Professional Documents

Culture Documents

Data Collection Normalization

Data Collection Normalization

Uploaded by

naren.bansalCopyright:

Available Formats

You might also like

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Gartley Velcoty RelativeDocument3 pagesGartley Velcoty Relativenaren.bansalNo ratings yet

- Hydranautics ManualDocument139 pagesHydranautics ManualMinto Raharjo100% (2)

- Adv 885 Ro Pac M QuickrefguideDocument8 pagesAdv 885 Ro Pac M QuickrefguideAlejandroOdioCastilloNo ratings yet

- ASTM D4516 00 - D4516.tynq3040Document3 pagesASTM D4516 00 - D4516.tynq3040Ran Nadav100% (2)

- Item D-12 Attachment 1 Pt.3 LinkDocument27 pagesItem D-12 Attachment 1 Pt.3 LinksamsNo ratings yet

- Best-Practises RO PlantDocument25 pagesBest-Practises RO PlantjdadhaNo ratings yet

- Troubleshooting Your RO: Page 1 of 6 01/23/01Document6 pagesTroubleshooting Your RO: Page 1 of 6 01/23/01anuvnairNo ratings yet

- HydranauticsDocument17 pagesHydranauticsNafian AwaludinNo ratings yet

- Feedwater Characteristics: What You Need To Know AboutDocument4 pagesFeedwater Characteristics: What You Need To Know AboutSomaia Al-AkrasNo ratings yet

- Documento de HenryDocument16 pagesDocumento de HenryhenryNo ratings yet

- Foulants and Cleaning Procedures For Composite Polyamide RO - NF Membrane ElementsDocument17 pagesFoulants and Cleaning Procedures For Composite Polyamide RO - NF Membrane ElementsonlynameNo ratings yet

- Lenntech: Technical Service BulletinDocument0 pagesLenntech: Technical Service Bulletinengineer63No ratings yet

- TSB 107Document15 pagesTSB 107patelpiyushbNo ratings yet

- 5-4 Data NormalizationDocument4 pages5-4 Data NormalizationsamsNo ratings yet

- Lenntech: Technical Service BulletinDocument16 pagesLenntech: Technical Service Bulletindalton2003No ratings yet

- Interim Report 150 MLDDocument112 pagesInterim Report 150 MLDMaqsood Ibn Shaikhul ArfeenNo ratings yet

- Best Practices For RO OperationsDocument1 pageBest Practices For RO OperationsarmostaanNo ratings yet

- Reverse Osmosis Measurements: Product Application DataDocument2 pagesReverse Osmosis Measurements: Product Application DataVanessa VanegasNo ratings yet

- TroubleshootingBNR PDFDocument12 pagesTroubleshootingBNR PDFAbhisek BhattacharyaNo ratings yet

- Chemical cleaning 1 رائعة PDFDocument16 pagesChemical cleaning 1 رائعة PDFmohamed karem100% (1)

- Brackish Water Ro and NF Operations On High Tds Feed WatersDocument11 pagesBrackish Water Ro and NF Operations On High Tds Feed WatersAyahKenzieNo ratings yet

- Boilers & Cooling Towers: Application BulletinDocument2 pagesBoilers & Cooling Towers: Application BulletinashrvincentNo ratings yet

- SPE/IADC 124664 Roles of Managed Pressure Drilling Technique in Kick Detection and Wellcontrol Beginning of The New Conventional Drilling WayDocument10 pagesSPE/IADC 124664 Roles of Managed Pressure Drilling Technique in Kick Detection and Wellcontrol Beginning of The New Conventional Drilling WaynabiNo ratings yet

- Lenntech: What Is Membrane Performance Normalization?Document6 pagesLenntech: What Is Membrane Performance Normalization?Manuel Alejandro Echeverry LopezNo ratings yet

- Common Mistakes in Design, Use of Reverse Osmosis SystemsDocument4 pagesCommon Mistakes in Design, Use of Reverse Osmosis SystemsihllhmNo ratings yet

- PC 191 Technical SheetDocument4 pagesPC 191 Technical Sheetأبو محمدNo ratings yet

- Design, Qualification, and Validation of Water SystemsDocument14 pagesDesign, Qualification, and Validation of Water SystemsEverton MonteiroNo ratings yet

- DBNPA inDocument7 pagesDBNPA inทรงพลกายบริบูรณ์No ratings yet

- 15 PR Paper 165574 FinalDocument12 pages15 PR Paper 165574 FinaljoeNo ratings yet

- 12 PretreatmentDocument3 pages12 PretreatmentRajesh MukkavilliNo ratings yet

- EDI System Report FinalDocument9 pagesEDI System Report FinalgiahaoNo ratings yet

- Hydranautics Membrane FoulantsCleaning Tech D402Document14 pagesHydranautics Membrane FoulantsCleaning Tech D402saaroomaniNo ratings yet

- User Guide CSMPRO v5.0Document27 pagesUser Guide CSMPRO v5.0Walter BastidasNo ratings yet

- SPE 126845 Risk Analysis and Decision Making in Relative Permeability Modifier Water Shut-Off TreatmentDocument14 pagesSPE 126845 Risk Analysis and Decision Making in Relative Permeability Modifier Water Shut-Off TreatmentLeopold Roj DomNo ratings yet

- TSB ManualDocument138 pagesTSB ManualruwaaquaNo ratings yet

- TSB107Document16 pagesTSB107OmarNo ratings yet

- AMTA 2017 Paper TanuwidjajaDocument11 pagesAMTA 2017 Paper TanuwidjajaJulio VicenteNo ratings yet

- Sensitivity of SDI AnalysisDocument7 pagesSensitivity of SDI AnalysisMichael AngeloNo ratings yet

- Module 5: SWRO Plant Engineering Design: Why Ro Plants For Water DesalinationDocument7 pagesModule 5: SWRO Plant Engineering Design: Why Ro Plants For Water Desalinationمروة نبوي محمد السيد ١٧١٠٢٦٢٢No ratings yet

- Filmtec™ Membranes Flow Factor For Ro System DesignDocument3 pagesFilmtec™ Membranes Flow Factor For Ro System DesignJuan MendozaNo ratings yet

- Hydranautics PDFDocument16 pagesHydranautics PDFfarhadzakerNo ratings yet

- Phase Pressure Measurements: Simultaneous and Direct Derivation of Relative Permeability and Dynamic Capillary PressureDocument13 pagesPhase Pressure Measurements: Simultaneous and Direct Derivation of Relative Permeability and Dynamic Capillary PressureRosa K Chang HNo ratings yet

- Micro & Ultra-Filtration in Reverse Osmosis Pretreatment: Page 1 of 17Document17 pagesMicro & Ultra-Filtration in Reverse Osmosis Pretreatment: Page 1 of 17sdahidiNo ratings yet

- Reverse Osmosis: Boiler Water Operator Training NotesDocument6 pagesReverse Osmosis: Boiler Water Operator Training NotesSheikh SahabNo ratings yet

- AVS Overview Avista Essential User Guide - AVSUS - 2020Document32 pagesAVS Overview Avista Essential User Guide - AVSUS - 2020Yanina Aliaga100% (1)

- Membrane Filtration LimeDocument11 pagesMembrane Filtration Limenermeen ahmedNo ratings yet

- Completion Fluid SelectionDocument31 pagesCompletion Fluid Selectionandrew_yeap_2100% (3)

- Solution of Sample QuestionsDocument10 pagesSolution of Sample QuestionsMuataman KhNo ratings yet

- Technotes: Basics of Ro TroubleshootingDocument4 pagesTechnotes: Basics of Ro TroubleshootingWaqas ButtNo ratings yet

- R.O Check ListDocument4 pagesR.O Check ListRavi MadhavanNo ratings yet

- Theoretical Uncertainty of Orifice Flow Measurement TechWpaperDocument8 pagesTheoretical Uncertainty of Orifice Flow Measurement TechWpaperFikri AchdanNo ratings yet

- Membrane Technology: Real World Studies Utilizing For SDWA ComplianceDocument2 pagesMembrane Technology: Real World Studies Utilizing For SDWA ComplianceIndra Budhi KurniawanNo ratings yet

- TSB Manual May2007Document141 pagesTSB Manual May2007altayehmNo ratings yet

- Standard methods for the examination of water and sewageFrom EverandStandard methods for the examination of water and sewageNo ratings yet

- Water Remote Sensing: Advancements in Computer Vision Techniques for Water Remote SensingFrom EverandWater Remote Sensing: Advancements in Computer Vision Techniques for Water Remote SensingNo ratings yet

- Chemical Marine Monitoring: Policy Framework and Analytical TrendsFrom EverandChemical Marine Monitoring: Policy Framework and Analytical TrendsNo ratings yet

- Cytogenetic Laboratory Management: Chromosomal, FISH and Microarray-Based Best Practices and ProceduresFrom EverandCytogenetic Laboratory Management: Chromosomal, FISH and Microarray-Based Best Practices and ProceduresNo ratings yet

- "Jootsing" - The Key To CreativityDocument4 pages"Jootsing" - The Key To Creativitynaren.bansalNo ratings yet

- 00K - Antifragile Asset Allocation Model - GioeleGiordano - 1st PlaceDocument19 pages00K - Antifragile Asset Allocation Model - GioeleGiordano - 1st Placenaren.bansalNo ratings yet

- Kase Bars (Equal Truerange Bar Chart)Document2 pagesKase Bars (Equal Truerange Bar Chart)naren.bansalNo ratings yet

- R.O.Dm Plant and DM Plant: CPP, JbilDocument3 pagesR.O.Dm Plant and DM Plant: CPP, JbilShahin AfrozNo ratings yet

- Basics of Reverse Osmosis PDFDocument14 pagesBasics of Reverse Osmosis PDFVinod KumarNo ratings yet

- Sulphate and Salt Minerals: The Problem of Treating Mine WasteDocument3 pagesSulphate and Salt Minerals: The Problem of Treating Mine WasteMiguel De La HozNo ratings yet

- Offer For Mineral Water Plant MPDocument33 pagesOffer For Mineral Water Plant MPmohit malviyaNo ratings yet

- Performance and Characteristics of Reverse Osmosis MembranesDocument11 pagesPerformance and Characteristics of Reverse Osmosis Membranestata_77No ratings yet

- Water Conservation in The Professional Car Wash IndustryDocument57 pagesWater Conservation in The Professional Car Wash Industryericpolc69No ratings yet

- Best Practice Water ManagementDocument40 pagesBest Practice Water ManagementSafa el oued100% (2)

- Bap - Uf SystemDocument88 pagesBap - Uf SystemGloria HamiltonNo ratings yet

- Ocean Whisper - Technical SpecificationsDocument8 pagesOcean Whisper - Technical SpecificationsAtanasio PerezNo ratings yet

- Letter On Price List AnnouncementDocument10 pagesLetter On Price List AnnouncementsunnyooiNo ratings yet

- Dialyser Reuse/Reprocessing HistoryDocument73 pagesDialyser Reuse/Reprocessing HistoryKushalDpNo ratings yet

- QuenchSea User Manual V4 16-10-2022Document4 pagesQuenchSea User Manual V4 16-10-2022lackoibolyaNo ratings yet

- Reverse Osmasis TrainingDocument12 pagesReverse Osmasis TrainingSarah FrazierNo ratings yet

- Pharmaceuticals in WaterDocument49 pagesPharmaceuticals in Waterapi-256236481No ratings yet

- Never Underestimate Your Fresh Water Needs: Coral Sea Key FeaturesDocument7 pagesNever Underestimate Your Fresh Water Needs: Coral Sea Key FeaturesIrda OnesNo ratings yet

- Plumbing Bank 2 PDFDocument14 pagesPlumbing Bank 2 PDFRichardPerezFabian100% (2)

- Technical Specification - Water SystemDocument2 pagesTechnical Specification - Water Systemkamel saboundjiNo ratings yet

- Bongsuwan D 2008Document7 pagesBongsuwan D 2008Liona MargaritaNo ratings yet

- Reverse OsmosisDocument2 pagesReverse Osmosistcd_usaNo ratings yet

- Resin RegenerationDocument9 pagesResin Regenerationdafteri11No ratings yet

- Membrane 45-D01750-EnDocument4 pagesMembrane 45-D01750-EnkepetrosNo ratings yet

- Elix 3 (UV), Elix 5 (UV), Elix 10 (UV) RiOs 3, RiOs 5, RiOs 8, RiOs 16 PDFDocument47 pagesElix 3 (UV), Elix 5 (UV), Elix 10 (UV) RiOs 3, RiOs 5, RiOs 8, RiOs 16 PDFKamel MahdiNo ratings yet

- Desalination FinalDocument30 pagesDesalination FinalYashika Bhathiya JayasingheNo ratings yet

- Economic and Technical Assessment of Desalination TechnologiesDocument0 pagesEconomic and Technical Assessment of Desalination Technologiesaaarun1010No ratings yet

- Removal of Total Ammonia Nitrogen TAN NiDocument13 pagesRemoval of Total Ammonia Nitrogen TAN NiAlina DumitracheNo ratings yet

- Battery MFG DD Vol 2 1984Document711 pagesBattery MFG DD Vol 2 1984Mahmudul HasanNo ratings yet

- DOW UF Case Study For High Turbid WaterDocument5 pagesDOW UF Case Study For High Turbid WaterWendyNo ratings yet

- DEGREMONT GUIDE2012 EN REV02 BDDocument30 pagesDEGREMONT GUIDE2012 EN REV02 BDnermeen ahmedNo ratings yet

- Waterland Water Treatment Environmental TechnologiesDocument36 pagesWaterland Water Treatment Environmental TechnologiesSiraj AL sharifNo ratings yet

- Behavior of Sio2 With ResinsDocument10 pagesBehavior of Sio2 With ResinsPiyush BanerjeeNo ratings yet

Data Collection Normalization

Data Collection Normalization

Uploaded by

naren.bansalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Collection Normalization

Data Collection Normalization

Uploaded by

naren.bansalCopyright:

Available Formats

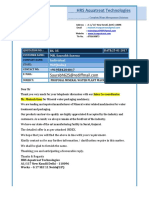

Reverse Osmosis Data Collection and Normalization

The purpose of Reverse Osmosis (RO) data collection ana analysis is to understand true RO membrane

conditions and help troubleshoot any potential problems before they become serious. Normalizing data

factors with external elements that affect membrane performace enables apples-to-apples comparisons

when reviewing performance data. Normalized RO performance data is compared to an established

baseline, such as when the membranes were new, replaced, or cleaned.

The following raw data is collected to determine RO membrane health:

1. Feed Temp (F⁰)

2. Permeate Flow (GPM)

3. Concentrate Flow (GPM)

4. Feed Pressure (PSI)

5. Permeate Pressure (PSI)

6. Feed Conductivity

7. Permeate Conductivity

All these operating conditions directly affect the quality and amount of permeate water the RO membranes

can produce. However, since these operating conditions are constantly changing, it is impossible to compare

the observed performance of certain parameters at one point and compare them to another point under

different operating conditions. Changing factors, such as temperature, feed water quality, permeate flow,

and system recovers all affect membrane performance.

Normalizing RO data allows the user to compare RO membrane performance to a set standard which does

not depend on changing operating conditions. Normalized data will measure the direct condition of the RO

membrane and show the true RO membrane performance and health.

Data that is not normalized can be misleading, since so many variables can cause changes that may appear

to be problems when, in fact, they are not. Feed water temperature is the most noticeable condition

affecting RO system performance. The general rule of thumb is to estimate a 1.5% permeate flow change per

degree Fahrenheit (F⁰) change.

For example, if an RO produced 50 GPM of permeate when the feed water was 60 F⁰ and then the feed

water temperature dropped 5 F⁰, then the RO would produce approximately 46 GPM. The 4 GPM decrease

in product is perfectly normal with the temperature drop.

Data Interpretation

An RO operator is ultimately concerned about two outcomes: the quality and quantity of water being

produced. As mentioned above, these two factors can be influenced by a number of variables such as feed

water pressure, system recovery, and changes in feed water quality, to name a few.

There are three calculated values which help give a better picture of true membrane performance and help

accurately troubleshoot potential RO system problems involving the quantity and quality of water produced

by the RO system. By collecting operating data, normalizing the data, and then trending the normalized data

©2024 Puretec Industrial Water

RO Data Collection and Normalization 2

over time, and comparing the values to the baseline (calculated from the start-up values when the RO

membranes were new or after they have been cleaned or replaced) enables proactive action to address any

problems before irreversible damage to the RO membranes occurs.

The three calculated values used to monitor and trend are:

• Normalized Permeate Flow (NPF)

• Normalized Salt Rejection (NSR)

• Normalized Pressure Differential (NPD)

Normalized Permeate Flow (NPF)

NPF measures the amount of permeate water the RO is producing. If the NPF drops 10% to 15% below the

baseline value (the NPF reading at start up with new membranes or when membranes were replaced or

cleaned) then this indicates RO membrane fouling or scaling and the RO membranes should be cleaned.

If the NPF increases, then this implies there is damage to the RO membrane. The damage can be caused by

chemical attack (from an oxidizer like chlorine) on the membrane or a mechanical issue (like an O-ring

failure).

See Fig 1 to learn how NPF is calculated.

Normalized Salt Rejection (NSR)

NSR indicates how well the RO membrane is rejecting salts (contaminants) and so affects permeate water

quality. If the NSR decreases, then the volume of salts going through the RO membrane increases creating

lower quality permeate. An NSR decrease can indicate RO membrane fouling, scaling, or degradation.

A well performing RO membrane should be providing 97% to 99% rejection. A membrane is considered

“bad” when the RO rejection drops to 90% or less. A normal RO operation span features a steady NSR

decline during continuous use.

RO membranes usually last several years before they require replacement and a steady decline in NSR is a

normal sign of an aging membrane. A proper RO membrane cleaning regiment can help improve the NSR.

©2024 Puretec Industrial Water

RO Data Collection and Normalization 3

NSR can be helpful for identifying biofouling issues. When biofouling is a concern, often the NSR will

increase and the NPF will decrease. This is because the biofoulant will actually seal small imperfections in the

RO membrane thereby increasing the rejection of salts.

Over time, the biofoulant layer ages and begins to die and chemicals such as CO2, methane, and/or organic

acids begin to diffuse through the membrane affecting permeate water quality (less salt rejection resulting in

a lower NSR).

See Fig 2 to learn how the NSR is calculated.

Normalized Pressure Differential (NPD)

The NPD tells us how clean the feed water spacer is on the membrane, These spacers are only around 30-

thousandths of an inch thick and are extremely susceptible to plugging. As plugging occurs, the resistance to

flow increases and pressure dop increases.

The NPD will begin to increase over time due to fouling and scaling. The RO membranes should be cleaned

when the DPD increases by 15% to 25% above the baseline value. NPD and NPF should be monitored together

to determine when the RO membranes should be cleaned. Often the NPF will decrease, and the NPD will

remain unchanged. This is simply because the fouling/scaling issues have yet to plug the feed water spacers. In

time, the NPD will increase in conjunction with the drop in NPF.

A decrease in NPD is usually due to faulty instrumentation or mistakes made during data collection.

If NPD can be measured for each stage of an RO, usually problems can be identified between fouling and

scaling based on the location of the increased pressure drop. An increase in NPD in the front stage of an RO

indicates fouling issue, and an NPD increase in the second stage indicates scaling.

For more information, please visit our site at www.purewater.com

800.906.6060 ⚫ www.puretecwater.com

©2024 Puretec Industrial Water

RO Data Collection and Normalization 4

Figure 1 – Normalized Permeate Flow Calculation

©2024 Puretec Industrial Water

RO Data Collection and Normalization 5

Figure 2 – Normalized Salt Rejection

NSR monitors the amount of salt that passes through the membrane.

©2024 Puretec Industrial Water

RO Data Collection and Normalization 6

Figure 3 – Normalized Pressure Differential

The Pressure Differential can help identify if the membrane is dirty. The normalized value (NPD) will account for

changes in flow and temperature. An increase in the NPD is an early warning of scaling and/or fouling. To

prevent complex problems, the membrane should be cleaned if the NPD is 15% or greater than the baseline.

©2024 Puretec Industrial Water

You might also like

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Gartley Velcoty RelativeDocument3 pagesGartley Velcoty Relativenaren.bansalNo ratings yet

- Hydranautics ManualDocument139 pagesHydranautics ManualMinto Raharjo100% (2)

- Adv 885 Ro Pac M QuickrefguideDocument8 pagesAdv 885 Ro Pac M QuickrefguideAlejandroOdioCastilloNo ratings yet

- ASTM D4516 00 - D4516.tynq3040Document3 pagesASTM D4516 00 - D4516.tynq3040Ran Nadav100% (2)

- Item D-12 Attachment 1 Pt.3 LinkDocument27 pagesItem D-12 Attachment 1 Pt.3 LinksamsNo ratings yet

- Best-Practises RO PlantDocument25 pagesBest-Practises RO PlantjdadhaNo ratings yet

- Troubleshooting Your RO: Page 1 of 6 01/23/01Document6 pagesTroubleshooting Your RO: Page 1 of 6 01/23/01anuvnairNo ratings yet

- HydranauticsDocument17 pagesHydranauticsNafian AwaludinNo ratings yet

- Feedwater Characteristics: What You Need To Know AboutDocument4 pagesFeedwater Characteristics: What You Need To Know AboutSomaia Al-AkrasNo ratings yet

- Documento de HenryDocument16 pagesDocumento de HenryhenryNo ratings yet

- Foulants and Cleaning Procedures For Composite Polyamide RO - NF Membrane ElementsDocument17 pagesFoulants and Cleaning Procedures For Composite Polyamide RO - NF Membrane ElementsonlynameNo ratings yet

- Lenntech: Technical Service BulletinDocument0 pagesLenntech: Technical Service Bulletinengineer63No ratings yet

- TSB 107Document15 pagesTSB 107patelpiyushbNo ratings yet

- 5-4 Data NormalizationDocument4 pages5-4 Data NormalizationsamsNo ratings yet

- Lenntech: Technical Service BulletinDocument16 pagesLenntech: Technical Service Bulletindalton2003No ratings yet

- Interim Report 150 MLDDocument112 pagesInterim Report 150 MLDMaqsood Ibn Shaikhul ArfeenNo ratings yet

- Best Practices For RO OperationsDocument1 pageBest Practices For RO OperationsarmostaanNo ratings yet

- Reverse Osmosis Measurements: Product Application DataDocument2 pagesReverse Osmosis Measurements: Product Application DataVanessa VanegasNo ratings yet

- TroubleshootingBNR PDFDocument12 pagesTroubleshootingBNR PDFAbhisek BhattacharyaNo ratings yet

- Chemical cleaning 1 رائعة PDFDocument16 pagesChemical cleaning 1 رائعة PDFmohamed karem100% (1)

- Brackish Water Ro and NF Operations On High Tds Feed WatersDocument11 pagesBrackish Water Ro and NF Operations On High Tds Feed WatersAyahKenzieNo ratings yet

- Boilers & Cooling Towers: Application BulletinDocument2 pagesBoilers & Cooling Towers: Application BulletinashrvincentNo ratings yet

- SPE/IADC 124664 Roles of Managed Pressure Drilling Technique in Kick Detection and Wellcontrol Beginning of The New Conventional Drilling WayDocument10 pagesSPE/IADC 124664 Roles of Managed Pressure Drilling Technique in Kick Detection and Wellcontrol Beginning of The New Conventional Drilling WaynabiNo ratings yet

- Lenntech: What Is Membrane Performance Normalization?Document6 pagesLenntech: What Is Membrane Performance Normalization?Manuel Alejandro Echeverry LopezNo ratings yet

- Common Mistakes in Design, Use of Reverse Osmosis SystemsDocument4 pagesCommon Mistakes in Design, Use of Reverse Osmosis SystemsihllhmNo ratings yet

- PC 191 Technical SheetDocument4 pagesPC 191 Technical Sheetأبو محمدNo ratings yet

- Design, Qualification, and Validation of Water SystemsDocument14 pagesDesign, Qualification, and Validation of Water SystemsEverton MonteiroNo ratings yet

- DBNPA inDocument7 pagesDBNPA inทรงพลกายบริบูรณ์No ratings yet

- 15 PR Paper 165574 FinalDocument12 pages15 PR Paper 165574 FinaljoeNo ratings yet

- 12 PretreatmentDocument3 pages12 PretreatmentRajesh MukkavilliNo ratings yet

- EDI System Report FinalDocument9 pagesEDI System Report FinalgiahaoNo ratings yet

- Hydranautics Membrane FoulantsCleaning Tech D402Document14 pagesHydranautics Membrane FoulantsCleaning Tech D402saaroomaniNo ratings yet

- User Guide CSMPRO v5.0Document27 pagesUser Guide CSMPRO v5.0Walter BastidasNo ratings yet

- SPE 126845 Risk Analysis and Decision Making in Relative Permeability Modifier Water Shut-Off TreatmentDocument14 pagesSPE 126845 Risk Analysis and Decision Making in Relative Permeability Modifier Water Shut-Off TreatmentLeopold Roj DomNo ratings yet

- TSB ManualDocument138 pagesTSB ManualruwaaquaNo ratings yet

- TSB107Document16 pagesTSB107OmarNo ratings yet

- AMTA 2017 Paper TanuwidjajaDocument11 pagesAMTA 2017 Paper TanuwidjajaJulio VicenteNo ratings yet

- Sensitivity of SDI AnalysisDocument7 pagesSensitivity of SDI AnalysisMichael AngeloNo ratings yet

- Module 5: SWRO Plant Engineering Design: Why Ro Plants For Water DesalinationDocument7 pagesModule 5: SWRO Plant Engineering Design: Why Ro Plants For Water Desalinationمروة نبوي محمد السيد ١٧١٠٢٦٢٢No ratings yet

- Filmtec™ Membranes Flow Factor For Ro System DesignDocument3 pagesFilmtec™ Membranes Flow Factor For Ro System DesignJuan MendozaNo ratings yet

- Hydranautics PDFDocument16 pagesHydranautics PDFfarhadzakerNo ratings yet

- Phase Pressure Measurements: Simultaneous and Direct Derivation of Relative Permeability and Dynamic Capillary PressureDocument13 pagesPhase Pressure Measurements: Simultaneous and Direct Derivation of Relative Permeability and Dynamic Capillary PressureRosa K Chang HNo ratings yet

- Micro & Ultra-Filtration in Reverse Osmosis Pretreatment: Page 1 of 17Document17 pagesMicro & Ultra-Filtration in Reverse Osmosis Pretreatment: Page 1 of 17sdahidiNo ratings yet

- Reverse Osmosis: Boiler Water Operator Training NotesDocument6 pagesReverse Osmosis: Boiler Water Operator Training NotesSheikh SahabNo ratings yet

- AVS Overview Avista Essential User Guide - AVSUS - 2020Document32 pagesAVS Overview Avista Essential User Guide - AVSUS - 2020Yanina Aliaga100% (1)

- Membrane Filtration LimeDocument11 pagesMembrane Filtration Limenermeen ahmedNo ratings yet

- Completion Fluid SelectionDocument31 pagesCompletion Fluid Selectionandrew_yeap_2100% (3)

- Solution of Sample QuestionsDocument10 pagesSolution of Sample QuestionsMuataman KhNo ratings yet

- Technotes: Basics of Ro TroubleshootingDocument4 pagesTechnotes: Basics of Ro TroubleshootingWaqas ButtNo ratings yet

- R.O Check ListDocument4 pagesR.O Check ListRavi MadhavanNo ratings yet

- Theoretical Uncertainty of Orifice Flow Measurement TechWpaperDocument8 pagesTheoretical Uncertainty of Orifice Flow Measurement TechWpaperFikri AchdanNo ratings yet

- Membrane Technology: Real World Studies Utilizing For SDWA ComplianceDocument2 pagesMembrane Technology: Real World Studies Utilizing For SDWA ComplianceIndra Budhi KurniawanNo ratings yet

- TSB Manual May2007Document141 pagesTSB Manual May2007altayehmNo ratings yet

- Standard methods for the examination of water and sewageFrom EverandStandard methods for the examination of water and sewageNo ratings yet

- Water Remote Sensing: Advancements in Computer Vision Techniques for Water Remote SensingFrom EverandWater Remote Sensing: Advancements in Computer Vision Techniques for Water Remote SensingNo ratings yet

- Chemical Marine Monitoring: Policy Framework and Analytical TrendsFrom EverandChemical Marine Monitoring: Policy Framework and Analytical TrendsNo ratings yet

- Cytogenetic Laboratory Management: Chromosomal, FISH and Microarray-Based Best Practices and ProceduresFrom EverandCytogenetic Laboratory Management: Chromosomal, FISH and Microarray-Based Best Practices and ProceduresNo ratings yet

- "Jootsing" - The Key To CreativityDocument4 pages"Jootsing" - The Key To Creativitynaren.bansalNo ratings yet

- 00K - Antifragile Asset Allocation Model - GioeleGiordano - 1st PlaceDocument19 pages00K - Antifragile Asset Allocation Model - GioeleGiordano - 1st Placenaren.bansalNo ratings yet

- Kase Bars (Equal Truerange Bar Chart)Document2 pagesKase Bars (Equal Truerange Bar Chart)naren.bansalNo ratings yet

- R.O.Dm Plant and DM Plant: CPP, JbilDocument3 pagesR.O.Dm Plant and DM Plant: CPP, JbilShahin AfrozNo ratings yet

- Basics of Reverse Osmosis PDFDocument14 pagesBasics of Reverse Osmosis PDFVinod KumarNo ratings yet

- Sulphate and Salt Minerals: The Problem of Treating Mine WasteDocument3 pagesSulphate and Salt Minerals: The Problem of Treating Mine WasteMiguel De La HozNo ratings yet

- Offer For Mineral Water Plant MPDocument33 pagesOffer For Mineral Water Plant MPmohit malviyaNo ratings yet

- Performance and Characteristics of Reverse Osmosis MembranesDocument11 pagesPerformance and Characteristics of Reverse Osmosis Membranestata_77No ratings yet

- Water Conservation in The Professional Car Wash IndustryDocument57 pagesWater Conservation in The Professional Car Wash Industryericpolc69No ratings yet

- Best Practice Water ManagementDocument40 pagesBest Practice Water ManagementSafa el oued100% (2)

- Bap - Uf SystemDocument88 pagesBap - Uf SystemGloria HamiltonNo ratings yet

- Ocean Whisper - Technical SpecificationsDocument8 pagesOcean Whisper - Technical SpecificationsAtanasio PerezNo ratings yet

- Letter On Price List AnnouncementDocument10 pagesLetter On Price List AnnouncementsunnyooiNo ratings yet

- Dialyser Reuse/Reprocessing HistoryDocument73 pagesDialyser Reuse/Reprocessing HistoryKushalDpNo ratings yet

- QuenchSea User Manual V4 16-10-2022Document4 pagesQuenchSea User Manual V4 16-10-2022lackoibolyaNo ratings yet

- Reverse Osmasis TrainingDocument12 pagesReverse Osmasis TrainingSarah FrazierNo ratings yet

- Pharmaceuticals in WaterDocument49 pagesPharmaceuticals in Waterapi-256236481No ratings yet

- Never Underestimate Your Fresh Water Needs: Coral Sea Key FeaturesDocument7 pagesNever Underestimate Your Fresh Water Needs: Coral Sea Key FeaturesIrda OnesNo ratings yet

- Plumbing Bank 2 PDFDocument14 pagesPlumbing Bank 2 PDFRichardPerezFabian100% (2)

- Technical Specification - Water SystemDocument2 pagesTechnical Specification - Water Systemkamel saboundjiNo ratings yet

- Bongsuwan D 2008Document7 pagesBongsuwan D 2008Liona MargaritaNo ratings yet

- Reverse OsmosisDocument2 pagesReverse Osmosistcd_usaNo ratings yet

- Resin RegenerationDocument9 pagesResin Regenerationdafteri11No ratings yet

- Membrane 45-D01750-EnDocument4 pagesMembrane 45-D01750-EnkepetrosNo ratings yet

- Elix 3 (UV), Elix 5 (UV), Elix 10 (UV) RiOs 3, RiOs 5, RiOs 8, RiOs 16 PDFDocument47 pagesElix 3 (UV), Elix 5 (UV), Elix 10 (UV) RiOs 3, RiOs 5, RiOs 8, RiOs 16 PDFKamel MahdiNo ratings yet

- Desalination FinalDocument30 pagesDesalination FinalYashika Bhathiya JayasingheNo ratings yet

- Economic and Technical Assessment of Desalination TechnologiesDocument0 pagesEconomic and Technical Assessment of Desalination Technologiesaaarun1010No ratings yet

- Removal of Total Ammonia Nitrogen TAN NiDocument13 pagesRemoval of Total Ammonia Nitrogen TAN NiAlina DumitracheNo ratings yet

- Battery MFG DD Vol 2 1984Document711 pagesBattery MFG DD Vol 2 1984Mahmudul HasanNo ratings yet

- DOW UF Case Study For High Turbid WaterDocument5 pagesDOW UF Case Study For High Turbid WaterWendyNo ratings yet

- DEGREMONT GUIDE2012 EN REV02 BDDocument30 pagesDEGREMONT GUIDE2012 EN REV02 BDnermeen ahmedNo ratings yet

- Waterland Water Treatment Environmental TechnologiesDocument36 pagesWaterland Water Treatment Environmental TechnologiesSiraj AL sharifNo ratings yet

- Behavior of Sio2 With ResinsDocument10 pagesBehavior of Sio2 With ResinsPiyush BanerjeeNo ratings yet