Professional Documents

Culture Documents

Pages From Pages From Pages 11-12 AURTTK2001

Pages From Pages From Pages 11-12 AURTTK2001

Uploaded by

ZF ECTBCopyright:

Available Formats

You might also like

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Blender Operator Manual PDFDocument16 pagesBlender Operator Manual PDFFrank N100% (1)

- SW-65A-0316-00 SW-65A - EngishDocument20 pagesSW-65A-0316-00 SW-65A - Engishmani nadar100% (1)

- Is My Machine OK?: A Field Guide to Assessing Process MachineryFrom EverandIs My Machine OK?: A Field Guide to Assessing Process MachineryNo ratings yet

- JSA SOIL TEST AT SETTLEMENT 4 TerbaruDocument3 pagesJSA SOIL TEST AT SETTLEMENT 4 Terbarumauizah permatasari100% (2)

- Automotive Measuring ToolsDocument24 pagesAutomotive Measuring ToolsBrendan BrodieNo ratings yet

- Lab Session: 01: ObjectiveDocument4 pagesLab Session: 01: ObjectiveAli RazaNo ratings yet

- Tle g8 Automotive Week-2Document8 pagesTle g8 Automotive Week-2Kristell Lyka LasmariasNo ratings yet

- How To Use Vernier Caliper - MicrometerDocument35 pagesHow To Use Vernier Caliper - MicrometerJuan Manuel Ortega PérezNo ratings yet

- JamarDocument6 pagesJamarViolaNo ratings yet

- Basics of Applied Benchwork 1Document136 pagesBasics of Applied Benchwork 1gawik gawikNo ratings yet

- Experiment No. 2: 1.0 TitleDocument6 pagesExperiment No. 2: 1.0 TitleKaranpal SinghNo ratings yet

- CalibrationDocument25 pagesCalibrationWaqarAhmedButtNo ratings yet

- 1 Vernier CalliperDocument6 pages1 Vernier CalliperJonathan PereiraNo ratings yet

- Quality Control and Quality AssuranceDocument4 pagesQuality Control and Quality AssurancerampdwnNo ratings yet

- Reporting Tools (Machine Shop)Document56 pagesReporting Tools (Machine Shop)joshuamullet1No ratings yet

- Unidad Focalizada 5 Vernier CaliperDocument7 pagesUnidad Focalizada 5 Vernier CaliperJuan Pablo BautistaNo ratings yet

- EM 111ET Metrology CONTENTS WK 10 13Document25 pagesEM 111ET Metrology CONTENTS WK 10 13kim salameraNo ratings yet

- How To Use An Inside MicrometerDocument11 pagesHow To Use An Inside MicrometerdutchrvlogsNo ratings yet

- Procedimento Calibração TorquimetroDocument4 pagesProcedimento Calibração TorquimetroRonaldo SilvaNo ratings yet

- Lab Manual MeterologyDocument10 pagesLab Manual MeterologyWaris Nawaz KhanNo ratings yet

- Linear Measurements: References: 1. Handbok of Dimensional Measurement 2. Http://fetweb - Ju.edu - Jo/staff/me/jyaminDocument70 pagesLinear Measurements: References: 1. Handbok of Dimensional Measurement 2. Http://fetweb - Ju.edu - Jo/staff/me/jyaminRodel VerzosaNo ratings yet

- Me3581 Metrology and Dynamics Lab Manual R2021actDocument133 pagesMe3581 Metrology and Dynamics Lab Manual R2021actmarakamadhu800No ratings yet

- Vernier Calipers & MicrometrsDocument14 pagesVernier Calipers & Micrometrsفتى الجحيمNo ratings yet

- 4.4 Tractor Instrument PanelDocument7 pages4.4 Tractor Instrument Panelkumar100% (1)

- Unit Ii: Paavai Institutions Department of MechDocument37 pagesUnit Ii: Paavai Institutions Department of Mechanon_319307852No ratings yet

- Exp No. 01 Study and Use of Linear Measuring InstrumentsDocument11 pagesExp No. 01 Study and Use of Linear Measuring Instrumentsrohit thorawadeNo ratings yet

- Hand Arm Vibration (HAV) : A Step-by-Step GuideDocument17 pagesHand Arm Vibration (HAV) : A Step-by-Step GuideAndre Santos SantosNo ratings yet

- BME UNIT II MeasurementDocument55 pagesBME UNIT II MeasurementVivek Patel100% (1)

- Mechanical Measuring TooltrainingDocument9 pagesMechanical Measuring TooltrainingMustafa AbdelrahmanNo ratings yet

- Basic Measurement 2Document9 pagesBasic Measurement 2irghazaliNo ratings yet

- Lecture 2. Measuring Tools-Rules and CalipersDocument45 pagesLecture 2. Measuring Tools-Rules and CalipersJohnNo ratings yet

- Unit 5Document14 pagesUnit 5Devan SaiNo ratings yet

- Metrology and Quality Assurance Lab: Department of Mechanical EngineeringDocument7 pagesMetrology and Quality Assurance Lab: Department of Mechanical EngineeringAliNo ratings yet

- T.E. (Mechanical) - 2012 Course Metrology and Quality Control (302044)Document42 pagesT.E. (Mechanical) - 2012 Course Metrology and Quality Control (302044)Mahesh JawaleNo ratings yet

- Preventive Maintenance Procedure - Rev.01Document1 pagePreventive Maintenance Procedure - Rev.01lemanhcuong1503No ratings yet

- Systematic Errors (Controllable Errors) - Random Errors.: Measurement ErrorDocument14 pagesSystematic Errors (Controllable Errors) - Random Errors.: Measurement Errorlaxmikanta sahuNo ratings yet

- Unit - V FinalDocument20 pagesUnit - V FinalSantosh SantuNo ratings yet

- Scales, Rules, Verniers and MicrometersDocument29 pagesScales, Rules, Verniers and MicrometersHao DinhNo ratings yet

- 1 Measuring Instruments and GaugesDocument59 pages1 Measuring Instruments and GaugesWbamlak AshebrNo ratings yet

- Machineshopnotes 150924174711 Lva1 App6891 PDFDocument71 pagesMachineshopnotes 150924174711 Lva1 App6891 PDFRezende JulioNo ratings yet

- Hios HP-100 Operating ManualDocument15 pagesHios HP-100 Operating ManualIngeniería AirtechNo ratings yet

- Lab ReportDocument20 pagesLab ReportRounak Mehta0% (1)

- Dial Calibration TesterDocument2 pagesDial Calibration TesterAdityaKochar100% (1)

- Techniques of Visual InspectionDocument80 pagesTechniques of Visual InspectiontranngNo ratings yet

- 1.1-LABORATORY-No.-1-MICROMETER-AND-VERNIER-CALIPER - GALILEI - FAJARDODocument8 pages1.1-LABORATORY-No.-1-MICROMETER-AND-VERNIER-CALIPER - GALILEI - FAJARDORandom JaiNo ratings yet

- Mentor EI65 ServiceDocument36 pagesMentor EI65 ServiceFrank William Romero OrjuelaNo ratings yet

- Measuring Instruments and Their UsesDocument62 pagesMeasuring Instruments and Their UsesRamji KaasiNo ratings yet

- Unit-Ii 3Document30 pagesUnit-Ii 3k.ghanemNo ratings yet

- Use and Maintain Measuring Equipment in An Automotive WorkplaceDocument8 pagesUse and Maintain Measuring Equipment in An Automotive WorkplaceajayNo ratings yet

- Lab Report MQADocument10 pagesLab Report MQAMuhammad QasimNo ratings yet

- Metrology Lab-1Document3 pagesMetrology Lab-1MD AFSHANNo ratings yet

- Linear MeasurementsDocument54 pagesLinear MeasurementsNaman Dave100% (1)

- Mutoh RJ4100 PDFDocument407 pagesMutoh RJ4100 PDFKlema HanisNo ratings yet

- Tmike eDocument37 pagesTmike eElyel GonzalezNo ratings yet

- Why Is The Calibration RequiredDocument3 pagesWhy Is The Calibration Requiredsaranya saiganeshNo ratings yet

- MATChapter 6AutoMathMeasurements PDFDocument21 pagesMATChapter 6AutoMathMeasurements PDFBrendan BrodieNo ratings yet

- 6 ComparatorsDocument17 pages6 Comparatorsmuhammad afzzalNo ratings yet

- DYNEX Newton Balancing CradleDocument16 pagesDYNEX Newton Balancing CradleAekDzLaiNo ratings yet

- Digital Temperature Controllers: User's Manual E5 CDocument350 pagesDigital Temperature Controllers: User's Manual E5 CPham Khac LuNo ratings yet

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Edisp WSM 0000453 01Document25 pagesEdisp WSM 0000453 01ZF ECTBNo ratings yet

- Edisp WSM 0000469 99Document4 pagesEdisp WSM 0000469 99ZF ECTBNo ratings yet

- AMAN Jun08 7509D-MADocument16 pagesAMAN Jun08 7509D-MAZF ECTBNo ratings yet

- d700 - CurveDocument3 pagesd700 - CurveZF ECTBNo ratings yet

- Couplings: Torque Converters and HydraulicDocument2 pagesCouplings: Torque Converters and Hydraulicajkbro8No ratings yet

- Gearbox Identification: Code Letters, Gearbox Allocation, Ratios, CapacitiesDocument7 pagesGearbox Identification: Code Letters, Gearbox Allocation, Ratios, CapacitiesSrđan Basarić KennedyNo ratings yet

- 12.13 101870341001 101870349999 EngineDocument9 pages12.13 101870341001 101870349999 Engineeshopmanual EnamNo ratings yet

- BW177D ManualDocument114 pagesBW177D ManualEric GrunstNo ratings yet

- Eapp Position PaperDocument3 pagesEapp Position PaperShenisse OrnopiaNo ratings yet

- Master Thesis Analysis and Specification of An AUTOSAR Based ECU in Compliance With ISO ... (PDFDrive)Document100 pagesMaster Thesis Analysis and Specification of An AUTOSAR Based ECU in Compliance With ISO ... (PDFDrive)Christoph KabekNo ratings yet

- HPV PorDocument2 pagesHPV PorChris ChrisNo ratings yet

- D3E801B9571-Air Conditioning System With Refrigerant R134aDocument115 pagesD3E801B9571-Air Conditioning System With Refrigerant R134aDaniel PelteaNo ratings yet

- L8FA / 08FA 08FH 12FT 12FH Part Name Part Number L6Fa / T6Fa / 06FA 06FHDocument1 pageL8FA / 08FA 08FH 12FT 12FH Part Name Part Number L6Fa / T6Fa / 06FA 06FHjasperzeus crisostomoNo ratings yet

- Car Rental TasDocument3 pagesCar Rental TasanaNo ratings yet

- Methodology of Work and Sequence of ActivitiesDocument6 pagesMethodology of Work and Sequence of ActivitiesAmitNo ratings yet

- Sem 655Document6 pagesSem 655rizalcorp97No ratings yet

- SM 20Document440 pagesSM 20gustavo renzoNo ratings yet

- 45.electrical Component LocationsDocument60 pages45.electrical Component LocationsKuba SwkNo ratings yet

- Basic EngineDocument2 pagesBasic Engineyoga_jpbmbmNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document11 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Albertojose8a Ochoa LopezNo ratings yet

- Asahi India Glass Initiation - 210702Document31 pagesAsahi India Glass Initiation - 210702vandit dharamshi100% (1)

- B Ing-DikonversiDocument6 pagesB Ing-DikonversiVEMBERIONo ratings yet

- C66 D5L - Data Sheet PDFDocument4 pagesC66 D5L - Data Sheet PDFJavier SanchezNo ratings yet

- Manual Raket85Document20 pagesManual Raket85Leandro BergamoNo ratings yet

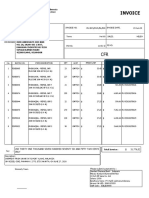

- Invoice: PT. Pacific Lubritama IndonesiaDocument1 pageInvoice: PT. Pacific Lubritama IndonesiaArfansyah RamdhaniNo ratings yet

- Design: Brushed Axial Flux DC MotorDocument2 pagesDesign: Brushed Axial Flux DC MotorAkshay DeolasiNo ratings yet

- SP Marino LC 5040: Lubricating Oil For Slow Speed 2-Stroke Engine CylindersDocument2 pagesSP Marino LC 5040: Lubricating Oil For Slow Speed 2-Stroke Engine CylindersSinh LeNo ratings yet

- Universal JointDocument15 pagesUniversal Jointmos3ad2006100% (1)

- Brake Lever Setup Important Information Setup Procedure: DATA SHEET: Ds-Brleval ISSUE S1003Document2 pagesBrake Lever Setup Important Information Setup Procedure: DATA SHEET: Ds-Brleval ISSUE S1003mamatnamakuNo ratings yet

- Pro 8055Document2 pagesPro 8055Ankur MestryNo ratings yet

- Dinanath Manohar Lad: Basic ExperienceDocument2 pagesDinanath Manohar Lad: Basic ExperienceSagar PatilNo ratings yet

- Parker (MR, MRE, MR350, MR450, MRE500) Hydraulic Motors, Denison Calzoni, Radial Piston MotorDocument24 pagesParker (MR, MRE, MR350, MR450, MRE500) Hydraulic Motors, Denison Calzoni, Radial Piston MotorAngel Santiago Brusini OrozcoNo ratings yet

- Allison MD/B 300/B 400 Series On-Highway Transmissions Parts CatalogDocument2 pagesAllison MD/B 300/B 400 Series On-Highway Transmissions Parts CatalogZafiro Feliz Galan100% (1)

Pages From Pages From Pages 11-12 AURTTK2001

Pages From Pages From Pages 11-12 AURTTK2001

Uploaded by

ZF ECTBOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pages From Pages From Pages 11-12 AURTTK2001

Pages From Pages From Pages 11-12 AURTTK2001

Uploaded by

ZF ECTBCopyright:

Available Formats

Introduction to Measuring

Measuring and checking are two of the most important procedures that are performed in

an automotive workshop, and they must be done accurately. In most types of mechanical

service or repair, some type of measurement is taken or a check made of the size, fit,

clearance, pressure or other specification.

Checking and adjusting spark plug gaps, ignition points and valve tappet clearance are

just a few examples of where measuring instruments are used.

Insert the feeler

High point

between the cam

of cam lobe

and rocker arm

Rocker arm

Feeler gauge

Figure 1: Adjusting tappet clearance, OHC engine

Measuring accurately

To be able to measure accurately you must learn to:

•• handle and use measuring tools correctly

•• select measuring tools that are suitably accurate for the work

•• check that the measuring tool is reading accurately.

All measuring tools are liable to damage resulting in inaccurate readings if they are

dropped or mis-handled.

In particular, instruments capable of reading 0.1mm or less, can be damaged or put out

of adjustment by unskilled or careless handling, they must be checked regularly to ensure

accurate readings.

Learner’s Information and Activity Workbook Version 1/2015 11

Measuring equipment covered in this resource includes:

1. Feeler gauge 5. Vernier Caliper

2. Straight edge 6. Outside Micrometer

3. Steel rule 7. Dial Indicator

4. Caliper

Figure 2: Various measuring equipment

12 © Australian Automotive Centre of Excellence, 2015 Version 1/2015 AURTTK2001 | Use & Maintain Measuring Equipment

You might also like

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Blender Operator Manual PDFDocument16 pagesBlender Operator Manual PDFFrank N100% (1)

- SW-65A-0316-00 SW-65A - EngishDocument20 pagesSW-65A-0316-00 SW-65A - Engishmani nadar100% (1)

- Is My Machine OK?: A Field Guide to Assessing Process MachineryFrom EverandIs My Machine OK?: A Field Guide to Assessing Process MachineryNo ratings yet

- JSA SOIL TEST AT SETTLEMENT 4 TerbaruDocument3 pagesJSA SOIL TEST AT SETTLEMENT 4 Terbarumauizah permatasari100% (2)

- Automotive Measuring ToolsDocument24 pagesAutomotive Measuring ToolsBrendan BrodieNo ratings yet

- Lab Session: 01: ObjectiveDocument4 pagesLab Session: 01: ObjectiveAli RazaNo ratings yet

- Tle g8 Automotive Week-2Document8 pagesTle g8 Automotive Week-2Kristell Lyka LasmariasNo ratings yet

- How To Use Vernier Caliper - MicrometerDocument35 pagesHow To Use Vernier Caliper - MicrometerJuan Manuel Ortega PérezNo ratings yet

- JamarDocument6 pagesJamarViolaNo ratings yet

- Basics of Applied Benchwork 1Document136 pagesBasics of Applied Benchwork 1gawik gawikNo ratings yet

- Experiment No. 2: 1.0 TitleDocument6 pagesExperiment No. 2: 1.0 TitleKaranpal SinghNo ratings yet

- CalibrationDocument25 pagesCalibrationWaqarAhmedButtNo ratings yet

- 1 Vernier CalliperDocument6 pages1 Vernier CalliperJonathan PereiraNo ratings yet

- Quality Control and Quality AssuranceDocument4 pagesQuality Control and Quality AssurancerampdwnNo ratings yet

- Reporting Tools (Machine Shop)Document56 pagesReporting Tools (Machine Shop)joshuamullet1No ratings yet

- Unidad Focalizada 5 Vernier CaliperDocument7 pagesUnidad Focalizada 5 Vernier CaliperJuan Pablo BautistaNo ratings yet

- EM 111ET Metrology CONTENTS WK 10 13Document25 pagesEM 111ET Metrology CONTENTS WK 10 13kim salameraNo ratings yet

- How To Use An Inside MicrometerDocument11 pagesHow To Use An Inside MicrometerdutchrvlogsNo ratings yet

- Procedimento Calibração TorquimetroDocument4 pagesProcedimento Calibração TorquimetroRonaldo SilvaNo ratings yet

- Lab Manual MeterologyDocument10 pagesLab Manual MeterologyWaris Nawaz KhanNo ratings yet

- Linear Measurements: References: 1. Handbok of Dimensional Measurement 2. Http://fetweb - Ju.edu - Jo/staff/me/jyaminDocument70 pagesLinear Measurements: References: 1. Handbok of Dimensional Measurement 2. Http://fetweb - Ju.edu - Jo/staff/me/jyaminRodel VerzosaNo ratings yet

- Me3581 Metrology and Dynamics Lab Manual R2021actDocument133 pagesMe3581 Metrology and Dynamics Lab Manual R2021actmarakamadhu800No ratings yet

- Vernier Calipers & MicrometrsDocument14 pagesVernier Calipers & Micrometrsفتى الجحيمNo ratings yet

- 4.4 Tractor Instrument PanelDocument7 pages4.4 Tractor Instrument Panelkumar100% (1)

- Unit Ii: Paavai Institutions Department of MechDocument37 pagesUnit Ii: Paavai Institutions Department of Mechanon_319307852No ratings yet

- Exp No. 01 Study and Use of Linear Measuring InstrumentsDocument11 pagesExp No. 01 Study and Use of Linear Measuring Instrumentsrohit thorawadeNo ratings yet

- Hand Arm Vibration (HAV) : A Step-by-Step GuideDocument17 pagesHand Arm Vibration (HAV) : A Step-by-Step GuideAndre Santos SantosNo ratings yet

- BME UNIT II MeasurementDocument55 pagesBME UNIT II MeasurementVivek Patel100% (1)

- Mechanical Measuring TooltrainingDocument9 pagesMechanical Measuring TooltrainingMustafa AbdelrahmanNo ratings yet

- Basic Measurement 2Document9 pagesBasic Measurement 2irghazaliNo ratings yet

- Lecture 2. Measuring Tools-Rules and CalipersDocument45 pagesLecture 2. Measuring Tools-Rules and CalipersJohnNo ratings yet

- Unit 5Document14 pagesUnit 5Devan SaiNo ratings yet

- Metrology and Quality Assurance Lab: Department of Mechanical EngineeringDocument7 pagesMetrology and Quality Assurance Lab: Department of Mechanical EngineeringAliNo ratings yet

- T.E. (Mechanical) - 2012 Course Metrology and Quality Control (302044)Document42 pagesT.E. (Mechanical) - 2012 Course Metrology and Quality Control (302044)Mahesh JawaleNo ratings yet

- Preventive Maintenance Procedure - Rev.01Document1 pagePreventive Maintenance Procedure - Rev.01lemanhcuong1503No ratings yet

- Systematic Errors (Controllable Errors) - Random Errors.: Measurement ErrorDocument14 pagesSystematic Errors (Controllable Errors) - Random Errors.: Measurement Errorlaxmikanta sahuNo ratings yet

- Unit - V FinalDocument20 pagesUnit - V FinalSantosh SantuNo ratings yet

- Scales, Rules, Verniers and MicrometersDocument29 pagesScales, Rules, Verniers and MicrometersHao DinhNo ratings yet

- 1 Measuring Instruments and GaugesDocument59 pages1 Measuring Instruments and GaugesWbamlak AshebrNo ratings yet

- Machineshopnotes 150924174711 Lva1 App6891 PDFDocument71 pagesMachineshopnotes 150924174711 Lva1 App6891 PDFRezende JulioNo ratings yet

- Hios HP-100 Operating ManualDocument15 pagesHios HP-100 Operating ManualIngeniería AirtechNo ratings yet

- Lab ReportDocument20 pagesLab ReportRounak Mehta0% (1)

- Dial Calibration TesterDocument2 pagesDial Calibration TesterAdityaKochar100% (1)

- Techniques of Visual InspectionDocument80 pagesTechniques of Visual InspectiontranngNo ratings yet

- 1.1-LABORATORY-No.-1-MICROMETER-AND-VERNIER-CALIPER - GALILEI - FAJARDODocument8 pages1.1-LABORATORY-No.-1-MICROMETER-AND-VERNIER-CALIPER - GALILEI - FAJARDORandom JaiNo ratings yet

- Mentor EI65 ServiceDocument36 pagesMentor EI65 ServiceFrank William Romero OrjuelaNo ratings yet

- Measuring Instruments and Their UsesDocument62 pagesMeasuring Instruments and Their UsesRamji KaasiNo ratings yet

- Unit-Ii 3Document30 pagesUnit-Ii 3k.ghanemNo ratings yet

- Use and Maintain Measuring Equipment in An Automotive WorkplaceDocument8 pagesUse and Maintain Measuring Equipment in An Automotive WorkplaceajayNo ratings yet

- Lab Report MQADocument10 pagesLab Report MQAMuhammad QasimNo ratings yet

- Metrology Lab-1Document3 pagesMetrology Lab-1MD AFSHANNo ratings yet

- Linear MeasurementsDocument54 pagesLinear MeasurementsNaman Dave100% (1)

- Mutoh RJ4100 PDFDocument407 pagesMutoh RJ4100 PDFKlema HanisNo ratings yet

- Tmike eDocument37 pagesTmike eElyel GonzalezNo ratings yet

- Why Is The Calibration RequiredDocument3 pagesWhy Is The Calibration Requiredsaranya saiganeshNo ratings yet

- MATChapter 6AutoMathMeasurements PDFDocument21 pagesMATChapter 6AutoMathMeasurements PDFBrendan BrodieNo ratings yet

- 6 ComparatorsDocument17 pages6 Comparatorsmuhammad afzzalNo ratings yet

- DYNEX Newton Balancing CradleDocument16 pagesDYNEX Newton Balancing CradleAekDzLaiNo ratings yet

- Digital Temperature Controllers: User's Manual E5 CDocument350 pagesDigital Temperature Controllers: User's Manual E5 CPham Khac LuNo ratings yet

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Edisp WSM 0000453 01Document25 pagesEdisp WSM 0000453 01ZF ECTBNo ratings yet

- Edisp WSM 0000469 99Document4 pagesEdisp WSM 0000469 99ZF ECTBNo ratings yet

- AMAN Jun08 7509D-MADocument16 pagesAMAN Jun08 7509D-MAZF ECTBNo ratings yet

- d700 - CurveDocument3 pagesd700 - CurveZF ECTBNo ratings yet

- Couplings: Torque Converters and HydraulicDocument2 pagesCouplings: Torque Converters and Hydraulicajkbro8No ratings yet

- Gearbox Identification: Code Letters, Gearbox Allocation, Ratios, CapacitiesDocument7 pagesGearbox Identification: Code Letters, Gearbox Allocation, Ratios, CapacitiesSrđan Basarić KennedyNo ratings yet

- 12.13 101870341001 101870349999 EngineDocument9 pages12.13 101870341001 101870349999 Engineeshopmanual EnamNo ratings yet

- BW177D ManualDocument114 pagesBW177D ManualEric GrunstNo ratings yet

- Eapp Position PaperDocument3 pagesEapp Position PaperShenisse OrnopiaNo ratings yet

- Master Thesis Analysis and Specification of An AUTOSAR Based ECU in Compliance With ISO ... (PDFDrive)Document100 pagesMaster Thesis Analysis and Specification of An AUTOSAR Based ECU in Compliance With ISO ... (PDFDrive)Christoph KabekNo ratings yet

- HPV PorDocument2 pagesHPV PorChris ChrisNo ratings yet

- D3E801B9571-Air Conditioning System With Refrigerant R134aDocument115 pagesD3E801B9571-Air Conditioning System With Refrigerant R134aDaniel PelteaNo ratings yet

- L8FA / 08FA 08FH 12FT 12FH Part Name Part Number L6Fa / T6Fa / 06FA 06FHDocument1 pageL8FA / 08FA 08FH 12FT 12FH Part Name Part Number L6Fa / T6Fa / 06FA 06FHjasperzeus crisostomoNo ratings yet

- Car Rental TasDocument3 pagesCar Rental TasanaNo ratings yet

- Methodology of Work and Sequence of ActivitiesDocument6 pagesMethodology of Work and Sequence of ActivitiesAmitNo ratings yet

- Sem 655Document6 pagesSem 655rizalcorp97No ratings yet

- SM 20Document440 pagesSM 20gustavo renzoNo ratings yet

- 45.electrical Component LocationsDocument60 pages45.electrical Component LocationsKuba SwkNo ratings yet

- Basic EngineDocument2 pagesBasic Engineyoga_jpbmbmNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document11 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Albertojose8a Ochoa LopezNo ratings yet

- Asahi India Glass Initiation - 210702Document31 pagesAsahi India Glass Initiation - 210702vandit dharamshi100% (1)

- B Ing-DikonversiDocument6 pagesB Ing-DikonversiVEMBERIONo ratings yet

- C66 D5L - Data Sheet PDFDocument4 pagesC66 D5L - Data Sheet PDFJavier SanchezNo ratings yet

- Manual Raket85Document20 pagesManual Raket85Leandro BergamoNo ratings yet

- Invoice: PT. Pacific Lubritama IndonesiaDocument1 pageInvoice: PT. Pacific Lubritama IndonesiaArfansyah RamdhaniNo ratings yet

- Design: Brushed Axial Flux DC MotorDocument2 pagesDesign: Brushed Axial Flux DC MotorAkshay DeolasiNo ratings yet

- SP Marino LC 5040: Lubricating Oil For Slow Speed 2-Stroke Engine CylindersDocument2 pagesSP Marino LC 5040: Lubricating Oil For Slow Speed 2-Stroke Engine CylindersSinh LeNo ratings yet

- Universal JointDocument15 pagesUniversal Jointmos3ad2006100% (1)

- Brake Lever Setup Important Information Setup Procedure: DATA SHEET: Ds-Brleval ISSUE S1003Document2 pagesBrake Lever Setup Important Information Setup Procedure: DATA SHEET: Ds-Brleval ISSUE S1003mamatnamakuNo ratings yet

- Pro 8055Document2 pagesPro 8055Ankur MestryNo ratings yet

- Dinanath Manohar Lad: Basic ExperienceDocument2 pagesDinanath Manohar Lad: Basic ExperienceSagar PatilNo ratings yet

- Parker (MR, MRE, MR350, MR450, MRE500) Hydraulic Motors, Denison Calzoni, Radial Piston MotorDocument24 pagesParker (MR, MRE, MR350, MR450, MRE500) Hydraulic Motors, Denison Calzoni, Radial Piston MotorAngel Santiago Brusini OrozcoNo ratings yet

- Allison MD/B 300/B 400 Series On-Highway Transmissions Parts CatalogDocument2 pagesAllison MD/B 300/B 400 Series On-Highway Transmissions Parts CatalogZafiro Feliz Galan100% (1)