Professional Documents

Culture Documents

Top Down Method

Top Down Method

Uploaded by

Hammad hammadCopyright:

Available Formats

You might also like

- Nanotechnology Understanding Small Systems 3rd Rogers Solution ManualDocument12 pagesNanotechnology Understanding Small Systems 3rd Rogers Solution ManualBrian Prater100% (44)

- Eric Drexler Engines of Creation PDFDocument2 pagesEric Drexler Engines of Creation PDFKris0% (4)

- Closeup2 - Final Test - Unit 1 - 5 - g9.2Document9 pagesCloseup2 - Final Test - Unit 1 - 5 - g9.2Thu Uyên NguyễnNo ratings yet

- Self Cleaning Finishes For TextilesDocument28 pagesSelf Cleaning Finishes For TextilesShanti Kumari100% (1)

- NanomaterialsDocument22 pagesNanomaterialsRaghuNo ratings yet

- Unit 1 IntroductionDocument18 pagesUnit 1 IntroductionnavtrekNo ratings yet

- Nanotechnology Lecture Notes 4Document9 pagesNanotechnology Lecture Notes 4shivamkhandelwal200329No ratings yet

- The Nano Word 1Document41 pagesThe Nano Word 1Mark Darius A. MabborangNo ratings yet

- Surface Modification Methods For Improving The Dyeability of Textile FabricsDocument20 pagesSurface Modification Methods For Improving The Dyeability of Textile Fabricshamidrahmany3657No ratings yet

- NanotechnologyDocument20 pagesNanotechnologyjainetiNo ratings yet

- 09 - Chapter 2 PDFDocument34 pages09 - Chapter 2 PDFrajkumarNo ratings yet

- Synthesis of nanomaterialsDocument58 pagesSynthesis of nanomaterialsShubham JarandeNo ratings yet

- Nano Material Synthesis Techniques Top-Down and Bottom-Up Nanofabrication, Synthesis ofDocument6 pagesNano Material Synthesis Techniques Top-Down and Bottom-Up Nanofabrication, Synthesis ofsanthoshNo ratings yet

- Running Head: NANOMATERIALS 1Document7 pagesRunning Head: NANOMATERIALS 1brian momataNo ratings yet

- By Alemayehu Getahun ASTU : Nanoparticles: Properties, Applications and ToxicitiesDocument37 pagesBy Alemayehu Getahun ASTU : Nanoparticles: Properties, Applications and ToxicitiesALEMAYEHUNo ratings yet

- Nanomaterials For Practical Functional Uses: M.G. LinesDocument4 pagesNanomaterials For Practical Functional Uses: M.G. LinesEmerson Rodrigues de CamargoNo ratings yet

- Nanomaterials For Practical Functional UsesDocument4 pagesNanomaterials For Practical Functional UsesPonczekNo ratings yet

- Physics Activity Group 7Document21 pagesPhysics Activity Group 7Nayan DeogadeNo ratings yet

- Fabrication of Nanomaterials by Top-Down and Bottom-Up Approaches - An OverviewDocument5 pagesFabrication of Nanomaterials by Top-Down and Bottom-Up Approaches - An OverviewApexa SharmaNo ratings yet

- Catalytic Application of NanomaterialsDocument23 pagesCatalytic Application of NanomaterialsViji VijithaNo ratings yet

- Nanochemistry OverviewDocument16 pagesNanochemistry OverviewSohail AhmedNo ratings yet

- Nasa NanotecnologiDocument20 pagesNasa Nanotecnologimatbz29No ratings yet

- NANOMATERIALSDocument18 pagesNANOMATERIALSShem RuinaNo ratings yet

- Cristian TraductorDocument16 pagesCristian TraductorCristian PaezNo ratings yet

- High-Pressure HighTemperature Microreactors For Nanostructure SynthesisDocument7 pagesHigh-Pressure HighTemperature Microreactors For Nanostructure SynthesisArun EbenezerNo ratings yet

- NT Chap-6Document23 pagesNT Chap-6190140105012.hardikdhameliyaNo ratings yet

- Synthesis of Nanomaterials: (Top-Down and Bottom-Up Approaches)Document225 pagesSynthesis of Nanomaterials: (Top-Down and Bottom-Up Approaches)divyansh golaniNo ratings yet

- NanomaterialsDocument5 pagesNanomaterialssanjit0907_982377739No ratings yet

- Assignment 6 NanoDocument8 pagesAssignment 6 NanoAhmed ImranNo ratings yet

- Nano-Concrete: Innovative Build. MaterialDocument24 pagesNano-Concrete: Innovative Build. Materialrazia8akhtar100% (1)

- Science Technology and SocietyDocument11 pagesScience Technology and SocietyChristian Dela PenaNo ratings yet

- Method of Generation of NanomaterialsDocument24 pagesMethod of Generation of NanomaterialsAnsh MidhaNo ratings yet

- Nanotechnology: Karla B. RiveroDocument5 pagesNanotechnology: Karla B. RiveroJess CandaNo ratings yet

- NanomaterialsDocument15 pagesNanomaterialsPritesh MoroliyaNo ratings yet

- Micromachines 12 00991 v2Document24 pagesMicromachines 12 00991 v2Sergio RodríguezNo ratings yet

- NanometrologyDocument13 pagesNanometrologyYULIANA MADRID FLOREZNo ratings yet

- Introduction To NemsDocument17 pagesIntroduction To Nemshrishikeshdeka18No ratings yet

- DARPA White Paper LatestDocument15 pagesDARPA White Paper LatestSteven SullivanNo ratings yet

- STS 8 9Document8 pagesSTS 8 9dumpyyNo ratings yet

- Nano Composites) (Minahal 029)Document9 pagesNano Composites) (Minahal 029)Minahal AminNo ratings yet

- Finalact#4 GranadaDocument3 pagesFinalact#4 GranadaAnna LouisaNo ratings yet

- BshrehrthhrtDocument2 pagesBshrehrthhrtDianne LabisNo ratings yet

- Synthesis of Nanometerscale MaterialsDocument50 pagesSynthesis of Nanometerscale MaterialsBhakti HiraniNo ratings yet

- NanolithogrDocument21 pagesNanolithogrAmrita ThapaNo ratings yet

- Nano BasicsDocument22 pagesNano BasicsMuhamed BadhushaNo ratings yet

- Nano NanostructuresDocument16 pagesNano NanostructuresCHARLES BENEDICT MARQUEZNo ratings yet

- Lecture40 NptelDocument37 pagesLecture40 NptelSitaramaraju VengalarajuNo ratings yet

- Unit-Iv Nanomaterials and Nanotechnology: Part-ADocument4 pagesUnit-Iv Nanomaterials and Nanotechnology: Part-AKrishna ThiruvengadamNo ratings yet

- Meltblown Fabrics From Biodegradable Polymers: Original PaperDocument7 pagesMeltblown Fabrics From Biodegradable Polymers: Original PaperalbertoNo ratings yet

- Nanotechnoloy Presentation BobyDocument21 pagesNanotechnoloy Presentation Bobyvashumavi868No ratings yet

- NANOTECHNOLOGY SeminarDocument30 pagesNANOTECHNOLOGY SeminarArvind Singh KasanaNo ratings yet

- NanotechnologyDocument7 pagesNanotechnologyASJADI SHEIKHNo ratings yet

- ManufacturingDocument24 pagesManufacturingMiled HoussemNo ratings yet

- NanotechnologyDocument22 pagesNanotechnologyKunal ChauhanNo ratings yet

- NanoTechnology GK VKDocument12 pagesNanoTechnology GK VKapi-19799369No ratings yet

- 3.c)Document2 pages3.c)Mad MaxNo ratings yet

- Intoduction To NanomaterialsDocument26 pagesIntoduction To NanomaterialsYajnadatta PattanayakNo ratings yet

- The Nano WorldDocument15 pagesThe Nano Worldevangelista.jantristan.c220845100% (1)

- PHYSICS BroDocument15 pagesPHYSICS BroASHWATH G (RA2111018010045)No ratings yet

- Civil Nano ConcreteDocument23 pagesCivil Nano ConcreteSaif TadpatriNo ratings yet

- NanoconcreteDocument3 pagesNanoconcretenn5899170No ratings yet

- Spring 2024_Lecture_2_Synthetic Methodology of NanomaterialsDocument23 pagesSpring 2024_Lecture_2_Synthetic Methodology of Nanomaterialss-zeyad.mawjoudNo ratings yet

- Civil Nano ConcreteDocument22 pagesCivil Nano Concretemanju bhargavNo ratings yet

- Nanotechnology: The Limitless Possibilities of Tiny ScienceFrom EverandNanotechnology: The Limitless Possibilities of Tiny ScienceNo ratings yet

- Knoevengel CondensationDocument11 pagesKnoevengel CondensationHammad hammadNo ratings yet

- HaemoglobinDocument19 pagesHaemoglobinHammad hammadNo ratings yet

- Organic ChemistryDocument15 pagesOrganic ChemistryHammad hammadNo ratings yet

- ChlorideDocument17 pagesChlorideHammad hammadNo ratings yet

- PotassiumDocument8 pagesPotassiumHammad hammadNo ratings yet

- Assignment No 2 LanthanideDocument9 pagesAssignment No 2 LanthanideHammad hammadNo ratings yet

- Boltzman LawDocument5 pagesBoltzman LawHammad hammadNo ratings yet

- Claisen Schmidt ReactionsDocument6 pagesClaisen Schmidt ReactionsHammad hammadNo ratings yet

- Biochemistry LectureDocument19 pagesBiochemistry LectureHammad hammadNo ratings yet

- Lecture 10 PlatyhelminthesDocument12 pagesLecture 10 PlatyhelminthesHammad hammadNo ratings yet

- Why The Future Doesn't Need Us - REVIEWERDocument1 pageWhy The Future Doesn't Need Us - REVIEWERJosa Camille BungayNo ratings yet

- Quantum Dot-Sensitized Solar Cells Photovoltaic Properties and Photoexcited Carrier DynamicsDocument25 pagesQuantum Dot-Sensitized Solar Cells Photovoltaic Properties and Photoexcited Carrier DynamicsRayes SwathNo ratings yet

- LIGA Process: LIGA Process Is One of The Fabrication Techniques For MEMSDocument4 pagesLIGA Process: LIGA Process Is One of The Fabrication Techniques For MEMSChirag.S. ShettyNo ratings yet

- Mrsptu Ug Open Electives-Ii 2016 Batch Onwards Updated On 17.09.2019Document25 pagesMrsptu Ug Open Electives-Ii 2016 Batch Onwards Updated On 17.09.2019jellymaniNo ratings yet

- NanophotonicsDocument3 pagesNanophotonicsreenadkNo ratings yet

- IntroductionDocument4 pagesIntroductionShahab ShafiNo ratings yet

- Syllabus For B.SC Physics Semester Pattern2013Document23 pagesSyllabus For B.SC Physics Semester Pattern2013GnetTechnologies GondiaNo ratings yet

- Brochure (English)Document22 pagesBrochure (English)Anasya Arsita LaksmiNo ratings yet

- Paper Presentation ON: 4 Semester COMPDocument36 pagesPaper Presentation ON: 4 Semester COMPRavinNo ratings yet

- Arthur, J. R. (2002) - Molecular Beam Epitaxy. Surface Science, 500 (1), 189-217Document16 pagesArthur, J. R. (2002) - Molecular Beam Epitaxy. Surface Science, 500 (1), 189-217Malik SahabNo ratings yet

- Title: Nanocatalyst Used in The Production of PetrochemicalDocument3 pagesTitle: Nanocatalyst Used in The Production of PetrochemicalChris AngNo ratings yet

- Introduction To and Nano Scale: DR Partha S Mallick Vellore Institute of Technology, India Winter 2018-19Document30 pagesIntroduction To and Nano Scale: DR Partha S Mallick Vellore Institute of Technology, India Winter 2018-19sahale sheraNo ratings yet

- Sapsford2013 LEERDocument171 pagesSapsford2013 LEERJimmy SimpsonNo ratings yet

- Study About Scope of Nano Technology in Real World Past, Present and FutureDocument3 pagesStudy About Scope of Nano Technology in Real World Past, Present and FutureSAMI UR REHMANNo ratings yet

- 5 - Efficient Dielectric Function For FDTD Simulation of The Optical Properties of Silver and Gold NanoparticlesDocument4 pages5 - Efficient Dielectric Function For FDTD Simulation of The Optical Properties of Silver and Gold NanoparticlesMarcio Antônio CostaNo ratings yet

- Cientifica WP3 PDFDocument11 pagesCientifica WP3 PDFRupesh KumarNo ratings yet

- Ijms 22 00385 v3Document21 pagesIjms 22 00385 v3Rangga Dwi PutraNo ratings yet

- Eee231 PDFDocument15 pagesEee231 PDFJagadish YadavNo ratings yet

- Mach-Drive Nano EnerzigerDocument53 pagesMach-Drive Nano Enerzigerdeepak dubeyNo ratings yet

- Pokropivny 2007Document4 pagesPokropivny 2007vasanthanilNo ratings yet

- Nanotechnology in Sports EquipmentDocument9 pagesNanotechnology in Sports Equipmentbillyyyy950% (1)

- Molecular Computing PPT (Rachit N Ravneet)Document26 pagesMolecular Computing PPT (Rachit N Ravneet)Anit SachdevaNo ratings yet

- Whitby, M. and N. Quirke (2007) - Fluid Flow in Carbon Nanotubes and Nanopipes. Nature Nanotechnology 2 87 To 94.Document8 pagesWhitby, M. and N. Quirke (2007) - Fluid Flow in Carbon Nanotubes and Nanopipes. Nature Nanotechnology 2 87 To 94.vandelfinNo ratings yet

- Peskin Uri Quantum Mechanics in Nanoscience and EngineeringDocument491 pagesPeskin Uri Quantum Mechanics in Nanoscience and EngineeringStrahinja DonicNo ratings yet

- Innovation Technology Award Nanotech 2003Document286 pagesInnovation Technology Award Nanotech 2003Vincent J. CataldiNo ratings yet

- Nano World - Lesson With Answer KeyDocument26 pagesNano World - Lesson With Answer KeyAngelie JalandoniNo ratings yet

Top Down Method

Top Down Method

Uploaded by

Hammad hammadCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Top Down Method

Top Down Method

Uploaded by

Hammad hammadCopyright:

Available Formats

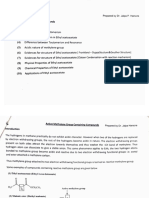

Top Down Method Bottom Up Method

Involves breaking down bulk materials into Involves building up nanomaterials from atomic

smaller structures until reaching the desired or molecular components, gradually assembling

nanoscale dimensions. them into larger structures

Particle size reduction to nanosize Growth of particles from atomic or molecular

size

Suitable for large-scale production and can Offers excellent control over size, shape, and

handle a wide range of materials. However, it composition at the nanoscale. However, it may

may face challenges in achieving precise control be limited in terms of scalability and efficiency

over size, shape, and composition at the for large-scale production.

nanoscale.

The process is used for hard and brittle materials The process is used for gases, liquids and solids

All partices may not be broken down to required We may control the size

particle size Provides precise control over atomic

Limited control over the atomic arrangement and arrangement and surface properties, allowing for

surface properties of nanomaterials due to the the design of custom nanomaterials with specific

initial properties of the bulk material. properties.

May require significant energy input, especially Generally more energy-efficient as it relies on

in processes such as milling or lithography. chemical reactions and self-assembly processes.

Commonly used for producing nanomaterials on Widely employed in fields requiring precise

large scale. control over material properties, such as

nanoelectronics, drug delivery, and catalysis

Often simpler and more straightforward, as it Can be more complex and may require careful

involves mechanical or physical processes to design of synthesis routes and reaction

break down materials. conditions to achieve the desired nanomaterials

Can be cost-effective for large-scale production May involve higher initial costs for synthesis

due to the utilization of existing bulk materials equipment and precursor materials but can offer

long-term cost benefits through precise control

and tailored properties.

Advantages Disadvantages

Large scale production: deposition over a large Ultra-fine nanoparticles, nanoshells, nanotubes

substrate is possible can be prepared

• Chemical purification is not required • Deposition parameters can be controlled

Broader size distribution

Expensive technique • Narrow size distribution is possible (1-20 nm)

• Cheaper technique

You might also like

- Nanotechnology Understanding Small Systems 3rd Rogers Solution ManualDocument12 pagesNanotechnology Understanding Small Systems 3rd Rogers Solution ManualBrian Prater100% (44)

- Eric Drexler Engines of Creation PDFDocument2 pagesEric Drexler Engines of Creation PDFKris0% (4)

- Closeup2 - Final Test - Unit 1 - 5 - g9.2Document9 pagesCloseup2 - Final Test - Unit 1 - 5 - g9.2Thu Uyên NguyễnNo ratings yet

- Self Cleaning Finishes For TextilesDocument28 pagesSelf Cleaning Finishes For TextilesShanti Kumari100% (1)

- NanomaterialsDocument22 pagesNanomaterialsRaghuNo ratings yet

- Unit 1 IntroductionDocument18 pagesUnit 1 IntroductionnavtrekNo ratings yet

- Nanotechnology Lecture Notes 4Document9 pagesNanotechnology Lecture Notes 4shivamkhandelwal200329No ratings yet

- The Nano Word 1Document41 pagesThe Nano Word 1Mark Darius A. MabborangNo ratings yet

- Surface Modification Methods For Improving The Dyeability of Textile FabricsDocument20 pagesSurface Modification Methods For Improving The Dyeability of Textile Fabricshamidrahmany3657No ratings yet

- NanotechnologyDocument20 pagesNanotechnologyjainetiNo ratings yet

- 09 - Chapter 2 PDFDocument34 pages09 - Chapter 2 PDFrajkumarNo ratings yet

- Synthesis of nanomaterialsDocument58 pagesSynthesis of nanomaterialsShubham JarandeNo ratings yet

- Nano Material Synthesis Techniques Top-Down and Bottom-Up Nanofabrication, Synthesis ofDocument6 pagesNano Material Synthesis Techniques Top-Down and Bottom-Up Nanofabrication, Synthesis ofsanthoshNo ratings yet

- Running Head: NANOMATERIALS 1Document7 pagesRunning Head: NANOMATERIALS 1brian momataNo ratings yet

- By Alemayehu Getahun ASTU : Nanoparticles: Properties, Applications and ToxicitiesDocument37 pagesBy Alemayehu Getahun ASTU : Nanoparticles: Properties, Applications and ToxicitiesALEMAYEHUNo ratings yet

- Nanomaterials For Practical Functional Uses: M.G. LinesDocument4 pagesNanomaterials For Practical Functional Uses: M.G. LinesEmerson Rodrigues de CamargoNo ratings yet

- Nanomaterials For Practical Functional UsesDocument4 pagesNanomaterials For Practical Functional UsesPonczekNo ratings yet

- Physics Activity Group 7Document21 pagesPhysics Activity Group 7Nayan DeogadeNo ratings yet

- Fabrication of Nanomaterials by Top-Down and Bottom-Up Approaches - An OverviewDocument5 pagesFabrication of Nanomaterials by Top-Down and Bottom-Up Approaches - An OverviewApexa SharmaNo ratings yet

- Catalytic Application of NanomaterialsDocument23 pagesCatalytic Application of NanomaterialsViji VijithaNo ratings yet

- Nanochemistry OverviewDocument16 pagesNanochemistry OverviewSohail AhmedNo ratings yet

- Nasa NanotecnologiDocument20 pagesNasa Nanotecnologimatbz29No ratings yet

- NANOMATERIALSDocument18 pagesNANOMATERIALSShem RuinaNo ratings yet

- Cristian TraductorDocument16 pagesCristian TraductorCristian PaezNo ratings yet

- High-Pressure HighTemperature Microreactors For Nanostructure SynthesisDocument7 pagesHigh-Pressure HighTemperature Microreactors For Nanostructure SynthesisArun EbenezerNo ratings yet

- NT Chap-6Document23 pagesNT Chap-6190140105012.hardikdhameliyaNo ratings yet

- Synthesis of Nanomaterials: (Top-Down and Bottom-Up Approaches)Document225 pagesSynthesis of Nanomaterials: (Top-Down and Bottom-Up Approaches)divyansh golaniNo ratings yet

- NanomaterialsDocument5 pagesNanomaterialssanjit0907_982377739No ratings yet

- Assignment 6 NanoDocument8 pagesAssignment 6 NanoAhmed ImranNo ratings yet

- Nano-Concrete: Innovative Build. MaterialDocument24 pagesNano-Concrete: Innovative Build. Materialrazia8akhtar100% (1)

- Science Technology and SocietyDocument11 pagesScience Technology and SocietyChristian Dela PenaNo ratings yet

- Method of Generation of NanomaterialsDocument24 pagesMethod of Generation of NanomaterialsAnsh MidhaNo ratings yet

- Nanotechnology: Karla B. RiveroDocument5 pagesNanotechnology: Karla B. RiveroJess CandaNo ratings yet

- NanomaterialsDocument15 pagesNanomaterialsPritesh MoroliyaNo ratings yet

- Micromachines 12 00991 v2Document24 pagesMicromachines 12 00991 v2Sergio RodríguezNo ratings yet

- NanometrologyDocument13 pagesNanometrologyYULIANA MADRID FLOREZNo ratings yet

- Introduction To NemsDocument17 pagesIntroduction To Nemshrishikeshdeka18No ratings yet

- DARPA White Paper LatestDocument15 pagesDARPA White Paper LatestSteven SullivanNo ratings yet

- STS 8 9Document8 pagesSTS 8 9dumpyyNo ratings yet

- Nano Composites) (Minahal 029)Document9 pagesNano Composites) (Minahal 029)Minahal AminNo ratings yet

- Finalact#4 GranadaDocument3 pagesFinalact#4 GranadaAnna LouisaNo ratings yet

- BshrehrthhrtDocument2 pagesBshrehrthhrtDianne LabisNo ratings yet

- Synthesis of Nanometerscale MaterialsDocument50 pagesSynthesis of Nanometerscale MaterialsBhakti HiraniNo ratings yet

- NanolithogrDocument21 pagesNanolithogrAmrita ThapaNo ratings yet

- Nano BasicsDocument22 pagesNano BasicsMuhamed BadhushaNo ratings yet

- Nano NanostructuresDocument16 pagesNano NanostructuresCHARLES BENEDICT MARQUEZNo ratings yet

- Lecture40 NptelDocument37 pagesLecture40 NptelSitaramaraju VengalarajuNo ratings yet

- Unit-Iv Nanomaterials and Nanotechnology: Part-ADocument4 pagesUnit-Iv Nanomaterials and Nanotechnology: Part-AKrishna ThiruvengadamNo ratings yet

- Meltblown Fabrics From Biodegradable Polymers: Original PaperDocument7 pagesMeltblown Fabrics From Biodegradable Polymers: Original PaperalbertoNo ratings yet

- Nanotechnoloy Presentation BobyDocument21 pagesNanotechnoloy Presentation Bobyvashumavi868No ratings yet

- NANOTECHNOLOGY SeminarDocument30 pagesNANOTECHNOLOGY SeminarArvind Singh KasanaNo ratings yet

- NanotechnologyDocument7 pagesNanotechnologyASJADI SHEIKHNo ratings yet

- ManufacturingDocument24 pagesManufacturingMiled HoussemNo ratings yet

- NanotechnologyDocument22 pagesNanotechnologyKunal ChauhanNo ratings yet

- NanoTechnology GK VKDocument12 pagesNanoTechnology GK VKapi-19799369No ratings yet

- 3.c)Document2 pages3.c)Mad MaxNo ratings yet

- Intoduction To NanomaterialsDocument26 pagesIntoduction To NanomaterialsYajnadatta PattanayakNo ratings yet

- The Nano WorldDocument15 pagesThe Nano Worldevangelista.jantristan.c220845100% (1)

- PHYSICS BroDocument15 pagesPHYSICS BroASHWATH G (RA2111018010045)No ratings yet

- Civil Nano ConcreteDocument23 pagesCivil Nano ConcreteSaif TadpatriNo ratings yet

- NanoconcreteDocument3 pagesNanoconcretenn5899170No ratings yet

- Spring 2024_Lecture_2_Synthetic Methodology of NanomaterialsDocument23 pagesSpring 2024_Lecture_2_Synthetic Methodology of Nanomaterialss-zeyad.mawjoudNo ratings yet

- Civil Nano ConcreteDocument22 pagesCivil Nano Concretemanju bhargavNo ratings yet

- Nanotechnology: The Limitless Possibilities of Tiny ScienceFrom EverandNanotechnology: The Limitless Possibilities of Tiny ScienceNo ratings yet

- Knoevengel CondensationDocument11 pagesKnoevengel CondensationHammad hammadNo ratings yet

- HaemoglobinDocument19 pagesHaemoglobinHammad hammadNo ratings yet

- Organic ChemistryDocument15 pagesOrganic ChemistryHammad hammadNo ratings yet

- ChlorideDocument17 pagesChlorideHammad hammadNo ratings yet

- PotassiumDocument8 pagesPotassiumHammad hammadNo ratings yet

- Assignment No 2 LanthanideDocument9 pagesAssignment No 2 LanthanideHammad hammadNo ratings yet

- Boltzman LawDocument5 pagesBoltzman LawHammad hammadNo ratings yet

- Claisen Schmidt ReactionsDocument6 pagesClaisen Schmidt ReactionsHammad hammadNo ratings yet

- Biochemistry LectureDocument19 pagesBiochemistry LectureHammad hammadNo ratings yet

- Lecture 10 PlatyhelminthesDocument12 pagesLecture 10 PlatyhelminthesHammad hammadNo ratings yet

- Why The Future Doesn't Need Us - REVIEWERDocument1 pageWhy The Future Doesn't Need Us - REVIEWERJosa Camille BungayNo ratings yet

- Quantum Dot-Sensitized Solar Cells Photovoltaic Properties and Photoexcited Carrier DynamicsDocument25 pagesQuantum Dot-Sensitized Solar Cells Photovoltaic Properties and Photoexcited Carrier DynamicsRayes SwathNo ratings yet

- LIGA Process: LIGA Process Is One of The Fabrication Techniques For MEMSDocument4 pagesLIGA Process: LIGA Process Is One of The Fabrication Techniques For MEMSChirag.S. ShettyNo ratings yet

- Mrsptu Ug Open Electives-Ii 2016 Batch Onwards Updated On 17.09.2019Document25 pagesMrsptu Ug Open Electives-Ii 2016 Batch Onwards Updated On 17.09.2019jellymaniNo ratings yet

- NanophotonicsDocument3 pagesNanophotonicsreenadkNo ratings yet

- IntroductionDocument4 pagesIntroductionShahab ShafiNo ratings yet

- Syllabus For B.SC Physics Semester Pattern2013Document23 pagesSyllabus For B.SC Physics Semester Pattern2013GnetTechnologies GondiaNo ratings yet

- Brochure (English)Document22 pagesBrochure (English)Anasya Arsita LaksmiNo ratings yet

- Paper Presentation ON: 4 Semester COMPDocument36 pagesPaper Presentation ON: 4 Semester COMPRavinNo ratings yet

- Arthur, J. R. (2002) - Molecular Beam Epitaxy. Surface Science, 500 (1), 189-217Document16 pagesArthur, J. R. (2002) - Molecular Beam Epitaxy. Surface Science, 500 (1), 189-217Malik SahabNo ratings yet

- Title: Nanocatalyst Used in The Production of PetrochemicalDocument3 pagesTitle: Nanocatalyst Used in The Production of PetrochemicalChris AngNo ratings yet

- Introduction To and Nano Scale: DR Partha S Mallick Vellore Institute of Technology, India Winter 2018-19Document30 pagesIntroduction To and Nano Scale: DR Partha S Mallick Vellore Institute of Technology, India Winter 2018-19sahale sheraNo ratings yet

- Sapsford2013 LEERDocument171 pagesSapsford2013 LEERJimmy SimpsonNo ratings yet

- Study About Scope of Nano Technology in Real World Past, Present and FutureDocument3 pagesStudy About Scope of Nano Technology in Real World Past, Present and FutureSAMI UR REHMANNo ratings yet

- 5 - Efficient Dielectric Function For FDTD Simulation of The Optical Properties of Silver and Gold NanoparticlesDocument4 pages5 - Efficient Dielectric Function For FDTD Simulation of The Optical Properties of Silver and Gold NanoparticlesMarcio Antônio CostaNo ratings yet

- Cientifica WP3 PDFDocument11 pagesCientifica WP3 PDFRupesh KumarNo ratings yet

- Ijms 22 00385 v3Document21 pagesIjms 22 00385 v3Rangga Dwi PutraNo ratings yet

- Eee231 PDFDocument15 pagesEee231 PDFJagadish YadavNo ratings yet

- Mach-Drive Nano EnerzigerDocument53 pagesMach-Drive Nano Enerzigerdeepak dubeyNo ratings yet

- Pokropivny 2007Document4 pagesPokropivny 2007vasanthanilNo ratings yet

- Nanotechnology in Sports EquipmentDocument9 pagesNanotechnology in Sports Equipmentbillyyyy950% (1)

- Molecular Computing PPT (Rachit N Ravneet)Document26 pagesMolecular Computing PPT (Rachit N Ravneet)Anit SachdevaNo ratings yet

- Whitby, M. and N. Quirke (2007) - Fluid Flow in Carbon Nanotubes and Nanopipes. Nature Nanotechnology 2 87 To 94.Document8 pagesWhitby, M. and N. Quirke (2007) - Fluid Flow in Carbon Nanotubes and Nanopipes. Nature Nanotechnology 2 87 To 94.vandelfinNo ratings yet

- Peskin Uri Quantum Mechanics in Nanoscience and EngineeringDocument491 pagesPeskin Uri Quantum Mechanics in Nanoscience and EngineeringStrahinja DonicNo ratings yet

- Innovation Technology Award Nanotech 2003Document286 pagesInnovation Technology Award Nanotech 2003Vincent J. CataldiNo ratings yet

- Nano World - Lesson With Answer KeyDocument26 pagesNano World - Lesson With Answer KeyAngelie JalandoniNo ratings yet