Professional Documents

Culture Documents

50b8dfa0-4a35-41f3-9f43-b141a77c423f

50b8dfa0-4a35-41f3-9f43-b141a77c423f

Uploaded by

madhani akhil0 ratings0% found this document useful (0 votes)

1 views13 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

1 views13 pages50b8dfa0-4a35-41f3-9f43-b141a77c423f

50b8dfa0-4a35-41f3-9f43-b141a77c423f

Uploaded by

madhani akhilCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 13

KP GATE CLASSES, NEW DELHI - INDIA’S No. 1 Architecture COACHING

Contents

Contents

CHAPTER 1. BUILDING MATERIALS.

11 TIMBER

11.1 CLASSIFICATION OF TIMBER...

1.1.2 CROSS-SECTION OF TIMBER,

1.1.3 SAWING OF TIMBER......

114 SEASONING OF TIMBER.......

115 PRESERVATIVES FOR TIMBER...

14.6 DEFECTS IN TIMBER....sssnsssnnnnnne

11.7 ENGINEERED TIMBER vise

1.1.8 BAMBOO IN CONSTRUCTION...

12 BRICK rg

12.1 | MUD IN CONSTRUCTION

122 TYPES OF SOIL sic

123 CLAY BRICK MANUFACTURING,

1.2.4 COMPOSITION OF COMMON CLAY BRICKS.

1.2.5 STANDARDS FOR CLAY BRICKS.

1d

1.26 — CLASSIFICATION OF CLAY BRICKS. estes ener 0

12.7 BRICK ORIENTATIONS, GUTS &SHAPES......... asa 22

128 DEFECTS IN CLAY BRICK... 26

129 ALTERNATIVEMATERIAL FOR BRICK..... 27

13: STON Bhvnngggnnlgfenm tonnes tester 28

1.3.1 CLASSIFICATION OF NATURAL ROCKS. . o 28

1.3.2 STONE FINISHES ......c0ss0ennnnnnnininnnnnninnnnnnnnnnsses SO

1.3.3, SM DEFECTS IN STONE .....csnne stent onesnnsene SL

13.4. ENGINEERED STONE IN CONSTRUCTION ..

1.4) CONCRETE wissesnseiennne

14.2 CEMENT ee

33

1.42 AGGREGATE IN CONCRETE. 34

143 WATER-CEMENT RATIO 36

1.4.4 WORKABILITY OF CONCRETE wwesss

14.5 ADMIXTURES IN CONCRETE

14.6 GRADES OF CONCRETE ..

14.7 CURING OF CONCRETE

148 TYPES OF CONCRETE 42

i

KP GATE Classes, New Delhi | Coaching for GATE & Other Recruitment Tests in Architecture & Planning

KP GATE CLASSES, NEW DELHI - INDIA’S No. 1 Architecture COACHING

1.5 OTHER BUILDING MATERIALS ......000000

151

152

153

15.4

16

CHAPTER 2. BUILDING CONSTRUCTION oo...

MORTARS

METALS & ALLOYS.

GLASS...

PAINT...

PRACTICE QUESTIONS...

2.1 STONE MASONRY.

244

212

21.3

2.2

2.21

2.22

223

224

2.25

2.3. TIMBER & STEEL TRUSSES...

231

232

233

234

24

241

242

243

244

245)

246

2a,

248

25

CHAPTER 3, ESTIMATION & PROJECT MANAGEMENT

3a

ada

312

313

TERMINOLOGY

JOINTS IN STONE MASONRY

CLASSIFICATION OF STONE MASONRY .....

BRICK MASONRY enone .

TERMINOLOGY sev

TOOLS USED IN MASONRY scons

BONDS IN BRICK MASONRY.

CONECTIONS IN BRICK MASONRY

TYPES OF MASONRY JOINTS...

TERMINOLOGY (TIMBER TRUSSES).

TYPES OF TIMBER TRUSS...

TERMINOLOGY (STEELTRUSSES)

TYPES OF STEELTRUSS...

IMPORTANT BUILDING COMPONENTS...

FOUNDATION & ITSITYPES .occesesne

ROORE ITS TYPES...

STAIRCASE.

DOOR

winoow

ARCH ...

RETAINING WALLS..

DAMP PROOF COURSE

PRACTICE QUESTIONS...

ESTIMATION snnnnnnnnininnnnnnnennnnnnnn

BASIC FORMULAE ....ssssninestinnnnniinnnnnnnnnnnnsne

UNITS OF MEASUREMENT .....ssnsssenminnnnnnnnnnnnee

METHODS OF APPROXIMATE CONSRUCTION COST ESTIMATION

45

45

46

a7

49

SL

58

son

5A

57

58

63

so

so 68

65

69

73

sou

son TA

75

7

78

80

80

so 82

86

89

st

93

96

98

99

100

101

seonened OL

sone 03

105

KP GATE Classes, New Delhi | Coaching for GATE & Other Recruitment Tests in Architecture & Planning

KP GATE CLASSES, NEW DELHI - INDIA’S No. 1 Architecture COACHING

3.2 PROJECT MANAGEMENT. nnn 106

3.21 — CRITICAL PATH METHOD (CPM). 106

322 GANTT CHARTS 106

3.23 PROJECT COST AND PROJECT CRASHING. ses seve dO?

3.24 — PERT... ese ses ene 0B

3.2.5 — CONSTRUCTION CONTRACTS ween 110

CHAPTER 4, BASICS OF STRUCTURES woes

4.1 BASICS OF STRENGTH OF MATERIALS...... sessenennnnnnnnnnnn

3.2.6 PROPERTIES OF ENGINEERING MATERIALS 14

32.7 THEORY OF ELASTICITY 115

44.1 HOOKE’S LAW vines enna 116

4.1.2 STRESS-STRAIN DIAGRAM... 119

4.2. BASICS OF SUPPORTS & BEAMS... 120

3.28 TYPES OF STRUCTURAL SUPPORTS...... . 120

329 TYPES OF BEAMS AND SUPPORT REACTIONS 122

4.3 SHEAR FORCE & BENDING MOMENT 124

3.2.10 SFD AND BMD. se se 124

3.2.11 MAXIMUM SHEAR FORCE AND BENDING MOMENT..... 126

4.4 BENDING STRESSES & SHEAR STRESSES. 126

3.2.12 BENDING STRESSES... ooo snes evenness 26

3.213 MOMENT OF INERTIA 128

3.2.14 SHEAR STRESSES icon 130

4.5 STRUCTURAL DESIGN OF BRIDGES ..0.0.00 132

3.2.15 132

8.216 ARCH Grn tinrnmnnnnnnsinsnsesennnn 182

3.2.17 SUSPENSION). a snes onesie 82

3.2.18 CANTILEVER... a snes cones 83

3.249 CABLE-STAYED 133

4.6 MISCELLANEOUS. nnn nesses pened Mh

3.2:20.... LONG VS SHORT COLUMN ..ssseesse 134

2.2.21 ONE-WAY VS TWO-WAY SLAB w....ssnnnnninnnnnnnnnnnnnsnnninn 135

3.222 STRUCTURAL PRINCIPLE OF ARCH ...0. sn 135

iii

KP GATE Classes, New Delhi | Coaching for GATE & Other Recruitment Tests in Architecture & Planning

KP GATE CLASSES, NEW DELHI - INDIA’S No. 1 Architecture COACHING

CHAPTER 1.” BUILDING MATERIALS

1

CHAPTER 1: BUILDING MATERIALS

KP GATE CLASSES, NEW DELHI - INDIA’S No. 1 Architecture COACHING

11 TIMBER

Wood derived from trees is processed into planks for use in construction. Such wood prepared for use

in construction and carpentry is termed as “timber”.

1.1.1 CLASSIFICATION OF TIMBER

Timber can be classified into categories based on many criteria, Few such parameters are; growth

characteristics, wood characteristics, and grading.

Based on growth characteristics, timber is classified into exogenous and endogenous. Exogefous trees

grow outward by adding distinct consecutive rings known as growth rings or annual rings, In'such trees

it is possible to estimate the age of timber by counting the number of rings. Endogenous, trees. grow

inwards. In these trees, fresh fibrous mass is in the inner most portion. Examples of endogenous trees

are bamboo and cane,

Based on wood characteristics, timber is classified into hardwood and softwood. HafdWiood is generally

derived from deciduous trees (characterized by broad leaves). Hardwood'ls generally dark and heavy

with good strength and fire resistance. Softwood is generally @erived™from coniferous trees

(characterized by cone shaped fruits). Softwood is generally light in Colour and weight with lower

strength and fire resistance compared to hardwood.

Based on grading as per IS 883:1994, timber is classified into three Groups. The classification is based

on strength properties, namely, modulus of elasticity (E)and extreme fiber stress in bending and tension

(f), The classification is tabulated below:

Group A E above 12.6 x 10° Nimmé, f abovalté.0 Nimm?

Group B E above 9.8 x 10° Nimm? and up f6 12.6 x 10° Nimm?; f above 12.0 Nimm?

and up to 18.0 N/mm?

Group C E above 5.6 x 10° Nigim? and up to 9.8 x 10 Nimm*, Fabove 8.5 Nimm? and

up to 12.0 imme

1.1.2 CROSS-SECTIONORTIMBER

Cross-section of timber for a typical exogenous tree is characterized by concentric growth rings. The

dead inner rings are called “heartwood” which is relatively dry and living outer rings are called ‘sap

‘wood’ which is relatively moist. Other important parts are marked in the figure below:

Sap wood Our bare

SS Heart wood

iE Pam

Inner bark

‘Annual ring

‘Cambium layer

Medullary rays

1 Cross-section of Timber

2

CHAPTER 1: BUILDING MATERIALS

KP GATE CLASSES, NEW DELHI - INDIA’S No. 1 Architecture COACHING

a. Pith: Iti the inner most part of the tree and hence the oldest part of exogeneous tree when the plant

becomes old, the pith dies and becomes fibrous and dark. It varies in size and shape.

b. Heart Wood: This is the portion surrounding pith. It is dark in colour and strong. This portion is

Useful for various engineering purpose, This is the dead part of wood. It consists of multiple growth

rings.

c. Sap Wood: It is the layer next to heart wood. It is composed of newer growth and contains sap. It

takes active part in the growth of trees by allowing sap to move in upward direction. The growth

rings of sap wood are light in colour. Sap wood is also termed as alburnum.

d. Cambium Layer: Itis thin layer of fresh sap lying between sap wood and the inner bark(It contains

‘sap which is not yet converted into sap wood.

e. Inner Bark: It is an inner skin of tree protecting the cambium layer.

f. Outer Bark; Itis the outer skin of the tree and consists of wood fibers. Sometimes it contains fissures

and cracks.

9. Medullary Rays: These are thin radial fibers extending from pith to cambium layer. They hold

annular rings together. In some of trees they are broken and sométimes may not be visually

prominent.

1.1.3 SAWING OF TIMBER

Tree logs (trees after felled) if not cut/sawn for aelong'duration, would result in circumferential

shrinkage due to moisture drying from the outer part (sapwood). The outer most rings shrink more as

compared to inner rings. As a result, star shakes or cracks (discussed under defects) would appear on

the surface of log and deteriorate the timber quality.

There are four main methods of sawing! They"re; Ordinary sawing, Quarter sawing, Tangential sawing

and Radial sawing,

Tangential Sawing Riftor Radial Sawing

2.Sawing of Timber

a, Ordinary Sawing: This is the most economical and widely used method of sawing. Here, long

parallel planks are cut from the tree log. As the inner portion (heart wood) is hard and outer portion

(sap wood) is soft, after drying there can be unequal shrinkage. So, the planks are liable to wrap

and twist.

b. Quarter Sawing: In Quarter sawing the logs are cut or sawn in quarter and each quarter is then cut

in such a way that the sawn members bend in transverse direction, This method is generally adopted

‘when no distinct medullary rays are present,

3

CHAPTER 1: BUILDING MATERIALS

KP GATE CLASSES, NEW DELHI - INDIA’S No. 1 Architecture COACHING

¢. Tangential Sawing: Tangential sawing is generally used if annual rings are well formed and

medullary rays are not well formed. In this method, cuts are made tangent to the annual rings. Planks

obtained by this method wrap too much and must not be used for costly structural works or for

flooring,

d. Radial Sawing: In this method logs are sawn parallel to medullary rays and perpendicular to annual

rings. This method gives least shrinkage but has highest wastage. This method gives most

decorative grain patterns in which medullary rays are marked. This method yields timber planks

‘with least shrinkage because of the property of medullary rays to resist shrinkage. This method is

also known as Rift Sawing

1.1.4 SEASONING OF TIMBER

Controlled reduction of moisture content from timber is termed as “Seasoning”. Moisturé contént of

trees may sometimes be as high as 60 percent. Proper seasoning of timber brings, down this,moisture

Content to as low as 10 percent.

Seasoning of timber is necessary to reduce the moisture content and thereby increase the strength of

timber. Seasoning of timber also reduces development of shrinkage defects and rests in longer life of

the timber.

‘Methods for seasoning of timber can be classified into two types’ Natural seasoning and Artificial

seasoning. Natural seasoning is of two main types; Water seasoning and Air seasoning. Artificial

seasoning is of four main types; Seasoning by boilig, Kiln seasoning, Chemical seasoning and

Electrical seasoning, The flowchart below summarizes the, classification of methods for seasoning

timber:

Air Seasoning

Nérural Seasoning

Water Seasoning

Seasoniti’ Of Timber Seasoning by Boiling

Kiln Seasoning

(| amtificial Seasoning

Chemical Seasoning

Electrical Seasoning

3 Classification of Timber Seasoning

A. Natural Seasoning: Seasoning of timber using natural elements like air and water is called ‘Natural

Seasoning’. This type of seasoning does not make use of extemal energy sources like fuel,

electricity or chemicals. Natural seasoning is of two main types as explained below,

4

CHAPTER 1: BUILDING MATERIALS

KP GATE CLASSES, NEW DELHI - INDIA’S No. 1 Architecture COACHING

~ Air Seasoning: This process involves exposing timber to air flow for seasoning. At first, a

platform or block piers are built on the ground to about 300mm height from ground level. Then

the arrangement of timber in layers is prepared above the platform. Air circulation is

maintained between timber planks to help reduce the moisture content. Even though this is a

slow process, itis an economical method suitable for large scale seasoning,

Sloped roof

Sticker

Level surface

Brick upstand

4 Air Seasoning

- Water Seasoning: This process is carried along riverbanks or streams where removal of wood

sap is achieved by immersing logs into water flows, This helps in replacement of wood sap of

‘wood cells by water. The water-saturated. wood, dries quicker as compared to sap-saturated

‘wood. This is a time-consuming process but aff economical method.

B. Artificial Seasoning: Antficial seasoning is a faster alternative process for seasoning timber but is

costlier compared to natural processes. Types of artificial seasoning processes are discussed below:

= Seasoning by Boiling: Seasoning of timber is achieved by boiling it in water for 3 to 4 hours.

‘After boiling, timber'isyallowed to dry. For large quantity of timber where boiling can be

difficult, hot steam i8 passed through timber logs in an enclosed space. The boiling or steaming

process devélops the strength and elasticity of timber but it is costlier process,

- Kiln Seasoning: inthis method timber is subjected to hot air in an air tight chamber. The hot

air.irculates betwieen the timber logs and reduces the moisture content. The temperature inside

the chamber is raised with the help of heating coils. When the required temperature is obtained

‘moisture content and relative humidity gets reduced and timber gets seasoned. Even though it

is acostly process it gives good results with respect to strength.

= "Chemical Seasoning: In chemical seasoning, timber is stored in suitable salt solution for some

time. The salt solution used has the tendency to absorb water from the timber. So, the moisture

content is reduced, and then timber surface is allowed to dry. Even though this a quick process,

it may sometimes affect the strength of timber.

= Electrical Seasoning: Dry wood is non-conductor of electricity while moist timber is a

conductor and can allow alternating current to pass through it. So, in this method alternating

current is used for drying the cells of timber by creating heat. As electricity is used, this process

is not economical

5

CHAPTER 1: BUILDING MATERIALS

KP GATE CLASSES, NEW DELHI - INDIA’S No. 1 Architecture COACHING

1.1.5 PRESERVATIVES FOR TIMBER

Timber being an organic material, it may decay with time, This process of deterioration may be rapid

in some exposure conditions. Generally, rotting of timber due to growth of fungus or insects like

termites, is seen in moist or humid conditions.

There are many timber preservatives available which can reduce decay of timber by controlling the

growth and spread of fungi and termites. These preservatives can be applied by using a suitable process

like, brushing, spraying, injecting under pressure, etc

‘Some important timber preservatives are discussed below:

Coal tar: Itisa thick dark liquid which isa by-product of coal gas production. Coal taris‘applied

to preserve timber from growth of fungi. It penetrates into wood tissue and s6 can have high

degree of performance for a long duration of time. It has unpleasant smell and also results in

unpleasant surface appearance on timber.

ASCU preservatives: ASCU (from chemical symbols for Arsenic and, Coppa) preservatives

are dissolved in water to prepare preservative solution. This odorféss solution is sprayed on to

timber to protect it from white ants

Chemical salts: Water soluble chemical salts like copper sulphatey'mercury chloride, zinc

chloride, sodium fluoride, sodium fluosilicates, etc. are used toxprepare a water based liquid

solution and are applied onto timber surface. The demerit iftUsing these salts is that they can be

‘washed away if the timber is exposed to moist conditions.

Solignum preservative: Solignum paints/@te appliethin hot condition using brush. They ere

‘well suitable for preserving timber from white ants. Solignum paints can be used by adding

colour pigments and so the timber can have good appearance

Creosote oil: Creosote oil is prepared.by the distillation of tar. Its black or brown in colour. It

has an unpleasant smell Its applied in a process where itis injected into timber under pressure.

Itisa flammable oil and s0 is avoided for timber works near fireplaces. It is generally used for

railway sleepers and woodentpoles.

There are some alternative titber preservation processes like charting and use of termite shields.

Charting: Itistcommon method used for preserving timber poles and posts that are to be dug

into the ground. The outer part of the lower ends is charred (incompletely burnt) before insertion

into the ground. The charcoal layer so formed is an easy safeguard against attacks by fungi or

termite (as these organisms do not find any food in charcoal).

Termite shields: The base of major timber columns may be preserved against organic attack by

‘constructing a suitable barrier between the timber and the ground. These barriers are termed as

“Tetmite Shields’

FLOOR voist

§ Termite Shield

6

CHAPTER 1: BUILDING MATERIALS

KP GATE CLASSES, NEW DELHI - INDIA’S No. 1 Architecture COACHING

1.1.6 DEFECTS IN TIMBER

Defects in timber can develop due to different reasons, viz., defects due to natural forces, defects due

to attack by insects and fungi, defects due to defective seasoning, etc. Various defects in timber are

categorized below:

A. DEFECTS DUE TO NATURAL FORCES: Defects in timber may arise due to natural forces like

wind or natural phenomenon like tree growth characteristics. Some important defects under this

category are listed below:

@ Knots

- Most common defect caused due £0 natural

forces

= When lower branches die, they remain inthe

tree as it grows. These) bases create

imperfections known as knots

= Knots are of 2 types 1ivé"Riozs which are

sound and firmevs ‘dead knots” which are

loose caused by damaged’ branches drying

and falling out

Gi) Shakes

Cup shakes

1 )

‘Shakes afe timber defects that occur around

the annual ring or growth ring of a timber. In

‘Other words, cracks or splits in the woods are

called shakes, which are of four types

(a))Cup shakes: Shakes which result in partial

separation along the growth rings

(b) Ring shakes: Shakes which result in

Complete separation along the grovith rings

(©) Star shakes: These shakes start

propagating from bark towards the sapwood

along the medullary rays. These shakes are

usually wider at bark and narrower inside.

(@) Heart shakes: These start propagating

from the pith to the sapwood along the lines

Of medullary rays caused sue to shrinkage of

interior part

Improper cutting of branches causes

abnormal growth of bark, called Rind gall

Wood from this portion lacks strength

- When wound of the tree is covered by a soft

skin, itis called as callus

~ Upsets in various wood indicate that the tree

was subjected to crushing or compression.

Improper felling of trees, heavy wind

blowing during the young age of the tree

these are the main reasons behind this type of

defect.

7

CHAPTER 1: BUILDING MATERIALS

KP GATE CLASSES, NEW DELHI - INDIA’S No. 1 Architecture COACHING

B. DEFECTS DUE TO ATTACK BY INSECTS: Insects like beetles, termites or marine boars eat

‘wood, make holes and weaken the strength of the wood. Beetles are small insects that make holes

in almost all the sapwood. The larvae make tunnels through the sapwood in all directions and turn

‘wood into powder. Termites live in a colony. They are very fast in eating woods and making tunnels

through it. Only a few good kinds of wood can withstand the action of termites.

CC. DEFECTS DUE TO ATTACK BY FUNGI: There are multiple types of defects that may arise in

timber due to growth of fungi. Growth of fungi is generally stimulated by presence of moisture

Some important defects under this category are listed below:

@__ Stain

‘When fungi feed only on sapwood, where the food materials ara

stored, it causes a stain,

= Heartwood doesn’t contain these kinds of food materials andis not

affected by it

- Stain action causes colour but does not affeet’the strength of the

wood.

= Wood eating or wood destroying fungus is.résponsible for this type

of defect in wood.

= Thistype of fungi breaks down thé cell structure, Both sapwood and

heartwood are affectediby them.

= Considerable stréngth reduietion occurs due to this defect,

= Dry rotis caused By ceftain type of fungi which actually eats wood

for their living, They make food by converting timber into dry

ppovider form.

= This occurs mainly when there is no ventilation of air or if the wood

improperly seasoned.

Sep This Can be prevented by using well-seasoned wood and also by

painting the timber surface with copper sulphate.

Gi) : rot

iv) Wetfot

~ Wet rot is caused by fungi which decomposes the timber and

Converts it into grayish brown powder form.

- Wet rot causing fungi growths mainly due to an alternating dry and

‘wet conditions of timber.

v) Heart rot

- Heart rot is caused in the trees when the heart wood is attacked by

fungi through its newly formed branch

~ This type of fungi makes the tree hollow by consuming heart wood

This defect is known as heart rot.

(vi) Othertypes [= Brown rot: wood brownish defect is called as brown rot

~ White rot: Unaffected cellulase results in white rot

~ Blue Stain: Defect caused by some fungi which makes timber bluish

8

CHAPTER 1: BUILDING MATERIALS

KP GATE CLASSES, NEW DELHI - INDIA’S No. 1 Architecture COACHING

D. DEFECTS IN TIMBER DUE TO DEFECTIVE SEASONING: Faulty method of seasoning causes

serious defects in woods. During seasoning of timber, exterior or surface layer of the timber dries

before the interior surface. So, stress is developed due to the difference in shrinkage. In a perfect,

seasoning process, stress is Kept minimum by controlling the shrinkage. Some of the defects

resulting from defective seasoning are as follows:

Bow: Curvature formed in | Cup: Curvature formed in the | Check is a kind of crack that

direction of the length of the | transverse direction of the | separates fibres, but it doesn’t

timber is called bow. timber is called a cup, extend from one end to

another.

Split: Split isa special type of | Twist: Twist is formed when | Honey.Gémbing: Stress is

heck that extends from one | the timber piece is spirally | developed. inythe heartwood

end to another. distorted along its length. It | during’the drying process or

looks like propeller blade after | seasoning. For these stresses,

twisting. cracks-are created in the form

‘ofhoneycomb texture.

Case Hardening: Case is the | Collapse During drying, some | Wrap: The loss of shape of

top surface of wood which'\,part of the wood may dry | wood due to stresses

dries rapidly during | rapidly while some may not. | developed during drying is

seasoning, but the inner part,| Because of this improper | called warping.

did not. Then.this defect is drying shrinkage of wood

called as case hardening ‘occurs which results the defect

called collapse.

1.1.7 ENGINEERED TIMBER

Engineered wood, also termed as composite wood, or manufactured board, includes a range of

derivative wood products are manufactured by binding or fixing the strands, particles, fibres,

or veneers or boards of wood, together with adhesives, or other methods of fixation to form composite

‘material. Some important types of engineered wood are discussed below:

9

CHAPTER 1: BUILDING MATERIALS

KP GATE CLASSES, NEW DELHI - INDIA’S No. 1 Architecture COACHING

sheets of laminated veneer bonded under heat and pressure

with durable, moisture resistant adhesives. Panel strength

and stiffness in both directions is maximized by cross-

orienting alternate layers, Cross-orienting is altering the

grain orientation of veneers from layer to layer.

‘A. Plywood: Plywood is a wood panel manufactured from

Particle board: Particle board is manufactured from wood

chips, sawmill shavings, or even sawdust, and a synthetic

resin or other suitable binder, which is pressed and

extruded. Particle board is cheaper, and more uniform than

conventional wood and plywood. So, it is substituted for

them when cost is more important than strength and

appearance

Fibreboard: Fibreboard is made by breaking down

hardwood or softwood residuals into wood fibres,

combining it with wax and a resin binder, and forming

panels by applying high temperature and pressure.

Processed wood fibres are compacted to various degrees to,

give various grades of fibreboards; Low-density fibreboard

(LDF), Medium-density fibreboard (MDF) and High-

density fibreboard (HDF).

Oriented strand board: Oriented strand board (OSB) i8\a)

‘wood structural panel manufactured from, rectangular-

shaped strands of wood that are oriented lengthwise and.

then arranged in layers, laid up into mats, and bonded

together with moisture-resistant, heat*cured adhesives.

The individual layers can be? cfass-oriented to provide

strength and stiffness to the/panel.

‘Most of the engineered timber,surfaceS are not finished to give good interior appearance (like in

plywood). So, engineered timber is finished with laminate or veneer on the external surface, Sheets of

laminate or veneer are Struck onto the surface of engineered wood using adhesives.

Laminate

Veneer

Engineered from paperand pl

‘Made from natural hardwood

‘Appearance achieved from printed sheet on top

‘Appearance is from natural grains of wood

Available if numerous colours and shades with

textured, high gloss, soft and matte finishes

Since itis a natural material, limited number of

shades available

Easier to maintain. They are scratch-resistant,

‘waterproof and usually retain their look for years.

Require more maintenance. Veneer surfaces

should be polished from time to time

Usually affordable

Costlier than laminates

10

CHAPTER 1: BUILDING MATERIALS

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 1Document2 pages1madhani akhilNo ratings yet

- B2G Consultancy Proposal SMCDocument3 pagesB2G Consultancy Proposal SMCmadhani akhilNo ratings yet

- Online Seva Pooja BookingDocument4 pagesOnline Seva Pooja Bookingmadhani akhilNo ratings yet

- 49e6f26f-7324-4ab1-afa3-994bbfb158daDocument12 pages49e6f26f-7324-4ab1-afa3-994bbfb158damadhani akhilNo ratings yet

- 358a5eff-2eb4-4357-b7c6-1695849a6d38Document13 pages358a5eff-2eb4-4357-b7c6-1695849a6d38madhani akhilNo ratings yet

- 795e05d0-152b-4deb-af16-080397913073 (1)Document12 pages795e05d0-152b-4deb-af16-080397913073 (1)madhani akhilNo ratings yet

- Aee Civil GRL Todisplay-1-70Document70 pagesAee Civil GRL Todisplay-1-70madhani akhilNo ratings yet

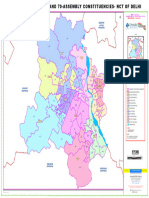

- Delhi Wards MapDocument1 pageDelhi Wards Mapmadhani akhilNo ratings yet