Professional Documents

Culture Documents

1734-Ob2e Ob4e

1734-Ob2e Ob4e

Uploaded by

tony.pearce1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1734-Ob2e Ob4e

1734-Ob2e Ob4e

Uploaded by

tony.pearce1Copyright:

Available Formats

Installation Instructions

POINT I/O Protected Output Module

(Cat. No. 1734-OB2E and -OB4E Series C)

9

us le

at u

St od

M

D s rk

O a tu o

S et t w

N

E:

N

O ou DC

pu e

S 4V

u t rc

t

2

4

1

B 4

O 73

4E

3

2

8

7

10

1

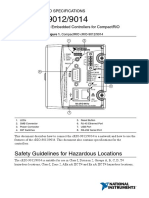

Description Description

1 Mounting Base1 6 RTB Removal Handle

2 Mechanical Keying (orange) 7 Removable Terminal Block (RTB)1

3 Module Wiring Diagram 8 DIN Rail Locking Screw (orange)

4 Module Locking Mechanism 9 Slide-in Writable Label

5 Insertable I/O Module 10 Interlocking Side Pieces

1

Wiring Base Assembly consists of item 1) mounting base, 1734-MB and item 7) removable

terminal block, 1734-RT or -RTS.

POINT I/O is a trademark of Rockwell Automation

DeviceNet is a trademark of ODVA, Inc. Publication 1734-IN056C-EN-P - April 2002

2 POINT I/O Protected Output Module

This Series C product can be used with DeviceNet and PROFIBUS

adapters. It can be used with ControlNet and Ethernet adapters using

RSLogix 5000, version 11 (or higher) software.

Important User Information

Because of the variety of uses for the products described in this publication,

those responsible for the application and use of these products must satisfy

themselves that all necessary steps have been taken to assure that each

application and use meets all performance and safety requirements, including

any applicable laws, regulations, codes and standards. In no event will

Allen-Bradley be responsible or liable for indirect or consequential damage

resulting from the use or application of these products.

Any illustrations, charts, sample programs, and layout examples shown in this

publication are intended solely for purposes of example. Since there are many

variables and requirements associated with any particular installation,

Allen-Bradley does not assume responsibility or liability (to include intellectual

property liability) for actual use based upon the examples shown in this

publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application,

Installation and Maintenance of Solid-State Control (available from your local

Allen-Bradley office), describes some important differences between

solid-state equipment and electromechanical devices that should be taken into

consideration when applying products such as those described in this

publication.

Reproduction of the contents of this copyrighted publication, in whole or

part, without written permission of Rockwell Automation, is prohibited.

Throughout this publication, notes may be used to make you aware of safety

considerations. The following annotations and their accompanying statements

help you to identify a potential hazard, avoid a potential hazard, and recognize

the consequences of a potential hazard.

Identifies information about practices or

WARNING

circumstances that can cause an explosion in a

hazardous environment, which may lead to

! personal injury or death, property damage, or

economic loss.

Publication 1734-IN056C-EN-P - April 2002

POINT I/O Protected Output Module 3

Identifies information about practices or

ATTENTION

circumstances that can lead to personal injury or

death, property damage, or economic loss.

!

Identifies information that is critical for

IMPORTANT

successful application and understanding of the

product.

Publication 1734-IN056C-EN-P - April 2002

4 POINT I/O Protected Output Module

Environment and Enclosure

ATTENTION

This equipment is intended for use in a Pollution Degree 2

! industrial environment, in overvoltage Category II applications

(as defined in IEC publication 60664-1), at altitudes up to 2000

meters without derating.

This equipment is considered Group 1, Class A industrial

equipment according to IEC/CISPR Publication 11. Without

appropriate precautions, there may be potential difficulties

ensuring electromagnetic compatibility in other environments

due to conducted as well as radiated disturbance.

This equipment is supplied as "open type" equipment. It must

be mounted within an enclosure that is suitably designed for

those specific environmental conditions that will be present and

appropriately designed to prevent personal injury resulting from

accessibility to live parts. The interior of the enclosure must be

accessible only by the use of a tool. Subsequent sections of this

publication may contain additional information regarding

specific enclosure type ratings that are required to comply with

certain product safety certifications.

See NEMA Standards publication 250 and IEC publication

60529, as applicable, for explanations of the degrees of

protection provided by different types of enclosure. Also, see the

appropriate sections in this publication, as well as the

Allen-Bradley publication 1770-4.1 ("Industrial Automation

Wiring and Grounding Guidelines"), for additional installation

requirements pertaining to this equipment.

POINT I/O is grounded through the DIN rail to

ATTENTION

chassis ground. Use zinc plated, yellow chromated

steel DIN rail to assure proper grounding. Using

! other DIN rail materials (e.g. aluminum, plastic,

etc.) which can corrode, oxidize or are poor

conductors can result in improper or intermittent

platform grounding.

Publication 1734-IN056C-EN-P - April 2002

POINT I/O Protected Output Module 5

EXPLOSION HAZARD

WARNING

• Do not disconnect equipment unless power has been

removed or the area is known to be nonhazardous.

! • Do not disconnect connections to this equipment unless

power has been removed or the area is known to be

nonhazardous. Secure any external connections that mate

to this equipment by using screws, sliding latches, threaded

connectors, or other means provided with this product.

• Substitution of components may impair suitability for Class

I, Division 2.

• If this product contains batteries, they must only be

changed in an area known to be nonhazardous.

Preventing Electrostatic Discharge

ATTENTION

This equipment is sensitive to electrostatic

discharge, which can cause internal damage and

! affect normal operation. Follow these guidelines

when you handle this equipment:

• Touch a grounded object to discharge potential

static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component

boards.

• Do not touch circuit components inside the

equipment.

• If available, use a static-safe workstation.

• When not in use, store the equipment in

appropriate static-safe packaging.

Publication 1734-IN056C-EN-P - April 2002

6 POINT I/O Protected Output Module

Installing the Mounting Base

To install the mounting base on the DIN rail, proceed as follows.

1. Position the mounting base vertically above the installed units

(adapter, power supply or existing module.

2. Slide the mounting base down allowing the interlocking side pieces to

engage the adjacent module or adapter.

3. Press firmly to seat the mounting base on the DIN rail. The mounting

base will snap into place.

4. To remove the mounting base from the DIN rail, remove the module,

and use a small bladed screwdriver to rotate the base locking screw to

a vertical position. This releases the locking mechanism. Then lift

straight up to remove.

Installing the I/O Module

The module can be installed before, or after base installation. Make sure that

the mounting base is correctly keyed before installing the module into the

mounting base. In addition, make sure the mounting base locking screw is

positioned horizontal referenced to the base.

When you insert or remove the module while

WARNING

backplane power is on, an electrical arc can

occur. This could cause an explosion in

! hazardous location installations. Be sure that

power is removed or the area is nonhazardous

before proceeding.

1. Using a bladed screwdriver, rotate the keyswitch (2) on the

mountingbase clockwise until the number required for the type of

module being installed aligns with the notch in the base.

2. Make certain the DIN rail locking screw is in the horizontal position.

(You cannot insert the module if the locking mechanism is unlocked.)

Publication 1734-IN056C-EN-P - April 2002

POINT I/O Protected Output Module 7

3. Insert the module straight down into the mounting base and press to

secure. The module will lock into place.

Installing the Removable Terminal Block (RTB)

A removable terminal block is supplied with your wiring base assembly. To

remove, pull up on the RTB handle. This allows the mounting base to be

removed and replaced as necessary without removing any of the wiring. To

reinsert the removable terminal block, proceed as follows.

1. Insert the end opposite the handle into the base unit. This end has a

curved section that engages with the wiring base.

2. Rotate the terminal block into the wiring base until it locks itself in

place.

3. If an I/O module is installed, snap the RTB handle into place on the

module.

When you connect or disconnect the Removable

WARNING

Terminal Block (RTB) with field side power

applied, an electrical arc can occur. This could

! cause an explosion in hazardous location

installations.

Be sure that power is removed or the area is

nonhazardous before proceeding.

Publication 1734-IN056C-EN-P - April 2002

8 POINT I/O Protected Output Module

Removing a Mounting Base

To remove a mounting base, you must remove any installed module, and the

module installed in the base to the right. Remove the removable terminal

block (if wired).

1. Unlatch the RTB handle on the I/O module.

2. Pull on the RTB handle to remove the removable terminal block.

When you connect or disconnect the Removable

WARNING

Terminal Block (RTB) with field side power

applied, an electrical arc can occur. This could

! cause an explosion in hazardous location

installations.

Be sure that power is removed or the area is

nonhazardous before proceeding.

3. Press on the module lock on the top of the module.

4. Pull on the I/O module to remove from the base.

When you insert or remove the module while

WARNING

backplane power is on, an electrical arc can

occur. This could cause an explosion in

! hazardous location installations. Be sure that

power is removed or the area is nonhazardous

before proceeding.

5. Repeat steps 1, 2, 3 and 4 for the module to the right.

6. Use a small bladed screwdriver to rotate the orange base locking

screw to a vertical position. This releases the locking mechanism.

7. Then lift straight up to remove.

Publication 1734-IN056C-EN-P - April 2002

POINT I/O Protected Output Module 9

Communicating with Your Module

I/O messages are sent to (consumed) and received from (produced) the

POINT I/O modules. These messages are mapped into the processor’s

memory. This POINT I/O output module produces 1 byte of input data

(scanner Rx) (status). It consumes 1 byte of I/O data (scanner Tx).

Default Data Map for the 1734-OB2E Output Module

Message size: 1 Byte

7 6 5 4 3 2 1 0

Produces Not used Ch1 Ch0 Channel status

(scanner Rx)

Where: 0 = no error, 1 = error

Message size: 1 Byte

7 6 5 4 3 2 1 0

Consumes Not used Ch1 Ch0 Channel state

(scanner Tx)

Where: 0 = Off, 1 = On

Publication 1734-IN056C-EN-P - April 2002

10 POINT I/O Protected Output Module

Default Data Map for the 1734-OB4E Output Module

Message size: 1 Byte

7 6 5 4 3 2 1 0

Produces Not used Ch3 Ch2 Ch1 Ch0 Channel

(scanner Rx) status

Where: 0 = no error, 1 = error

Message size: 1 Byte

7 6 5 4 3 2 1 0

Consumes Not used Ch3 Ch2 Ch1 Ch0 Channel

(scanner Tx) state

Where: 0 = Off, 1 = On

Publication 1734-IN056C-EN-P - April 2002

POINT I/O Protected Output Module 11

Wiring the Protected Output Modules

1734-OB2E 1734-OB4E

Module

Status

Module Status Module

Status

Network

Status

Network Status

Network

NODE: Status

NODE:

24VDC

Source 24VDC

Output Source

Status of Output 0 Output

0

0

1

Status of Output 1

1

Status of Output 2

2

Status of Output 3

3

1734

OB2E 1734

OB4E

Output 0 Output 1

Output 0 Output 1

Connection Connection

Connection Connection

Output 0 Output 1 Output 2 Output 3

Connection Connection Connection Connection

C C C C

C C

V V

C = Common

42016

V = Supply

Publication 1734-IN056C-EN-P - April 2002

12 POINT I/O Protected Output Module

dc Output Module Cat. No. 1734-OB2 and -OB4E

1734-OB2E

0 1

Out 0 Out 1

2 3

Out 0 Out 1

Load Load

4 5

C C

6 7

V V

42014

V = 12/24V dc, C = Common

Field power is supplied from internal power bus

Output Terminal Common Terminal Power

Channel 0 0, 2 4 6

Channel 1 1, 3 5 7

Module power is supplied from the internal power bus.

1734-OB4E 0 1

Out 0 Out 1

2 3

Out 2 Out 3

Load Load Load Load

4 5

C C

6 7

C C

42015

V = 12/24V dc, C = Common

Field power is supplied from internal power bus

Output Terminal Common Terminal Power

Channel 0 0 6

Channel 1 1 7

Channel 2 2 4

Channel 3 3 5

Module power is supplied from internal power bus.

Publication 1734-IN056C-EN-P - April 2002

POINT I/O Protected Output Module 13

Troubleshooting with the Indicators

1734-OB2E 1734-OB4E

Module Module

Status Module Status Status

Network Network

Status

NODE:

Network Status Status

NODE:

24VDC 24VDC

Source Source

Output Output

0 Status of Output 0 0

1 Status of Output 1 1

Status of Output 2 2

3

1734

Status of Output 3 1734

OB2E OB4E

Indication Probable Cause

Module Status

Off No power applied to device

Green Device operating normally

Flashing Green Device needs commissioning due to configuration missing,

incomplete or incorrect.

Flashing Red Recoverable fault.

Red Unrecoverable fault may require device replacement

Flashing Device is in self-test

Red/Green

Publication 1734-IN056C-EN-P - April 2002

14 POINT I/O Protected Output Module

Indication Probable Cause

Network Status

Off Device is not on-line

- Device has not completed dup_MAC_id test.

- Device not powered - check module status indicator

Flashing Green Device is on-line but has no connections in the established

state.

Green Device on-line and has connections in the established state.

Flashing Red One or more I/O connections in timed-out state

Red Critical link failure - failed communication device. Device

detected error that prevents it communicating on the

network.

Flashing Communication faulted device - the device has detected a

Red/Green network access error and is in communication faulted state.

Device has received and accepted an Identify

Communication Faulted Request - long protocol message.

Indication Probable Cause

I/O Status

Off All outputs inactive

Yellow One or more output is active and under control

Flashing Red Open circuit detected. No load. (Off-State only)

Red Short circuit detected. No load (On-State only)

Publication 1734-IN056C-EN-P - April 2002

POINT I/O Protected Output Module 15

Safety Approvals

The following information applies when Informations sur l’utilisation de cet équipement

operating this equipment in hazardous en environnements dangereux:

locations:

Products marked “CL I, DIV 2, GP A, B, C, D” are suitable Les produits marqués “CL I, DIV 2, GP A, B, C, D” ne

for use in Class I Division 2 Groups A, B, C, D, Hazardous conviennent qu’à une utilisation en environnements de Classe

Locations and nonhazardous locations only. Each product I Division 2 Groupes A, B, C, D dangereux et non dangereux.

is supplied with markings on the rating nameplate Chaque produit est livré avec des marquages sur sa plaque

indicating the hazardous location temperature code. When d’identification qui indiquent le code de température pour les

combining products within a system, the most adverse environnements dangereux. Lorsque plusieurs produits sont

temperature code (lowest “T” number) may be used to combinés dans un système, le code de température le plus

help determine the overall temperature code of the défavorable (code de température le plus faible) peut être

system. Combinations of equipment in your system are utilisé pour déterminer le code de température global du

subject to investigation by the local Authority Having système. Les combinaisons d’équipements dans le système

Jurisdiction at the time of installation. sont sujettes à inspection par les autorités locales qualifiées

au moment de l’installation.

EXPLOSION HAZARD - RISQUE D’EXPLOSION –

WARNING • Do not disconnect equipment unless AVERTISSEMENT • Couper le courant ou s’assurer que

power has been removed or the area l’environnement est classé non

is known to be nonhazardous. dangereux avant de débrancher

• Do not disconnect connections to l'équipement.

! this equipment unless power has

been removed or the area is known

to be nonhazardous. Secure any

external connections that mate to

! • Couper le courant ou s'assurer que

l’environnement est classé non

dangereux avant de débrancher les

connecteurs. Fixer tous les connecteurs

this equipment by using screws, externes reliés à cet équipement à

sliding latches, threaded l'aide de vis, loquets coulissants,

connectors, or other means provided connecteurs filetés ou autres moyens

with this product. fournis avec ce produit.

• Substitution of components may • La substitution de composants peut

impair suitability for Class I, Division rendre cet équipement inadapté à une

2. utilisation en environnement de Classe

• If this product contains batteries, 1, Division 2.

they must only be changed in an • S’assurer que l’environnement est

area known to be nonhazardous. classé non dangereux avant de changer

les piles.

Publication 1734-IN056C-EN-P - April 2002

16 POINT I/O Protected Output Module

Specifications - 1734-OB2E and -OB4E Protected Output Modules

Output Specifications

Number of Outputs 1734-OB2E - 2 (1 group of 2) non-isolated, sourcing

1734-OB4E - 4 (1 group of 4) non-isolated, sourcing

ON-State Voltage Range 10V dc minimum

24V dc nominal

28.8V dc maximum

ON-State Voltage Drop 0.2V dc maximum

ON-State Current 1.0mA minimum per channel

OFF-State Voltage 28.8V dc maximum

OFF-State Leakage 0.5mA maximum

Output Signal Delay1

OFF to ON 0.1ms maximum

ON to OFF 0.1ms maximum

Output Current Rating Maximum 1.0A per output

2.0A maximum per module

Surge Current 2A for 10ms, repeatable every 3 seconds

Indicators (field side 1734-OB2E

indication, logic driven) 2 yellow output status;

2 red output fault

2 green/red module/network status

1734-OB4E

4 yellow output status;

4 red output fault

2 green/red module/network status

Keyswitch Position 1

General Specifications

Module Location 1734-TB or -TBS wiring base assembly

Pointbus Current 75mA maximum @ 5V dc

Power Dissipation 1734-OB2E - 0.8W maximum @ 28.8V dc

1734-OB4E - 1.2W maximum @ 28.8V dc

Thermal Dissipation 1734-OB2E - 2.7 BTU/hr maximum @ 28.8V dc

1734-OB4E - 4.1 BTU/hr maximum @ 28.8V dc

Isolation Voltage 1250V rms/V ac

External dc Power

Supply Voltage 24V dc nominal

Voltage Range 10 to 28.8V dc

Supply Current 1734-OB2E - 8mA

1734-OB4E - 16mA

Dimensions Inches 2.21H x 0.47W x 2.97L

(Millimeters) (56.0H x 12.0W x 75.5L)

Publication 1734-IN056C-EN-P - April 2002

POINT I/O Protected Output Module 17

Environmental Conditions

Operational Temperature IEC 60068-2-1 (Test Ad, Operating Cold),

IEC 60068-2-2 (Test Bd, Operating Dry Heat),

IEC 60068-2-14 (Test Nb, Operating Thermal

Shock):

-20 to 55°C (-4 to 131°F)

Storage Temperature IEC 60068-2-1 (Test Ab, Unpackaged Nonoperating

Cold),

IEC 60068-2-2 (Test Bb, Unpackaged Nonoperating

Dry Heat),

IEC 60068-2-14 (Test Na, Unpackaged

Nonoperating Thermal Shock):

-40 to 85°C (-40 to 185°F)

Relative Humidity IEC 60068-2-30 (Test Db, Unpackaged

Nonoperating

Damp Heat):

5 to 95% noncondensing

Shock IEC 60068-2-27 (Test Ea, Unpackaged Shock)

Operating 30g peak acceleration

Non-operating 50g peak acceleration

Vibration IEC 60068-2-6, (Test Fc, Operating)

Tested 5g @ 10-500Hz

ESD Immunity IEC 61000-4-2:

6kV contact discharges

8kV air discharges

Radiated RF Immunity IEC 61000-4-3:

10V/m with 1kHz sine-wave 80%AM from 30MHz

to 1000MHz

10V/m with 200Hz 50% Pulse 100%AM at 900Mhz

EFT/B Immunity IEC 61000-4-4:

±2kV at 5kHz on signal ports

Surge Transient Immunity IEC 61000-4-5:

±1kV line-line(DM) and ±2kV line-earth(CM) on

signal ports

Conducted RF Immunity IEC 61000-4-6:

10Vrms with 1kHz sine-wave 80%AM from 150kHz

to 80MHz

Emissions CISPR 11

Group 1, Class A

Enclosure Type Rating None (open-style)

Conductors Wire Size 14 AWG (2.5mm2) - 22 AWG (0.25mm2) solid or

stranded copper wire rated at 75°C or greater

3/64 inch (1.2mm) insulation maximum

Category 22

Publication 1734-IN056C-EN-P - April 2002

Terminal Base Screw Torque 7 pound-inches (0.6Nm)

Field Wiring Terminations 1734-OB2E

0 - Output 0 1 - Output 1

2 - Output 0 3 - Output 1

4 - Common 5 - Common

6 - Supply 7 - Supply

1734-OB4E

0 - Output 0 1 - Output 1

2 - Output 2 3 - Output 3

4 - Common 5 - Common

6 - Common 7 - Common

Mass 1734-OB2E - 1.15 oz/32.60 grams

1734-OB4E - 1.17 oz/33.17 grams

Agency Certification (when C-UL-US - UL Listed Industrial Control Equipment,

product is marked) certified for US and Canada

C-UL-US - UL Listed for Class I, Division 2, Groups

A, B, C and D Hazardous locations, certified for US

and Canada

CE3 - European Union 89/336/EEC EMC Directive,

compliant with:

EN 50081-2; Industrial Emissions

EN 50082-2; Industrial Immunity

EN 61326; Meas./Control/Lab., Industrial

Requirements

EN 61000-6-2; Industrial Immunity

C-Tick3 - Australian Radiocommunications Act

compliant with AS/NZS 2064, Industrial Emissions

1 Off/on delay is time from a valid output “on” signal to output energization. On/off delay is time from a

valid output “off” signal to output deenergization.

2 Use this conductor category information for planning conductor routing as described in publication

1770-4.1, “Industrial Automation Wiring and Grounding Guidelines.”

3 See the Product Certification link at www.ab.com for Declaration of Conformity, Certificates, and

other certification details.

Publication 1734-IN056C-EN-P - April 2002 PN 957657-91

Supersedes Publication 1734-IN056B-EN-P - August 2000 © 2002 Rockwell International Corporation. Printed in USA

You might also like

- HF100 Ver.1.6.pdf Service Manual WebridgedDocument28 pagesHF100 Ver.1.6.pdf Service Manual WebridgedErnesto AcostaNo ratings yet

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosFrom EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosRating: 5 out of 5 stars5/5 (1)

- Instructions For Cutler-Hammer LDB, LD, HLD, HLDB, LDC, LW, HLW, LWC, CLD, CHLD, CLDC Circuit Breakers and L-Frame Series C SwitchesDocument12 pagesInstructions For Cutler-Hammer LDB, LD, HLD, HLDB, LDC, LW, HLW, LWC, CLD, CHLD, CLDC Circuit Breakers and L-Frame Series C Switchespayolin77No ratings yet

- POINT I/O 2 or 4 Relay Output Module: Installation InstructionsDocument24 pagesPOINT I/O 2 or 4 Relay Output Module: Installation InstructionsCarlos AB CHNo ratings yet

- 1734 Oe2cDocument16 pages1734 Oe2ctony.pearce1No ratings yet

- 1734 VHSC5 PDocument24 pages1734 VHSC5 Ptony.pearce1No ratings yet

- 1734 Ie2vDocument16 pages1734 Ie2vtony.pearce1No ratings yet

- PLC Hardware Manual PDFDocument35 pagesPLC Hardware Manual PDFskv004No ratings yet

- POINT I/O 4 Channel High Density Current Input Modules: Installation InstructionsDocument24 pagesPOINT I/O 4 Channel High Density Current Input Modules: Installation InstructionsGILBERTNo ratings yet

- 1746-BAS and 1746-BAS-T PDFDocument28 pages1746-BAS and 1746-BAS-T PDFtt cheneyNo ratings yet

- 1732e In004 - en eDocument20 pages1732e In004 - en eisaacsavioNo ratings yet

- POINT I/O Common Terminal Module and Voltage Terminal ModuleDocument16 pagesPOINT I/O Common Terminal Module and Voltage Terminal Moduleluisllumiquinga97No ratings yet

- 1762 Ob8 PDFDocument16 pages1762 Ob8 PDFRodríguez EdwardNo ratings yet

- Devicenet Armorblock™ Network Powered 16-Input Module: Installation InstructionsDocument16 pagesDevicenet Armorblock™ Network Powered 16-Input Module: Installation InstructionsJoel GallegosNo ratings yet

- 1746-Ib16 User ManualDocument48 pages1746-Ib16 User ManualC Raziel Fdz ONo ratings yet

- Armorblock Guard I/O Devicenet Safety: Installation InstructionsDocument24 pagesArmorblock Guard I/O Devicenet Safety: Installation InstructionsIvan Becerril GonzalezNo ratings yet

- POINT I/O Wiring Base Assembly: Environment and EnclosureDocument2 pagesPOINT I/O Wiring Base Assembly: Environment and EnclosureThanh BaronNo ratings yet

- Controllogix™ Ac (74-265V) Output Module: Installation InstructionsDocument16 pagesControllogix™ Ac (74-265V) Output Module: Installation InstructionsLuis Fernando García CienfuegosNo ratings yet

- 1764-24AWA - 24BWA - 28BXB Install (1764-In001A-MU-P Mar 2000) - SuperseededDocument122 pages1764-24AWA - 24BWA - 28BXB Install (1764-In001A-MU-P Mar 2000) - SuperseededjishyNo ratings yet

- Axis ServoDocument26 pagesAxis ServoDasun SusewhewaNo ratings yet

- FLEX Ex Thermocouple/RTD Input Module: Installation InstructionsDocument32 pagesFLEX Ex Thermocouple/RTD Input Module: Installation InstructionsBrian LewisNo ratings yet

- Ult REL Output Analog Modules 1734-In002 enDocument24 pagesUlt REL Output Analog Modules 1734-In002 enGabriel Constantin NastaseNo ratings yet

- 1756 Ob32Document20 pages1756 Ob32downpourguyNo ratings yet

- Micrologix™ 1200 Programmable Controllers: Installation InstructionsDocument114 pagesMicrologix™ 1200 Programmable Controllers: Installation InstructionsMarcela CayoNo ratings yet

- Controllogix™ DC (10-31.2V) Input Module: Installation InstructionsDocument18 pagesControllogix™ DC (10-31.2V) Input Module: Installation InstructionsRichard ReyesNo ratings yet

- Controllogix Ethernet Communication Interface Module: Installation InstructionsDocument20 pagesControllogix Ethernet Communication Interface Module: Installation InstructionsneoflashNo ratings yet

- Devicenet 1732 Armorblock I/O, Series A: Installation InstructionsDocument16 pagesDevicenet 1732 Armorblock I/O, Series A: Installation InstructionsMariano DavicoNo ratings yet

- 1732e-In004 - En-E (Dual Port Enet)Document20 pages1732e-In004 - En-E (Dual Port Enet)MarcosNo ratings yet

- ControlLogix AC (10-265V) DC (5-150V) Isolated Contact ModuleDocument20 pagesControlLogix AC (10-265V) DC (5-150V) Isolated Contact ModuleFrancisco Mones RuizNo ratings yet

- FLEX Ex I/O 24V DC 4 Non-Isolated Source Output Module: Installation InstructionsDocument32 pagesFLEX Ex I/O 24V DC 4 Non-Isolated Source Output Module: Installation InstructionsfelipeNo ratings yet

- FX Idc1b Kidde Manual InstalacionDocument2 pagesFX Idc1b Kidde Manual InstalacionAlexander Barrera SanchezNo ratings yet

- Instruction Manual: 5COV475800 - LPT - Rev00Document8 pagesInstruction Manual: 5COV475800 - LPT - Rev00Ratheesh KumarNo ratings yet

- General Monitors S5000 Manual-EnDocument22 pagesGeneral Monitors S5000 Manual-Enمحمد رمضانNo ratings yet

- 1797-In003 - En-P (1797-OE8, 1797-OE8H)Document52 pages1797-In003 - En-P (1797-OE8, 1797-OE8H)Brian LewisNo ratings yet

- Micrologix™ Analog Input/Output: Installation InstructionsDocument24 pagesMicrologix™ Analog Input/Output: Installation Instructionscamus1125No ratings yet

- Siprotec (7SJ80) SiemensDocument40 pagesSiprotec (7SJ80) SiemensMuhammad KuntoroNo ratings yet

- 20190822.installation Manual For LONGi Solar PV Modules - CompressedDocument28 pages20190822.installation Manual For LONGi Solar PV Modules - CompressedFelipe Valdivia MorenoNo ratings yet

- Micrologix 1500 Programmable Controller Base Units: Installation InstructionsDocument24 pagesMicrologix 1500 Programmable Controller Base Units: Installation InstructionsValentino FortNo ratings yet

- Armorblock 2-Port Ethernet/Ip Module: Installation InstructionsDocument20 pagesArmorblock 2-Port Ethernet/Ip Module: Installation InstructionsJulio EcheverríaNo ratings yet

- Micrologix 1200 Thermocouple/Mv Input Module: Installation InstructionsDocument24 pagesMicrologix 1200 Thermocouple/Mv Input Module: Installation InstructionsRexNo ratings yet

- AB ControlLogixOutputModule 1756 OF8Document20 pagesAB ControlLogixOutputModule 1756 OF8QuynhtnNo ratings yet

- Mapeo Direcciones Modbus Tcpip Micrologix 850Document266 pagesMapeo Direcciones Modbus Tcpip Micrologix 850Jose LunaNo ratings yet

- 56amxn In002 - en PDocument24 pages56amxn In002 - en PBAHARO ALYAUMA IEDNo ratings yet

- Amorblock 16point ethernetIP Module ManualDocument24 pagesAmorblock 16point ethernetIP Module ManualKhiêm Nguyễn TrườngNo ratings yet

- Q7800 - Base de RM7800Document6 pagesQ7800 - Base de RM7800Andrey VegaNo ratings yet

- Point I/O Devicenet Adapter: Installation InstructionsDocument28 pagesPoint I/O Devicenet Adapter: Installation InstructionsCarlosOtinianoNo ratings yet

- Controllogix Controlnet Bridge: Installation InstructionsDocument32 pagesControllogix Controlnet Bridge: Installation InstructionsneoflashNo ratings yet

- 8051 TutorialDocument47 pages8051 TutorialSumit OjhaNo ratings yet

- 1500 Micro LogixDocument100 pages1500 Micro LogixMisael CastilloNo ratings yet

- 1756 in 034 CenpDocument20 pages1756 in 034 CenpGuillermo LIZZANONo ratings yet

- Installation Manual Circontrol EVolve SmartDocument28 pagesInstallation Manual Circontrol EVolve SmartpeteatkoNo ratings yet

- Manual Armoblock ABDocument24 pagesManual Armoblock ABJermy Abraham CarrascoNo ratings yet

- FLEX Ex NAMUR Input Module: Installation InstructionsDocument28 pagesFLEX Ex NAMUR Input Module: Installation InstructionsRafa ANo ratings yet

- GuardPLC Digital Input Output Module PDFDocument20 pagesGuardPLC Digital Input Output Module PDFTarun BharadwajNo ratings yet

- Neptune 8: Supplement To Service Manual Neptune 5 / 7Document24 pagesNeptune 8: Supplement To Service Manual Neptune 5 / 7Abde EsselamNo ratings yet

- GuardPLC Digital Output Module PDFDocument16 pagesGuardPLC Digital Output Module PDFTarun BharadwajNo ratings yet

- Controllogix - Input Output PDFDocument312 pagesControllogix - Input Output PDFLuis Namuche MalcaNo ratings yet

- NI cRIO-9012/9014: Safety Guidelines For Hazardous LocationsDocument20 pagesNI cRIO-9012/9014: Safety Guidelines For Hazardous LocationsAbrahamNo ratings yet

- NXT4 Bia e 1.40Document20 pagesNXT4 Bia e 1.40agus triprasetyoNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Service Application Process: Jason B. Elamparo Mark C. ManjaresDocument37 pagesService Application Process: Jason B. Elamparo Mark C. Manjaresjopaypagas0% (1)

- Sample: 9.3 ElectromagnetsDocument10 pagesSample: 9.3 ElectromagnetshuongttNo ratings yet

- Repair Manual Genesis 200 CLS-GBDocument59 pagesRepair Manual Genesis 200 CLS-GBMARCEL1300No ratings yet

- A Practical Approach To A Compct Wide-Band SMT Directional CouplerDocument3 pagesA Practical Approach To A Compct Wide-Band SMT Directional Coupleragmnm1962No ratings yet

- 2015 Substation Controls - HicksDocument54 pages2015 Substation Controls - HicksDave ChaudhuryNo ratings yet

- Injection Actuation Pressure Control Valve - Test: TroubleshootingDocument10 pagesInjection Actuation Pressure Control Valve - Test: TroubleshootingsatyaNo ratings yet

- GifaDocument331 pagesGifaMatiasNo ratings yet

- Link Ekatalog Produk KoronkaDocument3 pagesLink Ekatalog Produk KoronkaIkadona L KaukabaNo ratings yet

- ANSI ESD STM12.1-2019 静电放电敏感物品防护试验方法.座椅.电阻测量Seating - Resistance MeasurementsDocument10 pagesANSI ESD STM12.1-2019 静电放电敏感物品防护试验方法.座椅.电阻测量Seating - Resistance MeasurementscdmingNo ratings yet

- Avani Instruction ManualDocument88 pagesAvani Instruction ManualPriya SinghNo ratings yet

- Free Breeze PS500-500kW EnglishDocument6 pagesFree Breeze PS500-500kW EnglishRey Martial RodriguezNo ratings yet

- ET-353, Lecture 19 (AM-VSB)Document28 pagesET-353, Lecture 19 (AM-VSB)Jahanzaib MushtaqNo ratings yet

- System Guide,: Volume I of IIDocument266 pagesSystem Guide,: Volume I of IIalaa fadhelNo ratings yet

- Low Voltage NH Knife Blade Fuse LinksDocument10 pagesLow Voltage NH Knife Blade Fuse LinksAlan EduardoNo ratings yet

- PD6 enDocument2 pagesPD6 enJoseRiveraNo ratings yet

- An Improved Algorithm For Photovoltaic System Sizing 2012 Energy ProcediaDocument9 pagesAn Improved Algorithm For Photovoltaic System Sizing 2012 Energy ProcediaManoj KumarNo ratings yet

- The Life Detection System Using L & S Band Microwaves in Space ApplicationsDocument34 pagesThe Life Detection System Using L & S Band Microwaves in Space Applicationsvenkat addepalliNo ratings yet

- ISWCS 2014 Program Web1Document31 pagesISWCS 2014 Program Web1ace.kris8117No ratings yet

- Mcquay MDBDocument120 pagesMcquay MDBerwin ktaNo ratings yet

- Lectures On Pipeline and Vector Processing: Unit 6Document27 pagesLectures On Pipeline and Vector Processing: Unit 6viihaanghtrivediNo ratings yet

- FM Demodulation: Eng .Dr./Ahmed HarmalDocument14 pagesFM Demodulation: Eng .Dr./Ahmed HarmalhaniNo ratings yet

- Form 5 Physics Labs 11 To 12 (Corrected)Document11 pagesForm 5 Physics Labs 11 To 12 (Corrected)CåłłmėĎäddyNo ratings yet

- Harmonic Mitigation Using 36-Pulse AC-DC Converter For Direct Torque Controlled Induction Motor DrivesDocument10 pagesHarmonic Mitigation Using 36-Pulse AC-DC Converter For Direct Torque Controlled Induction Motor DrivesNationalinstituteDsnrNo ratings yet

- 11kv Kiosk 1kprDocument26 pages11kv Kiosk 1kprerkamlakar2234No ratings yet

- Street Lighting Design - Layout & Calculations - Electrical4UDocument33 pagesStreet Lighting Design - Layout & Calculations - Electrical4Ulegasu zemene100% (1)

- List of Papers-IcastDocument3 pagesList of Papers-IcastAnonymous Ndsvh2soNo ratings yet

- Converter 156/04: User S ManualDocument31 pagesConverter 156/04: User S ManualIlhami DemirNo ratings yet

- Mitsubishi Electric PUHY-RP YJM-A Data Book EngDocument293 pagesMitsubishi Electric PUHY-RP YJM-A Data Book EngFelixNo ratings yet

- Thyristor Data SheetDocument7 pagesThyristor Data SheetJoab TorresNo ratings yet