Professional Documents

Culture Documents

Sb100579 - Iriz Persona Troubleshooting Method Steering Noise Issue

Sb100579 - Iriz Persona Troubleshooting Method Steering Noise Issue

Uploaded by

suain0074Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sb100579 - Iriz Persona Troubleshooting Method Steering Noise Issue

Sb100579 - Iriz Persona Troubleshooting Method Steering Noise Issue

Uploaded by

suain0074Copyright:

Available Formats

PERUSAHAAN OTOMOBIL NASIONAL SDN. BHD.

MARKET QUALITY INTERNAL USE ONLY

Page 1 of 4

SERVICE BULLETIN

SB.NO. / DATE PREVIOUS SB CATEGORY WARRANTY CLAIM TYPE MODEL DESTINATION

SB100579 TROUBLESHOOT IRIZ/PERSONA

NIL NORMAL CLAIM PESB

18/02/2021 METHOD IRIZ MC/PERSONA MC

SUBJECT TROUBLESHOOT METHOD ON STEERING RACK ASSY NOISE

1.0 Description

1.1 The current Service Bulletin SB100539, SB100515, SB100472, Technical Info TI10060 and Newsletter NL100313 are

withdrawn effectively from date of this Service Bulletin SB100579.

1.2 Service outlets are required to refer following troubleshooting method and repair regarding on steering noise during turning

while idling or driving.

1.3 If there is customer complaint as above said subject, service outlets are required to follow the contents as stated in this

bulletin.

2.0 Action

2.1 Technician are required to investigate and confirm noise during turning clockwise or anticlockwise.

2.2 Refer following table for troubleshooting method on Steering Rack noise.

Tightening Torque (T1): 1.5 ~ 2.0 kgfm/

15 ~ 20 Nm

Tightening Torque (T2): 2.0 ~ 3.4 kgfm/

20 ~ 34 Nm

Check Gap (LH): Maximum 2mm

Steering Rack Assy

Sub Frame Assy

RH

LH

Effective Date: 1 May 2020 Revision No.: 0 Doc. No.: PO-CQ-MQ-CS-02

DESCRIPTION PICTURE

1. Lift the car and check bellow and Tie-Rod end

dust cover (rubber parts) has damage or torn.

If have rubber part damage or torn, proceed

with normal repair.

2. Ensure the vehicle no sign of accident impact

at chassis area i.e.: Subframe Assy bent.

Please stated in R.O if there is sign of accident

impact as reference.

Check bellow & Tie Rod end dust

cover (rubber parts).

3. Remove bolt T1 at pinion to intermediate shaft.

Then, remove intermediate shaft (I-shaft) from

pinion.

Remove I-shaft from pinion

4. Remove bolt T2 at end of Tie-Rod at both

sides (LH&RH).

5. Check the Steering Rack pinion shaft for any

rust by using aid of torchlight.

Important note:

If found the pinion shaft rusty, replaced with

new Steering Rack Assy and apply Butyl

Tape at Dust Cover as shown in picture.

After replacement new Steering Rack Assy,

technician is required to proceed step 6 to

measure gap width.

Defective part must be returned to

PROTON HQ for verification.

Refer warranty claim procedure 4.2.

If no rusty, proceed on step 6 as below.

Rust/stain mark

on Dust Cover

Effective Date: 1 May 2020 Revision No.: 0 Doc. No.: PO-CQ-MQ-CS-02

DESCRIPTION PICTURE

6. Remove bolt and nut T4 (LH) and check gap

between steering gear mounting and subframe

interface.

Important Note:

Record the gap width in R.O (G2TX) as

reference.

LH

Measure gap width between Steering

Gear mounting & Subframe interface.

Standard: Maximum 2mm

7. Remove bolt and nut T4 (RH) and moving

Steering Rack Assy from seating on subframe

to relief stress. Then, re-assemble back with

right position on the Subframe.

No need to measure gap width.

No need to remove Steering Rack Assy

from vehicle.

RH

8. Tighten bolt and nut T4 consecutively LH

and RH per turn until reach tightening torque

following Sub Frame Assy. Standard is

11kgfm ± 1 kgfm (110 Nm ± 10 Nm).

Tightening Torque (T1): 1.5 ~ 2.0 kgfm/

9. Re-assemble bolt T1 (I-shaft) and T2 (Tie 15 ~ 20 Nm

Rod end LH &RH) with standard torque. Tightening Torque (T2): 2.0 ~ 3.4 kgfm/

20 ~ 34 Nm

10. Test drive and confirm the steering noise

disappeared during turning while idle or driving Preventive Action:

condition. If no noise, proceed with wheel Ensure the I-shaft is fully inserted into the Steering

alignment. Rack spline. The bolt must correctly in groove

position.

11. If the noise still exist, please submit M.I.R to

TFS_Technline@proton.com (TFS HQ) as

evidence to vendor for further investigation.

(Note: Include gap width in MIR as stated in

step 6 and attach any pictures/video as

supporting document )

Effective Date: 1 May 2020 Revision No.: 0 Doc. No.: PO-CQ-MQ-CS-02

3.0 Replacement Part Information (For case Pinion Shaft rusty only)

Ordering

Part Number Part Name Part Price Quantity/car Model

Methods

GEAR COMPL,MANUAL Iriz/New Persona

PW922623 Normal Price 1 PPCSB

STRG Iriz MC/Persona MC

4.0 Warranty Claim Procedure

4.1 Untightened & Reassemble with standard torque Steering Rack Assy

Claim Type Defective Part No. Operation Code Labour Hour Sundries A Code B Code

3102

Normal

VPB01 374002 25 2.0 Tyre Alignment 41A 80

Claim

(RM36.00 included Tax)

4.2 Replacement of Steering Rack Assy (rusty only)

Claim Type Defective Part No. Operation Code Labour Hour Sundries A Code B Code

2.3 3102

Normal

VPB01 374001 10 (included Butyl Tyre Alignment 30 80

Claim

Tape) (RM36.00 included Tax)

IMPORTANT NOTE:

1. For warranty claims submission all vehicle must comply with periodical service maintenance and warranty part list as

specified in service booklet.

2. All defective parts with correct defective part tagging must be returned to PROTON HQ for further investigation. Use address

per below.

Address: Proton Cose Service Centre, Km33.8 Westbound (KESAS)

Lebuhraya Shah Alam, 47600 Subang Jaya, Selangor,

Phone : 03-5888 1622 (En.Rosli)

PosLaju Account No: 8800336539

GL. Account No : 60220240

MARKET QUALITY

Copy to: This is a computer generated document therefore

CORPORATE QUALITY

COMPASS DBM PORTAL no signature is required.

TELEPHONE: +603-5888 1496

Effective Date: 1 May 2020 Revision No.: 0 Doc. No.: PO-CQ-MQ-CS-02

PERUSAHAAN OTOMOBIL NASIONAL SDN. BHD.

MARKET QUALITY INTERNAL USE ONLY

Page 1 of 4

SERVIS BULETIN

SB NO. / TARIKH SB SEBELUM KATEGORI JENIS WARRANTY CLAIM MODEL DESTINASI

SB100579 LANGKAH IRIZ/PERSONA

NIL NORMAL CLAIM PESB

18/02/2021 PEMBAIKAN IRIZ MC/PERSONA MC

SUBJEK LANGKAH-LANGKAH PEMBAIKAN BERKENAAN ISU STEERING RACK ASSY BERBUNYI

1.0 Penerangan

1.1 Servis Buletin yang tersedia ada dipasaran SB100539, SB100515, SB100472, Technical Info TI100060 dan Newsletter

NL100313 ditarik balik berkuatkuasa mulai tarikh Servis Buletin SB100579 ini.

1.2 Pusat Servis hendaklah merujuk langkah pembaikan untuk isu Steering Rack Assy berbunyi semasa membelok ketika

kenderaan pada keadaan ‘idle’ atau bergerak.

1.3 Sekiranya terdapat aduan pelanggan seperti yang dinyatakan di atas, pusat servis hendaklah mengikuti langkah-langkah

pembaikan yang terkandung di dalam buletin ini.

2.0 Langkah Penambahbaikan Kenderaan di Pasaran

2.1 Juruteknik hendaklah menyiasat dan mengenalpasti bunyi yang terhasil semasa memusingkan stereng mengikut arah jam

atau lawan jam.

2.2 Rujuk jadual di bawah untuk langkah-langkah pembaikan bagi permasalahan Steering Rack Assy berbunyi:

Tightening Torque (T1): 1.5 ~ 2.0 kgfm/

15 ~ 20 Nm

Tightening Torque (T2): 2.0 ~ 3.4 kgfm/

20 ~ 34 Nm

Check Gap (LH): Maximum 2mm

Steering Rack Assy

Sub Frame Assy

RH

LH

Effective Date: 1 May 2020 Revision No.: 0 Doc. No.: PO-CQ-MQ-CS-02

PENERANGAN GAMBAR

1. Naikkan kenderaan menggunakan lifter dan

periksa kondisi ‘bellow’ dan ‘Tie-Rod end dust

cover’ (bahagian yang bergetah) ada

kerosakan atau koyak.

Jika ada bahagian bergetah yang rosak, sila

baiki terlebih dahulu sebagai pembaikan

normal.

2. Periksa bawah kenderaan sekiranya ada

kesan kemalangan pada bahagian chassis

contoh: Sub Frame Assy bengkok. Jika ada

Periksa kondisi ‘bellow’ dan Tie Rod end

rekod pada R.O sebagai rujukan/bukti. dust cover’ (bahagian yang bergetah).

3. Tangalkan bolt T1 pada Intermediate Shaft.

Kemudian, tanggalkan intermediate shaft (I-

shaft) daripada pinion.

Tanggalkan I-shaft daripada pinion

4. Tanggalkan bolt T2 di hujung Tie-Rod pada

kedua-dua sisi (LH&RH).

5. Periksa ‘steering rack pinion shaft’ jika

terdapat kesan karat dengan menggunakan

lampu suluh.

Nota Penting:

Sekiranya mendapati ‘pinion shaft’

berkarat, teruskan penggantian dengan

Steering Rack Assy yang baru dan letak

Butyl Tape pada Dust Cover seperti

gambar rajah sebelah.

Selepas membuat pemasangan Steering

Rack Assy yang baru, juruteknik hendaklah

mengikuti langkah 6 dengan membuat

ukuran ‘gap width’.

Barang yang rosak hendaklah

dikembalikan kepada PROTON HQ untuk

tujuan pengesahan.

Rujuk prosedur tuntutan jaminan 4.2.

Sekiranya tiada kesan karat pada ‘pinion

shaft’, teruskan dengan langkah 6 seperti di

bawah. Kesan karat

pada Dust Cover

Effective Date: 1 May 2020 Revision No.: 0 Doc. No.: PO-CQ-MQ-CS-02

PENERANGAN GAMBAR

6. Tanggalkan bolt & nat T4 (LH) dahulu dan

ambil ukuran ‘gap width’ diantara ‘steering

gear mounting’ dan permukaan ‘subframe’.

Nota Penting:

Catatkan bacaan ‘gap width’ di dalam R.O

(G2TX) sebagai rujukan.

LH

Ukur ‘gap width’ diantara ‘Steering Gear

mounting’ & permukaan ‘Subframe

Standard: Maximum 2mm

7. Tanggalkan bolt & nut T4 (RH) dan gerakkan

’Steering Rack Assy’ daripada kedudukan atas

‘subframe’ untuk melegakan tekanan. Pasang

semula ‘Steering Rack Assy’ pada kedudukan

yang betul pada Subframe.

Tidak perlu membuat ukuran ‘gap width’.

Tidak perlu mengeluarkan Steering Rack

Assy daripada kenderaan.

RH

8. Ikat bolt & nat T4 secara berselang-seli

diantara LH dan RH mengikut giliran

sehingga ianya mencapai nilai ikatan tork

standard padaSub Frame Assy. Tork

Standard adalah 11kgfm ± 1 kgfm (110 Nm

± 10 Nm).

RH

LH

9. Pasang semula bolt T1 (I-shaft) dan T2 (Tie Tightening Torque (T1): 1.5 ~ 2.0 kgfm/

Rod end LH &RH) mengikut nilai tork 15 ~ 20 Nm

Tightening Torque (T2): 2.0 ~ 3.4 kgfm/

standard. 20 ~ 34 Nm

10. Pandu uji kenderaan dan dan sahkan bunyi

pada steering telah hilang semasa membelok Langkah Pencegahan:

pada keadaan idle atau bergerak. Jika tiada Pastikan pemasangan I-shaft is fully inserted

bunyi, teruskan dengan proses penjajaran into the Steering Rack spline. The bolt must

tayar. correctly in groove position.

11. Sekiranya bunyi tersebut masih kedengaran,

sila hantar M.I.R kepada

TFS_Technline@proton.com (TFS HQ)

sebagai bukti untuk penyiasatan lanjut oleh

pihak pembekal.

(Nota: Masukkan nilai ‘gap width’ di dalam

MIR seperti langkah 6 dan lampirkan

gambar/video sebagai dokumen sokongan)

Effective Date: 1 May 2020 Revision No.: 0 Doc. No.: PO-CQ-MQ-CS-02

3.0 Infomasi Alat Ganti (Untuk kes Pinion Shaft berkarat)

Ordering

Part Number Part Name Part Price Quantity/car Model

Methods

GEAR COMPL,MANUAL Iriz/New Persona

PW922623 Normal Price 1 PPCSB

STRG Iriz MC/Persona MC

4.0 Prosedur Tuntutan Jaminan

4.1 Buka & Pasang semula Steering Rack Assy dengan nilai tork standard

Claim Type Defective Part No. Operation Code Labour Hour Sundries A Code B Code

3102

Normal

VPB01 374002 25 2.0 Tyre Alignment 41A 80

Claim

(RM36.00 included Tax)

4.2 Penggantian Steering Rack Assy (isu berkarat sahaja)

Claim Type Defective Part No. Operation Code Labour Hour Sundries A Code B Code

2.3 3102

Normal

VPB01 374001 10 (included Butyl Tyre Alignment 30 80

Claim

Tape) (RM36.00 included Tax)

IMPORTANT NOTE:

1. Untuk tuntutan jaminan, semua kenderaan yang terlibat hendaklah mengikuti penyelenggaraan servis berkala dan di dalam

tempoh jaminan khas komponen seperti termaktub di dalam buku servis.

2. Semua komponen yang rosak hendaklah diletakkan ‘defective part tagging’ dan dikembalikan semula kepada pihak

PROTON HQ untuk siasatan lanjut. Rujuk alamat seperti di bawah:

Alamat: Proton Cose Service Centre, Km33.8 Westbound (KESAS)

Lebuhraya Shah Alam, 47600 Subang Jaya, Selangor,

Phone : 03-5888 1622 (En.Rosli)

PosLaju Account No: 8800336539

GL. Account No : 60220240

Copy to: MARKET QUALITY

Ini adalah dokumen janaan komputer

COMPASS DBM CORPORATE QUALITY

oleh itu, tiada tandatangan diperlukan.

PORTAL TELEPHONE: +603-5888 1496

Effective Date: 1 May 2020 Revision No.: 0 Doc. No.: PO-CQ-MQ-CS-02

Attachment: Example how to insert Gap Width in R.O (G2TX) as stated in Step 6.

Effective Date: 1 May 2020 Revision No.: 0 Doc. No.: PO-CQ-MQ-CS-02

You might also like

- Toyota 21R, 22R, 22RC Engine Repair Manual (1980.08) (Pub No. 36056E)Document283 pagesToyota 21R, 22R, 22RC Engine Repair Manual (1980.08) (Pub No. 36056E)Master Xeoto100% (5)

- JCB Adt: Service ManualDocument383 pagesJCB Adt: Service Manualcarlos arturo coral peñaNo ratings yet

- SM-Toyota 5FG33-45, 5FD33-45, 5FGE35, 5FDE35 Forklift Service Repair Manual PDFDocument559 pagesSM-Toyota 5FG33-45, 5FD33-45, 5FGE35, 5FDE35 Forklift Service Repair Manual PDFvadim vadim71% (7)

- Ps 11442003 2006 Sorento BL Torque On DemanD ToD TranSfer CaSeDocument16 pagesPs 11442003 2006 Sorento BL Torque On DemanD ToD TranSfer CaSeGheorghe HolteaNo ratings yet

- Manual de Servicio Hyundai HD120 D6DA PDFDocument413 pagesManual de Servicio Hyundai HD120 D6DA PDFMao Torres80% (15)

- Nissan fd6t Engine Manual PDFDocument3 pagesNissan fd6t Engine Manual PDFRonald Gareca Rueda54% (13)

- Automotive Sensor Testing and Waveform AnalysisFrom EverandAutomotive Sensor Testing and Waveform AnalysisRating: 4.5 out of 5 stars4.5/5 (13)

- Series 89 - CatamaransDocument29 pagesSeries 89 - CatamaransPobesneliMravNo ratings yet

- Manual ToyotaDocument37 pagesManual ToyotaBastian Tapia LopezNo ratings yet

- Caution / Notice / HintDocument15 pagesCaution / Notice / HintZouhair WahbiNo ratings yet

- Technical Service Bulletin: Combined TSB / Service Action: Forte (TD) Front Strut Noise Repair (Sa047)Document4 pagesTechnical Service Bulletin: Combined TSB / Service Action: Forte (TD) Front Strut Noise Repair (Sa047)Trọng Nghĩa VõNo ratings yet

- InstallationDocument17 pagesInstallationEdson CRNo ratings yet

- File PDFDocument43 pagesFile PDFKamrul Islam JashimNo ratings yet

- 1DZ EngineDocument181 pages1DZ EngineGonçalo SousaNo ratings yet

- Intarder 386 - e - 3626-011200 - en - Rev.5Document108 pagesIntarder 386 - e - 3626-011200 - en - Rev.5Herdre Van NiekerkNo ratings yet

- B70 Rock Breaker Care Operation Manual For TH86Document21 pagesB70 Rock Breaker Care Operation Manual For TH86Latifa EngineeringNo ratings yet

- Power Steering GearsDocument5 pagesPower Steering GearsDarren ANo ratings yet

- NTB02 037aDocument2 pagesNTB02 037aPMNo ratings yet

- Taper Grid Coupling: Operating and Maintenace ManualDocument4 pagesTaper Grid Coupling: Operating and Maintenace ManualFlorez Machado GhgustavoNo ratings yet

- T SB 0106 10Document3 pagesT SB 0106 10goombaNo ratings yet

- DisassemblyDocument8 pagesDisassemblyEdson CRNo ratings yet

- Foreword: Toyota Motor CorporationDocument32 pagesForeword: Toyota Motor CorporationSirine SurabayaNo ratings yet

- Annexure-1 (PG-3)Document16 pagesAnnexure-1 (PG-3)A A Mamun KhanNo ratings yet

- CK313 CVT P2757 Valve Body Replacement: T-SB-0150-16 Rev1 October 20, 2016Document12 pagesCK313 CVT P2757 Valve Body Replacement: T-SB-0150-16 Rev1 October 20, 2016Gearauto Power50% (2)

- U 1000Document5 pagesU 1000Fábio AngeliciNo ratings yet

- T SB 0119 10Document7 pagesT SB 0119 10goombaNo ratings yet

- 08 V6 Ticking 08-017Document3 pages08 V6 Ticking 08-017Tuomas KoskinenNo ratings yet

- Installation Checklist (NEXIEZ-MR) : Project NameDocument20 pagesInstallation Checklist (NEXIEZ-MR) : Project NameEtienneNo ratings yet

- 1 GRDocument11 pages1 GRGanbileg BatbilegNo ratings yet

- Kce10-91-V120-Ed High Mounted Stop Assembly Gap Adjusting & Paint Damage Repairment (Ceed 5door) (Revised Kce09-91-V240-Ed)Document5 pagesKce10-91-V120-Ed High Mounted Stop Assembly Gap Adjusting & Paint Damage Repairment (Ceed 5door) (Revised Kce09-91-V240-Ed)Alexandru NicolaNo ratings yet

- UM 80-06 Tachohalter EnglischDocument5 pagesUM 80-06 Tachohalter EnglischremydejongrsrNo ratings yet

- Tra 026Document7 pagesTra 026Trọng Nghĩa VõNo ratings yet

- Instruction Guide Combiflex Crimping ToolDocument2 pagesInstruction Guide Combiflex Crimping ToolAE,110 KV KanjikodeNo ratings yet

- Appendices V2Document76 pagesAppendices V2Nikola AngjelkovskiNo ratings yet

- AppendicesDocument69 pagesAppendicesIvan CanoNo ratings yet

- HPT Stage 1 Blades and Duct SegmentsDocument28 pagesHPT Stage 1 Blades and Duct SegmentsArabyAbdel Hamed SadekNo ratings yet

- t300 y T300e Parts MaanualDocument183 pagest300 y T300e Parts Maanualingedgartadeo.regemoNo ratings yet

- ReplacementDocument5 pagesReplacementEdson CRNo ratings yet

- BM Nozzle MaintenanceDocument6 pagesBM Nozzle Maintenancemartin.weisshaarNo ratings yet

- PT47A 21052instDocument9 pagesPT47A 21052instMohamad Isham MussaNo ratings yet

- John Deere 80C Excavator Service Repair Technical Manual (TM1939)Document18 pagesJohn Deere 80C Excavator Service Repair Technical Manual (TM1939)laopaodunNo ratings yet

- Rotary Type Torque Sensor Model Operating InstructionDocument8 pagesRotary Type Torque Sensor Model Operating InstructionEster MujicaNo ratings yet

- Team Update #1: General NoticesDocument5 pagesTeam Update #1: General NoticesWilliam MerchantNo ratings yet

- TSH5603G - 8 - P - 1 Arc WeldingDocument14 pagesTSH5603G - 8 - P - 1 Arc Weldinggüray bağdatlı100% (1)

- 17) 5 Annex D Part1 BLNG Tugs TemplateDocument4 pages17) 5 Annex D Part1 BLNG Tugs TemplateRomawi StevyandiNo ratings yet

- Corolla CVT T-SB-0150-16Document12 pagesCorolla CVT T-SB-0150-16ossoski100% (3)

- User'S Manul: 3Gp Series Steam Boiler Feed PumpDocument25 pagesUser'S Manul: 3Gp Series Steam Boiler Feed PumpEdinsonUribeTorresNo ratings yet

- Appendix A - Factory Specifications PDFDocument40 pagesAppendix A - Factory Specifications PDFRobert RooseNo ratings yet

- Dual Clutch Transmission (DCT) System (Automatic Transaxle (DCT) )Document33 pagesDual Clutch Transmission (DCT) System (Automatic Transaxle (DCT) )danyNo ratings yet

- TSB SC 082aDocument18 pagesTSB SC 082apacosworldNo ratings yet

- 2011+ Tow Hitch Install DirectionsDocument10 pages2011+ Tow Hitch Install Directionsmoeed.ahmed.baigNo ratings yet

- TSB ENG 157 YD Engine Vibration at Idle - SI - Final - 3649Document6 pagesTSB ENG 157 YD Engine Vibration at Idle - SI - Final - 3649Sadam HANo ratings yet

- Top Drive HSHCPackingListDocument6 pagesTop Drive HSHCPackingListjokoNo ratings yet

- Counterbalance, Standard Poppet Type Zero Differential Area: Common Cavity, Size 20Document2 pagesCounterbalance, Standard Poppet Type Zero Differential Area: Common Cavity, Size 20tecnicomanelNo ratings yet

- MPC 4502 - 5502 New Fuser Detect FuseDocument4 pagesMPC 4502 - 5502 New Fuser Detect FuseMatloob Khan0% (1)

- How To Use This Manual Transaxle Repair Manual: General InformationDocument3 pagesHow To Use This Manual Transaxle Repair Manual: General InformationMax K.No ratings yet

- Specifications: 14M and 16M Motor Graders Power TrainDocument40 pagesSpecifications: 14M and 16M Motor Graders Power Trainwilly1234512No ratings yet

- 20-1718 Rig Tongs AOTDocument10 pages20-1718 Rig Tongs AOTRahul M.R100% (1)

- 1LE1002 1CB23 4AA4 Z B14 Datasheet enDocument1 page1LE1002 1CB23 4AA4 Z B14 Datasheet enzeepython100% (1)

- Industrial Training: Exposure To Weld Shop Maruti Suzuki India LimitedDocument23 pagesIndustrial Training: Exposure To Weld Shop Maruti Suzuki India LimitedAnkush ChauhanNo ratings yet

- MPM 312 03 07Document5 pagesMPM 312 03 07Mousa PetrolNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Fairyland 3 Progress Test 4Document2 pagesFairyland 3 Progress Test 4ela.pryszczewska100% (1)

- Planning Your CareerDocument12 pagesPlanning Your Careerapi-330895609No ratings yet

- PortCalls March 30 2020Document12 pagesPortCalls March 30 2020PortCallsNo ratings yet

- Product Costing POC (For Training)Document94 pagesProduct Costing POC (For Training)topgun2011100% (3)

- Jeppview For Windows: General Information General InformationDocument22 pagesJeppview For Windows: General Information General InformationAfner OtnielNo ratings yet

- Taxicab Operators v. The Board of Transportation (GR L-59234, 30 September 1982) DigestsDocument1 pageTaxicab Operators v. The Board of Transportation (GR L-59234, 30 September 1982) DigestsjerushabrainerdNo ratings yet

- Set 3 Soal Uji Pengetahuan PPGDocument18 pagesSet 3 Soal Uji Pengetahuan PPGZinlong BejatNo ratings yet

- Bus ID No.: E-4580: Passenger InformationDocument1 pageBus ID No.: E-4580: Passenger InformationMadhavkumarNo ratings yet

- Snorkel - TB 60RTDocument2 pagesSnorkel - TB 60RTJuan Carlos ChaparroNo ratings yet

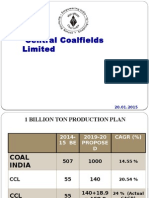

- CCL - 20.1.2015Document52 pagesCCL - 20.1.2015Arlene Baker100% (1)

- Fast Part CatalogueDocument31 pagesFast Part CatalogueAbhishek Kuwar100% (1)

- DRIVER TRAINING & EDUCATION (Driver Education Curriculum) : WARNING INDICATOR PDFDocument8 pagesDRIVER TRAINING & EDUCATION (Driver Education Curriculum) : WARNING INDICATOR PDFAli JavedNo ratings yet

- Import Process ANALYSIS: A Case Study of Glass Importing of Long Cam Co., LTDDocument44 pagesImport Process ANALYSIS: A Case Study of Glass Importing of Long Cam Co., LTDMai Sơn DươngNo ratings yet

- Ar 95-2Document115 pagesAr 95-2Steve SandersonNo ratings yet

- Manual of Contract Documents For Highway Works: August 1997Document17 pagesManual of Contract Documents For Highway Works: August 1997Srdjan KitanovicNo ratings yet

- Airliner Tech Series 07 - de Havilland CometDocument107 pagesAirliner Tech Series 07 - de Havilland CometAdriano Beluco100% (4)

- Waiver 2019-MotorstarDocument2 pagesWaiver 2019-MotorstarBelle Zyed GuilaoNo ratings yet

- Segway BrochureDocument9 pagesSegway BrochureEmelia JugdavNo ratings yet

- ExtractPage1 168Document168 pagesExtractPage1 168satenderroseNo ratings yet

- Traffic Signals: Finish Crossing If StartedDocument16 pagesTraffic Signals: Finish Crossing If StartedAnonymous PuEyutLNo ratings yet

- NTSB Investigation Party FormDocument14 pagesNTSB Investigation Party Formlaratani68No ratings yet

- GL - 2002Document68 pagesGL - 2002AshifurNo ratings yet

- An Efficient Emergency Vehicle Clearance Mechanism For Smart CitiesDocument20 pagesAn Efficient Emergency Vehicle Clearance Mechanism For Smart CitiesSimona NicoletaNo ratings yet

- Questionaire For 3/0: 1. What Is Contingency AnchorageDocument7 pagesQuestionaire For 3/0: 1. What Is Contingency AnchorageGerome Eugenio33% (3)

- EastmanDocument37 pagesEastmanKrishnananth SajuNo ratings yet

- Sulfur Tolerance Kit Installation Instruction QSG12 CM2350 G113 G110 Bulletin 5414618Document9 pagesSulfur Tolerance Kit Installation Instruction QSG12 CM2350 G113 G110 Bulletin 5414618Carlos D RamirezNo ratings yet

- LIFT Indian Standard List PDFDocument2 pagesLIFT Indian Standard List PDFsuresh kumarNo ratings yet

- Tomini AlizeDocument2 pagesTomini Alizedaniel.livamexNo ratings yet