PlasteringDocument2 pagesFORM004 Inspection Report For PlasteringAndile CeleNo ratings yet

- Insulation QAPDocument2 pagesInsulation QAPPavul RajNo ratings yet

- Itp Transfer Tower - Xls (Bvi Comment)Document52 pagesItp Transfer Tower - Xls (Bvi Comment)Alif Rahmat FebriantoNo ratings yet

- PIPING R04 101022 DraftDocument2 pagesPIPING R04 101022 DraftPavul RajNo ratings yet

- SUPPORT (Scaph, Ducting) QAP R02 080822Document2 pagesSUPPORT (Scaph, Ducting) QAP R02 080822Pavul RajNo ratings yet

- ITP For Handrail WeldingDocument2 pagesITP For Handrail WeldingKumar AbhishekNo ratings yet

- Condensate Collection Tank Qap 290722Document3 pagesCondensate Collection Tank Qap 290722Pavul RajNo ratings yet

- Prds & Piping QapDocument2 pagesPrds & Piping QapPavul RajNo ratings yet

- 1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureDocument6 pages1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureprasongNo ratings yet

- Piping Qap R03 250822Document2 pagesPiping Qap R03 250822Pavul RajNo ratings yet

- Wo Add PK - LHM Di BTHDocument3 pagesWo Add PK - LHM Di BTHrockmansatuNo ratings yet

- QAP Check ListDocument1 pageQAP Check Listbed passNo ratings yet

- Elevator LinkDocument2 pagesElevator LinkMuhammed AthaullahNo ratings yet

- Itp Tank-29jan 07Document3 pagesItp Tank-29jan 07Anonymous lv8SNRyNo ratings yet

- QAP For Ducting V1 R0Document1 pageQAP For Ducting V1 R0Hema NandhNo ratings yet

- 4-ITP For Installation & Testing of Lighting Fixtures.Document9 pages4-ITP For Installation & Testing of Lighting Fixtures.Haggag AbouelkhairNo ratings yet

- Ducting QAP R02 080822Document2 pagesDucting QAP R02 080822Pavul RajNo ratings yet

- Inspection Testing Plan (ITP)Document1 pageInspection Testing Plan (ITP)Kdown 99100% (1)

- FORM005 Inspection Report For PaintingDocument2 pagesFORM005 Inspection Report For PaintingAndile CeleNo ratings yet

- Itp STR Slpg-Q-0000-24001-032-001-4-ADocument11 pagesItp STR Slpg-Q-0000-24001-032-001-4-AsivagnanamNo ratings yet

- 03 V-3125-001-A-702 (Site Inspection and Test Plan) ITP - 0Document4 pages03 V-3125-001-A-702 (Site Inspection and Test Plan) ITP - 0AlfaNo ratings yet

- TS-PTX-QUA-049-E-R03 Rotary Bushing Cat IIIDocument3 pagesTS-PTX-QUA-049-E-R03 Rotary Bushing Cat IIIict petrexNo ratings yet

- Sil FQP - STRUDocument19 pagesSil FQP - STRUPrasanta ParidaNo ratings yet

- Updated Standard Qap 14.07.22Document6 pagesUpdated Standard Qap 14.07.22Karna Satish KumarNo ratings yet

- Acc Fqap Rev 1 - DundigalDocument2 pagesAcc Fqap Rev 1 - DundigalHema NandhNo ratings yet

- Rekomendasi Vibrasi BC-02 072023Document2 pagesRekomendasi Vibrasi BC-02 072023putel_ajaNo ratings yet

- Asa-146 NSH Apco Ir 040Document10 pagesAsa-146 NSH Apco Ir 040Fahad AhmadNo ratings yet

- F-Qac-20 Sample Layout Inspection ReportDocument10 pagesF-Qac-20 Sample Layout Inspection Reportcer.qualityNo ratings yet

- Form10 Shipment Report - Nov 2020Document1 pageForm10 Shipment Report - Nov 2020darithNo ratings yet

- 7-Itp For Ups Installation and Testing.Document7 pages7-Itp For Ups Installation and Testing.Haggag AbouelkhairNo ratings yet

- Engineering Work Order: Turbo Aviation PVT LTDDocument2 pagesEngineering Work Order: Turbo Aviation PVT LTDsivaNo ratings yet

- R03 C03B01 Mag MTS Ci 0006 - 01Document26 pagesR03 C03B01 Mag MTS Ci 0006 - 01Syed AliNo ratings yet

- TMK - Insp of Fuel Filter.342Document2 pagesTMK - Insp of Fuel Filter.342sivaNo ratings yet

- Oksb-Itp-Cr2610-2022 1 Rev 00 OnshoreDocument4 pagesOksb-Itp-Cr2610-2022 1 Rev 00 OnshoreMohd Ayman YazidNo ratings yet

- Slip Type Elevator Cat. IVDocument2 pagesSlip Type Elevator Cat. IVRanjithNo ratings yet

- QAP1Document2 pagesQAP1akshaymehra2354No ratings yet

- Transformer: Quality Assurance PlanDocument9 pagesTransformer: Quality Assurance PlanRadhakrishnan VNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNo ratings yet

- Investment Performance Measurement: Evaluating and Presenting ResultsFrom EverandInvestment Performance Measurement: Evaluating and Presenting ResultsPhilip Lawton, CIPMRating: 1 out of 5 stars1/5 (1)

- 2018 Publications Catalog FinalDocument29 pages2018 Publications Catalog Finalibrahim hegazyNo ratings yet

- 977 - Painting Procedure Rev.02Document19 pages977 - Painting Procedure Rev.02ibrahim hegazyNo ratings yet

- MN4 Log-Sheets 24-03-2024Document1 pageMN4 Log-Sheets 24-03-2024ibrahim hegazyNo ratings yet

- MN4 Log-Sheets 24-03-2024-5Document1 pageMN4 Log-Sheets 24-03-2024-5ibrahim hegazyNo ratings yet

- Paintng ReportDocument1 pagePaintng Reportibrahim hegazyNo ratings yet

- Fit UpDocument1 pageFit Upibrahim hegazyNo ratings yet

- Inspection ReportDocument7 pagesInspection Reportibrahim hegazyNo ratings yet

- Welding Visual Inspection ReportDocument1 pageWelding Visual Inspection Reportibrahim hegazyNo ratings yet

- Lab Report MN4Document1 pageLab Report MN4ibrahim hegazyNo ratings yet

- Tighting Torque MethodDocument6 pagesTighting Torque Methodibrahim hegazyNo ratings yet

- Report # 016-220127-PDocument1 pageReport # 016-220127-Pibrahim hegazyNo ratings yet

- Cub Test ReportDocument1 pageCub Test Reportibrahim hegazyNo ratings yet

- Tweak Build - PropDocument3 pagesTweak Build - PropBang mipNo ratings yet

- Accropode IIDocument4 pagesAccropode IIAhmad Balah100% (1)

- Assessment of Air Preheater Effects On Power Plant EfficiencyDocument38 pagesAssessment of Air Preheater Effects On Power Plant Efficiencysugianto barusNo ratings yet

- Wartsila 20 TR - 2004Document16 pagesWartsila 20 TR - 2004Jage100% (1)

- PhysicsDocument142 pagesPhysicsairbuk doeingNo ratings yet

- Rammed EarthDocument3 pagesRammed EarthLeonardoGarza100% (3)

- Engine Ajh Awc Mechanics Eng PDFDocument290 pagesEngine Ajh Awc Mechanics Eng PDFNPNo ratings yet

- Cf34-8 CMM Index PDFDocument12 pagesCf34-8 CMM Index PDFHaithem BrebishNo ratings yet

- Pulsed Discharge Detector Models D-3-I-HP and D-3-I-7890 Instruction ManualDocument25 pagesPulsed Discharge Detector Models D-3-I-HP and D-3-I-7890 Instruction ManualTrinh Đình VũNo ratings yet

- K220 Accessories BrochureDocument6 pagesK220 Accessories Brochurehh8g9y6ggcNo ratings yet

- DS 1147 SS CMCDT2100LTC ADocument3 pagesDS 1147 SS CMCDT2100LTC ANightcrawlerNo ratings yet

- Slides On Drawing Lecture-2: Demonstration On Complete Drawing of An Architectural StructureDocument11 pagesSlides On Drawing Lecture-2: Demonstration On Complete Drawing of An Architectural StructureReal NazihNo ratings yet

- Adiabatic FBR DesignDocument10 pagesAdiabatic FBR DesignRana UzairNo ratings yet

- Gaskets: Standard Definitions of Terms Relating ToDocument2 pagesGaskets: Standard Definitions of Terms Relating ToAhmad Zubair RasulyNo ratings yet

- Stability and Control Iit KanpurDocument844 pagesStability and Control Iit KanpursankalpNo ratings yet

- Single Replacement Reactions LabDocument3 pagesSingle Replacement Reactions Labapi-241225667No ratings yet

- Seismic Earth Pressures Against Structures With Restrained DisplaDocument9 pagesSeismic Earth Pressures Against Structures With Restrained DisplavttrlcNo ratings yet

- SM 15 PDFDocument357 pagesSM 15 PDFEnrique Arevalo LeyvaNo ratings yet

- Otech Analysis of Carsington Dam PDFDocument9 pagesOtech Analysis of Carsington Dam PDF0808276kNo ratings yet

- Errores y Alarmas Servo-Drivers (INGLES)Document36 pagesErrores y Alarmas Servo-Drivers (INGLES)ernesto.conde.navarroNo ratings yet

- Maintenance Schedule 6R183 - M050525 - 02EDocument4 pagesMaintenance Schedule 6R183 - M050525 - 02EdattienNo ratings yet

- Integral Plant Maintenance: Maximum Performance From Your AssetsDocument12 pagesIntegral Plant Maintenance: Maximum Performance From Your AssetsWALDO MOLINA PINTONo ratings yet

- MSDS MethanolDocument6 pagesMSDS Methanolcrni rokoNo ratings yet

- Ac Parts CatalogDocument98 pagesAc Parts CatalogLoïka Manuela DjomgouéNo ratings yet

- FT Aeroterme Systemair PDFDocument20 pagesFT Aeroterme Systemair PDFCrisTimNo ratings yet