Professional Documents

Culture Documents

(Asce) MT 1943-5533 0000095

(Asce) MT 1943-5533 0000095

Uploaded by

Rachit SharmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(Asce) MT 1943-5533 0000095

(Asce) MT 1943-5533 0000095

Uploaded by

Rachit SharmaCopyright:

Available Formats

TECHNICAL NOTES

Empirical Stress-Strain Model for Unconfined High-Strength

Concrete under Uniaxial Compression

Zhao-Hui Lu1 and Yan-Gang Zhao, M.ASCE2

Abstract: In this note, a number of empirical models available in the literature of the complete stress-strain curve for unconfined

high-strength concrete under uniaxial compression are reviewed and investigated using the published experimental data. Based on the

investigations, a new empirical model with emphasis on the softening branch is proposed to generate the complete stress-strain relation-

ship for high-strength concrete. An application of the new empirical model to published experimental data on normal weight concretes

over a wide strength range demonstrates that the present model gives a good representation of the mean behavior of the actual stress-strain

response.

DOI: 10.1061/共ASCE兲MT.1943-5533.0000095

CE Database subject headings: Stress strain relations; High-strength concrete; Compression.

Author keywords: Stress-strain relations; High-strength concrete; Compression.

Introduction searchers for generating the complete stress-strain relationship for

HSC and to propose a new model that can give a good represen-

The use of high-strength concrete 共HSC兲 in civil and building tation of the mean behavior of the actual stress-strain response.

engineering systems is increasing around the world because it Available experimental data of stress-strain curves for unconfined

offers many advantages over conventional concrete. A complete HSC under uniaxial compression published in the literature are

stress-strain curve for unconfined HSC subjected to uniaxial com- used for this purpose.

pression is necessary for the nonlinear analysis of structural mem-

bers and as a basis for the derivation of design curves. Moreover,

it can serve as the basis for the stress-strain relationships of HSC Review and Assessment of Existing Empirical

under a biaxial or triaxial state of stress due to the active or Models

passive constraints from surrounding concrete or structural mem-

bers. A considerable volume of experimental and theoretical re- In general, existing empirical models of stress-strain relationships

search has been conducted, and several empirical models have for normal weight HSC can be divided into two categories ac-

been proposed in the past few decades 共e.g., Wang et al. 1978; cording to their expressional forms. One category is based on

Tomaszewicz 1984; Carreira and Chu 1985; Dahl 1992; Hsu and equations suggested by Popovics 共1973兲 and the other category

Hsu 1994; Wee et al. 1996; Van Gysel and Taerwe 1996; Kumar uses a form of equations proposed by Sargin et al. 共1971兲, which

2004兲. These models usually show good agreement with some are, respectively, listed in Tables 1 and 2. In these models, se-

experiments, especially with the results used for the model devel- lected parameters were included in the stress-strain curves and

opment, but there is uncertainty whether they can provide satis- then they were calibrated using the test results 共Lokuge et al.

factory predictions or not in many other cases. 2005兲.

Therefore, the main objective of the present note is to evaluate According to the definition of  in Tomaszewicz’s 共1984兲 for-

the applicability of the existing models proposed by various re- mula, when f ⬘c ⬎ 85 MPa 共12.33 ksi兲,  will be less than zero.

That is to say, the use of the Tomaszewicz’s formula is limited to

1

Associate Professor, School of Civil Engineering and Architecture, f ⬘c ⬍ 85 MPa 共12.33 ksi兲, which is apparently not useful because

Central South Univ., 22 Shaoshannan Rd., Changsha 410075, China; for- nowadays HSC with higher compressive stress is available for

merly, JSPS Postdoctoral Research Fellow, Dept. of Architecture, Kana- structural applications.

gawa Univ., 3-27-1 Rokkakubashi, Kanagawa-ku, Yokohama 221-8686, A set of experimental stress-strain curves has been used by

Japan. E-mail: Lzh2076@hotmail.com Wee et al. 共1996兲 to assess the empirical models proposed by

2

Professor, Dept. of Architecture and Building Engineering, Hognestad 共1951兲, Wang et al. 共1978兲, Comité Euro-International

Kanagawa Univ., 3-27-1 Rokkakubashi, Kanagawa-ku, Yokohama 221- du Béton-Fédération Internationale de la Précontrainte 共CEB-FIP兲

8686, Japan 共corresponding author兲. E-mail: Zhao@kanagawa-u.ac.jp

共1993兲, and Carreira and Chu 共1985兲. It was found that for HSC

Note. This manuscript was submitted on August 14, 2008; approved

on March 4, 2010; published online on March 6, 2010. Discussion period

with compressive strength higher than 60 MPa 共8.70 ksi兲, the

open until April 1, 2011; separate discussions must be submitted for equation proposed by Hognestad 共1951兲 is no longer applicable

individual papers. This technical note is part of the Journal of Materials and the computation involved in generating the stress-strain

in Civil Engineering, Vol. 22, No. 11, November 1, 2010. ©ASCE, ISSN curves using the model of Wang et al. 共1978兲 is rather tedious and

0899-1561/2010/11-1181–1186/$25.00. complex since two sets of coefficients are used, respectively, for

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / NOVEMBER 2010 / 1181

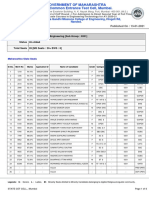

Table 1. Stress-Strain Models for HSC Based on Popovics 共1973兲

Researchers Equations

Popovics 共1973兲 f c = f c⬘共 / 0兲 / 关 − 1 + 共 / 0兲 兴;

0 = 735共f c⬘兲0.25 ⫻ 10−6;  = 1.0+ 0.058f c⬘

Tomaszewicz 共1984兲 0 ⱕ ⱕ 0, f c = f c⬘共 / 0兲 / 关 − 1 + 共 / 0兲兴;

⬎ 0, f c = f c⬘共 / 0兲 / 关 − 1 + 共 / 0兲k兴;

0 = 700共f c⬘兲0.31 ⫻ 10−6;  = 8.32/ 关8.32− 共f c⬘兲0.475兴; k = f c⬘ / 20

Carreira and Chu 共1985兲 f c = f c⬘共 / 0兲 / 关 − 1 + 共 / 0兲兴;

= 1 / 关1 − 共f c⬘ / 0Eit兲兴; Eit = 0.073 6w1.51共f c⬘兲0.3; 0 = 共1 , 680+ 7.1f c⬘兲 ⫻ 10−6

Hsu and Hsu 共1994兲 0 ⱕ ⱕ d, f c = nf c⬘共 / 0兲 / 关n − 1 + 共 / 0兲n兴;  = 共f c⬘ / 65.23兲3 + 2.59

For 0 ⱕ ⱕ 0, n = 1;

For 0 ⱕ ⱕ d, n = 1 if 0 ⬍ f c⬘ ⬍ 62 MPa; n = 2 if 62ⱕ f c⬘ ⬍ 76 MPa;

n = 3 if 76ⱕ f c⬘ ⬍ 90 MPa; and n = 5 if f c⬘ ⱖ 90 MPa

⬎ d, f c = 0.3f c⬘ exp关−0.8共 / 0 − d / 0兲0.5兴

Wee et al. 共1996兲 0 ⱕ ⱕ 0, f c = f c⬘共 / 0兲 / 关 − 1 + 共 / 0兲兴;

⬎ 0, f c = k1 f c⬘共 / 0兲 / 关k1 − 1 + 共 / 0兲k2兴;

0 = 780共f c⬘兲1/4 ⫻ 10−6; Eit = 10, 200共f c⬘兲1/3;

= 1 / 关1 − f c⬘ / 共0Eit兲兴; k1 = 共50/ f c⬘兲3 and k2 = 共50/ f c⬘兲1.3

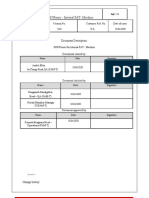

Table 2. Stress-Strain Models for HSC Based on Sargin et al. 共1971兲

Researchers Equations

Sargin et al. 共1971兲 f c = f c⬘关A共 / 0兲 + 共D − 1兲共 / 0兲 兴 / 关1 + 共A − 2兲共 / 0兲 + D共 / 0兲2兴;

2

A = Eit0 / f c⬘; D = 0.65− 7.25f c⬘ ⫻ 10−3; Eit = 5975共f c⬘兲1/2; 0 = 0.0024

Wang et al. 共1978兲 f c = f c⬘关A共 / 0兲 + B共 / 0兲2兴 / 关1 + C共 / 0兲 + D共 / 0兲2兴

共Two different sets of coefficients are used for the ascending and descending

branches兲

Comité Euro-International du Béton-Fédération Internationale 0 ⱕ ⱕ max, f c = f c⬘关共Eit / E0兲共 / 0兲 − 共 / 0兲2兴 / 关1 + 共Eit / E0 − 2兲共 / 0兲0兴;

de la Précontrainte 共CEB-FIP兲 共1993兲

⬎ max, f c = f c⬘兵关 / 共max / 0兲 − 2 / 共max / 0兲2兴共 / 0兲2 + 关4 / 共max / 0兲 − 兴共 / 0兲其;

max = 0兵关Eit / 共2E0兲 + 1兴 / 2 + 关Eit / 共2E0兲 + 1兴2 / 4 − 关1 / 2兴1/2其

= 4关共max / 0兲2共Eit / E0 − 2兲 + 2共max / 0兲 − Eit / E0兴 / 关共max / 0兲共Eit / E0 − 2兲 + 1兴2

0 = 0.002 2; Eit = 21, 500␣E共f c⬘ / 10兲1/3

Van Gysel and Taerwe 共1996兲 0 ⱕ ⱕ max, f c = f c⬘关共Eit / E0兲共 / 0兲 − 共 / 0兲2兴 / 关1 + 共Eit / E0 − 2兲共 / 0兲兴

⬎ max, f c = f c⬘ / 兵1 + 关共 / 0 − 1兲 / 共max / 0 − 1兲兴2其

max = 0兵关Eit / 共2E0兲 + 1兴 / 2 + 关Eit / 共2E0兲 + 1兴2 / 4 − 关1 / 2兴1/2其

Eit = 21, 500␣E共f c⬘ / 10兲1/3; 0 = 700共f c⬘兲0.31 ⫻ 10−6

Fig. 1. Comparisons of stress-strain curves generated by the model of Wee et al. 共1996兲 with experimental data of Wang et al. 共1978兲 and Hsu

and Hsu 共1994兲

1182 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / NOVEMBER 2010

Fig. 2. Comparisons of stress-strain curves generated by the models of Hsu and Hsu 共1994兲 and Van Gysel and Taerwe 共1996兲 with experimental

data of Wee et al. 共1996兲

the ascending and descending branches. It was also shown that shown in Fig. 1, an application of this improved model to the

the Comité Euro-International du Béton-Fédération Internationale experimental data of Wang et al. 共1978兲 and Hsu and Hsu 共1994兲

de la Précontrainte 共CEB-FIP兲 共1993兲 model predicts too steep a demonstrates its inapplicability and limitation for modeling the

drop in the postpeak region of the curve for HSC and Carreira and strain softening behavior of HSC.

Chu’s model 共Carreira and Chu 1985兲 does not adequately repre- In order to investigate the models of Hsu and Hsu 共1994兲 and

sent the descending portion of the stress-strain curves of HSC for

Van Gysel and Taerwe 共1996兲, the complete stress-strain curves of

a wide range of concrete strengths.

HSC with compressive strength f ⬘c = 80 and 100 MPa 共11.60 and

Based on the same test data, Wee et al. 共1996兲 proposed a

modification of Carreira and Chu’s 共1985兲 equation. The agree- 14.50 ksi兲 generated by the two models are depicted in Fig. 2,

ment between the predictions of this improved equation and the compared with the experimental curves obtained by Wee et al.

experiment data mentioned above is very good. However, there is 共1996兲. Fig. 2 reveals that:

a discontinuity of the tangent at the peak stress. Furthermore, as 1. Both of the models can give a good representation of the

Fig. 3. Illustration of quantitative comparison of the proposed model with Wee et al.’s model 共Wee et al. 1996兲 and Van Gysel and Taerwe’s

model 共Van Gysel and Taerwe 1996兲

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / NOVEMBER 2010 / 1183

Fig. 4. Verification of proposed model against test results of Wang et al. 共1978兲

ascending branch of the experimental stress-strain curves of strain relationship include the concrete strength f ⬘c , the initial tan-

HSC. However, neither of them gives a good fit for the de- gent modulus Eit, and the strain at peak stress e0, and needless to

scending part. say, all of these parameters can be obtained experimentally.

2. The residual strength of Van Gysel and Taerwe’s 共1996兲 Typical stress-strain curves of normal weight concrete with

model at high strains tends to zero, which is contrary to the compressive strength f ⬘c = 50, 80, 110, and 140 MPa 共7.25, 11.60,

experimental observations. 15.95, and 20.31 ksi兲 generated using the proposed empirical

3. The tangent is discontinuous at the point ed, which seems to model are shown in Fig. 3, together with those of the models of

be a shortcoming of the Hsu and Hsu’s model 共Hsu and Hsu Wee et al. 共1996兲 and Van Gysel and Taerwe 共1996兲. One can see

1994兲. from Fig. 3 that:

In view of the foregoing, it is necessary to propose a new empiri- 1. The ascending branches predicted by all the three models are

cal model to represent the complete stress-strain curves for HSC. in close agreement with each other.

2. Compared with the model of Van Gysel and Taerwe 共1996兲,

the present model decreases the steepness of the descending

New Proposal for Complete Stress-Strain Curve part of the stress-strain curve for HSC.

of HSC in Compression 3. The discontinuity of the tangent at the peak stress in the

model of Wee et al. 共1996兲 becomes more apparent as the

As aforementioned, Van Gysel and Taerwe’s 共1996兲 model can concrete strength becomes larger, i.e., it is slightly weak in

give fairly good prediction for the ascending portion of the stress- the region just after the peak. The present model eliminates

strain curves. On the other hand, in order to avoid the shortcom- such a shortcoming and provides smaller residual stress at

ing in the model of Wee et al. 共1996兲, i.e., discontinuity of the high strains when compared with the model of Wee et al.

tangent at the peak stress, similar to the model of Van Gysel and 共1996兲.

Taerwe 共1996兲, two equations are proposed to describe the stress-

strain relationship for two ranges of concrete strains. For 0 ⱕ

Verification of the Proposed Model

ⱕ L, where L = concrete strain corresponding to a stress value of

0.8 f ⬘c on the descending branch of the stress-strain curve In order to verify the new empirical stress-strain model for un-

冋 册

confined HSC under uniaixal compression, the stress-strain

共Eit/E0兲共/0兲 − 共/0兲

2

curves generated by the proposed model are compared with the

f c = f ⬘c 共1兲

1 + 共Eit/E0 − 2兲共/0兲 published experimental data on normal weight concretes over a

wide strength range. Figs. 4–6, respectively, show the verification

in which

L = 0 冋冉 1 Eit 4

+

10 E0 5

+ 冊 冑冉 1 Eit 4

+

10 E0 5

冊 册 2

−

4

5

共2兲

and for ⬎ L, a correction factor, is introduced in the model of

Van Gysel and Taerwe 共1996兲 for decreasing the steepness of the

descending part of the stress-strain curve

f ⬘c

fc = 共3兲

1 + 关共/0兲 − 1/共L/0兲 − 1兴2共1−兲

The continuity of the complete stress-strain curves implies that

for the predefined value = L, f c in Eq. 共3兲 will be equal to

0.8 f ⬘c . Therefore, can be determined as

1

= 4 共4兲

From Eqs. 共1兲–共3兲, one can clearly see that the most important Fig. 5. Verification of proposed model against test results of Hsu and

parameters with physical significance used to define the stress- Hsu 共1994兲

1184 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / NOVEMBER 2010

Fig. 6. Verification of proposed model against test results of Wee et al. 共1996兲

of the proposed model against experimental results of Wang et al. Notation

共1978兲, Hsu and Hsu 共1994兲, and Wee et al. 共1996兲. It can be seen

from Figs. 4–6 that although the new proposed empirical model is The following symbols are used in this technical note:

simple, generally, it represents the mean behavior of experimental 共f c , 兲 ⫽ coordinates of any point in the stress-strain

data quite well for both ascending and descending branches. curve;

f ⬘c ⫽ unconfined concrete compressive strength;

Eit ⫽ initial tangent modulus of elasticity;

Conclusions E0 ⫽ secant modulus at peak stress 共E0 = f ⬘c / 0兲;

k , k1, and k2 ⫽ correction factors;

A new empirical stress-strain model for unconfined HSC under n ,  ⫽ material parameters;

uniaixal compression with emphasis on the softening branch is w ⫽ concrete unit weight;

proposed. An application of the proposed model to published ex- ␣E ⫽ coarse aggregate coefficient 共1.20 for basalt,

perimental data on normal weight concretes over a wide strength dense limestone aggregates, 1.00 for quartzite

range demonstrates that the present model gives a good represen- aggregates, 0.90 for limestone aggregates,

tation of the mean behavior of the actual stress-strain response. and 0.70 for sandstone aggregates兲;

d ⫽ strain corresponds to a stress value of 0.3 f ⬘c

in the descending part of the stress-strain

curve;

max ⫽ concrete strain when concrete stress is equal

Acknowledgments

to 0.5 f ⬘c on the descending part of the

stress-strain curve;

This study is partially supported by the start-up funds from Cen- 0 ⫽ peak strain of unconfined concrete strength

tral South University, the “Grant-in-Aid for Scientific Research f ⬘c ; and

共Tokubetsu Kenkyuin Shorei-hi兲” from the Japan Society for the ⫽ coefficient.

Promotion of Science 共JSPS兲 共No. 19 07399兲 and the Joint Re-

search Fund for Overseas Chinese, Hong Kong and Macao Young

Scholars 共No. 50828801兲 from the National Natural Science References

Foundation of China. The support is gratefully acknowledged.

Finally, the writers wish to thank the reviewers of this note for Carreira, D. J., and Chu, K. H. 共1985兲. “Stress-strain relationship for plain

their critical comments and suggestions. concrete in compression.” ACI J., 82共6兲, 797–804.

JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / NOVEMBER 2010 / 1185

Comité Euro-International du Béton-Fédération Internationale de la Pré- Popovics, S. 共1973兲. “A numerical approach to the complete stress-strain

contrainte 共CEB-FIP兲. 共1993兲. CEB-FIP model code 1990, Thomas curve of concrete.” Cem. Concr. Res., 3共5兲, 583–599.

Telford, London. Sargin, M., Ghosh, S. K., and Handa, V. K. 共1971兲. “Effects of lateral

Dahl, K. K. B. 共1992兲. “A constitutive model for normal and high- reinforcement upon the strength and deformation properties of con-

strength concrete.” Rep. No. R 287, Dept. of Structural Engineering, crete.” Mag. Concrete Res., 23共75–76兲, 99–110.

TU Denmark, Lyngby, Denmark. Tomaszewicz, A. 共1984兲. “Betongens Arbeidsdiagram.” SINTEF Rep. No.

Hognestad, E. 共1951兲. “A study of combined bending and axial load in STF 65A84605, Trondheim.

reinforced concrete members.” Bull. Ser. No. 399, Univ. Illinois En- Van Gysel, A., and Taerwe, L. 共1996兲. “Analytical formulation of the

gineering Experimental Station, Champaign, IL.

complete stress-strain curve for high strength concrete.” Mater.

Hsu, L. S., and Hsu, C. T. T. 共1994兲. “Complete stress-strain behavior of

Struct., 29, 529–533.

high-strength concrete under compression.” Mag. Concrete Res.,

46共169兲, 301–312. Wang, P. T., Shah, S. P., and Naaman, A. E. 共1978兲. “Stress-strain curves

Kumar, P. 共2004兲. “A compact analytical material model for unconfined of normal and lightweight concrete in compression.” ACI J., 75共11兲,

concrete under uni-axial compression.” Mater. Struct., 37, 585–590. 603–611.

Lokuge, W. P., Sanjayan, J. G., and Setunge, S. 共2005兲. “Stress-strain Wee, T. H., Chin, M. S., and Mansur, M. A. 共1996兲. “Stress-strain rela-

model for laterally confined concrete.” J. Mater. Civ. Eng., 17共6兲, tionship of high-strength concrete in compression.” J. Mater. Civ.

607–616. Eng., 8共2兲, 70–76.

1186 / JOURNAL OF MATERIALS IN CIVIL ENGINEERING © ASCE / NOVEMBER 2010

You might also like

- (Duerr, D.,2006) - Pinned Connection Strength and BehaviorDocument14 pages(Duerr, D.,2006) - Pinned Connection Strength and Behaviorchristos032No ratings yet

- 1963-Paris, P. ErdoganA Critical Analysis of Crack Propagation LawsDocument6 pages1963-Paris, P. ErdoganA Critical Analysis of Crack Propagation LawsAna Isabel Aguilar ReyesNo ratings yet

- BU1 Technical ManualDocument16 pagesBU1 Technical ManualkevinjonescomNo ratings yet

- The Failure Behavior of An Epoxy Resin Subject To Multiaxial LoadingDocument9 pagesThe Failure Behavior of An Epoxy Resin Subject To Multiaxial Loadingbibekananda87No ratings yet

- Stress-Strain Relations For Dry and Saturated Sands Part I: Incremental ModelDocument20 pagesStress-Strain Relations For Dry and Saturated Sands Part I: Incremental ModelDanielAlexanderVillarrealNo ratings yet

- Strength of Transverse Fillet Welded JointsDocument7 pagesStrength of Transverse Fillet Welded Jointshemant_durgawaleNo ratings yet

- Materials: Fatigue Life of Aluminum Alloys Based On Shear and Hydrostatic StrainDocument21 pagesMaterials: Fatigue Life of Aluminum Alloys Based On Shear and Hydrostatic StrainvikryaNo ratings yet

- Of Failure, Weak Formations Can Be Strengthened By: Oil, J 0Document9 pagesOf Failure, Weak Formations Can Be Strengthened By: Oil, J 0Hafiz AsyrafNo ratings yet

- A New Sinusoidal Shear Deformation Theory For Bending, Buckling-1Document13 pagesA New Sinusoidal Shear Deformation Theory For Bending, Buckling-1Chien Thai-hoangNo ratings yet

- Teoría de FricciónDocument11 pagesTeoría de FricciónJuan Luis FuentesNo ratings yet

- A Counter-Rotating Vortex Pair in Inviscid FluidDocument9 pagesA Counter-Rotating Vortex Pair in Inviscid FluidMadeeha MalikNo ratings yet

- 20 Zienkiewicz, O. C., Watson, M., and King, I. P., A Numerical Method of Visco-Elastic PDFDocument21 pages20 Zienkiewicz, O. C., Watson, M., and King, I. P., A Numerical Method of Visco-Elastic PDFTariq MahmoodNo ratings yet

- Cmes 2006 012 121Document16 pagesCmes 2006 012 121tijsnoyonNo ratings yet

- Deformation Characteristics of Dry Hostun Sand With Principal Stress Axes RotationDocument12 pagesDeformation Characteristics of Dry Hostun Sand With Principal Stress Axes RotationABDELILAH ERRAHALINo ratings yet

- Lampa MM 2020 MareauDocument33 pagesLampa MM 2020 MareauSrimanthula SrikanthNo ratings yet

- Stress Concentration Solution For A 2D Dent in An Internally Pressurized CylinderDocument10 pagesStress Concentration Solution For A 2D Dent in An Internally Pressurized CylinderkhalidmhNo ratings yet

- Numerical Study of Particle, Bubble Movements and Tube Erosion in Gas Fluidized BedsDocument10 pagesNumerical Study of Particle, Bubble Movements and Tube Erosion in Gas Fluidized BedsflaviocolmanNo ratings yet

- Applied Mathematics and Computation: Jason F. Hammond, David M. BortzDocument12 pagesApplied Mathematics and Computation: Jason F. Hammond, David M. BortzAndrei Michel SontagNo ratings yet

- Secondary Compression Behavior in One-Dimensional Consolidation TestsDocument6 pagesSecondary Compression Behavior in One-Dimensional Consolidation TestsBookAncestorNo ratings yet

- Int. J. Muhiphase FlowDocument18 pagesInt. J. Muhiphase FlowPrantik DasNo ratings yet

- Finite Deformation Continuum Model For Single-Walled Carbon NanotubesDocument9 pagesFinite Deformation Continuum Model For Single-Walled Carbon NanotubesEduardo GarciaNo ratings yet

- A Novel Cavity Expansion Based Analytical Tool and Its Potential Application For Energy Pile FoundationDocument7 pagesA Novel Cavity Expansion Based Analytical Tool and Its Potential Application For Energy Pile FoundationMARCOSNo ratings yet

- TPG4170 Rock Acoustics: Lecture NotesDocument46 pagesTPG4170 Rock Acoustics: Lecture Notessorena70No ratings yet

- SPH Mass ConservationDocument15 pagesSPH Mass ConservationnahkbceNo ratings yet

- Modeling of Nevada Sand Behavior Using CHSOIL: February 2011Document9 pagesModeling of Nevada Sand Behavior Using CHSOIL: February 2011Zhenhe SongNo ratings yet

- Spe-5544-Ms (The Equation For Geopressure Prediction From Well Logs)Document11 pagesSpe-5544-Ms (The Equation For Geopressure Prediction From Well Logs)Azriel Naufal FadilahNo ratings yet

- Homogeneization Periodic Guy Bonnet IJSS 2016Document47 pagesHomogeneization Periodic Guy Bonnet IJSS 2016auslenderNo ratings yet

- A Constitutive Model For Sand in Triaxial CompressionDocument24 pagesA Constitutive Model For Sand in Triaxial CompressionLiz RvNo ratings yet

- K01 Iso Ortho TH 2Document8 pagesK01 Iso Ortho TH 2Tanu RdNo ratings yet

- Physics of Strain Effects in Semiconductors and Metal-Oxide-Semiconductor Field-Effect TransistorsDocument23 pagesPhysics of Strain Effects in Semiconductors and Metal-Oxide-Semiconductor Field-Effect TransistorsJOSE CARLOS LEON GONZALEZNo ratings yet

- On The Development of A DRP Dual Compact Upwind Scheme For Convection-Diffusion EquationDocument16 pagesOn The Development of A DRP Dual Compact Upwind Scheme For Convection-Diffusion EquationEvgeny ShavelzonNo ratings yet

- Stress-Strain Response of High Strength Concrete and Application of The Existing ModelsDocument18 pagesStress-Strain Response of High Strength Concrete and Application of The Existing ModelshabibbuetNo ratings yet

- كاز داينمكDocument15 pagesكاز داينمكAsoo AsoshNo ratings yet

- Simulating Vortex Shedding at High Reynolds NumbersDocument6 pagesSimulating Vortex Shedding at High Reynolds NumbersDeniz ümit BayraktutarNo ratings yet

- SPE 94062 Numerical Simulation of Fully Coupled Fluid-Flow/Geomechanical Deformation in Hydraulically Fractured ReservoirsDocument5 pagesSPE 94062 Numerical Simulation of Fully Coupled Fluid-Flow/Geomechanical Deformation in Hydraulically Fractured ReservoirsAli NakhaeeNo ratings yet

- Evaluation of Various Turbulence Models in Enclosed Environment CFDDocument18 pagesEvaluation of Various Turbulence Models in Enclosed Environment CFDbenjamin.arfi06No ratings yet

- A Review of Simple Formulae For Elastic Hoop StressDocument24 pagesA Review of Simple Formulae For Elastic Hoop StressbookppNo ratings yet

- Sadhan K Adhikari - Mean-Field Model of Jet Formation in A Collapsing Bose-Einstein CondensateDocument10 pagesSadhan K Adhikari - Mean-Field Model of Jet Formation in A Collapsing Bose-Einstein CondensateLomewcxNo ratings yet

- 1VECF1 - Analysis of Crack-Tip Constraint Due To V - and U - Side Grooves in C (T) SpecimensDocument11 pages1VECF1 - Analysis of Crack-Tip Constraint Due To V - and U - Side Grooves in C (T) SpecimensslvjayaprakashNo ratings yet

- Forcing Term in Single-Phase and Shan-Chen-type Multiphase Lattice Boltzmann Models - 2011 - PRE - Huang - KrafczykDocument15 pagesForcing Term in Single-Phase and Shan-Chen-type Multiphase Lattice Boltzmann Models - 2011 - PRE - Huang - Krafczyk10_DAVID_10No ratings yet

- AnnualDocument29 pagesAnnualtoufik saouchiNo ratings yet

- 200100-A Plasticity Model With Yield Surface DDocument15 pages200100-A Plasticity Model With Yield Surface DzwenbitNo ratings yet

- The Liquid Film and The Core Region Velocity Profiles in Annular Two-Phase FlowDocument14 pagesThe Liquid Film and The Core Region Velocity Profiles in Annular Two-Phase FlowNishant ManepalliNo ratings yet

- SMiRT-23 Paper 552Document10 pagesSMiRT-23 Paper 552SamNo ratings yet

- Numerical Study of Gas Fluidized Beds With Imersed Tubes: (Single Blank Line Size 14)Document9 pagesNumerical Study of Gas Fluidized Beds With Imersed Tubes: (Single Blank Line Size 14)flaviocolmanNo ratings yet

- Multi Scale Mixed Finite Element Modeling of Coupled Wellbore Near-Well FlowDocument9 pagesMulti Scale Mixed Finite Element Modeling of Coupled Wellbore Near-Well Flowpetar_damyanovNo ratings yet

- Pra Eit 053806Document7 pagesPra Eit 053806aniket misraNo ratings yet

- Kang 2015Document7 pagesKang 2015ahmet ergüveNo ratings yet

- A Curved Finite Element For Thin ElasticDocument38 pagesA Curved Finite Element For Thin ElasticJosé Cléber Rodrigues da SilvaNo ratings yet

- Jo, Cement BehaviorDocument13 pagesJo, Cement Behaviorjsever1No ratings yet

- Ajassp 2004 5 11Document7 pagesAjassp 2004 5 11Junk JettisonNo ratings yet

- Analysis of Torsional Stresses - GDLC - 8618Document15 pagesAnalysis of Torsional Stresses - GDLC - 8618Ahmed AafaqNo ratings yet

- Supplementary File - Surface Waves in Granular Phononic CystalsDocument5 pagesSupplementary File - Surface Waves in Granular Phononic CystalsVenkatesan Thanigai ArasuNo ratings yet

- Bull IAEG (1977) Nº16 - pgs.198 - 200Document3 pagesBull IAEG (1977) Nº16 - pgs.198 - 200RitaPimentaNo ratings yet

- Hot Spot Stress Determination For A Tubular T-Joint Under Combined Axial and Bending LoadingDocument8 pagesHot Spot Stress Determination For A Tubular T-Joint Under Combined Axial and Bending LoadinggiuseppeNo ratings yet

- A Simplified Method To Simulate Residual Stresses in PlatesDocument8 pagesA Simplified Method To Simulate Residual Stresses in PlatesJosé Manuel Antunes Mendes GordoNo ratings yet

- The Influence of Vertical Fractures Intercepting Active and Observation Wells On Interference TestsDocument12 pagesThe Influence of Vertical Fractures Intercepting Active and Observation Wells On Interference Testsleonelz6aNo ratings yet

- 2127 - Mahatma Gandhi Missions College of Engineering, Hingoli RD, NandedDocument8 pages2127 - Mahatma Gandhi Missions College of Engineering, Hingoli RD, NandedAjit DeshmukhNo ratings yet

- Unit 1 Nissim Ezekiel and Eunice de Souza: 1.0 ObjectivesDocument14 pagesUnit 1 Nissim Ezekiel and Eunice de Souza: 1.0 ObjectivesJasmineNo ratings yet

- Simultaneous Equations O/LDocument13 pagesSimultaneous Equations O/LVenuja De SilvaNo ratings yet

- Exercise Oracle Forms 6i TrainingDocument5 pagesExercise Oracle Forms 6i TrainingFarooq Shahid100% (1)

- CCE Catalogue DetailedDocument28 pagesCCE Catalogue DetailedIshaan SinghNo ratings yet

- Optare Electric Vehicles: Embracing The EnvironmentDocument4 pagesOptare Electric Vehicles: Embracing The EnvironmentarrenNo ratings yet

- Excavation TrainingDocument60 pagesExcavation TrainingFahad Abdul HaqNo ratings yet

- Futures - Tiempos Futuros BBDocument10 pagesFutures - Tiempos Futuros BBLuz DuranteNo ratings yet

- Sharp Edge OrificeDocument2 pagesSharp Edge Orificeleo.caguimbal6433No ratings yet

- Let's Celebrate Diversity! : English: Level A2+Document10 pagesLet's Celebrate Diversity! : English: Level A2+JAIR DIEGO VIDAURRE QUISPENo ratings yet

- Item Wise Rate TenderDocument5 pagesItem Wise Rate TenderB-05 ISHA PATELNo ratings yet

- Fun With Magnets PDFDocument4 pagesFun With Magnets PDFMohamed SoudhNo ratings yet

- 03 Molar Volume of A Gas Long ReportDocument5 pages03 Molar Volume of A Gas Long ReportHoomehr TayariyanNo ratings yet

- E4nb71 PDFDocument99 pagesE4nb71 PDFtambache69100% (1)

- Paper 1 Each Questions Is Followed by Options A, B, and C. Circle The Correct AnswerDocument9 pagesPaper 1 Each Questions Is Followed by Options A, B, and C. Circle The Correct AnswerWan SafinaNo ratings yet

- Chebyshev Filter: Linear Analog Electronic FiltersDocument10 pagesChebyshev Filter: Linear Analog Electronic FiltersSri Jai PriyaNo ratings yet

- En0389 (Utilities Ii) PDFDocument127 pagesEn0389 (Utilities Ii) PDFGabriel GabrielNo ratings yet

- Front Wheel Assy. DrumDocument2 pagesFront Wheel Assy. DrumSoroj BiswasNo ratings yet

- Heater: Hydrate PreventionDocument12 pagesHeater: Hydrate PreventionMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Bill of QuantityDocument6 pagesBill of QuantityKhairoden SangcopanNo ratings yet

- On Arushi Murder CaseDocument8 pagesOn Arushi Murder Case0000No ratings yet

- SOP - Internal FAT-MachineDocument12 pagesSOP - Internal FAT-MachineSarvesh DaradeNo ratings yet

- Half-Cell Potential Test From The Upper-Side and The Lower-Side of Reinforced Concrete Slabs: A Comparative StudyDocument6 pagesHalf-Cell Potential Test From The Upper-Side and The Lower-Side of Reinforced Concrete Slabs: A Comparative StudyANNADURAINo ratings yet

- MBB and DR PG Data2kDocument143 pagesMBB and DR PG Data2kYogesh PalNo ratings yet

- Manas Arora 3 Year - B Roll No. 3 Vastu Kala AcademyDocument12 pagesManas Arora 3 Year - B Roll No. 3 Vastu Kala AcademyManasAroraNo ratings yet

- Integration Strategies and New Identities in Vs Naipaul's The Mimic Men and Caryl Phillips's CambridgeDocument7 pagesIntegration Strategies and New Identities in Vs Naipaul's The Mimic Men and Caryl Phillips's CambridgeIjahss JournalNo ratings yet

- Appositives and AdjectiveDocument2 pagesAppositives and AdjectiveRinda RiztyaNo ratings yet

- List Product YellowDocument10 pagesList Product YellowfitriNo ratings yet

- Elements Cmpds Mix Ws-AnswersDocument2 pagesElements Cmpds Mix Ws-Answerseric sivaneshNo ratings yet