Professional Documents

Culture Documents

Product Data Sheet - Hempel Polybest Eng

Product Data Sheet - Hempel Polybest Eng

Uploaded by

Carlos ArteagaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Data Sheet - Hempel Polybest Eng

Product Data Sheet - Hempel Polybest Eng

Uploaded by

Carlos ArteagaCopyright:

Available Formats

Product Data

HEMPEL’S POLYBEST 55551

BASE 55559 with CURING AGENT 95370

Description: HEMPEL’S POLYBEST 55551 is a high-gloss, two-component polyurethane enamel

especially suited for application by brush. It has excellent gloss and colour retention.

Resistant to water, wear, and marine atmosphere.

Recommended use: As a finishing coat on surfaces above the waterline on glass fibre, aluminium, steel,

ferro-cement, plywood and other non-yielding wooden surfaces.

Availability: Subject to confirmation.

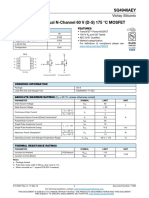

PHYSICAL CONSTANTS:

Colours/Shade nos: White/10001 Black/19990

Finish: High-gloss High-gloss

Volume solids, %: 54 ± 1 52 ± 1

Theoretical spreading rate: 15.4 m²/litre - 35 micron 14.9 m²/litre - 35 micron

619 sq.ft./US gallon - 1.4 mils 619 sq.ft./US gallon - 1.4 mils

Flash point: 30°C/86°F 30°C/86°F

Specific gravity: 1.3 kg/litre - 10.8 lbs/US gallon 1.1 kg/litre - 9.2 lbs/US gallon

Dry to touch: 6-8 hours at 20°C/68°F 6-8 hours at 20°C/68°F

14-18 hours at 10°C/50°F 14-18 hours at 10°C/50°F

Dry to sand: 24 (app) hours at 20°C/68°F 24 (app) hours at 20°C/68°F

54 (app) hours at 10°C/50°F 54 (app) hours at 10°C/50°F

Fully cured: 7 days at 20°C/68°F 7 days at 20°C/68°F

14 days at 10°C/50°F 14 days at 10°C/50°F

V.O.C.: 410 g/litre - 3.4 lbs/US gallon 440 g/litre - 3.7 lbs/US gallon

*Other shades according to assortment list.

The physical constants stated are nominal data according to the HEMPEL Group's approved formulas. They are

subject to normal manufacturing tolerances and where stated, being standard deviation according to ISO 3534-1.

APPLICATION DETAILS:

Mixing ratio for 55551: Base 55559 : Curing Agent 95370

2 : 1 by volume

Application method: Airspray Brush/Paint pad (See REMARKS overleaf)

Thinner (max.vol.): 08510 (15-35%) 08710 (5%)

Airspray Conventional Conventional Conventional

HVLP: Gravity feed: Suction feed: Pressure feed:

Fluid tip: 1.2-1.5 mm 1.4-1.6 mm 1.4-1.8 mm 1.0-1.2 mm

Air pressure 0.7 bar at nozzle 3-4 bar 3-4 bar 4-6 bar

(Spray data is indicative and subject to adjustment).

Spray viscosity (20°C/68°F): DIN 4: 17-18 seconds

FORD 4: 17-19 seconds

ANOR 4: 19-21 seconds

Pot life: 6 hours (20°C/68°F)

12 hours (10°C/50°F)

Cleaning of tools: HEMPEL’S THINNER 08710 or 08510

Indicated film thickness, dry: 35 micron/1.4 mils

Indicated film thickness, wet: 75 micron/3 mils

Recoat interval, min: 16 hours (20°C/68°F)

36 hours (10°C/50°F)

Recoat interval, max: 5 days (20°C/68°F) (See REMARKS overleaf)

10 days (10°C/50°F) (See REMARKS overleaf)

Safety: Handle with care. Before and during use, observe all safety labels on packaging and

paint containers, consult HEMPEL Material Safety Data Sheets and follow all local or

national safety regulations. Avoid inhalation, avoid contact with skin and eyes, and do

not swallow. Take precautions against possible risks of fire or explosions as well as

protection of the environment. Apply only in well ventilated areas.

Issued: October 2007 Page 1 of 2

HEMPEL

Product Data Sheet

HEMPEL’S POLYBEST 55551

APPLICATION Apply only where application and curing can proceed at temperatures above 5°C/41°F. The

CONDITIONS: surface must be clean and dry, and its temperature must be above the dew point to avoid

condensation. Best results are obtained at temperatures between 15-20°C/59-68°F. High relative

humidity or condensation within the first 24 hours after application (20°C/68°F) may impair the

film formation. Moisture content in wood should not exceed 16%. In confined spaces provide

adequate ventilation during application and drying.

PRECEDING HEMPEL’S LIGHT PRIMER 45551 or according to specification.

COAT:

REMARKS: Dry exposure only:

Service Periodical, maximum: 120°C/248°F

temperatures: Peak, maximum: 140°C/284°F

At service temperatures above 100°C/212°F, slight discoloration may be expected.

May be specified in another film thickness than indicated depending on purpose and area of use.

Normal range is 30-40 micron/1.2-1.6 mils.

Thinning: The amount of thinning relates to conditions of application: Method, temperature, ventilation and

substrate.

Recoating: Maximum recoat interval refers to exterior surfaces exposed to periodical immersion, splash,

condensation or abrasion during service life of the coating system. On other areas no maximum

recoat interval for adhesion. If maximum recoat interval is exceeded, roughening of the surface is

necessary to ensure intercoat adhesion. A completely clean surface is mandatory to ensure

intercoat adhesion, especially at long recoat intervals. Any dirt, oil and grease has to be removed,

e.g. with suitable detergent followed by (high pressure) fresh water cleaning. Salts to be removed

by fresh water hosing.

To check an adequate quality of the surface cleaning a test patch is recommended before actual

overcoating.

In case of overcoating with other paint materials maximum will be 1-3 days at 20°C/68°F), 2-6

days at 10°C/50°F, depending on type.

CURING AGENT 95370 is sensitive to moisture. Store in a dry place and keep the can tightly

closed until use. Open curing agent cans with caution as overpressure might exist. Even small

traces of water in the mixed paint will reduce the pot life and result in film defects. If only part of

the CURING AGENT is to be used, do not remove the lid, but make two holes in the bottom of the

can. After use, close the holes tightly with tape. The cans should be opened with care as there

may be risk of overpressure, especially in the can containing the curing agent. Do not fix the lid on

cans containing mixed paint.

Note: The information given in the Product Data Sheet is intended for commercial use.

ISSUED BY: HEMPEL A/S - 5555110001CS001

This Product Data Sheet supersedes those previously issued.

For

Thisexplanations,

Product Datadefinitions and scope,

Sheet supersedes seepreviously

those “Explanatory Notes” in the HEMPEL Book.

issued.

Data, specifications,

For explanations, directionsand

definitions andscope,

recommendations givenNotes”

see “Explanatory in this in

data

thesheet

HEMPELrepresent

Book. only test results or

experience obtained under

Data, specifications, controlled

directions or specially defined

and recommendations circumstances.

given in this data Their

sheetaccuracy,

representcompleteness or or

only test results

appropriateness underunder

experience obtained the actual conditions

controlled of any defined

or specially intendedcircumstances.

use of the Products Their herein must

accuracy, be determined

completeness or

exclusively by theunder

appropriateness Buyerthe

and/or User.

actual conditions of any intended use of the Products herein must be determined

The Products

exclusively byare

thesupplied and allUser.

Buyer and/or technical assistance is given subject to HEMPEL's GENERAL CONDITIONS OF

SALES, DELIVERY

The Products AND SERVICE,

are supplied unless otherwise

and all technical expressly

assistance is givenagreed

subjectin writing. The Manufacturer

to HEMPEL's and SellerOF

GENERAL CONDITIONS

disclaim, and Buyer

SALES, DELIVERY and/or

AND User waive

SERVICE, unlessall claims involving,

otherwise expresslyany liability,

agreed including

in writing. Thebut not limited to

Manufacturer negligence,

and Seller

except as and

disclaim, expressed in said User

Buyer and/or GENERAL

waiveCONDITIONS for all results,

all claims involving, injury including

any liability, or direct or

butconsequential

not limited tolosses or

negligence,

damages arising from the use of the Products as recommended above, on the overleaf or otherwise.

except as expressed in said GENERAL CONDITIONS for all results, injury or direct or consequential losses or

Product data

damages are subject

arising from thetouse

change

of thewithout notice

Products and become void

as recommended five on

above, years

the from the date

overleaf of issue.

or otherwise.

Issued: October 2007 Page 2 of 2 Product Data Sheet

You might also like

- Zuessy - TIMEDocument75 pagesZuessy - TIMEcoupko100% (1)

- Pds Hempadur Glass Flake 35851 En-GbDocument2 pagesPds Hempadur Glass Flake 35851 En-Gbkalpesh parmarNo ratings yet

- 55210Document2 pages55210whah11No ratings yet

- DSA 2011 01590 - HEMPATHANE 55210 DatasheetDocument2 pagesDSA 2011 01590 - HEMPATHANE 55210 DatasheetMehedi HasanNo ratings yet

- Hempathane Hs 55610 55610 En-GbDocument2 pagesHempathane Hs 55610 55610 En-GbfaizalNo ratings yet

- Pds Hempathane Topcoat 55210 En-GbDocument2 pagesPds Hempathane Topcoat 55210 En-GbSachin NambiarNo ratings yet

- PDS HEMPATHANE TOPCOAT 55210 en-GB PDFDocument2 pagesPDS HEMPATHANE TOPCOAT 55210 en-GB PDFQA QCNo ratings yet

- Hempathane Topcoat 55210 en-GBDocument2 pagesHempathane Topcoat 55210 en-GBSanjay TekriwalNo ratings yet

- PDS Hempathane Topcoat 55210 en-GBDocument2 pagesPDS Hempathane Topcoat 55210 en-GBJames PittsNo ratings yet

- Product DataDocument2 pagesProduct Dataabdulgafoor54No ratings yet

- Product Data: Hempel's Light Primer 45550Document2 pagesProduct Data: Hempel's Light Primer 45550satish rongalaNo ratings yet

- Product DataDocument2 pagesProduct DatapoerwntiNo ratings yet

- PDS HEMPATHANE ENAMEL 55100 en-GBDocument2 pagesPDS HEMPATHANE ENAMEL 55100 en-GBMohamed NouzerNo ratings yet

- PDS HEMPATHANE HS 55610 en-GBDocument2 pagesPDS HEMPATHANE HS 55610 en-GBPravas PadhihariNo ratings yet

- PDS 15700Document2 pagesPDS 15700altipatlarNo ratings yet

- Product DataDocument2 pagesProduct DataegomoNo ratings yet

- Hempadur 15590Document2 pagesHempadur 15590Yosses Sang NahkodaNo ratings yet

- Pds Hempathane Topcoat 55210 En-GbDocument2 pagesPds Hempathane Topcoat 55210 En-GbDoni HardiNo ratings yet

- Hempadur 15130Document2 pagesHempadur 15130MuthuKumarNo ratings yet

- PDS Light Primer 45551Document2 pagesPDS Light Primer 45551Grimmo1979No ratings yet

- Hempels - Anti Condens - 617usDocument3 pagesHempels - Anti Condens - 617usnarmathaNo ratings yet

- Pds Hempel's Silicone Aluminium 56914 En-GbDocument2 pagesPds Hempel's Silicone Aluminium 56914 En-GbMatej ZirdumNo ratings yet

- PDS Hempadur Hi-Build 45200 en-GBDocument2 pagesPDS Hempadur Hi-Build 45200 en-GBvitharvanNo ratings yet

- PDS HEMPADUR 85671 en-GB PDFDocument2 pagesPDS HEMPADUR 85671 en-GB PDFMohamed Farhan B PositiveNo ratings yet

- Galvosil 15700 DSDocument2 pagesGalvosil 15700 DSIssam TrikiNo ratings yet

- PDS Hempathane HS 55610 en-GBDocument3 pagesPDS Hempathane HS 55610 en-GBalouisNo ratings yet

- 151SGDocument2 pages151SGdcsamaraweeraNo ratings yet

- PDS Hempathane HS 55610 en-GBDocument3 pagesPDS Hempathane HS 55610 en-GBAnonymous HPlNDhM6ejNo ratings yet

- Product Data: HEMPADUR 85671Document2 pagesProduct Data: HEMPADUR 85671EngTamerNo ratings yet

- PDS Hempalin Primer 12050 en-GBDocument2 pagesPDS Hempalin Primer 12050 en-GBErwin MalmsteinNo ratings yet

- PDS en-GB 45751Document2 pagesPDS en-GB 45751Anuar SalehNo ratings yet

- Pds Hempadur Glass Flake 35851 En-GbDocument2 pagesPds Hempadur Glass Flake 35851 En-GbIlham NugrohoNo ratings yet

- PDS Hempatex Hi-Build 46370 en-GBDocument2 pagesPDS Hempatex Hi-Build 46370 en-GBRauf AliyevNo ratings yet

- PDS Hempadur Multi-Strength 45753 en-GBDocument2 pagesPDS Hempadur Multi-Strength 45753 en-GBJosip LasanNo ratings yet

- PDS Hempadur 85671 en-GBDocument3 pagesPDS Hempadur 85671 en-GBvitharvanNo ratings yet

- DSA 2011 01590 - HEMPADUR ZINC 15343 DatasheetDocument2 pagesDSA 2011 01590 - HEMPADUR ZINC 15343 DatasheetMehedi HasanNo ratings yet

- Hempathane 55610Document2 pagesHempathane 55610Luciano Salituri0% (1)

- 15553Document2 pages15553danish100% (1)

- Pds Hempadur Spray-Guard 35493 En-GbDocument2 pagesPds Hempadur Spray-Guard 35493 En-GbKhyle Laurenz DuroNo ratings yet

- Pds Hempel's Silicone Acrylic 56940 En-GbDocument2 pagesPds Hempel's Silicone Acrylic 56940 En-GbsenthilkumarNo ratings yet

- Pds Hemparea DTM 55973 En-GbDocument2 pagesPds Hemparea DTM 55973 En-GbFreddy Carl FredricksenNo ratings yet

- Hempadur Multi-Strength GF 35870 PDFDocument3 pagesHempadur Multi-Strength GF 35870 PDFAnuar SalehNo ratings yet

- Hempels Galvosil 15780Document7 pagesHempels Galvosil 15780Yosses Sang NahkodaNo ratings yet

- PDS HEMPADUR EASY 47700 en GBDocument3 pagesPDS HEMPADUR EASY 47700 en GBharshana divankaNo ratings yet

- Hempel'S Galvosil 15780: DescriptionDocument2 pagesHempel'S Galvosil 15780: DescriptionEngTamer100% (1)

- Hempel's Epoxy Filler 35250 35253 En-GbDocument2 pagesHempel's Epoxy Filler 35250 35253 En-GbajuhaseenNo ratings yet

- PDS HEMUCRYL ENAMEL HI-BUILD 58030 en-GBDocument2 pagesPDS HEMUCRYL ENAMEL HI-BUILD 58030 en-GBFreddy Carl FredricksenNo ratings yet

- Product DataDocument2 pagesProduct DataMuhammad AsifNo ratings yet

- Pds Hempel's Silicone Aluminium 56910 En-GbDocument2 pagesPds Hempel's Silicone Aluminium 56910 En-GbjakelowNo ratings yet

- HempadurDocument2 pagesHempadurLuciano SalituriNo ratings yet

- Hempel's Galvosil 15790 15790 En-GbDocument2 pagesHempel's Galvosil 15790 15790 En-GbRoberto_PrrNo ratings yet

- HEMPADUR ZINC 15360 15360 en-GB PDFDocument2 pagesHEMPADUR ZINC 15360 15360 en-GB PDFErwin MalmsteinNo ratings yet

- Creative Resin: Easy techniques for contemporary resin artFrom EverandCreative Resin: Easy techniques for contemporary resin artNo ratings yet

- Bathtub and Shower Tray Repair: How to Prevent Remedials and Make the Repair Future-proofFrom EverandBathtub and Shower Tray Repair: How to Prevent Remedials and Make the Repair Future-proofNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Analisys and application of dry cleaning materials on unvarnished pain surfacesFrom EverandAnalisys and application of dry cleaning materials on unvarnished pain surfacesNo ratings yet

- Transfer of TI's Wi-Fi Alliance Certifications To CC3x00/CC3x20/CC3x35-Based Product Using The WFA Derivative Certification PolicyDocument10 pagesTransfer of TI's Wi-Fi Alliance Certifications To CC3x00/CC3x20/CC3x35-Based Product Using The WFA Derivative Certification PolicyFlex 377No ratings yet

- BailmentsDocument4 pagesBailmentsKaruna SarafNo ratings yet

- Hempel Paint TDSDocument3 pagesHempel Paint TDSKelly BatesNo ratings yet

- BE2 en en-USDocument812 pagesBE2 en en-USConcucac NovNo ratings yet

- Ug906 Vivado Design Analysis PDFDocument128 pagesUg906 Vivado Design Analysis PDFUPPALAPATI NAGARAJUNo ratings yet

- LPe15XXX 16XXX FWBT RN1202 100 2CSDocument6 pagesLPe15XXX 16XXX FWBT RN1202 100 2CSY.FNo ratings yet

- Kbu8A, Kbu8B, Kbu8D, Kbu8G, Kbu8J, Kbu8K, Kbu8M: Vishay General SemiconductorDocument4 pagesKbu8A, Kbu8B, Kbu8D, Kbu8G, Kbu8J, Kbu8K, Kbu8M: Vishay General SemiconductorGedealdo TorresNo ratings yet

- FP10000 Service Manual-29723Document41 pagesFP10000 Service Manual-29723Freddy Herrera100% (2)

- Ultrasonic Thickness GaugeDocument3 pagesUltrasonic Thickness Gaugesandeepsingh_1108No ratings yet

- Airport Privatization in India: Lessons From The Bidding Process in Delhi and MumbaiDocument54 pagesAirport Privatization in India: Lessons From The Bidding Process in Delhi and MumbaiRahul ShastriNo ratings yet

- 501a 17 PDFDocument28 pages501a 17 PDFhikary2.032100% (1)

- Meter User & Installation Manual: IQ 100 Series (130/140/150)Document94 pagesMeter User & Installation Manual: IQ 100 Series (130/140/150)Hamilton GutierrezNo ratings yet

- Money Dot Trading SystemDocument15 pagesMoney Dot Trading SystemBradNo ratings yet

- Krohne OPTIFLUX1000 ManualDocument36 pagesKrohne OPTIFLUX1000 ManualMildoggNo ratings yet

- Viking Pools 2012 CatalogDocument32 pagesViking Pools 2012 CatalogViking PoolsNo ratings yet

- Android Open Source LicensesDocument432 pagesAndroid Open Source Licensesjosemanuelsolano991No ratings yet

- Hvac Duct User Manual Software PDFDocument59 pagesHvac Duct User Manual Software PDFgarciajoyaNo ratings yet

- Stainless Steel Grades Listed in The International Standard ISO 15510:2010Document3 pagesStainless Steel Grades Listed in The International Standard ISO 15510:2010tugulea72 GabiNo ratings yet

- Sophose Standalone Startup GuideDocument17 pagesSophose Standalone Startup Guidesorachut1989No ratings yet

- R.B.C. Diluting Fluid (Hayem's) : CompositionDocument2 pagesR.B.C. Diluting Fluid (Hayem's) : CompositionGlobal LaboratoryNo ratings yet

- GZ10 PDFDocument3 pagesGZ10 PDFEong Huat Corporation Sdn BhdNo ratings yet

- Spa Pcdmis 2015.1 Portable ManualDocument211 pagesSpa Pcdmis 2015.1 Portable ManualTomás ManzanoNo ratings yet

- BINA AUSHADHI KE KAYAKALP by Shri Ram Sharma PDFDocument48 pagesBINA AUSHADHI KE KAYAKALP by Shri Ram Sharma PDFALPESH KOTHARINo ratings yet

- Manual de Dren AutomaticoDocument42 pagesManual de Dren AutomaticoDarvin chi tecNo ratings yet

- User's Manual: FP7 CPU UnitDocument156 pagesUser's Manual: FP7 CPU UnitHamid KharazmiNo ratings yet

- Gas Skid Honeywell Radar LT RM71-ManualDocument168 pagesGas Skid Honeywell Radar LT RM71-ManualCPP UTILITYNo ratings yet

- SQ 4946 AeyDocument10 pagesSQ 4946 AeyMoxGameplayYTutorialesNo ratings yet

- TG20-13 Supplement 1Document4 pagesTG20-13 Supplement 1Abdul Hadhi100% (1)