Professional Documents

Culture Documents

WPS PQR - P22 SS 18042024

WPS PQR - P22 SS 18042024

Uploaded by

mahesh kumar0 ratings0% found this document useful (0 votes)

2 views5 pagesOriginal Title

WPS-PQR_P22-SS-18042024 (1)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

2 views5 pagesWPS PQR - P22 SS 18042024

WPS PQR - P22 SS 18042024

Uploaded by

mahesh kumarCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 5

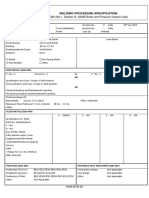

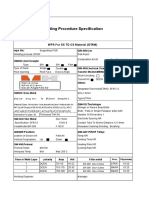

QW‐482 WELDING PROCEDURE SPECIFICATION (WPS)

(See QW‐200.1, Section IX, ASME Boiler and Pressure Vessel Code)

Company Name: General Instrument Consortium.

WPS No.: GIC/WPS/P22‐SS/001, DT 05/05/2016

Supporting PQR No.: GIC/PQR/P22‐SS/001, DT 15/04/2016

Welding process: GTAW + SMAW

Code: ASME Section IX – 2013 Type: Manual

Application: Welding of SA335 P22 to SA312 SS 316

Joints(QW‐402)

Groove Design : As per production drawing

Backing : No

Backing Material Type : NA

Retainer : NA

Base metal(QW‐403)

P‐No.: 5A Group No.: 1 to P No.: 8 Group No. : 1

OR

Specification and type /grade : SA 335 P22 to Specification and type /grade : SA312 SS316

Test Coupon Size – 6”ɸ X 10MM (THK)

Qualified Range‐

Base Metal Thk : Groove – 1.5MM to 20 MM Filet ‐ All

Pipe Dia. Range : Groove – All Fillet – All

FILLER METALS(QW‐404) GTAW SMAW

Specification No.(SFA) : 5.9 5.4

AWS No.(Classification) : ER 309LMo E309LMo

Filler material size : 1.6 & 3.15MM 4.0MM

Filler Material Product Form : Bare(Solid) Flux Coated

Supplemental Filler Material : NA NA

F‐Number :6 5

A‐Number : 8 8

Weld metal Thickness range : 2t mm max 2t Max

Consumable Inert : Nil Nil

Flux : NA NA

Positions (QW‐405)

Position of Groove : 5G

Welding Progression : Uphill

Positions of fillet : ALL

Preheat (QW‐406)

Preheat temp. : Min 177 °C

Inter pass temp : Max 200 °C

Preheat maintenance : NA

Post weld Heat Treatment (QW‐407)

Temperature Range : 715 °C ±15 °C

Time Range : 1 Hr / 25mm

Other : NA

GAS (QW – 408) Gas Mixture Flow Rate in LPM

Shielding gas Argon 99.995% 14‐15

Trail gas NA N.A N. A.

Backing gas for min 2 layers: Argon 99.995% 8‐10

TUV Job Reference No.: 8113244402 (106-045-16-02)

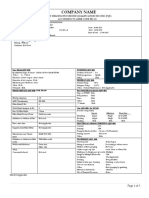

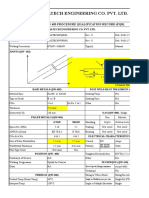

QW‐483 PROCEDURE QUALIFICATION RECORDS [PQR]

(See QW‐200.1, Section IX, ASME Boiler and Pressure Vessel Code)

Company Name: General Instrument Consortium.

PQR No.: GIC/PQR/P22‐SS/001, DT 05/05/2016

WPS No.: GIC/WPS/P22‐SS/001, DT 05/05/2016

Welding process: GTAW+SMAW Type: Manual

Joints [QW‐402]

Base Metal [QW‐403) POSTWELD HEAT TREATMENT [QW‐407]

P‐No. 5A Group No. 1 to P No. 8 Group No. 1 Temperature : 715 °C ±15 °C

OR Soaking Period : 1 Hr / 25mm

Specification and type /grade: Other : Nil

SA 335 P22 to SA 312 SS316 GAS [QW‐408]

Thickness of Test Coupon : 10MM Percent Composition

Size of Test Coupon: 6” (168.3mm) Gas(es) Mixture Flow Rate

Other: …. LPM

Shielding Argon 99.995% 8‐16

Filler Metal [QW‐404] GTAW SMAW Trailing NA NA NA

SFA Specification : 5.9 5.4

Backing Argon 99.995% 8‐16

AWS Classification : ER309LMo E309LMo

Filler Metal F.No. : 6 5

ELECTRICAL CHARACTERISTICS [QW‐409]

Weld Metal Analysis A. No.: 8 8

Size of Filler Metal : 1.6 & 3.15 4.0 Current :Direct Current (DC)

Filler Metal Product Form : Solid Bare Flux Coated Polarity : Electrode Negative (For GTAW)

Supplemental Filler Metal : NA NA Amps : 140‐160A

Volts : 10.6 – 30.1 V

Weld Metal Thickness : 3 mm 10mm

Tungsten Electrode Size & type: 1.6 & 3.15 mm

Other : Make: Mode of Metal Transfer : NA

Other: NIL

POSITION [QW‐405] Pulsing current : NIL

Position of Groove : 5G

Weld Progression : Uphill TECHNIQUE [QW‐410]

Other : NIL

Travel Speed: 30‐40mm/min

String /Weave Bead

PREHEAT [QW‐406]

RootString Rest Weave

Preheat temperature : Min 177 °C Oscillation : 3xwire Dia.(max)

Inter pass temperature : Max 200 °C Multiple or Single Pass [per side]: Multiple

Preheat maintenance : NA Single or Multiple Electrode : Single

Post Heat : NA Other: DP Test carried out after root & hot run

Soaking Time : NA welding

Peening: NA

Use of thermal process: NA

Closed to out chamber: NA

Manual or automatic: Manual

TUV Job Reference No.: 8113244402 (106-045-16-02)

You might also like

- WPS, PQR & WPQ - Duplex 2205Document20 pagesWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (6)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- PQRDocument2 pagesPQRHoangNo ratings yet

- Wps Format Asme Sec - IxDocument2 pagesWps Format Asme Sec - IxDeepu ChandranNo ratings yet

- Martyrologium Lent 2012Document60 pagesMartyrologium Lent 2012Filip100% (1)

- Balajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Document2 pagesBalajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Eswara Rao BodduNo ratings yet

- Aic Asf PQR 0122Document2 pagesAic Asf PQR 0122AHMED MEDANYNo ratings yet

- Welding Procedure Specification (WPS) : Supporting PQR 01Document2 pagesWelding Procedure Specification (WPS) : Supporting PQR 01duyanhNo ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- Aic Asf PQR 0120Document2 pagesAic Asf PQR 0120AHMED MEDANYNo ratings yet

- RK PWPS PC 001Document2 pagesRK PWPS PC 001SudeepDPoojaryNo ratings yet

- Procedure Qualification Record (PQR)Document3 pagesProcedure Qualification Record (PQR)Senthil KumaranNo ratings yet

- PQR 03 2014Document2 pagesPQR 03 2014vinuNo ratings yet

- Wps For Ss 304Document3 pagesWps For Ss 304Sajit PillaiNo ratings yet

- PQR A106 HAL-1Document1 pagePQR A106 HAL-1Budi Setia RahmanNo ratings yet

- WPS&PQR For PipeDocument5 pagesWPS&PQR For PipeKAMALNo ratings yet

- Form No. 101 - 401 Bharat Heavy Electricals Limited Tiruchirappalli-620014 Welding Technology Centre Page 1 of 2Document10 pagesForm No. 101 - 401 Bharat Heavy Electricals Limited Tiruchirappalli-620014 Welding Technology Centre Page 1 of 2JithinAbrahamNo ratings yet

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNo ratings yet

- QW 482 WPS (Gtaw+smaw) 04.01.2015Document8 pagesQW 482 WPS (Gtaw+smaw) 04.01.2015Srikant GanjiNo ratings yet

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDocument10 pagesWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- Aic Asf PQR 0119Document2 pagesAic Asf PQR 0119AHMED MEDANYNo ratings yet

- WPS Gtaw+smawDocument2 pagesWPS Gtaw+smawAnand GNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- Aic Asf PQR 0121Document2 pagesAic Asf PQR 0121AHMED MEDANYNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- QW - 483 Procedure Qualification Record: Wps No. Welding Process (Es) Type (Manual, Automatic, Semi-Auto)Document3 pagesQW - 483 Procedure Qualification Record: Wps No. Welding Process (Es) Type (Manual, Automatic, Semi-Auto)Alesol EquipmentNo ratings yet

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- Aic Asf PQR 133Document3 pagesAic Asf PQR 133AHMED MEDANYNo ratings yet

- PQR With-PwhtDocument2 pagesPQR With-PwhtKarthikNo ratings yet

- Larsen & Toubro Minerals & MetalsDocument2 pagesLarsen & Toubro Minerals & MetalsneerajNo ratings yet

- Mechanical Engineering M.Abdul GhoziDocument4 pagesMechanical Engineering M.Abdul GhoziRizaldy PhoenksNo ratings yet

- Welding Procedure Specification: Wps For Ss To Cs Material (Gtaw+Smaw)Document1 pageWelding Procedure Specification: Wps For Ss To Cs Material (Gtaw+Smaw)Lipika GayenNo ratings yet

- WPS, PQR, WPQ PoojaDocument10 pagesWPS, PQR, WPQ PoojaRajmahesh Dakhore100% (1)

- O O O O: Illustration: Joint Design, Weld Layers and Bead Sequence 3.5+0.5Document1 pageO O O O: Illustration: Joint Design, Weld Layers and Bead Sequence 3.5+0.5Ali MoosaviNo ratings yet

- Weld Procedure Specification (WPS)Document2 pagesWeld Procedure Specification (WPS)Senthil Kumaran50% (2)

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocument2 pagesBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarNo ratings yet

- WPS CuNiDocument4 pagesWPS CuNiSripathyNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- Swathi Industries: JOINT (QW 402)Document10 pagesSwathi Industries: JOINT (QW 402)Mustu AkolawalaNo ratings yet

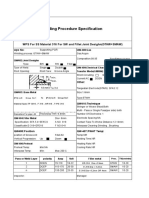

- Welding Procedure Specification: WPS For SS Material 316 For SW and Fillet Joint Desighn (GTAW+SMAW)Document1 pageWelding Procedure Specification: WPS For SS Material 316 For SW and Fillet Joint Desighn (GTAW+SMAW)Lipika GayenNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Nit 2019 20 56 Wps 1569579575Document16 pagesNit 2019 20 56 Wps 1569579575vijayachiduNo ratings yet

- Welding Procedure Specification: WPS For SS TO CS Material (GTAW)Document1 pageWelding Procedure Specification: WPS For SS TO CS Material (GTAW)Lipika GayenNo ratings yet

- WPS 7018+70S2Document8 pagesWPS 7018+70S2rajuNo ratings yet

- Welding Procedure SpecificationDocument4 pagesWelding Procedure SpecificationBhargav BbvsNo ratings yet

- PQR 01 PDFDocument2 pagesPQR 01 PDFVijay BhaleraoNo ratings yet

- QW-482 Welding Procedure Specification: Section IX, ASME Boiler & Pressure Vessel CodeDocument2 pagesQW-482 Welding Procedure Specification: Section IX, ASME Boiler & Pressure Vessel CodeRamzi ZoghlamiNo ratings yet

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- Welding Procedure Specification "WPS": O O O ODocument1 pageWelding Procedure Specification "WPS": O O O OAli Moosavi100% (1)

- Wps Ss r0 AdaniDocument2 pagesWps Ss r0 Adanigunasekhar kamireddiNo ratings yet

- QW 483 - PQR (Gtaw+smaw) 04.01.17Document8 pagesQW 483 - PQR (Gtaw+smaw) 04.01.17Srikant GanjiNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Sensory FunctionDocument34 pagesSensory FunctionFahra FadhillaNo ratings yet

- Q2 - Lesson 6 Student Listening Complete The Notes Below. Write Numbers and / or No More Than Three Words For Each AnswerDocument7 pagesQ2 - Lesson 6 Student Listening Complete The Notes Below. Write Numbers and / or No More Than Three Words For Each AnswerLương Huệ PhươngNo ratings yet

- University of Tripoli HS120: - C. - D. Dense Regular Connective TissueDocument4 pagesUniversity of Tripoli HS120: - C. - D. Dense Regular Connective TissueAnn AnooshNo ratings yet

- Notes of Cost (Microeconomics)Document10 pagesNotes of Cost (Microeconomics)Nishant DoshiNo ratings yet

- EIA Tps RaghunathpurDocument18 pagesEIA Tps RaghunathpurthiyagarajankNo ratings yet

- Which Functor Is The Projective Line?Document16 pagesWhich Functor Is The Projective Line?flores3831_814460512No ratings yet

- 2015 - Fracking Minding The Gaps - INGLESDocument14 pages2015 - Fracking Minding The Gaps - INGLESGersonMendozaUscateguiNo ratings yet

- Accelerated Storage, Shelf Life and Color of Mango PowderDocument19 pagesAccelerated Storage, Shelf Life and Color of Mango PowderAmandaInggitaNo ratings yet

- The Varnes Classification of Landslide TypesDocument3 pagesThe Varnes Classification of Landslide TypesGerson Isaac SoriaNo ratings yet

- Top Survival Tips - Kevin Reeve - OnPoint Tactical PDFDocument8 pagesTop Survival Tips - Kevin Reeve - OnPoint Tactical PDFBillLudley5100% (1)

- Letter and Resume PDFDocument2 pagesLetter and Resume PDFEarl DupitasNo ratings yet

- Class 10 English Sermon at BenarasDocument8 pagesClass 10 English Sermon at BenarasG Yogeeta JainNo ratings yet

- MCNW2820 ThinkBook 16p Gen 4 v041423Document131 pagesMCNW2820 ThinkBook 16p Gen 4 v041423james cabrezosNo ratings yet

- Semikron Datasheet SKT 551 01890270Document5 pagesSemikron Datasheet SKT 551 01890270Ga3ielNo ratings yet

- Airburst - Hendrick.r17 LRDocument2 pagesAirburst - Hendrick.r17 LRManuel Javier Rodríguez VNo ratings yet

- Factors Contributing To Burberry'S Failure 1Document16 pagesFactors Contributing To Burberry'S Failure 1benjaminNo ratings yet

- Algorithmic Fairness: From Social Good To A Mathematical FrameworkDocument2 pagesAlgorithmic Fairness: From Social Good To A Mathematical Frameworkjshen5No ratings yet

- Genetic: Introduction To Genetic AlgorithmsDocument44 pagesGenetic: Introduction To Genetic AlgorithmsMeyer Al-HayaliNo ratings yet

- Chapter 9 - Segmentation - Targeting - PositioningDocument37 pagesChapter 9 - Segmentation - Targeting - PositioningMariano Jose MerubiaNo ratings yet

- Android Quiz App 22617 MADDocument19 pagesAndroid Quiz App 22617 MADSandip kotkarNo ratings yet

- Dsa PaperDocument24 pagesDsa Paperhimanshusharma15868No ratings yet

- Rehab-Plans-and-Exercises Hip-Arthroscopy Protocol-For-Physiotherapy-Following-SurgeryDocument2 pagesRehab-Plans-and-Exercises Hip-Arthroscopy Protocol-For-Physiotherapy-Following-SurgeryMellow Moon RecordsNo ratings yet

- Detecon Study Customer Experience Management in The Telecommunications Industry. Market Survey and Action Recommendations For The Optimal Design of Customer ExperiencesDocument58 pagesDetecon Study Customer Experience Management in The Telecommunications Industry. Market Survey and Action Recommendations For The Optimal Design of Customer ExperiencesDetecon InternationalNo ratings yet

- GD - or MPW 84918 1 300 GD - OR..editedDocument2 pagesGD - or MPW 84918 1 300 GD - OR..editediolcdhnlNo ratings yet

- Clarinet GroveDocument38 pagesClarinet GroveLaMusica IlMio:nomeNo ratings yet

- Rapid Reserver PDFDocument2 pagesRapid Reserver PDFSime ToddNo ratings yet

- A Sad Hy Arogan Ivar An A MantraDocument9 pagesA Sad Hy Arogan Ivar An A MantraKrishNo ratings yet

- FGT1 02 Logging and MonitoringDocument19 pagesFGT1 02 Logging and MonitoringMax Olguin MellaNo ratings yet

- Real-Time Workshop: For Use With SimulinkDocument130 pagesReal-Time Workshop: For Use With SimulinkNadjib HadjaliNo ratings yet