Professional Documents

Culture Documents

Permanent Aerial Construction Speccs

Permanent Aerial Construction Speccs

Uploaded by

aryanvertexOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Permanent Aerial Construction Speccs

Permanent Aerial Construction Speccs

Uploaded by

aryanvertexCopyright:

Available Formats

4.16.

2 PERMANENT AERIAL CABLING WITH ADSS OFC

4.16.2.1 GI Pole to be used as per drawing which approved by Planning.

4.16.2.2 Proper Porcelain pulley or metal pulley or supporting clamps to be used for OFC

rolling as per provided pics.

4.16.2.3 Pole should be undergrounded at least 1M and fix with proper 1:2:4 concreting

(200mm (dia)*500mm (Height) all-around of Pole.

4.16.2.4 Approx. 2- 3 mm dia GI string wire (PVC coated) to be used for support of OFC and

OFC not to be tighten directly by wire (in case Aerial cabling done with OFC other

than ADSS OFC).

4.16.2.5 OFC loop approx. 10 m to be kept at every 5th Pole or every turning Points with

mounted “O” ring or clamp on Pole loop radius should not be less than 0.6M.

4.16.2.6 OFC closure should be kept at proper order to avoid OFC bend.

4.16.2.7 Spiral clamp to be used at the pole to tighten the OFC which helps to avoid the

direct tension on the OFC.

Permanent Aerial laying Pics

Permanent Aerial laying Pics

Pole Specification of Permanent Aerial.

A) G.I.pole is to be supplied & installed as per detailed specification given below

a. Overall Height of the pole : 7.00 M

b. Height above the ground : 5.80 M (or as per the site (requirement)

c. Planting depth : 1.20 M (or as per the site(requirement)

d. Section Height of the pole : Bottom - 4.00 M

: Middle - 1.50 M

: Top - 1.50 M

e. Only Hot Dip Galvanized Pole to be used, specification – 410-SP-1 with base plate & vent

hole (Guarantee of Galvanised minimum 30 years)

f. Cross hole is required 20 mm at the height of 600mm from bottom of pole, and 16mm

bar will be used –m300 mm long at the time of grouting/concreting as per drawing.

g. Pole to Pole distance 45 meter only or as per site requirement and as advise by Engineer-

in-charge.

B) Cement Concrete -M-20, Size of the Concrete area -500 mm x 500mm x 1200 mm or 500mm dia

from bottom level to surface level with a height of 1200 mm & additional 300mm dia -250mm

height Concrete to be given above the SGL.

C) The OFC cable drawn along with the G.I. pole with the following materials mentioned below:

a. Pole Clamp as per the size of Pole head, G.I., Shackle Insulator/Spool Insulator along

with Adjustor / turn buckle & nut bolt to be use on pole in zig -zag route & in straight

road, "round shackle" insulator can be use along with wrapping with aluminum wire and

as advised engineer-in-charge.

b. Joint of ADSS cable as per the specification and joint closure to be fix with the Pole by

openable closure box with nut bolt. Maintaining a minimum height of Joint closure 2.50

Mtr from the ground level.

c. Earthing should be done in all erected G.I.Pole by 8/10 swg G.l.wire only.

d. Loop is required at city area in alternative pole & in case of other than cities /Town, at

a distance of 180-220 Mtr or as advice given by the engineer in charge (Maximum loop 10

mtr), Loop to be done properly binding with cable tie and hang on the pole with extra

G.I. cross arm (40 mm x 40 mm x 6mm) with U clamp.

e. Pole marking and numbering in all erected poles.

f. For crossing of river and long distance valley / curve double pole with cross arm to be

used.

You might also like

- En 1090 IngDocument17 pagesEn 1090 IngAkademi NDTNo ratings yet

- 11kV Line - WorkDocument4 pages11kV Line - Worksbpathi50% (2)

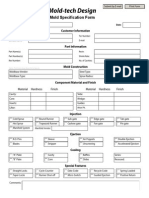

- Mold Design Spec SheetDocument1 pageMold Design Spec Sheetomerscheen0% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- External Mep Services Layout-Ex-1001Document4 pagesExternal Mep Services Layout-Ex-1001Srinivas RegulavalasaNo ratings yet

- iwCmY6WPaXBR - BOQ RABAI 220KV FINALDocument11 pagesiwCmY6WPaXBR - BOQ RABAI 220KV FINALkajale.shrikantNo ratings yet

- SpecifiDocument5 pagesSpecifigokulNo ratings yet

- Cablofil - Cable TrenchDocument2 pagesCablofil - Cable Trenchsubidubi99No ratings yet

- Fencing SpecificationDocument6 pagesFencing Specificationkanji yamashitaNo ratings yet

- Section VII. Technical SpecificationDocument10 pagesSection VII. Technical SpecificationBalkrishna PangeniNo ratings yet

- Technical Specification: Section - C1Document5 pagesTechnical Specification: Section - C1Anonymous EVFw59No ratings yet

- Electrical Scope Part 7Document4 pagesElectrical Scope Part 7shameemNo ratings yet

- BoQ Street LightDocument3 pagesBoQ Street Lightsmshiva59No ratings yet

- Section VII. Technical Specification: Telescopic Steel PoleDocument10 pagesSection VII. Technical Specification: Telescopic Steel PoleBalkrishna PangeniNo ratings yet

- Enquiry - Extranal LightDocument12 pagesEnquiry - Extranal Lightrkpatel40No ratings yet

- Page 164-166 RecommendationsDocument3 pagesPage 164-166 RecommendationsSahil GrgNo ratings yet

- Description of Item Unit Qty Supply Rate: Sl. NoDocument50 pagesDescription of Item Unit Qty Supply Rate: Sl. NoKrishan PandyaNo ratings yet

- Conical MS PoleDocument6 pagesConical MS PoleDivanshu SeerviNo ratings yet

- Technical DetailsDocument2 pagesTechnical DetailsPrashant TrivediNo ratings yet

- Sample Specification From Monoxivent Corrosion Composites: SECTION 15800Document4 pagesSample Specification From Monoxivent Corrosion Composites: SECTION 15800Ahmed NabilNo ratings yet

- Towers ErectionDocument60 pagesTowers Erectionshoaib100% (1)

- RCDocument14 pagesRClexterNo ratings yet

- 228 Specificationofworks Annexure AFinalDocument19 pages228 Specificationofworks Annexure AFinalRoshanNo ratings yet

- Installation 4.5M Motorised Antenna-NEWDocument11 pagesInstallation 4.5M Motorised Antenna-NEWPardomuan SinagaNo ratings yet

- TECHNICAL SPECIFICATIONS CONSTRUCTION RodelDocument12 pagesTECHNICAL SPECIFICATIONS CONSTRUCTION Rodelmary joy PanamaNo ratings yet

- Plano de Balanza Camionera 3x18mDocument1 pagePlano de Balanza Camionera 3x18mRoberto Santos Silva100% (3)

- Sinogulf Project IR Ref No: A.V.-ATC-IR-M-0033 Description: Mock Up For Fan GI Duct Work at C5Document2 pagesSinogulf Project IR Ref No: A.V.-ATC-IR-M-0033 Description: Mock Up For Fan GI Duct Work at C5Ban Saad Abu HammourNo ratings yet

- Section VII. Technical SpecificationDocument17 pagesSection VII. Technical SpecificationBalkrishna PangeniNo ratings yet

- FIRE FIGHTING WORKS (Hydrant System With Wet Riser) N.no: Description of Works QuantityDocument11 pagesFIRE FIGHTING WORKS (Hydrant System With Wet Riser) N.no: Description of Works QuantityHunkNo ratings yet

- DK Z DK Uke % Xzke Ia%&: Phed BSR 2019 2.1.1Document5 pagesDK Z DK Uke % Xzke Ia%&: Phed BSR 2019 2.1.1Sunita SainiNo ratings yet

- Technical Specs of PoleDocument22 pagesTechnical Specs of Poleanon_237992751No ratings yet

- Kohinoor Square ProjectDocument12 pagesKohinoor Square ProjectAnonymous zIYeDYU7zoNo ratings yet

- Specification of Steel Tubular Poles 4009Document2 pagesSpecification of Steel Tubular Poles 4009Akshay DharNo ratings yet

- Technical Specifications 45990Document4 pagesTechnical Specifications 45990Ravi RajNo ratings yet

- Enquiry No. E-1444/Psnr/Scp/Opr Annexure-IDocument6 pagesEnquiry No. E-1444/Psnr/Scp/Opr Annexure-Isreedevi gummadiNo ratings yet

- Mechanical & Electrical Services Checklist Design Stage: Comply N.A. WaiverDocument4 pagesMechanical & Electrical Services Checklist Design Stage: Comply N.A. WaiverKhay Saad0% (1)

- Street Pole - Specification PDFDocument5 pagesStreet Pole - Specification PDFSiddharth RoyNo ratings yet

- Feeder PillarsDocument43 pagesFeeder PillarsRyan BrittNo ratings yet

- Cable Ladder Inspection Report ELDDocument9 pagesCable Ladder Inspection Report ELDNuman SaleemNo ratings yet

- TSS Building MethodDocument7 pagesTSS Building MethodAnubhav Hem Kumar JainNo ratings yet

- Proforma of SchedulesDocument13 pagesProforma of SchedulesAmit Sharma100% (1)

- ANSI-AISC 358-20 - C7SA - InglésDocument7 pagesANSI-AISC 358-20 - C7SA - InglésmanuelNo ratings yet

- Rock Anchor MethodologyDocument7 pagesRock Anchor Methodologyzee shanNo ratings yet

- Streetlight Pole BoqDocument3 pagesStreetlight Pole BoqNitin kambleNo ratings yet

- Chain Link Fencing: Galvanised Green Pve Coated/Galvanised CoreDocument3 pagesChain Link Fencing: Galvanised Green Pve Coated/Galvanised CorevanmurthyNo ratings yet

- Bill of Quantities For James Kituri 4 Bed VillaDocument100 pagesBill of Quantities For James Kituri 4 Bed VillaRic ReeNo ratings yet

- Spec (1) .11 KV Rocking Type Tpgo IsolatorDocument7 pagesSpec (1) .11 KV Rocking Type Tpgo Isolatorarindam90No ratings yet

- Elec BoqDocument4 pagesElec BoqSarvajeet VermaNo ratings yet

- Technical SpecificationsDocument11 pagesTechnical SpecificationsClaude ReyesNo ratings yet

- Requirements of Tower/AntennasDocument8 pagesRequirements of Tower/Antennasvaram1No ratings yet

- CE302 BDocument3 pagesCE302 BsahilkaushikNo ratings yet

- Office NoteDocument6 pagesOffice NoteS N satyanarayanaNo ratings yet

- Method Statement For Construction of PilesDocument27 pagesMethod Statement For Construction of PilesShakti SharmaNo ratings yet

- RANGS R.K SQUARE - BOQ - Plumbing - 140719Document18 pagesRANGS R.K SQUARE - BOQ - Plumbing - 140719Md. Mominul IslamNo ratings yet

- Methodology For Pile Foundation 08-09Document4 pagesMethodology For Pile Foundation 08-09Jeremy Jenkins86% (7)

- Techinical Specifications Welcome To NescoDocument54 pagesTechinical Specifications Welcome To NescotejzabNo ratings yet

- Technical Specifications: Philippine Science High School - Mimaropa Region CampusDocument20 pagesTechnical Specifications: Philippine Science High School - Mimaropa Region CampusNathaniel Gutierez Mangubat100% (1)

- Technical Specifications 11kvDocument106 pagesTechnical Specifications 11kvprasanthvenkatesh60% (5)

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- ADDownload To Read AdDocument15 pagesADDownload To Read AdHaseen KhanNo ratings yet

- PO07132 Overhead Line Distribution Design ManualDocument81 pagesPO07132 Overhead Line Distribution Design Manualnyala chisolaNo ratings yet

- P23008-St-Ti Tree Dry Mess-Rvt21-001 - Sheet - 7m-5650-S-00005 - Dry Mess Foundation PlanDocument1 pageP23008-St-Ti Tree Dry Mess-Rvt21-001 - Sheet - 7m-5650-S-00005 - Dry Mess Foundation Planmaodcb5No ratings yet

- V1-07 Kloeckner Westok A5 Pocket Guide Jun 2020Document36 pagesV1-07 Kloeckner Westok A5 Pocket Guide Jun 2020vomawew647No ratings yet

- Ce Project Prelim Final OutputDocument20 pagesCe Project Prelim Final OutputEDELMIRA ONIFANo ratings yet

- About Metcon Concrete Floor ContractorsDocument9 pagesAbout Metcon Concrete Floor ContractorsMohand EliassNo ratings yet

- Bca Approved Training and Testing Centres (Attcs) in SingaporeDocument3 pagesBca Approved Training and Testing Centres (Attcs) in Singaporesuresh62650% (1)

- GPL-NZ-Quality-F-03 - Determination of Specific Gravity Fine AggregateDocument1 pageGPL-NZ-Quality-F-03 - Determination of Specific Gravity Fine AggregatelavekushNo ratings yet

- SIWES Report Example For Civil Engineering StudentDocument46 pagesSIWES Report Example For Civil Engineering Studentolayinkar30No ratings yet

- Boq Fire FightingDocument23 pagesBoq Fire FightingKEYSTONE INFRA PVT LTDNo ratings yet

- Saes T 744 PDFDocument4 pagesSaes T 744 PDFabdullah sahibNo ratings yet

- Inert Waste Guidance DocumentDocument5 pagesInert Waste Guidance Documentarv fejzNo ratings yet

- United States Patent: Price (45) Date of Patent: Apr. 22, 2008Document11 pagesUnited States Patent: Price (45) Date of Patent: Apr. 22, 2008Aslam KhanNo ratings yet

- Astm C1747 C1747M 13Document2 pagesAstm C1747 C1747M 13KarnalPreethNo ratings yet

- Rigid Non-Metallic Conduit (PVC)Document25 pagesRigid Non-Metallic Conduit (PVC)Mark Edison Mirando100% (1)

- PB 30.5Mm Flush HD Mom N/Ill 1no 1Nc Black Catalogue No:: SpecificationsDocument2 pagesPB 30.5Mm Flush HD Mom N/Ill 1no 1Nc Black Catalogue No:: SpecificationsLogan Marquez AguayoNo ratings yet

- Sea Conquest-Daily Site Safety Review - 22th 24 HRS PTW Valid 22-01-23 To 04-02-2023Document6 pagesSea Conquest-Daily Site Safety Review - 22th 24 HRS PTW Valid 22-01-23 To 04-02-2023Abdul WaheedNo ratings yet

- Basements: Costs: Cost Study of Houses With BasementsDocument32 pagesBasements: Costs: Cost Study of Houses With BasementsJeff TanNo ratings yet

- Assignment No.1 Midterm Part IDocument6 pagesAssignment No.1 Midterm Part IMadonna AradoNo ratings yet

- NFPA-220-2018 - Norma Sobre Tipos de Construcción de Edificios en Función de La Combustibilidad y El Grado de Resistencia Al Fuego de Los Elementos Estructurales de Un Edificio.Document21 pagesNFPA-220-2018 - Norma Sobre Tipos de Construcción de Edificios en Función de La Combustibilidad y El Grado de Resistencia Al Fuego de Los Elementos Estructurales de Un Edificio.aparisuanacNo ratings yet

- ID Specs - CarpetDocument5 pagesID Specs - CarpetGhayas JawedNo ratings yet

- FireSeal Catalouge - InbundenDocument36 pagesFireSeal Catalouge - InbundenNguyen Anh TungNo ratings yet

- 4.effects of Expanded Polystyrene (EPS) Particles On Fire Resistance, Thermal Conductivity and Compressive Strength of Foamed Concrete PDFDocument9 pages4.effects of Expanded Polystyrene (EPS) Particles On Fire Resistance, Thermal Conductivity and Compressive Strength of Foamed Concrete PDFManuel GutarraNo ratings yet

- Urvisha BrochureDocument51 pagesUrvisha BrochureSG Marine/Offshore ConsultantsNo ratings yet

- 2020 VSI Installation ManualDocument52 pages2020 VSI Installation ManualRJKcNo ratings yet

- AddtionalDocument16 pagesAddtionaljudithmaurice76No ratings yet

- BASKARAN.M (SP3D) 7 Yrs ExpDocument7 pagesBASKARAN.M (SP3D) 7 Yrs ExpsahaNo ratings yet