Professional Documents

Culture Documents

Chapter 8 - IWIS (Sep 27 - 1999)

Chapter 8 - IWIS (Sep 27 - 1999)

Uploaded by

mangeshsnt_121181Copyright:

Available Formats

You might also like

- Installation QualificationDocument14 pagesInstallation QualificationTuan Nguyen100% (1)

- Draft - Sat Procedure For Access Control SystemDocument11 pagesDraft - Sat Procedure For Access Control SystemVenkataramanan SNo ratings yet

- Rites of AstarothDocument100 pagesRites of AstarothEdina Mayara75% (16)

- SITXHRM001 - Workplace Feedback.v1.0Document4 pagesSITXHRM001 - Workplace Feedback.v1.0Ranju WagleNo ratings yet

- Concept Map For DenvDocument4 pagesConcept Map For Denvnikki sabs67% (3)

- FAT ProcedureDocument14 pagesFAT ProcedurePrashant Mohokar100% (1)

- IPT Test Plan-ProposalDocument16 pagesIPT Test Plan-ProposalOchie RomeroNo ratings yet

- Reliability Prediction from Burn-In Data Fit to Reliability ModelsFrom EverandReliability Prediction from Burn-In Data Fit to Reliability ModelsRating: 3 out of 5 stars3/5 (2)

- What Makes The Earth Suitable For LifeDocument1 pageWhat Makes The Earth Suitable For LifejinmenchieNo ratings yet

- CRH Produkt ProgramDocument28 pagesCRH Produkt ProgramHima KiranNo ratings yet

- Annexure 1Document9 pagesAnnexure 1faizan4033No ratings yet

- Automated Test & Alignment System For Telecom ApplicationsDocument4 pagesAutomated Test & Alignment System For Telecom ApplicationsMurali KrishnaNo ratings yet

- A Project On Automated Harness TesterDocument42 pagesA Project On Automated Harness TesterSantosh KumarNo ratings yet

- Cat 6 Shielded Patch Cords: Product SpecificationDocument5 pagesCat 6 Shielded Patch Cords: Product SpecificationAngelica Baena CuestaNo ratings yet

- Electronic Syatem Design PPT - Design For TestabilityDocument9 pagesElectronic Syatem Design PPT - Design For TestabilityAnoop Mathew0% (1)

- Paddle Switch CombinedDocument10 pagesPaddle Switch CombinedPriyanshu GuptaNo ratings yet

- ECE 617 - Fault Testable Design Dr. Janusz Starzyk: School of EECS Ohio University Athens, OH, 45701Document79 pagesECE 617 - Fault Testable Design Dr. Janusz Starzyk: School of EECS Ohio University Athens, OH, 45701sivapothiNo ratings yet

- Solution Brief - Ethernet OAMDocument2 pagesSolution Brief - Ethernet OAMbakh777196No ratings yet

- Technical Specification of Automatic Relay Test KitDocument13 pagesTechnical Specification of Automatic Relay Test KitEBENo ratings yet

- Guide To Choosing The Right Cable Test Tool To Meet Your Testing NeedsDocument4 pagesGuide To Choosing The Right Cable Test Tool To Meet Your Testing Needsricx31No ratings yet

- Exhibit K - (REDACTED) - System Acceptance Plan v2 (FINAL)Document105 pagesExhibit K - (REDACTED) - System Acceptance Plan v2 (FINAL)Mohammed F. ShehataNo ratings yet

- A Briefing On IEEE 1149.1 - 1990 Standard Test Access Port and Boundary-Scan Architecture (AKA JTAG)Document12 pagesA Briefing On IEEE 1149.1 - 1990 Standard Test Access Port and Boundary-Scan Architecture (AKA JTAG)Raghul SambathkumarNo ratings yet

- CETECOM - Module Integration PresentationDocument16 pagesCETECOM - Module Integration PresentationAjit SubramanyamNo ratings yet

- XJ Products Brochures enDocument64 pagesXJ Products Brochures enMika Kadju RapalangiNo ratings yet

- Copper Certification Testing: Best Practices Pocket GuideDocument16 pagesCopper Certification Testing: Best Practices Pocket GuidedexiNo ratings yet

- 61a1 ReadingDocument7 pages61a1 Readingishu vohraNo ratings yet

- C-54 NocDocument41 pagesC-54 NocRochdi SahliNo ratings yet

- ANSI - SCTE - 47 - 2007 Test Method For Coaxial Cable AttenuationDocument7 pagesANSI - SCTE - 47 - 2007 Test Method For Coaxial Cable AttenuationYung SangNo ratings yet

- E2 Relay CommissioningDocument14 pagesE2 Relay CommissioningShailesh ChettyNo ratings yet

- Trusted Safety System PDFDocument2 pagesTrusted Safety System PDFalimohebbi1361No ratings yet

- Essential 6 Field Testing Procedure 1 PDFDocument9 pagesEssential 6 Field Testing Procedure 1 PDFAnonymous GIjAfAD6100% (1)

- Sequencing With Next-Generation Non-Signaling Test EquipmentDocument7 pagesSequencing With Next-Generation Non-Signaling Test EquipmentCường MchwNo ratings yet

- Acceptance Testing, Conformance & Quality Assurance of IEC61850 DevicesDocument5 pagesAcceptance Testing, Conformance & Quality Assurance of IEC61850 DeviceschangNo ratings yet

- Research Designs and Standards Organisation Manak Nagar, Lucknow - 226 011, IndiaDocument41 pagesResearch Designs and Standards Organisation Manak Nagar, Lucknow - 226 011, IndiaChandra Mohan RawatNo ratings yet

- An Experimental Chip To Evaluate Test TechniquesDocument10 pagesAn Experimental Chip To Evaluate Test TechniquesVinod KheraNo ratings yet

- Lesson 41 PDFDocument23 pagesLesson 41 PDFAre VijayNo ratings yet

- Embedded Jtag Boundary Scan TestDocument9 pagesEmbedded Jtag Boundary Scan TestAurelian ZaharescuNo ratings yet

- Copper Testing Best PracticesDocument16 pagesCopper Testing Best PracticesArnie GajudoNo ratings yet

- Acterna EDT135Document8 pagesActerna EDT135reivajjwNo ratings yet

- FOUNDATION™ Fieldbus: Factory Acceptance Test and Device CommissioningDocument16 pagesFOUNDATION™ Fieldbus: Factory Acceptance Test and Device CommissioningNelson P. ColoNo ratings yet

- PLC Details of Agc PlantDocument93 pagesPLC Details of Agc PlantamalgceNo ratings yet

- Brochure TestPro 11032022Document12 pagesBrochure TestPro 11032022highcomcalaNo ratings yet

- Pump Station PLC ControlDocument9 pagesPump Station PLC ControldanderjNo ratings yet

- ATS Flyer System @station 181005Document12 pagesATS Flyer System @station 181005Phạm Tiến SaoNo ratings yet

- Method Statement - CCTVDocument8 pagesMethod Statement - CCTVYazan ZahalqaNo ratings yet

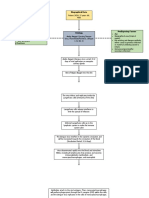

- 5100 12. Post Inspection Sampling Mandatory sampling and inspection after 100% visual inspection. Sampling plan as per ANSI/ASQ Z1.4 – 2008 (or ISO 2859-1): General Inspection Level – II, Single sampling plans for Normal inspection with an AQL of 0.65%. Batch releasing criteria: NMT the specified number of units contains visible particulates. Special level sampling (reduced sample quantity) for destructive inspections (for powder filled, lyophilized products, coloured containers, etc.). AQL Failure Is the test Destructive ? Investigation Re-inspection of 100% units Batch Rejection Yes No PerformAQLinspection Slide No. 12 13. Particle Separation, Identification and Characterization Manufacturers should have knowledge on their particulate matter rejections. Type of particles. Source of each particle type. Routine trend / capability of particulate rejections. Morphology of each type of particle. Chemistry of each particle type. Manufacturers should have comprehensiveDocument9 pages5100 12. Post Inspection Sampling Mandatory sampling and inspection after 100% visual inspection. Sampling plan as per ANSI/ASQ Z1.4 – 2008 (or ISO 2859-1): General Inspection Level – II, Single sampling plans for Normal inspection with an AQL of 0.65%. Batch releasing criteria: NMT the specified number of units contains visible particulates. Special level sampling (reduced sample quantity) for destructive inspections (for powder filled, lyophilized products, coloured containers, etc.). AQL Failure Is the test Destructive ? Investigation Re-inspection of 100% units Batch Rejection Yes No PerformAQLinspection Slide No. 12 13. Particle Separation, Identification and Characterization Manufacturers should have knowledge on their particulate matter rejections. Type of particles. Source of each particle type. Routine trend / capability of particulate rejections. Morphology of each type of particle. Chemistry of each particle type. Manufacturers should have comprehensiveschumonNo ratings yet

- Est3 Installation&Service ManualDocument388 pagesEst3 Installation&Service Manualsumankashyap100% (1)

- Tcst11101r0 CommunicationDocument127 pagesTcst11101r0 CommunicationengrandyNo ratings yet

- Radio Network Drive Test GuideDocument12 pagesRadio Network Drive Test Guidek_muange897No ratings yet

- Quality: Optimum Ive ReliabilityDocument3 pagesQuality: Optimum Ive ReliabilityLuJo NarañaNo ratings yet

- Automotive Electronics Council: AEC - Q100-005 - REV-C September 7, 2004Document10 pagesAutomotive Electronics Council: AEC - Q100-005 - REV-C September 7, 2004KL ChanNo ratings yet

- Abbreviations: OQ Exploration and Production LLCDocument3 pagesAbbreviations: OQ Exploration and Production LLCHamza ShujaNo ratings yet

- Relay Testing and CommissioningDocument28 pagesRelay Testing and CommissioningKailash PanthaNo ratings yet

- Chap1 Lect01 OverviewDocument12 pagesChap1 Lect01 OverviewGlen ChenNo ratings yet

- IEC 61850 Testing and Commissioning Advantages Using GOOSE MessagingDocument5 pagesIEC 61850 Testing and Commissioning Advantages Using GOOSE MessagingAlanMolinaNo ratings yet

- Technical Compliance MatrixDocument4 pagesTechnical Compliance Matrixyanaca asociadosNo ratings yet

- AirGateway LR QSGDocument24 pagesAirGateway LR QSGAndreyNo ratings yet

- Jtag - AN IEEE 1149.1 STDDocument42 pagesJtag - AN IEEE 1149.1 STDkanchanstiwariNo ratings yet

- Industrial Process Control: Advances and ApplicationsFrom EverandIndustrial Process Control: Advances and ApplicationsRating: 2 out of 5 stars2/5 (1)

- 5G NR: Architecture, Technology, Implementation, and Operation of 3GPP New Radio StandardsFrom Everand5G NR: Architecture, Technology, Implementation, and Operation of 3GPP New Radio StandardsRating: 3.5 out of 5 stars3.5/5 (8)

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- GROUP 1 Pr2Document23 pagesGROUP 1 Pr2MarYNo ratings yet

- MC 1 Operation Manual EnglishDocument44 pagesMC 1 Operation Manual EnglishHirabteb Arshia Co. IVD ManufacturerNo ratings yet

- User Manual Back-UPS BE600M1/600M1-LM/670M1, BN650M1/650M1-CA/675M1Document2 pagesUser Manual Back-UPS BE600M1/600M1-LM/670M1, BN650M1/650M1-CA/675M1World NewNo ratings yet

- SBEC3622-OCW 3 OSHEnvironmentDocument17 pagesSBEC3622-OCW 3 OSHEnvironmentnzy06No ratings yet

- Service and Operator ManualDocument46 pagesService and Operator ManualBersanz SrlNo ratings yet

- Training Needs of Resident Adults BasisDocument22 pagesTraining Needs of Resident Adults BasisZoe OBNo ratings yet

- Soal Ukp 2022 by Kevin JoshuaDocument133 pagesSoal Ukp 2022 by Kevin JoshuaADI ARI IRAWANNo ratings yet

- Infographics LibitjodielynDocument1 pageInfographics LibitjodielynJodielyn Bombane LibitNo ratings yet

- Peptic Ulcer Disease NCLEX ReviewDocument16 pagesPeptic Ulcer Disease NCLEX ReviewBianca Trish ManlangitNo ratings yet

- GS Specification Traction - BatteryDocument8 pagesGS Specification Traction - BatteryDedy CjNo ratings yet

- Persuasive Speech Topics 8cDocument2 pagesPersuasive Speech Topics 8cIsaid OrtegaNo ratings yet

- Sika Raintite: Acrylic WaterproofingDocument2 pagesSika Raintite: Acrylic WaterproofingWahyudi AminotoNo ratings yet

- 05-CurrentTransformers ENG 2017.compressedDocument59 pages05-CurrentTransformers ENG 2017.compressedVinodraj YalagiNo ratings yet

- PHREEQ C Modelling Tool Application To Determine The Effect of Anions On Speciation of Selected Metals in Water Systems Within Kajiado North Constituency in KenyaDocument71 pagesPHREEQ C Modelling Tool Application To Determine The Effect of Anions On Speciation of Selected Metals in Water Systems Within Kajiado North Constituency in KenyaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Escherichia Coli Plasmid Production in FermenterDocument8 pagesEscherichia Coli Plasmid Production in Fermenterdary.podoliak03No ratings yet

- A High-Power High-Voltage Power Supply For Long-Pulse Applications IEEE TPS 20101Document9 pagesA High-Power High-Voltage Power Supply For Long-Pulse Applications IEEE TPS 20101Cesar LopezNo ratings yet

- Test Your Prepositions 1 - in Order To Get To JeffsDocument3 pagesTest Your Prepositions 1 - in Order To Get To JeffsfurkanalpatNo ratings yet

- KenyaEMR 18 7 0 Release NotesDocument7 pagesKenyaEMR 18 7 0 Release NotesMigori ArtNo ratings yet

- SMCL100 CatalogDocument2 pagesSMCL100 CatalogHéctor Eduardo Hernández LópezNo ratings yet

- Polymer Synthesis CHEM 421Document17 pagesPolymer Synthesis CHEM 421Nagjibhai MakwanaNo ratings yet

- Vocabulary Synonyms Antonyms PDFDocument134 pagesVocabulary Synonyms Antonyms PDFTusharPatelNo ratings yet

- Solved ProblemsDocument8 pagesSolved Problemsali.alhayki2002No ratings yet

- Layout of Pharmacy in HospitalDocument8 pagesLayout of Pharmacy in HospitalUmar JadoonNo ratings yet

- HCE ReviewerDocument11 pagesHCE ReviewerLorraine RiegoNo ratings yet

- English FixxxxxDocument33 pagesEnglish FixxxxxINDAH WRETNONo ratings yet

Chapter 8 - IWIS (Sep 27 - 1999)

Chapter 8 - IWIS (Sep 27 - 1999)

Uploaded by

mangeshsnt_121181Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 8 - IWIS (Sep 27 - 1999)

Chapter 8 - IWIS (Sep 27 - 1999)

Uploaded by

mangeshsnt_121181Copyright:

Available Formats

IWIS-Revision 1.

3-Intel Proprietary

5/4/2024

8. TESTING AND VALIDATION

8.1 General

Prior to the system being installed the test plan needs to be defined such that the installer

can comply and perform the required tests. The testing should meet the minimum

requirements as stated in Appendix A, EIA/TIA 568, TSB 36 and TSB 40.

Testing should include a pre-install test, post-install test, certification test, and a

validation test

procedure. All testing should be documented as part of the final acceptance before the

system goes on-line. As-built drawings of the system shall be part of the final acceptance

from the installer and should be placed into a suitable database.

The test procedures defined in this section relate to the horizontal and work area

subsystems for UTP and for all fiber applications. Campus and vertical UTP subsystem

testing is specific to the application (i.e. Voice), and may require different test methods.

8.2 Pre-Installation Testing

8.2.1 100-ohm UTP

Prior to installation a sampling plan should be designed to provide statistically valid data

either on a per lot or per pallet basis. At a minimum a continuity test, using the TDR

( Time Domain Reflectometer), method shall be conducted.

UTP Connecting Hardware

Test methods and set-up, wiring practices, and measurement procedures for UTP

hardware are documented in TIA/EIA TSB 40. Transmission performance requirements

are included in Appendix A of this document.

8.2.2 Optical Fiber Cable

Prior to installation each cable will be tested on the spool. The testing is a continuity test

using the OTDR method. Since fiber is typically used as the backbone cabling it is

important the installer and Intel ensure the cable is free from defects prior to installation.

The results of the OTDR should be documented and verified with manufactures’ data

prior to installation.

8.3 Post-Installation Testing

Post installation testing is the installers final phase of installation for all cable types. It is

important that the tests are well documented and the method of testing is in

compliance with Intel industry standards. The most common tools for UTP and STP

copper cable plant is the NEXT Scanner and the Beckman Tester. The installer must be

certified on either piece of equipment. Full documentation must be presented to Intel for

Company Confidential - For Internal Use Only

51

IWIS-Revision 1.3-Intel Proprietary

5/4/2024

the installation to be considered complete. For Fiber the most common tools for OTDR

testing are either the Tektronix fiber-master or the Siecor OTDR.

8.3.1 100-ohm UTP

Both Category 3 grade and Category 5 grade post-installation testing require a minimum

of TDR, Polarity, Impedance, Attenuation, and Near Cross Talk ( NEXT) at multiple

frequencies up to 20MHZ for Category 3 and 100MHZ for Category 5. The installer will

document these results on 100% of the terminated pairs from the punch down blocks or

patch panels to the TOs. All testing is to be performed in accordance with EIA/TIA TSB

67 Transmission Performance Specifications for Field Testing of Twisted-Pair Cabling

Systems (October 1995).

UTP Connecting Hardware

Test methods and set-up, wiring practices, and measurement procedures for UTP

connecting hardware are documented in TIA/EIA TSB 40. Transmission performance

requirements are included in Appendix A of this document.

8.3.2 Optical Fiber Cable

100% of all fiber strands will be tested after installation. A minimum of 2 test

methods are required to verify fiber installation quality. The first method is OTDR. The

results of the OTDR must be documented and compared to pre-installation test results for

any macro or micro bending problems as well termination issues. The second method is

the optical power meter method to measure the dB loss from end to end at the

appropriate frequency (wavelength for the type of fiber-multi mode or single mode per

Appendix A).

8.4 Certification Testing

Certification testing should be done by either a certified 3rd party or by a certified Intel

technician to insure the test results reported by the installer are valid and accurate before

the system is accepted by Intel and put into production. A valid statistical sample plan for

fiber cable and copper cable should be followed (this is equivalent to a QA test method

and procedure).

8.5 Application Testing

Application specific acceptance testing shall be conducted to ensure end to end delivery

of the level of service required to support each individual application. This testing shall

simulate accessibility of the applications from a user perspective

8.5.1 Phone Validation

Intel or a 3rd party (other than installer) will validate functionality via dial tone and ring

test on 100% of the activity hand sets.

Company Confidential - For Internal Use Only

52

IWIS-Revision 1.3-Intel Proprietary

5/4/2024

8.5.2 B1 Validation

Same as Phone Validation.

8.5.3 Mainframe ( IBM ) Validation

Intel or Intel’s Contractor shall validate system functionality via system login menu to

the mainframe on 100% of the active nodes.

8.5.4 Asynchronous (Serial) Connection Validation

Intel or Intel’s Contractor shall validate system functionality via system login prompts on

100% of the activity connections. ( i.e., for VAX - local prompt, for SECS-emulate send

and receive ). The method of validation for serial connectivity is the same as how the

system will be used.

8.5.5 Ethernet Validation

Intel or Intel’s Contractor shall validate LAN connectivity either through successful login

to a local LAN (i.e. BANYAN) server. In the case where LAN connectivity can not be

made, an analyzer should be used to validate customer equipment on 100% of the

connections.

Company Confidential - For Internal Use Only

53

You might also like

- Installation QualificationDocument14 pagesInstallation QualificationTuan Nguyen100% (1)

- Draft - Sat Procedure For Access Control SystemDocument11 pagesDraft - Sat Procedure For Access Control SystemVenkataramanan SNo ratings yet

- Rites of AstarothDocument100 pagesRites of AstarothEdina Mayara75% (16)

- SITXHRM001 - Workplace Feedback.v1.0Document4 pagesSITXHRM001 - Workplace Feedback.v1.0Ranju WagleNo ratings yet

- Concept Map For DenvDocument4 pagesConcept Map For Denvnikki sabs67% (3)

- FAT ProcedureDocument14 pagesFAT ProcedurePrashant Mohokar100% (1)

- IPT Test Plan-ProposalDocument16 pagesIPT Test Plan-ProposalOchie RomeroNo ratings yet

- Reliability Prediction from Burn-In Data Fit to Reliability ModelsFrom EverandReliability Prediction from Burn-In Data Fit to Reliability ModelsRating: 3 out of 5 stars3/5 (2)

- What Makes The Earth Suitable For LifeDocument1 pageWhat Makes The Earth Suitable For LifejinmenchieNo ratings yet

- CRH Produkt ProgramDocument28 pagesCRH Produkt ProgramHima KiranNo ratings yet

- Annexure 1Document9 pagesAnnexure 1faizan4033No ratings yet

- Automated Test & Alignment System For Telecom ApplicationsDocument4 pagesAutomated Test & Alignment System For Telecom ApplicationsMurali KrishnaNo ratings yet

- A Project On Automated Harness TesterDocument42 pagesA Project On Automated Harness TesterSantosh KumarNo ratings yet

- Cat 6 Shielded Patch Cords: Product SpecificationDocument5 pagesCat 6 Shielded Patch Cords: Product SpecificationAngelica Baena CuestaNo ratings yet

- Electronic Syatem Design PPT - Design For TestabilityDocument9 pagesElectronic Syatem Design PPT - Design For TestabilityAnoop Mathew0% (1)

- Paddle Switch CombinedDocument10 pagesPaddle Switch CombinedPriyanshu GuptaNo ratings yet

- ECE 617 - Fault Testable Design Dr. Janusz Starzyk: School of EECS Ohio University Athens, OH, 45701Document79 pagesECE 617 - Fault Testable Design Dr. Janusz Starzyk: School of EECS Ohio University Athens, OH, 45701sivapothiNo ratings yet

- Solution Brief - Ethernet OAMDocument2 pagesSolution Brief - Ethernet OAMbakh777196No ratings yet

- Technical Specification of Automatic Relay Test KitDocument13 pagesTechnical Specification of Automatic Relay Test KitEBENo ratings yet

- Guide To Choosing The Right Cable Test Tool To Meet Your Testing NeedsDocument4 pagesGuide To Choosing The Right Cable Test Tool To Meet Your Testing Needsricx31No ratings yet

- Exhibit K - (REDACTED) - System Acceptance Plan v2 (FINAL)Document105 pagesExhibit K - (REDACTED) - System Acceptance Plan v2 (FINAL)Mohammed F. ShehataNo ratings yet

- A Briefing On IEEE 1149.1 - 1990 Standard Test Access Port and Boundary-Scan Architecture (AKA JTAG)Document12 pagesA Briefing On IEEE 1149.1 - 1990 Standard Test Access Port and Boundary-Scan Architecture (AKA JTAG)Raghul SambathkumarNo ratings yet

- CETECOM - Module Integration PresentationDocument16 pagesCETECOM - Module Integration PresentationAjit SubramanyamNo ratings yet

- XJ Products Brochures enDocument64 pagesXJ Products Brochures enMika Kadju RapalangiNo ratings yet

- Copper Certification Testing: Best Practices Pocket GuideDocument16 pagesCopper Certification Testing: Best Practices Pocket GuidedexiNo ratings yet

- 61a1 ReadingDocument7 pages61a1 Readingishu vohraNo ratings yet

- C-54 NocDocument41 pagesC-54 NocRochdi SahliNo ratings yet

- ANSI - SCTE - 47 - 2007 Test Method For Coaxial Cable AttenuationDocument7 pagesANSI - SCTE - 47 - 2007 Test Method For Coaxial Cable AttenuationYung SangNo ratings yet

- E2 Relay CommissioningDocument14 pagesE2 Relay CommissioningShailesh ChettyNo ratings yet

- Trusted Safety System PDFDocument2 pagesTrusted Safety System PDFalimohebbi1361No ratings yet

- Essential 6 Field Testing Procedure 1 PDFDocument9 pagesEssential 6 Field Testing Procedure 1 PDFAnonymous GIjAfAD6100% (1)

- Sequencing With Next-Generation Non-Signaling Test EquipmentDocument7 pagesSequencing With Next-Generation Non-Signaling Test EquipmentCường MchwNo ratings yet

- Acceptance Testing, Conformance & Quality Assurance of IEC61850 DevicesDocument5 pagesAcceptance Testing, Conformance & Quality Assurance of IEC61850 DeviceschangNo ratings yet

- Research Designs and Standards Organisation Manak Nagar, Lucknow - 226 011, IndiaDocument41 pagesResearch Designs and Standards Organisation Manak Nagar, Lucknow - 226 011, IndiaChandra Mohan RawatNo ratings yet

- An Experimental Chip To Evaluate Test TechniquesDocument10 pagesAn Experimental Chip To Evaluate Test TechniquesVinod KheraNo ratings yet

- Lesson 41 PDFDocument23 pagesLesson 41 PDFAre VijayNo ratings yet

- Embedded Jtag Boundary Scan TestDocument9 pagesEmbedded Jtag Boundary Scan TestAurelian ZaharescuNo ratings yet

- Copper Testing Best PracticesDocument16 pagesCopper Testing Best PracticesArnie GajudoNo ratings yet

- Acterna EDT135Document8 pagesActerna EDT135reivajjwNo ratings yet

- FOUNDATION™ Fieldbus: Factory Acceptance Test and Device CommissioningDocument16 pagesFOUNDATION™ Fieldbus: Factory Acceptance Test and Device CommissioningNelson P. ColoNo ratings yet

- PLC Details of Agc PlantDocument93 pagesPLC Details of Agc PlantamalgceNo ratings yet

- Brochure TestPro 11032022Document12 pagesBrochure TestPro 11032022highcomcalaNo ratings yet

- Pump Station PLC ControlDocument9 pagesPump Station PLC ControldanderjNo ratings yet

- ATS Flyer System @station 181005Document12 pagesATS Flyer System @station 181005Phạm Tiến SaoNo ratings yet

- Method Statement - CCTVDocument8 pagesMethod Statement - CCTVYazan ZahalqaNo ratings yet

- 5100 12. Post Inspection Sampling Mandatory sampling and inspection after 100% visual inspection. Sampling plan as per ANSI/ASQ Z1.4 – 2008 (or ISO 2859-1): General Inspection Level – II, Single sampling plans for Normal inspection with an AQL of 0.65%. Batch releasing criteria: NMT the specified number of units contains visible particulates. Special level sampling (reduced sample quantity) for destructive inspections (for powder filled, lyophilized products, coloured containers, etc.). AQL Failure Is the test Destructive ? Investigation Re-inspection of 100% units Batch Rejection Yes No PerformAQLinspection Slide No. 12 13. Particle Separation, Identification and Characterization Manufacturers should have knowledge on their particulate matter rejections. Type of particles. Source of each particle type. Routine trend / capability of particulate rejections. Morphology of each type of particle. Chemistry of each particle type. Manufacturers should have comprehensiveDocument9 pages5100 12. Post Inspection Sampling Mandatory sampling and inspection after 100% visual inspection. Sampling plan as per ANSI/ASQ Z1.4 – 2008 (or ISO 2859-1): General Inspection Level – II, Single sampling plans for Normal inspection with an AQL of 0.65%. Batch releasing criteria: NMT the specified number of units contains visible particulates. Special level sampling (reduced sample quantity) for destructive inspections (for powder filled, lyophilized products, coloured containers, etc.). AQL Failure Is the test Destructive ? Investigation Re-inspection of 100% units Batch Rejection Yes No PerformAQLinspection Slide No. 12 13. Particle Separation, Identification and Characterization Manufacturers should have knowledge on their particulate matter rejections. Type of particles. Source of each particle type. Routine trend / capability of particulate rejections. Morphology of each type of particle. Chemistry of each particle type. Manufacturers should have comprehensiveschumonNo ratings yet

- Est3 Installation&Service ManualDocument388 pagesEst3 Installation&Service Manualsumankashyap100% (1)

- Tcst11101r0 CommunicationDocument127 pagesTcst11101r0 CommunicationengrandyNo ratings yet

- Radio Network Drive Test GuideDocument12 pagesRadio Network Drive Test Guidek_muange897No ratings yet

- Quality: Optimum Ive ReliabilityDocument3 pagesQuality: Optimum Ive ReliabilityLuJo NarañaNo ratings yet

- Automotive Electronics Council: AEC - Q100-005 - REV-C September 7, 2004Document10 pagesAutomotive Electronics Council: AEC - Q100-005 - REV-C September 7, 2004KL ChanNo ratings yet

- Abbreviations: OQ Exploration and Production LLCDocument3 pagesAbbreviations: OQ Exploration and Production LLCHamza ShujaNo ratings yet

- Relay Testing and CommissioningDocument28 pagesRelay Testing and CommissioningKailash PanthaNo ratings yet

- Chap1 Lect01 OverviewDocument12 pagesChap1 Lect01 OverviewGlen ChenNo ratings yet

- IEC 61850 Testing and Commissioning Advantages Using GOOSE MessagingDocument5 pagesIEC 61850 Testing and Commissioning Advantages Using GOOSE MessagingAlanMolinaNo ratings yet

- Technical Compliance MatrixDocument4 pagesTechnical Compliance Matrixyanaca asociadosNo ratings yet

- AirGateway LR QSGDocument24 pagesAirGateway LR QSGAndreyNo ratings yet

- Jtag - AN IEEE 1149.1 STDDocument42 pagesJtag - AN IEEE 1149.1 STDkanchanstiwariNo ratings yet

- Industrial Process Control: Advances and ApplicationsFrom EverandIndustrial Process Control: Advances and ApplicationsRating: 2 out of 5 stars2/5 (1)

- 5G NR: Architecture, Technology, Implementation, and Operation of 3GPP New Radio StandardsFrom Everand5G NR: Architecture, Technology, Implementation, and Operation of 3GPP New Radio StandardsRating: 3.5 out of 5 stars3.5/5 (8)

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- GROUP 1 Pr2Document23 pagesGROUP 1 Pr2MarYNo ratings yet

- MC 1 Operation Manual EnglishDocument44 pagesMC 1 Operation Manual EnglishHirabteb Arshia Co. IVD ManufacturerNo ratings yet

- User Manual Back-UPS BE600M1/600M1-LM/670M1, BN650M1/650M1-CA/675M1Document2 pagesUser Manual Back-UPS BE600M1/600M1-LM/670M1, BN650M1/650M1-CA/675M1World NewNo ratings yet

- SBEC3622-OCW 3 OSHEnvironmentDocument17 pagesSBEC3622-OCW 3 OSHEnvironmentnzy06No ratings yet

- Service and Operator ManualDocument46 pagesService and Operator ManualBersanz SrlNo ratings yet

- Training Needs of Resident Adults BasisDocument22 pagesTraining Needs of Resident Adults BasisZoe OBNo ratings yet

- Soal Ukp 2022 by Kevin JoshuaDocument133 pagesSoal Ukp 2022 by Kevin JoshuaADI ARI IRAWANNo ratings yet

- Infographics LibitjodielynDocument1 pageInfographics LibitjodielynJodielyn Bombane LibitNo ratings yet

- Peptic Ulcer Disease NCLEX ReviewDocument16 pagesPeptic Ulcer Disease NCLEX ReviewBianca Trish ManlangitNo ratings yet

- GS Specification Traction - BatteryDocument8 pagesGS Specification Traction - BatteryDedy CjNo ratings yet

- Persuasive Speech Topics 8cDocument2 pagesPersuasive Speech Topics 8cIsaid OrtegaNo ratings yet

- Sika Raintite: Acrylic WaterproofingDocument2 pagesSika Raintite: Acrylic WaterproofingWahyudi AminotoNo ratings yet

- 05-CurrentTransformers ENG 2017.compressedDocument59 pages05-CurrentTransformers ENG 2017.compressedVinodraj YalagiNo ratings yet

- PHREEQ C Modelling Tool Application To Determine The Effect of Anions On Speciation of Selected Metals in Water Systems Within Kajiado North Constituency in KenyaDocument71 pagesPHREEQ C Modelling Tool Application To Determine The Effect of Anions On Speciation of Selected Metals in Water Systems Within Kajiado North Constituency in KenyaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Escherichia Coli Plasmid Production in FermenterDocument8 pagesEscherichia Coli Plasmid Production in Fermenterdary.podoliak03No ratings yet

- A High-Power High-Voltage Power Supply For Long-Pulse Applications IEEE TPS 20101Document9 pagesA High-Power High-Voltage Power Supply For Long-Pulse Applications IEEE TPS 20101Cesar LopezNo ratings yet

- Test Your Prepositions 1 - in Order To Get To JeffsDocument3 pagesTest Your Prepositions 1 - in Order To Get To JeffsfurkanalpatNo ratings yet

- KenyaEMR 18 7 0 Release NotesDocument7 pagesKenyaEMR 18 7 0 Release NotesMigori ArtNo ratings yet

- SMCL100 CatalogDocument2 pagesSMCL100 CatalogHéctor Eduardo Hernández LópezNo ratings yet

- Polymer Synthesis CHEM 421Document17 pagesPolymer Synthesis CHEM 421Nagjibhai MakwanaNo ratings yet

- Vocabulary Synonyms Antonyms PDFDocument134 pagesVocabulary Synonyms Antonyms PDFTusharPatelNo ratings yet

- Solved ProblemsDocument8 pagesSolved Problemsali.alhayki2002No ratings yet

- Layout of Pharmacy in HospitalDocument8 pagesLayout of Pharmacy in HospitalUmar JadoonNo ratings yet

- HCE ReviewerDocument11 pagesHCE ReviewerLorraine RiegoNo ratings yet

- English FixxxxxDocument33 pagesEnglish FixxxxxINDAH WRETNONo ratings yet