Professional Documents

Culture Documents

AVCN2

AVCN2

Uploaded by

Lộc Nguyễn Sỹ QuýCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AVCN2

AVCN2

Uploaded by

Lộc Nguyễn Sỹ QuýCopyright:

Available Formats

Implementation of Small Hydro Power Plants in

Water Facilities

Martin Kral, Radomir Gono, Miroslava Gono

Department of Electrical Power Engineering

VSB - Technical University of Ostrava

Ostrava, Czech Republic

martin.kral.st3@vsb.cz, radomir.gono@vsb.cz, miroslava.gono@vsb.cz

Abstract—This paper deals with the issue of the location of the turbine into the chamber is well aerated and after

small hydro power plants in the water supply systems. Here are distribution throughout the water that is discharged through the

the possible positions of location the SHPPs in the water supply turbine into the chamber is well aerated and after distribution

system. An important part of the water supply system problems throughout the tank space contributes to better mixing of the

are the resulting losses due to faults in the water lines, which are dosed reagents with the treated water [1], [4-6].

also caused by excessive pressure in the water supply system. To

help with selecting a turbine for SHPP, an application was II. SELECTION OF APPROPRIATE LOCATION FOR SHPP

created. The application results are compared to the real ones.

Many control and regulation elements are used in water

Keywords—small hydro power plant; water facilities; control supply systems and water lines are divided into many pressure

valve bands. In most water mains, it is necessary to additionally

control the pressure, or if necessary flow rate in order to reduce

I. INTRODUCTION the hydrostatic pressure (or flow) in the pipeline within the

Hydro power plants are relatively stable in terms of power required limits, this pressure control (flow) is performed

supply over time. The flow does not change in the order of tens without utilization of excess water energy.

per second and can be estimated in advance in a sufficiently The function of the control valves can be represented by the

precise manner. Partially, retention of water can be utilized, SHPPs, which are able to convert the water energy into

which can then be used to regulate the electrical system at electricity, usable in the area for the self consumption of

intermediate and peak power consumption. The problem of demanding technological units. SHPPs in water supply systems

further development of hydro power plants is the fact that most have also other benefits. The need is for maximum utilization

suitable and economically efficient sites have already been of the production capacity of the proposed SHPP without

occupied. That is why it is a challenge to find new limiting the production activity of the water technology.

technological solutions that would allow building for so far

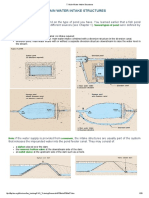

unoccupied sites. In addition to the installation of hydro power An example of possible positioning of the control valves is

plants into watercourses, it is possible to use the hydro- shown in Fig. 1.

energetic potential of the supply water - raw and drinking water

from the water treatment plants or water reservoirs and other

water facilities capacity (in the use of reducing valves,

Industrial Water Treatment, etc.). Under the water cycle in

water companies we understand all the basic activities related

to the operation of public water supply and sewerage systems.

Water Facilities belong to the energy-intensive facilities.

The installation of the SHPP will change its operation to self-

sufficient energy and in many cases allow surplus energy to be

sold to the public power grid. When installing SHPP in

drinking water supply systems, there is no need for long-term

interruption of water supply for the population, nor can it be

contaminated. The economic return of such projects is

calculated in the order of two to five years. The SHPP installed

on a penstock of the water treatment plant helps to optimize the

entire process of treating raw water to drinking water since the Fig. 1. Examples of possible placement of control valves [2].

water that is discharged through PS – pumping station, WR – water reservoir, WT – water treatment, 1 –

control valve of flow, 2 – control valve to maintain the water level in the

This research was partially supported by the SGS grant from VSB -

Technical University of Ostrava (No. SP2019/20) and by the project water reservoir, 3 – control valve of pressure

TUCENET (No. LO1404).

978-1-7281-1334-0/19/$31.00 ©2019 IEEE

The basic requirements for control valves can be defined:

• Pressure control,

• Flow control,

• Water level control.

An example of use of control valves in point 1 in Fig. 1:

Fig. 2. Possible placement of SHPP in the water supply system.

Basic regulation of flow rates at higher differential

gradients based on the principle of linear throttling. Elimination III. CONTROLLED SHPPS FOR REDUCE LOSSES IN WATER LINE

of starting pressure peaks without vibration, unacceptable noise Leaks in water distribution networks are the most common

limits or damage to the piping system due to cavitation erosion. causes of water losses, which can reach up to 50 % compared

An example of the use of control valves in point 2 in Fig. 1: to the amount of water produced by water facilities.

Investments spent on overcoming these problems tend to focus

When filling water reservoirs through pressure pipelines on intentions that aim only at further increasing water

from pumping stations or via gravity feeders, it is necessary to production, instead of supporting programs to reduce water

ensure that the energy of water and control the flow directly to losses.

the required water level according to current consumption. This

is done by sensing the height or pressure of the water column The basic aspect to change this way of thinking to more

with the signalling to the actuator of a suitable control valve. economic and also ecological is the introduction into the

operational practice of such technical applications based on the

An example of the use of control valves in point 3 in Fig. 1: principle of controlled pressure (flow) regulation.

Each of the two settlements is at different altitude relative An extremely efficient method can be achieved by using a

to the pumping station. Therefore, it is necessary to set combination of functions of control valves with modulation

different pressure zones on individual feeders using the control actuators with PID control. In this sense, the SHPPs can also

valves. operate in the water supply system, where it is possible to

The values of the pressure levels can be set as follows: control the energy consumption of water moving. This can be

done by, for example the following SHPP equipment features:

• fixed constant pressure setting over 24 hours,

• use of a synchronous generator,

• two-stage pressure setting - day mode, - night mode,

• use of asynchronous generator with Squirrel-cage rotor,

• Flexible modulating pressure control in relation to the

daily collection time (PID) [2]. • use of a turbine where rotor blades can be rotated.

Design of SHPP location in the water supply system: This issue is described in cases using control valves, which

can be replaced by placing the SHPP into the water supply

In the previous section II., the possibility of placing the system at the positions of the mentioned control valves.

SHPP in place of the control valves is indicated, due to the

unnecessarily thwart energy of the water in the control valves. While the production capacity of water is increasing, the

Each such valve consumes energy, and we can use SHPP to structure of water line systems, originally designed for much

produce energy. It is not necessary to change batteries so often, smaller quantities remains the same resulting is increases in

which brings operational and economic benefits. The most pressures.

environmentally friendly is not energy from renewable or In particular, commonly fitted valves, which must regulate

alternative sources, but the energy that we did not have to flow rates and pressures to maintain a constant supply of

consume. However, there are other possibilities of placing drinking water, can not perform their function in an appropriate

SHPP in water supply systems. It is not always necessary to manner.

regulate the pressure (flow) level to the desired value at places

where the SHPP can be placed. An example of this location is If these valves can not be controlled sufficiently flexibly,

in Fig. 2. As can be seen from the picture in the water supply large pressure differences occur in water line systems, resulting

system there are many suitable places where the SHPP can be in enormous water losses due to leakages on the water system

placed. The demonstrations shown are not just locations that and cracking of the pipes, eventually collapsing the entire

are suitable for downstream or flow rates in the waterline. But water line system.

some locations also have other positive effects on water supply When dealing with these conditions, control valves are used

systems, such as at point 2, the SHPP has a positive effect on to control pressure and flow.

the mixing of additives added to water for hygienic reasons. At

the other points: 1, 3, 4 and 5, high water level values are use. Frequent fluctuations pressures in water lines from large

water consumption during day and night, depending on the

weekly cycle or alternation of seasonal periods are the causes

of enormous losses of water in the lines and pipe cracking.

To limit such operating and fault conditions, it is necessary the input data of the water head and flow of the water for which

to ensure that pressures in the water supply system are kept at we want to recommend the turbine, a recommendation is

the lowest possible level to ensure that water supplies are indicated with a circle with a red yellow fill and a description

maintained in accordance with current requirements. of the inserted data. The advantage of this view is in the

graphical display, there is not one type of turbine strictly

In Fig. 3 shows the percentage distribution of leakage displayed, but the person using this application can choose a

losses in water supply systems. suitable turbine according to their preferences.

Fig. 3. Leaks in the water supply systems [3].

Invisible leaks with small range isn't possible to monitor

with acoustic method. These leaks are 25 % of total losses.

Invisible leaks with larger range is possible to monitor with

acoustic method. These leaks are 30 % of total losses.

Visible leaks is possible to monitoring with lot of

monitoring method. These leaks are 45 % of total losses.

IV. AUXILIARY APPLICATION FOR THE SELECTION OF A

SUITABLE TURBINE SHPP

This application is created in Microsoft Office Excel. Part

of the application is not just showing the appropriate type of

turbine for the SHPP, but also showing the group of SHPP. In

Fig. 4 is shown the cover page of the auxiliary application. You

can see a basic description of the features.

Fig. 5. Display of recommended SHPP turbine auxiliary application.

In order to illustrate the appropriate SHPP turbine, it is

indispensable to enter the parameters of the water flow and

For example after entering the input data with the flow Q =

water head.

2 / and the specific energy of water Y = 300 / . In this

case, the Francis turbine is the ideal choice.

To perform a real-time application functionality check:

We applied the test to real-time data for the SHPPs, and

compared the results with the data in the database:

http://mve.energetika.cz/uvodp/vod-dila.htm. We did the test

for hundreds of cases. For example, Table 1 shows a small

sample of the comparison results. It is clear that the results do

not always coincide with the real situation, these

inconsistencies are similar, and we can always observe a

discrepancy when selecting one of the two turbines: Kaplan -

Francis and Banki - Pelton. The real state tends to the first of

them, Kaplan and Banki. This discrepancy is possible to

explain by the investment demands and complexity of turbine

production.

Fig. 4. Entry page with the auxiliary application inputs.

Turbine selection depends primarily on location and flow. It is

dependent on the topographical conditions and flow again is

In Fig. 5 is then shown a Y / Q diagram with working areas associated with the population size and corresponding demand

of the basic types of water turbines, the data in the diagram are water. In the literature, we can find some research on

based on the information in the publication [4]. According to

estimating the potential of hydroelectric power plants in wastewater systems [8].

TABLE I. A SAMPLE OF SHPPS COMPARED WITH AN AUXILIARY APPLICATION

River Address Flow [ ∙ Energy of Installed Recommended type of Power of Efficiency [%]

] water [ ∙ turbine turbine SHPP

] [ ]

Žibřidovický Pusté

1,25 106,4 Francis Francis 93,68 70

potok Žibřidovice 71

Oslava u Hor.Dlouhá

0,4 39,2 Kaplan Kaplan 11,84 76

Sovince Loučka 11

Německý

Odra 1,6 39,2 Kaplan Kaplan 51,80 82

Jeseník 116

Velička Hranice n.Mor. 0,29 51,5 Francis Kaplan 11,54 77

Morava Potůčník 0,04 39,2 Pelton Banki 1,18 75

Morava Kopřivná 50 0,05 98,1 Pelton Banki 3,59 73

Třebůvka Loštice 78 1,5 26,5 Francis Kaplan 31,08 78

místní přítok

Rudoltovice 82 0,12 39,2 Pelton Banki 3,55 75

Odry

Desná Rejhotice 48/52 1,35 60,8 Kaplan Kaplan 66,60 81

Hustopeče nad

Bečva 0,9 31,4 Francis Kaplan 20,72 73

Bečvou 117

V. CONCLUSION Putting small scale hydropower stations into operation

will be increasingly advantageous, as they can exploit the

At the beginning there are mentioned the advantages of hydraulic potential of the given region. They represent a

using hydro power plants. But the new installation of hydro permanent source of propulsion which belongs to what we

power plants is not easy at the present time. Hydroelectric call “clean“, renewable energy sources. Their operation takes

potential can also be found in water supply and sewerage only minimum electricity necessary for the service of the

networks, irrigation and cooling systems and many other facility and does not pollute the environment. In contrast to

artificial water systems. There is also described an photovoltaic or wind power stations, the amount of

innovative way of placing small hydro power plants in water electricity produced by them does not fluctuate with the

supply facilities in the introduction. change of day into the night or immediate weather changes.

In the second chapter there are described the basic It is possible to plan supplies better and then power network

methods of regulation of pressure, water flow and level of is not overloaded.

water in water supply systems, and also the possible

placement of SHPPs in the water supply system.

Other chapter deals with the severity of water leaks from REFERENCES

the water supply systems and the solution of these situations [1] B. Leyland, Small hydroelectric engineering practice. Boca Raton:

using the control valves and the SHPPs. CRC Press, 2014.

[2] J. Chrástek, Regulační armatury ve vodárenství – volby, návrhy,

The final part describes the auxiliary application for the výpočty. Voda Zlín, 2015.

selection of a suitable turbine, the calculation of the power [3] J. Chrástek, Redukce ztrát netěsnostmi u vodárenských distribučních

and efficiency of the SHPP. To illustrate how the application sítí. Voda Zlín, 2007.

works, this chapter also shows a comparison of the installed [4] P. Gabriel, F. Čihák, P. Kalandra, Malé vodní elektrárny. Praha:

turbines in existing SHPPs and recommended types of ČVUT v Praze, 1998.

turbines for these places. [5] J. Kriš, Vodárenstvo I: zásobovanie vodou. Bratislava: Slovenská

technická univerzita v Bratislave vo Vydavateľstve STU, 2006.

We miss data about the size of this potential. Estimates [6] J. Holy, J. Skorpil, T. Klor, Z. Martinek, Trends and Technologies in

made in countries where power plants that use water from the Field of Energy Storage. Stara Lesna: Proceedings

existing artificial networks to produce energy are much more Elektroenergetika 2015, 2015.

widespread, indicate that this is a potential undervalued. For [7] E. Malicka, Co produkuja elektrownie wodne, czyli definicja

example, there are around 100 power plants in Switzerland hydroenergii w świetle przepisów prawnych. Kielce: Energetyka

Wodna, 2014.

using water and sewage networks for energy production,

[8] C. Bousquet, I. Samora, P. Manso, L. Rossi, P. Heller, A.J. Schleiss,

which produce more than 83 GWh of electricity annually. Assessment of hydropower potential in wastewater systems and

The number of power plants that could be built in such application to Switzerland. Renew. Energy 2017, 2017.

networks is five times higher. Together with existing ones,

they could produce nearly 310 GWh of energy annually [7].

You might also like

- EPRI Closed Cooling Water Chemistry Guideline, Revision 1Document182 pagesEPRI Closed Cooling Water Chemistry Guideline, Revision 1jycortes100% (7)

- Manual For Canal Maintenance OperationDocument71 pagesManual For Canal Maintenance OperationNguyen Van Kien100% (1)

- Control in Irrigation CanalsDocument12 pagesControl in Irrigation CanalsAnuragNo ratings yet

- Varying ViewsDocument5 pagesVarying Viewsforevertay2000No ratings yet

- Centrifugal Pump Performance Characteristics For DDocument6 pagesCentrifugal Pump Performance Characteristics For DPinaki SankarNo ratings yet

- UW16007FU1Document8 pagesUW16007FU1Nicko Samar IndicoNo ratings yet

- Energies: Water Hammer Control Analysis of An Intelligent Surge Tank With Spring Self-Adaptive Auxiliary Control SystemDocument19 pagesEnergies: Water Hammer Control Analysis of An Intelligent Surge Tank With Spring Self-Adaptive Auxiliary Control SystemMohamad KansoNo ratings yet

- Mto Inercia de Masas PDFDocument7 pagesMto Inercia de Masas PDFClaudio DualibeNo ratings yet

- Energy and Cost Savings Through Pumping Stations Rehabilitation. Case Study in BucharestDocument8 pagesEnergy and Cost Savings Through Pumping Stations Rehabilitation. Case Study in Bucharestrajamannar322No ratings yet

- Small Scale Hydropower: Generator Analysis and Optimization For Water Supply SystemsDocument8 pagesSmall Scale Hydropower: Generator Analysis and Optimization For Water Supply SystemsRobsonMbiziNo ratings yet

- Eng-Recycled-Cajethan Cajethan NwosuDocument10 pagesEng-Recycled-Cajethan Cajethan NwosuImpact JournalsNo ratings yet

- Design and Experimental Study of Oil-Based Pressure-Compensated Underwater Hydraulic SystemDocument12 pagesDesign and Experimental Study of Oil-Based Pressure-Compensated Underwater Hydraulic SystemGanesh ChodisettiNo ratings yet

- Intelligence-Based Hybrid Control For Power Plant Boiler: Wei Wang, Han-Xiong Li, and Jingtao ZhangDocument8 pagesIntelligence-Based Hybrid Control For Power Plant Boiler: Wei Wang, Han-Xiong Li, and Jingtao ZhangGanesh Kumar ArumugamNo ratings yet

- A Fault Tolerant and Energy Efficient Control Strategy For Primary Secondary Chilled Water Systems in Buildings 2011 Energy and BuildingsDocument11 pagesA Fault Tolerant and Energy Efficient Control Strategy For Primary Secondary Chilled Water Systems in Buildings 2011 Energy and BuildingsAravindan MohanNo ratings yet

- PPE Project HydroPowerDocument54 pagesPPE Project HydroPowerTejas SharmaNo ratings yet

- A Study of Energy Optimisation of Urban Water Distribution Systems Using Potential ElementsDocument19 pagesA Study of Energy Optimisation of Urban Water Distribution Systems Using Potential ElementsMaraah IssaNo ratings yet

- Water 15 03998Document14 pagesWater 15 03998jyotsna pandeyNo ratings yet

- Simulation in Turbine GoverningDocument4 pagesSimulation in Turbine GoverningChannaNo ratings yet

- Icecs 2002 Cd-Rom Proceedings: Welcome To TheDocument5 pagesIcecs 2002 Cd-Rom Proceedings: Welcome To TheosamahNo ratings yet

- Production Control SystemsDocument12 pagesProduction Control SystemsTony EduokNo ratings yet

- SEMINAR Project KC208H2 - Nguyen Huynh Tan NguyenDocument18 pagesSEMINAR Project KC208H2 - Nguyen Huynh Tan NguyenNguyên NguyễnNo ratings yet

- Accepted ManuscriptDocument33 pagesAccepted ManuscriptAbhishek Kumar SinhaNo ratings yet

- DesignofEnergyEfficient ISFP Beidaihe 2007 RydbergKEDocument8 pagesDesignofEnergyEfficient ISFP Beidaihe 2007 RydbergKEkyaw san ooNo ratings yet

- Energy Efficiency 2Document9 pagesEnergy Efficiency 2Uallace ReisNo ratings yet

- Constant Vs Variable FlowDocument2 pagesConstant Vs Variable FlowbatazivoNo ratings yet

- Designing An Optimized Model of Water Lifting Device Without Conventional PracticesDocument8 pagesDesigning An Optimized Model of Water Lifting Device Without Conventional PracticesKishore RaviNo ratings yet

- 1 s2.0 S0011916406003778 MainDocument12 pages1 s2.0 S0011916406003778 Mainmona aminNo ratings yet

- Surge Tank ChimeneaDocument15 pagesSurge Tank ChimeneaMiguel PrietoNo ratings yet

- 2-Guidelines For Design - Hydro PDFDocument19 pages2-Guidelines For Design - Hydro PDFceice2013No ratings yet

- Ijesat 2012 02 05 14 PDFDocument8 pagesIjesat 2012 02 05 14 PDFPuttaraje GowdaNo ratings yet

- 01chapter1 PDFDocument9 pages01chapter1 PDFJboar TbenecdiNo ratings yet

- Energy Efficient Hydraulic and Regenerative Cap - SICFP - 2005 - K-E RydbergDocument13 pagesEnergy Efficient Hydraulic and Regenerative Cap - SICFP - 2005 - K-E RydbergNemoz ZrNo ratings yet

- Energy: J. Chen, H.X. Yang, C.P. Liu, C.H. Lau, M. LoDocument10 pagesEnergy: J. Chen, H.X. Yang, C.P. Liu, C.H. Lau, M. LoNung NingNo ratings yet

- 1.2 Assignment Capstone Sir SamizieDocument15 pages1.2 Assignment Capstone Sir SamizieAfnanFadlanBinAzmiNo ratings yet

- Embedded System Based Monitoring and Control System of Submersible PumpDocument4 pagesEmbedded System Based Monitoring and Control System of Submersible PumpInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- 340 PumpsDocument5 pages340 Pumpsjemakl1568No ratings yet

- Dynamics of Hydronic SystemsDocument20 pagesDynamics of Hydronic Systemsmostafa mohamedNo ratings yet

- IJAPE018Document4 pagesIJAPE018chhandak beraNo ratings yet

- Pre and Post CompensationDocument10 pagesPre and Post CompensationRitesh SinghNo ratings yet

- Ppe Project.Document8 pagesPpe Project.bagwanhaji644No ratings yet

- Solar Agricultural Water Pumping System With Auto TrackingDocument48 pagesSolar Agricultural Water Pumping System With Auto Trackingvmurali.infoNo ratings yet

- U 47AlAinDocument2 pagesU 47AlAinkumarnadarajahNo ratings yet

- Water: Energy Recovery Using Micro-Hydropower Technology in Water Supply Systems: The Case Study of The City of FribourgDocument16 pagesWater: Energy Recovery Using Micro-Hydropower Technology in Water Supply Systems: The Case Study of The City of Fribourggilmark mongaliniNo ratings yet

- Paper Id 163Document9 pagesPaper Id 163Noor K. MalikNo ratings yet

- 2.water Lifting For IrrigationDocument32 pages2.water Lifting For IrrigationDavinder KandoriaNo ratings yet

- Energy Efficient Hydraulic Systems and Regenerative CapabilitiesDocument13 pagesEnergy Efficient Hydraulic Systems and Regenerative Capabilitiesn3tr0xNo ratings yet

- Ambor, Randi T. 10-19-2021Document31 pagesAmbor, Randi T. 10-19-2021AbdulJabbarLawiNo ratings yet

- Guidelines For Hydraulic Design of SHP - Chap5Document9 pagesGuidelines For Hydraulic Design of SHP - Chap5FlavioNo ratings yet

- Logic Gate Based Automatic Water Level CDocument6 pagesLogic Gate Based Automatic Water Level Cabu talha priyontoNo ratings yet

- Water Level Controller: Gpcet 1 Department of EceDocument36 pagesWater Level Controller: Gpcet 1 Department of EceKRVAMSI_432No ratings yet

- Solar Powered Water Pumping System PDFDocument46 pagesSolar Powered Water Pumping System PDFVijay Nishad100% (1)

- Cold Water Supply - Part2Document8 pagesCold Water Supply - Part2Derek YuNo ratings yet

- Modeling and Simulation of Prototype of Boiler Drum Level ControlDocument6 pagesModeling and Simulation of Prototype of Boiler Drum Level ControlJorge FrancoNo ratings yet

- Manual For Canal Maintenance Operation PDFDocument71 pagesManual For Canal Maintenance Operation PDFmanoj verma100% (1)

- Water: Hydropower Generation Through Pump As Turbine: Experimental Study and Potential Application To Small-Scale WDNDocument19 pagesWater: Hydropower Generation Through Pump As Turbine: Experimental Study and Potential Application To Small-Scale WDNJuuzou Tooru Karma TobioNo ratings yet

- SOMC, Vizag Paper Presentation For NTPC-IPS-2018Document6 pagesSOMC, Vizag Paper Presentation For NTPC-IPS-2018Sooraj Surendran SugathaNo ratings yet

- Pressure Booster SizingDocument4 pagesPressure Booster SizingSam Choi100% (1)

- PSD Ceu 177may11Document9 pagesPSD Ceu 177may11Del MoralesNo ratings yet

- Boiler Drum Level Control by Using WideDocument12 pagesBoiler Drum Level Control by Using WideChristianaPrasetya100% (2)

- Diagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceFrom EverandDiagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceNo ratings yet

- Water Supply Network in Rural AreaDocument17 pagesWater Supply Network in Rural Areaankitmehta131No ratings yet

- Study of Aquatic Protozoan in Neher-E-Ambary in Aurangabad VicinityDocument7 pagesStudy of Aquatic Protozoan in Neher-E-Ambary in Aurangabad Vicinitysouthraj5905No ratings yet

- Aqualife All-In Eng DatasheetDocument4 pagesAqualife All-In Eng DatasheetIsrael ExporterNo ratings yet

- MCGM BLDG Sor 13.11Document210 pagesMCGM BLDG Sor 13.11Shashi VaishNo ratings yet

- Code of Practice For Water SupplyDocument115 pagesCode of Practice For Water SupplyDoug WeirNo ratings yet

- Surveillance of Drinking Water UploadedDocument19 pagesSurveillance of Drinking Water UploadedPrasad DsaNo ratings yet

- 2-5b Contoh Standard Watermain DrawingsDocument59 pages2-5b Contoh Standard Watermain Drawingsizzati istiharaNo ratings yet

- Technical Specification: 12-SeriesDocument13 pagesTechnical Specification: 12-SeriesKhantoNo ratings yet

- RFP - Kamal Vihar 24.08.11Document88 pagesRFP - Kamal Vihar 24.08.11vineetvcebNo ratings yet

- MPRWA Agenda Packet 07-14-16Document32 pagesMPRWA Agenda Packet 07-14-16L. A. PatersonNo ratings yet

- Eweb Water Design and Construction Standards PDFDocument91 pagesEweb Water Design and Construction Standards PDFmarkigldmm918No ratings yet

- 1 - Pressure Control For Minimizing Leakage in Water Distribution SystemsDocument12 pages1 - Pressure Control For Minimizing Leakage in Water Distribution SystemsMiran SadiqNo ratings yet

- Governance Models For AguaClara PDFDocument127 pagesGovernance Models For AguaClara PDFAshley HeNo ratings yet

- SC13003-C9001-U10-0002-Commissioning Plan Procedure For MBOP - 24-08-2015 PDFDocument70 pagesSC13003-C9001-U10-0002-Commissioning Plan Procedure For MBOP - 24-08-2015 PDFArya Bima Aji KusumaNo ratings yet

- Water Supply ProjectDocument89 pagesWater Supply ProjectMustefa Mohammed Adem100% (3)

- 7 Fao OrgDocument20 pages7 Fao OrgJoey Cross fxNo ratings yet

- Hydraulic Structures at A Crossroads Towards The SDGsDocument12 pagesHydraulic Structures at A Crossroads Towards The SDGsBruna Dantas de SousaNo ratings yet

- Cold Water Plumbing Design NotesDocument18 pagesCold Water Plumbing Design NotesShahril Shahibullah100% (1)

- Creamery Juice HACCP Plan New - RtfwordDocument28 pagesCreamery Juice HACCP Plan New - RtfwordShenneth De CastroNo ratings yet

- Kruthumal Case Study Report - Final-Feb2014-1Document26 pagesKruthumal Case Study Report - Final-Feb2014-1Alamandha Madhan Kumar100% (1)

- Maximum Flow Velocities in Water SystemsDocument5 pagesMaximum Flow Velocities in Water SystemsFAIYAZ AHMADNo ratings yet

- Design and Sizing of Water Supply Systems Using Loading Units - Time For A Change?Document13 pagesDesign and Sizing of Water Supply Systems Using Loading Units - Time For A Change?Patrick PhoenixNo ratings yet

- FY 2022 Discretionary RequestDocument58 pagesFY 2022 Discretionary RequestEric WeissNo ratings yet

- ĐỀ SỐ 07-HSG ANH 9Document9 pagesĐỀ SỐ 07-HSG ANH 9Linh Trúc0% (1)

- 6 Great Benefits of Using Carbon Steel Pipe: In, byDocument3 pages6 Great Benefits of Using Carbon Steel Pipe: In, byMarnel Roy MayorNo ratings yet

- Noritz Tankless Water Heater Descale ProcedureDocument7 pagesNoritz Tankless Water Heater Descale ProcedureJennifer WatsonNo ratings yet

- Hybrid Solution and Pump-Storage Optimization in Water Supply System Efficiency: A Case StudyDocument7 pagesHybrid Solution and Pump-Storage Optimization in Water Supply System Efficiency: A Case StudyPatricio LeonardoNo ratings yet

- BLUE BOOK 1 DRPLN JM 2015 2019 Revisi 2016Document28 pagesBLUE BOOK 1 DRPLN JM 2015 2019 Revisi 2016Budi HarsonoNo ratings yet

- Dallas New Water Drought Contingency PlanDocument134 pagesDallas New Water Drought Contingency PlanRobert Wilonsky100% (1)