Professional Documents

Culture Documents

Globe 0.5in Up To 1.5in-Valve Spec - YTAN5 - R1

Globe 0.5in Up To 1.5in-Valve Spec - YTAN5 - R1

Uploaded by

Ammanda ErnawanCopyright:

Available Formats

You might also like

- A - Level Project Work Insights & ReflectionsDocument3 pagesA - Level Project Work Insights & ReflectionsKou Uraki0% (1)

- PQR 014 (Qualified Sa 106 GR BDocument5 pagesPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- 652-100-FINAL (ITP) Rev1Document4 pages652-100-FINAL (ITP) Rev1Anonymous AdofXEYAgENo ratings yet

- 4100XPB 4198 Grupo Mexico CananDocument758 pages4100XPB 4198 Grupo Mexico CananWalissonNo ratings yet

- API 510 Data SheetsDocument11 pagesAPI 510 Data SheetshahahNo ratings yet

- (A) Dimensions: (D) Cupping TestDocument5 pages(A) Dimensions: (D) Cupping Testanon_115606397100% (7)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Fundamentals of Nursing PDFDocument18 pagesFundamentals of Nursing PDFJamaica Manuel Iglesias100% (6)

- Item Inspected: CBLT-TPI-00F-186-12623Document16 pagesItem Inspected: CBLT-TPI-00F-186-12623Zulfadli RaniNo ratings yet

- Inspection and Test Plan / Ni-Al Bronze Manual Valves (Vendor Doc - No#: ITP-01-535)Document4 pagesInspection and Test Plan / Ni-Al Bronze Manual Valves (Vendor Doc - No#: ITP-01-535)Muthazhagan SaravananNo ratings yet

- WPQ Process As Per ISO-9606-1 2013Document4 pagesWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- Alstom IRDocument4 pagesAlstom IRkasi reddyNo ratings yet

- Smls Itp MpsDocument5 pagesSmls Itp MpsGabriel Caicedo RussyNo ratings yet

- WPS - Smaw - 2Document6 pagesWPS - Smaw - 2Harkesh RajputNo ratings yet

- ITP Piping Nitrogen SystemDocument48 pagesITP Piping Nitrogen Systemmohd as shahiddin jafriNo ratings yet

- Bdde PQR CS 001Document2 pagesBdde PQR CS 001mainur mechanical engineer0% (1)

- 0 Material Inspection SlideDocument116 pages0 Material Inspection SlideMinh VuuNo ratings yet

- Sample QAPDocument3 pagesSample QAPsniperiNo ratings yet

- Revise Insp Report - 1 PDFDocument4 pagesRevise Insp Report - 1 PDFShankar RajNo ratings yet

- Valtech - KR: Valve Inspection and Testing Inspection ValvesDocument11 pagesValtech - KR: Valve Inspection and Testing Inspection ValvesHARSHANo ratings yet

- Itp For SSDP Project Rev CDocument9 pagesItp For SSDP Project Rev CRachel FloresNo ratings yet

- GNL3Z PJ Piping InspectionDocument29 pagesGNL3Z PJ Piping Inspectiondon_romanticko281236No ratings yet

- Tag No., Batch No., Serial No., Cast, Heat No: SummaryDocument4 pagesTag No., Batch No., Serial No., Cast, Heat No: SummarySyed JafarNo ratings yet

- Welder Cirt TotalDocument78 pagesWelder Cirt TotalNguyễn ChâuNo ratings yet

- CERTIFICADO PLASSON PORTABRIDA 90 MMDocument1 pageCERTIFICADO PLASSON PORTABRIDA 90 MMangel rojasNo ratings yet

- Pages From 30.99.97.1612 Rev.1 SMR - Stock Material Request GuidelinesDocument1 pagePages From 30.99.97.1612 Rev.1 SMR - Stock Material Request GuidelinesPradeepNo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- Dots For Engineering Industries: Test Stump Recertification Document Package SN (D-N-RFL-1635)Document13 pagesDots For Engineering Industries: Test Stump Recertification Document Package SN (D-N-RFL-1635)Moustafa AshrafNo ratings yet

- IS 1703:2000 (Reaffirmed 2010) Reaffirmed 2009)Document14 pagesIS 1703:2000 (Reaffirmed 2010) Reaffirmed 2009)Rakesh Kumar VermaNo ratings yet

- TDC For Flanges SA 105NDocument2 pagesTDC For Flanges SA 105NRenny DevassyNo ratings yet

- Ydf Globo 1 PDFDocument3 pagesYdf Globo 1 PDFArnoldo Huertas garzonNo ratings yet

- nITP For Suspenion Hanger Pin Alt 2Document4 pagesnITP For Suspenion Hanger Pin Alt 2ABHISHEK KUMARNo ratings yet

- GNL3Z PJ PIPING INSPECTION Rev1Document41 pagesGNL3Z PJ PIPING INSPECTION Rev1Aris BulaongNo ratings yet

- Standard ITP For PEB Steel StructuresDocument2 pagesStandard ITP For PEB Steel StructuresEmirald MattaNo ratings yet

- QAP of HT Breaker Panel SchneiderDocument1 pageQAP of HT Breaker Panel Schneidermadhu_bedi12No ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- ITP For CS Is 1239 FittingsDocument1 pageITP For CS Is 1239 FittingsMaan RawatNo ratings yet

- 049-Itp For Lighting and Small Power (Building) PDFDocument15 pages049-Itp For Lighting and Small Power (Building) PDFKöksal Patan100% (1)

- Visual Check List For Control Valve: Rock Payvand Sanat ArvandDocument1 pageVisual Check List For Control Valve: Rock Payvand Sanat Arvandarmin heidariNo ratings yet

- Qap Rap PDFDocument1 pageQap Rap PDFtrushalpanchalNo ratings yet

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 pagesProcedure Qualification Record (PQR) Khewari Development Projectsar sarNo ratings yet

- 2009 BV SocketWelded DatasheetDocument2 pages2009 BV SocketWelded DatasheetAqib Khan VCSPNo ratings yet

- Valvulas de Compuerta 3-4 X 800Document3 pagesValvulas de Compuerta 3-4 X 800danielsalcedomringenierosNo ratings yet

- 16 Electrode QualificationDocument11 pages16 Electrode QualificationAkhilesh Kumar67% (3)

- TP-WMS-05816-DAS-A4-D1-L - Swing Check Valve DatasheetDocument1 pageTP-WMS-05816-DAS-A4-D1-L - Swing Check Valve Datasheetbmanojkumar16No ratings yet

- Tech Spec For Centrifugal PumpDocument5 pagesTech Spec For Centrifugal PumpRoby Mirza100% (1)

- 31-03-2020 C1 Generator Rotor Hydrogen Seal Ring - UTDocument6 pages31-03-2020 C1 Generator Rotor Hydrogen Seal Ring - UTDave CheungNo ratings yet

- RR3-3269 Eo1352Document2 pagesRR3-3269 Eo1352Deepak HoleNo ratings yet

- Omtech Tubes QAPDocument1 pageOmtech Tubes QAPPrathamesh OmtechNo ratings yet

- Burckhardt Compression (India) PVT - LTD.: 1.0 MaterialsDocument2 pagesBurckhardt Compression (India) PVT - LTD.: 1.0 MaterialsYOGESHNo ratings yet

- WPS SampleDocument6 pagesWPS SampleAshishNo ratings yet

- WPS SampleDocument6 pagesWPS SampleAshishNo ratings yet

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Document3 pagesWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaNo ratings yet

- Quality PlanDocument3 pagesQuality PlanhjgajjarNo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- Ir 5073 Ppa 005Document6 pagesIr 5073 Ppa 005ValiNo ratings yet

- Data Sheet 2 Less 800#-BV - FB - SW - NT-76 PDFDocument1 pageData Sheet 2 Less 800#-BV - FB - SW - NT-76 PDFSachin KumarNo ratings yet

- Docslide - Us - Itp Structural WorkDocument4 pagesDocslide - Us - Itp Structural Workomda4wadyNo ratings yet

- 31-03-2020 C1 Generator Rotor Hydrogen Seal Ring - PTDocument3 pages31-03-2020 C1 Generator Rotor Hydrogen Seal Ring - PTDave CheungNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Distribution Network of Coca-ColaDocument16 pagesDistribution Network of Coca-ColaRahul panditaNo ratings yet

- Learning Activity Sheet Electronics G10 Q3 W1Document5 pagesLearning Activity Sheet Electronics G10 Q3 W1Mark Anthony Discarga JetajobeNo ratings yet

- PHAS0027 RevisionDocument21 pagesPHAS0027 Revisionunknown.unknown9901No ratings yet

- 2442 4348 2 PBDocument8 pages2442 4348 2 PBdev iNo ratings yet

- Nine Day Novena of The Holy Face of JesusDocument25 pagesNine Day Novena of The Holy Face of Jesusangutoko benard100% (2)

- Lesson 3 Characteristics of Properly Designed PCBDocument11 pagesLesson 3 Characteristics of Properly Designed PCBJosephine QuinnNo ratings yet

- Anthe Junior Sample Paper Class IXDocument14 pagesAnthe Junior Sample Paper Class IXMota Chashma85% (62)

- MAC-LAB Assistant 5BDocument38 pagesMAC-LAB Assistant 5BAbdelhakszn SznNo ratings yet

- Sago Pudding - Recipes - Poh's KitchenDocument2 pagesSago Pudding - Recipes - Poh's KitchenXuxu TooNo ratings yet

- India Bulls Housing Finance LimitedDocument67 pagesIndia Bulls Housing Finance LimitedslohariNo ratings yet

- Pipe System Friction Loss CalculationDocument4 pagesPipe System Friction Loss Calculationtorbenchr100% (1)

- A Study On Occupational Hazards in Die Casting IndustriesDocument8 pagesA Study On Occupational Hazards in Die Casting IndustriesManik LakshmanNo ratings yet

- Riko Technical Brochure PDFDocument29 pagesRiko Technical Brochure PDFGrigoreOzonNo ratings yet

- Fantastic Four Drug For Heart FailureDocument47 pagesFantastic Four Drug For Heart FailurePutro Panji Asmoro BangunNo ratings yet

- Sec3 Well Spud and Guide StructuresDocument15 pagesSec3 Well Spud and Guide StructuresDonald StraubNo ratings yet

- 7.44.session VI EHa and LTR Process Flow and Steam Gathering System v3 PDFDocument56 pages7.44.session VI EHa and LTR Process Flow and Steam Gathering System v3 PDFadityaNo ratings yet

- Kiambu CidpDocument342 pagesKiambu CidpCharles ZihiNo ratings yet

- Physiology of Lymph SystemDocument7 pagesPhysiology of Lymph SystemMwangi NyawiraNo ratings yet

- Surgical Operation PDFDocument64 pagesSurgical Operation PDFshifna.latheefNo ratings yet

- Codes Standards RegulationsDocument11 pagesCodes Standards RegulationsEslNo ratings yet

- Women Mental Health:: Postpartum DepressionDocument62 pagesWomen Mental Health:: Postpartum DepressionTickablingbling Alwaysshine Likeatenglarious100% (1)

- Capinew Account June13Document7 pagesCapinew Account June13ashwinNo ratings yet

- Vegetarian Meals On College CampusesDocument14 pagesVegetarian Meals On College CampusesVegan FutureNo ratings yet

- Cavitation Models in PIPENETDocument3 pagesCavitation Models in PIPENETSamarth PawarNo ratings yet

- PDS - CS - Form - No - 212 SHERLADocument8 pagesPDS - CS - Form - No - 212 SHERLASherla Catulay Godinez NautanNo ratings yet

- Duolingo Word ListDocument30 pagesDuolingo Word ListSabira AlizadaNo ratings yet

- Normal Lab ValuesDocument4 pagesNormal Lab Valuesrmelendez001No ratings yet

Globe 0.5in Up To 1.5in-Valve Spec - YTAN5 - R1

Globe 0.5in Up To 1.5in-Valve Spec - YTAN5 - R1

Uploaded by

Ammanda ErnawanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Globe 0.5in Up To 1.5in-Valve Spec - YTAN5 - R1

Globe 0.5in Up To 1.5in-Valve Spec - YTAN5 - R1

Uploaded by

Ammanda ErnawanCopyright:

Available Formats

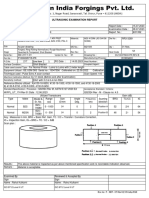

Valve I.D. No.

: YTAN5

GLOBE VALVE SPECIFICATION Spec. No.: Rev. No. :

CPDS 03-12-09 2

Required Notes Vendor Offering

Service: Boiler Feed Water and Steam

Manufacturing Standard (API, API STD 602

ASME, etc.):

Manufacturer and Fig. No.: Vendor to Advise

Body Type: T- Type

Size Range: NPS 1/2 up to 1-1/2

Pressure Rating (Class): Class 800

End Connection: SW ends to ASME B16.11

Temperature Limit: -29 up to 270°C

Body Construction (OS&Y, BB, BB, OS&Y

etc.):

Body and Bonnet Material : ASTM A105/A105M Normalized Forging

Gate/Wedge Material: 410 (13Cr)

Stem Material: 410 (13Cr)

API Trim Number: API trim 8 (13 Cr, hard faced Co-Cr A)

Packing Material: Flexible Graphite (Note 3)

Valve Bore/ Port Size (Std., Standard Port

Full, etc.):

Bolting: ASTM A193 GR.B7M A194 GR.2HM

with Zinc Plating basecoat +

Fluoropolymer topcoat

Operator (Handwheel, Gear, Handwheel operated

etc.):

Painting: As per Manufacturer Standard

Notes:

1 Deleted.

2 Specific exceptions to this data sheet and Notes shall be included in the Vendor Offering

section of this data sheet or attached to this data sheet.

3 The packing configuration shall consist of two end retainer rings made of braided graphite

and three intermediate rings made from die-formed flexible graphite with a density of 1120

to 1280 kg/m3 (70 to 80 lb/ft3).

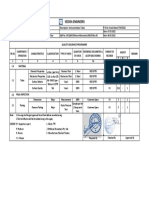

Valve I.D. No.: YTAN5

QA/QC Criteria Sheet Spec. No.: Rev. No.:

CPDS 03-12-09 2

Required Notes Vendor Offering

Product:

Forged body As per EMCL Approved Manufacturer List

Documentation: API 602 Monogramed

Material Certificate type 3.1 (Body, Disc,

Stem)

Cross Sectional GA Drawing

Pressure test procedure

Installation, operation, and maintenance

instructions/manual

Pressure Testing: Shell Test, Backseat Test and Low

Pressure Closure Test as per API 598.

Manufacture Design: API 602

Fire Safe Design to API 6FA or API 607

Hardness Testing: Not applicable

Manufacturing Forging: ASTM A105/A105M Normalized

Standard:

Body

Material Properties:

Body Forging:

Chemical comp: ASTM A105/A105M

Mechanical: ASTM A105/A105M

Grain Size: 8# or finer per ASTM E112

Hardness: -

Wedge & Stem Chemical comp: 410 (13Cr)

Mechanical: 410 (13Cr)

Hardness: N/A

Heat Treatment: -

Valve I.D. No.: YTAN5

INSPECTION AND TEST PLAN Spec. No.: Rev. No.:

CPDS 03-12-09 2

Inspection

Inspection Inspection Level

Acceptance Verified

No Description Ref Doc

Method Criteria Document

Vendor EMCL

1 Material Inspection Inspection Data Sheet ASTM Std. MTC P R

2 Hydrostatic test Inspection Pressure Test Pressure Test Report P SW

Procedure Procedure

3 Pneumatic Test Inspection Pressure Test Pressure Test Report P SW

Procedure Procedure

4 Visual & Dimension Test Inspection Data Sheet Data Sheet Report P W

Notes:

MTC = Material Test Certificate P = Prepare R = Review

SW = Spot Witnessed (10% from total quantity W = Witness (100%)

1. Notification for inspection shall be issued not less than 1 week prior of testing date

You might also like

- A - Level Project Work Insights & ReflectionsDocument3 pagesA - Level Project Work Insights & ReflectionsKou Uraki0% (1)

- PQR 014 (Qualified Sa 106 GR BDocument5 pagesPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- 652-100-FINAL (ITP) Rev1Document4 pages652-100-FINAL (ITP) Rev1Anonymous AdofXEYAgENo ratings yet

- 4100XPB 4198 Grupo Mexico CananDocument758 pages4100XPB 4198 Grupo Mexico CananWalissonNo ratings yet

- API 510 Data SheetsDocument11 pagesAPI 510 Data SheetshahahNo ratings yet

- (A) Dimensions: (D) Cupping TestDocument5 pages(A) Dimensions: (D) Cupping Testanon_115606397100% (7)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Fundamentals of Nursing PDFDocument18 pagesFundamentals of Nursing PDFJamaica Manuel Iglesias100% (6)

- Item Inspected: CBLT-TPI-00F-186-12623Document16 pagesItem Inspected: CBLT-TPI-00F-186-12623Zulfadli RaniNo ratings yet

- Inspection and Test Plan / Ni-Al Bronze Manual Valves (Vendor Doc - No#: ITP-01-535)Document4 pagesInspection and Test Plan / Ni-Al Bronze Manual Valves (Vendor Doc - No#: ITP-01-535)Muthazhagan SaravananNo ratings yet

- WPQ Process As Per ISO-9606-1 2013Document4 pagesWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- Alstom IRDocument4 pagesAlstom IRkasi reddyNo ratings yet

- Smls Itp MpsDocument5 pagesSmls Itp MpsGabriel Caicedo RussyNo ratings yet

- WPS - Smaw - 2Document6 pagesWPS - Smaw - 2Harkesh RajputNo ratings yet

- ITP Piping Nitrogen SystemDocument48 pagesITP Piping Nitrogen Systemmohd as shahiddin jafriNo ratings yet

- Bdde PQR CS 001Document2 pagesBdde PQR CS 001mainur mechanical engineer0% (1)

- 0 Material Inspection SlideDocument116 pages0 Material Inspection SlideMinh VuuNo ratings yet

- Sample QAPDocument3 pagesSample QAPsniperiNo ratings yet

- Revise Insp Report - 1 PDFDocument4 pagesRevise Insp Report - 1 PDFShankar RajNo ratings yet

- Valtech - KR: Valve Inspection and Testing Inspection ValvesDocument11 pagesValtech - KR: Valve Inspection and Testing Inspection ValvesHARSHANo ratings yet

- Itp For SSDP Project Rev CDocument9 pagesItp For SSDP Project Rev CRachel FloresNo ratings yet

- GNL3Z PJ Piping InspectionDocument29 pagesGNL3Z PJ Piping Inspectiondon_romanticko281236No ratings yet

- Tag No., Batch No., Serial No., Cast, Heat No: SummaryDocument4 pagesTag No., Batch No., Serial No., Cast, Heat No: SummarySyed JafarNo ratings yet

- Welder Cirt TotalDocument78 pagesWelder Cirt TotalNguyễn ChâuNo ratings yet

- CERTIFICADO PLASSON PORTABRIDA 90 MMDocument1 pageCERTIFICADO PLASSON PORTABRIDA 90 MMangel rojasNo ratings yet

- Pages From 30.99.97.1612 Rev.1 SMR - Stock Material Request GuidelinesDocument1 pagePages From 30.99.97.1612 Rev.1 SMR - Stock Material Request GuidelinesPradeepNo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- Dots For Engineering Industries: Test Stump Recertification Document Package SN (D-N-RFL-1635)Document13 pagesDots For Engineering Industries: Test Stump Recertification Document Package SN (D-N-RFL-1635)Moustafa AshrafNo ratings yet

- IS 1703:2000 (Reaffirmed 2010) Reaffirmed 2009)Document14 pagesIS 1703:2000 (Reaffirmed 2010) Reaffirmed 2009)Rakesh Kumar VermaNo ratings yet

- TDC For Flanges SA 105NDocument2 pagesTDC For Flanges SA 105NRenny DevassyNo ratings yet

- Ydf Globo 1 PDFDocument3 pagesYdf Globo 1 PDFArnoldo Huertas garzonNo ratings yet

- nITP For Suspenion Hanger Pin Alt 2Document4 pagesnITP For Suspenion Hanger Pin Alt 2ABHISHEK KUMARNo ratings yet

- GNL3Z PJ PIPING INSPECTION Rev1Document41 pagesGNL3Z PJ PIPING INSPECTION Rev1Aris BulaongNo ratings yet

- Standard ITP For PEB Steel StructuresDocument2 pagesStandard ITP For PEB Steel StructuresEmirald MattaNo ratings yet

- QAP of HT Breaker Panel SchneiderDocument1 pageQAP of HT Breaker Panel Schneidermadhu_bedi12No ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- ITP For CS Is 1239 FittingsDocument1 pageITP For CS Is 1239 FittingsMaan RawatNo ratings yet

- 049-Itp For Lighting and Small Power (Building) PDFDocument15 pages049-Itp For Lighting and Small Power (Building) PDFKöksal Patan100% (1)

- Visual Check List For Control Valve: Rock Payvand Sanat ArvandDocument1 pageVisual Check List For Control Valve: Rock Payvand Sanat Arvandarmin heidariNo ratings yet

- Qap Rap PDFDocument1 pageQap Rap PDFtrushalpanchalNo ratings yet

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 pagesProcedure Qualification Record (PQR) Khewari Development Projectsar sarNo ratings yet

- 2009 BV SocketWelded DatasheetDocument2 pages2009 BV SocketWelded DatasheetAqib Khan VCSPNo ratings yet

- Valvulas de Compuerta 3-4 X 800Document3 pagesValvulas de Compuerta 3-4 X 800danielsalcedomringenierosNo ratings yet

- 16 Electrode QualificationDocument11 pages16 Electrode QualificationAkhilesh Kumar67% (3)

- TP-WMS-05816-DAS-A4-D1-L - Swing Check Valve DatasheetDocument1 pageTP-WMS-05816-DAS-A4-D1-L - Swing Check Valve Datasheetbmanojkumar16No ratings yet

- Tech Spec For Centrifugal PumpDocument5 pagesTech Spec For Centrifugal PumpRoby Mirza100% (1)

- 31-03-2020 C1 Generator Rotor Hydrogen Seal Ring - UTDocument6 pages31-03-2020 C1 Generator Rotor Hydrogen Seal Ring - UTDave CheungNo ratings yet

- RR3-3269 Eo1352Document2 pagesRR3-3269 Eo1352Deepak HoleNo ratings yet

- Omtech Tubes QAPDocument1 pageOmtech Tubes QAPPrathamesh OmtechNo ratings yet

- Burckhardt Compression (India) PVT - LTD.: 1.0 MaterialsDocument2 pagesBurckhardt Compression (India) PVT - LTD.: 1.0 MaterialsYOGESHNo ratings yet

- WPS SampleDocument6 pagesWPS SampleAshishNo ratings yet

- WPS SampleDocument6 pagesWPS SampleAshishNo ratings yet

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Document3 pagesWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaNo ratings yet

- Quality PlanDocument3 pagesQuality PlanhjgajjarNo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- Ir 5073 Ppa 005Document6 pagesIr 5073 Ppa 005ValiNo ratings yet

- Data Sheet 2 Less 800#-BV - FB - SW - NT-76 PDFDocument1 pageData Sheet 2 Less 800#-BV - FB - SW - NT-76 PDFSachin KumarNo ratings yet

- Docslide - Us - Itp Structural WorkDocument4 pagesDocslide - Us - Itp Structural Workomda4wadyNo ratings yet

- 31-03-2020 C1 Generator Rotor Hydrogen Seal Ring - PTDocument3 pages31-03-2020 C1 Generator Rotor Hydrogen Seal Ring - PTDave CheungNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Distribution Network of Coca-ColaDocument16 pagesDistribution Network of Coca-ColaRahul panditaNo ratings yet

- Learning Activity Sheet Electronics G10 Q3 W1Document5 pagesLearning Activity Sheet Electronics G10 Q3 W1Mark Anthony Discarga JetajobeNo ratings yet

- PHAS0027 RevisionDocument21 pagesPHAS0027 Revisionunknown.unknown9901No ratings yet

- 2442 4348 2 PBDocument8 pages2442 4348 2 PBdev iNo ratings yet

- Nine Day Novena of The Holy Face of JesusDocument25 pagesNine Day Novena of The Holy Face of Jesusangutoko benard100% (2)

- Lesson 3 Characteristics of Properly Designed PCBDocument11 pagesLesson 3 Characteristics of Properly Designed PCBJosephine QuinnNo ratings yet

- Anthe Junior Sample Paper Class IXDocument14 pagesAnthe Junior Sample Paper Class IXMota Chashma85% (62)

- MAC-LAB Assistant 5BDocument38 pagesMAC-LAB Assistant 5BAbdelhakszn SznNo ratings yet

- Sago Pudding - Recipes - Poh's KitchenDocument2 pagesSago Pudding - Recipes - Poh's KitchenXuxu TooNo ratings yet

- India Bulls Housing Finance LimitedDocument67 pagesIndia Bulls Housing Finance LimitedslohariNo ratings yet

- Pipe System Friction Loss CalculationDocument4 pagesPipe System Friction Loss Calculationtorbenchr100% (1)

- A Study On Occupational Hazards in Die Casting IndustriesDocument8 pagesA Study On Occupational Hazards in Die Casting IndustriesManik LakshmanNo ratings yet

- Riko Technical Brochure PDFDocument29 pagesRiko Technical Brochure PDFGrigoreOzonNo ratings yet

- Fantastic Four Drug For Heart FailureDocument47 pagesFantastic Four Drug For Heart FailurePutro Panji Asmoro BangunNo ratings yet

- Sec3 Well Spud and Guide StructuresDocument15 pagesSec3 Well Spud and Guide StructuresDonald StraubNo ratings yet

- 7.44.session VI EHa and LTR Process Flow and Steam Gathering System v3 PDFDocument56 pages7.44.session VI EHa and LTR Process Flow and Steam Gathering System v3 PDFadityaNo ratings yet

- Kiambu CidpDocument342 pagesKiambu CidpCharles ZihiNo ratings yet

- Physiology of Lymph SystemDocument7 pagesPhysiology of Lymph SystemMwangi NyawiraNo ratings yet

- Surgical Operation PDFDocument64 pagesSurgical Operation PDFshifna.latheefNo ratings yet

- Codes Standards RegulationsDocument11 pagesCodes Standards RegulationsEslNo ratings yet

- Women Mental Health:: Postpartum DepressionDocument62 pagesWomen Mental Health:: Postpartum DepressionTickablingbling Alwaysshine Likeatenglarious100% (1)

- Capinew Account June13Document7 pagesCapinew Account June13ashwinNo ratings yet

- Vegetarian Meals On College CampusesDocument14 pagesVegetarian Meals On College CampusesVegan FutureNo ratings yet

- Cavitation Models in PIPENETDocument3 pagesCavitation Models in PIPENETSamarth PawarNo ratings yet

- PDS - CS - Form - No - 212 SHERLADocument8 pagesPDS - CS - Form - No - 212 SHERLASherla Catulay Godinez NautanNo ratings yet

- Duolingo Word ListDocument30 pagesDuolingo Word ListSabira AlizadaNo ratings yet

- Normal Lab ValuesDocument4 pagesNormal Lab Valuesrmelendez001No ratings yet