Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

4 viewsStart Spindle Turning

Start Spindle Turning

Uploaded by

elyasCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Scythe Peening ManualDocument16 pagesScythe Peening ManualBotan Anderson100% (1)

- Carpentry Tools and EquipmentDocument6 pagesCarpentry Tools and EquipmentErikson Morales79% (19)

- Wood Shells - A New Art Form: Steve GarrisonDocument43 pagesWood Shells - A New Art Form: Steve GarrisonRileyNo ratings yet

- The Beginners Guide To Sculpting Miniature FiguresDocument22 pagesThe Beginners Guide To Sculpting Miniature Figureskykendra82% (17)

- Morsa Vertical CaseraDocument4 pagesMorsa Vertical CaseraCarlos Fco Secco100% (1)

- Knife Making 101 TextDocument19 pagesKnife Making 101 Textrace egrNo ratings yet

- Improvebargainlute PDFDocument9 pagesImprovebargainlute PDFGrillo ParlerinoNo ratings yet

- Grizzly Ukulele Kit H3125 ManualDocument24 pagesGrizzly Ukulele Kit H3125 ManualChoo Seng QuahNo ratings yet

- A Circular Saw in The Furniture Shop-FinewoodworkingDocument4 pagesA Circular Saw in The Furniture Shop-Finewoodworkingkurt100% (1)

- WorkbenchesDocument162 pagesWorkbenchesHugoMuacho90% (10)

- How To Build A DoorDocument12 pagesHow To Build A DoorOkidok OkickiNo ratings yet

- 45 PenTurning 3Document6 pages45 PenTurning 3Chris HollidayNo ratings yet

- 5 Router PlaneDocument4 pages5 Router PlaneAngel R Rodriguez100% (1)

- Bench Hooks For WorkbenchDocument2 pagesBench Hooks For WorkbenchZahid AsifNo ratings yet

- 79 FT Latheless-Spindles FINALDocument4 pages79 FT Latheless-Spindles FINALAndrew LeeNo ratings yet

- SIEGEL Steady RestDocument6 pagesSIEGEL Steady RestHenry LopesNo ratings yet

- Queen Anne FootstoolDocument17 pagesQueen Anne FootstoolMonte William NorthNo ratings yet

- Kitless Pens Part 2Document3 pagesKitless Pens Part 2Inform7105No ratings yet

- Bolt Action 2Document10 pagesBolt Action 2spartywrxNo ratings yet

- Woodworking - Basics-Shopjigs PDFDocument4 pagesWoodworking - Basics-Shopjigs PDFv00d00blues100% (1)

- Woodworking: Complete Woodworking Guide for Beginner's With Step-by-Step Instructions (BONUS - 16,000 Woodworking Plans and Projects)From EverandWoodworking: Complete Woodworking Guide for Beginner's With Step-by-Step Instructions (BONUS - 16,000 Woodworking Plans and Projects)Rating: 3 out of 5 stars3/5 (12)

- New Inventions - Old ToolsDocument3 pagesNew Inventions - Old Toolswoodbee2No ratings yet

- Antique Tools: A Buyer's Guide To Many You Can UseDocument3 pagesAntique Tools: A Buyer's Guide To Many You Can UseAnonymous QJ5j94luLmNo ratings yet

- Pocket Hole JoineryDocument2 pagesPocket Hole JoineryFrancois Vaaltyn100% (1)

- Karpentiro PrintDocument22 pagesKarpentiro PrintErick MonteNo ratings yet

- Woodsmith - 063Document24 pagesWoodsmith - 063rsotoqp100% (2)

- The Basics Conga DrumDocument10 pagesThe Basics Conga DrumAidil Amin100% (1)

- Tambour Cabinet PlanDocument8 pagesTambour Cabinet Planvidawo1012No ratings yet

- Spoon Carving - by Peter FollansbeeDocument4 pagesSpoon Carving - by Peter FollansbeeAlan SouzaNo ratings yet

- Melting Display Shelves PlansDocument14 pagesMelting Display Shelves Plansmihai.stanNo ratings yet

- Mini La The Users GuideDocument9 pagesMini La The Users GuidepedjaNo ratings yet

- Bolt Action 10Document11 pagesBolt Action 10spartywrx100% (1)

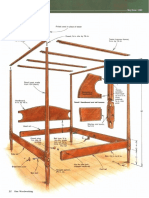

- Beds - Four Poster Bed PlansDocument8 pagesBeds - Four Poster Bed Planspoimandres100% (1)

- Joinery BasicsDocument36 pagesJoinery Basicsjohnnyd1234100% (11)

- How To Make Fishing Lures Vlad EvanoffDocument103 pagesHow To Make Fishing Lures Vlad Evanoffdescarao100% (3)

- Traditional Wooden Handplanes: How to Restore, Modify & Use Antique PlanesFrom EverandTraditional Wooden Handplanes: How to Restore, Modify & Use Antique PlanesRating: 5 out of 5 stars5/5 (1)

- Building A Kentucky RifleDocument27 pagesBuilding A Kentucky RifleTrinity Parore100% (2)

- An Everyday CabinetDocument8 pagesAn Everyday CabinetJonathan Hopkins100% (2)

- DIY Outdoors - The AtlatlDocument4 pagesDIY Outdoors - The AtlatlKasiaNo ratings yet

- Dart MakingDocument13 pagesDart MakingJNo ratings yet

- (Click Here For Home Page: Www.3rguitars - Co.uk) : 1960s Style SC or TC Neck BuildDocument38 pages(Click Here For Home Page: Www.3rguitars - Co.uk) : 1960s Style SC or TC Neck BuildAbraham TedyNo ratings yet

- Making Moldings With Hollows and Rounds (And A Few Other Planes)Document4 pagesMaking Moldings With Hollows and Rounds (And A Few Other Planes)hansolosnahNo ratings yet

- Literature Review Lathe MachineDocument5 pagesLiterature Review Lathe Machinecmppcmwgf100% (1)

- Box Joints On The Table SawsDocument4 pagesBox Joints On The Table SawsAnonymous QJ5j94luLmNo ratings yet

- 16 Metalworking Workshop Projects for Home Machinists: Practical & Useful Ideas for the Small ShopFrom Everand16 Metalworking Workshop Projects for Home Machinists: Practical & Useful Ideas for the Small ShopRating: 5 out of 5 stars5/5 (1)

- Basic Armouring - A Practical Introduction To Armour Making - Paul BlackwellDocument116 pagesBasic Armouring - A Practical Introduction To Armour Making - Paul Blackwellcliftoncage100% (6)

- A Benchtop BenchDocument2 pagesA Benchtop Benchcorneliu.modilca67% (3)

- The Return of Roubo: An 18th-Century French Workbench Is Quite Possibly The Most Perfect Design Ever Put To PaperDocument10 pagesThe Return of Roubo: An 18th-Century French Workbench Is Quite Possibly The Most Perfect Design Ever Put To PaperRodrigo Alonso Garrido StuardoNo ratings yet

- A Long-Term Survival Guide - Make A Survival StaffDocument9 pagesA Long-Term Survival Guide - Make A Survival Staffbuckonbeach100% (8)

- Making Guitar: The - ComponentsDocument9 pagesMaking Guitar: The - ComponentsIwan TejasukmanaNo ratings yet

- Tip #47 Resawing: There's A Fine Art To Making Thin Boards Out of Thick OnesDocument4 pagesTip #47 Resawing: There's A Fine Art To Making Thin Boards Out of Thick OnesAntonio Alberto Fonseca FilhoNo ratings yet

- The Home Craftsman (1906)Document10 pagesThe Home Craftsman (1906)Robert Elliott PH.dNo ratings yet

- Woodworking - Home Made Table Saw Box Joint JigDocument5 pagesWoodworking - Home Made Table Saw Box Joint Jigleehoin100% (2)

- OceanofPDF - Com The Basics of Beginning Leatherwork Begin - William SmithDocument63 pagesOceanofPDF - Com The Basics of Beginning Leatherwork Begin - William SmithOmar DionisiNo ratings yet

- Metal Guilhotine - Metal Working Shop From Scrap - Upload by Dave The RaveDocument5 pagesMetal Guilhotine - Metal Working Shop From Scrap - Upload by Dave The RaveAndy LNo ratings yet

- Fine - Woodworking.-.A Workbench That WorksDocument2 pagesFine - Woodworking.-.A Workbench That WorksSarasaNo ratings yet

- Woodrat: Genius or Just Another Jig? We Have The Answer Right HereDocument2 pagesWoodrat: Genius or Just Another Jig? We Have The Answer Right HereEric UzueliNo ratings yet

- Add A Router Table To A Table Saw: Step 1: Tools and MaterialsDocument8 pagesAdd A Router Table To A Table Saw: Step 1: Tools and Materialsafrica schoolNo ratings yet

- Felted Fiber Menagerie: Needle Felted Table ToppersFrom EverandFelted Fiber Menagerie: Needle Felted Table ToppersRating: 4 out of 5 stars4/5 (1)

- OMNI 6090 CNC Router QuotationDocument4 pagesOMNI 6090 CNC Router QuotationJosé PeNo ratings yet

- 001 2020 4 BDocument113 pages001 2020 4 BMyran PillayNo ratings yet

- Is53 Iso - 5836 - 1988Document8 pagesIs53 Iso - 5836 - 1988elvisonderNo ratings yet

- CBLM 5 Use Hand ToolsDocument127 pagesCBLM 5 Use Hand ToolsDonabel NoveroNo ratings yet

- Product Technical Data Sheet: 14-10 Bugle Head Part Threaded Type 17Document2 pagesProduct Technical Data Sheet: 14-10 Bugle Head Part Threaded Type 17jnudsaNo ratings yet

- Workshop Practice II LAB Manual by Bilal ZamanDocument24 pagesWorkshop Practice II LAB Manual by Bilal ZamanJawad NadeemNo ratings yet

- Trimmer: Instruction ManualDocument20 pagesTrimmer: Instruction ManualOnagro XNo ratings yet

- Wood Design Manual 2015 ErrataDocument1 pageWood Design Manual 2015 ErratanoobfNo ratings yet

- Shellac Flake: Restoration, Repair, & Finishing SuppliesDocument1 pageShellac Flake: Restoration, Repair, & Finishing SuppliesvajdazitaNo ratings yet

- Product: Metrotile UK Limited Metrobond 450 and Metrobond 900Document4 pagesProduct: Metrotile UK Limited Metrobond 450 and Metrobond 900Niroj MaharjanNo ratings yet

- Straight Razor How To Do PDFDocument10 pagesStraight Razor How To Do PDFRaziel MugsueNo ratings yet

- Vertical Shaft Impactor - : Design NotesDocument2 pagesVertical Shaft Impactor - : Design Notesilyas mursalNo ratings yet

- Partes y PiezasDocument2 pagesPartes y Piezasst.hpexNo ratings yet

- CherryMax Catalog CA-1016Document2 pagesCherryMax Catalog CA-1016Manuel Antonio Oñate CarvajalNo ratings yet

- QUEST® - Maintenance Manual PDFDocument196 pagesQUEST® - Maintenance Manual PDFMontserrat GuNo ratings yet

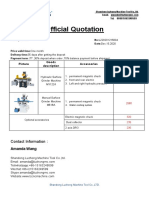

- Official Quotation: Picture Goods Description Accessories FOB Qingdao Port Price (USD)Document7 pagesOfficial Quotation: Picture Goods Description Accessories FOB Qingdao Port Price (USD)Hugh O'Brien GwazeNo ratings yet

- TDS Formula Gr12Document4 pagesTDS Formula Gr12Cvaldivia001No ratings yet

- Product Instructions - Barrel Press Kit InstructionsDocument7 pagesProduct Instructions - Barrel Press Kit InstructionsDale WadeNo ratings yet

- Installation of Stucco Exterior Finish Over WoodDocument6 pagesInstallation of Stucco Exterior Finish Over WoodFernando LlacayNo ratings yet

- The Pencil Post BedDocument6 pagesThe Pencil Post BedAnonymous QJ5j94luLmNo ratings yet

- Chapter 2Document32 pagesChapter 2Huzairee IsmailNo ratings yet

- Schedule - M - FORMULADocument148 pagesSchedule - M - FORMULAZainabu waziriNo ratings yet

- ATK LASERS-Company ProfileDocument9 pagesATK LASERS-Company ProfileATK LASERSNo ratings yet

- Assignment No.1 - Types and Costs of Materials in The Civil Engineering IndustryDocument17 pagesAssignment No.1 - Types and Costs of Materials in The Civil Engineering Industryvarun100% (1)

- SN11240 - Router Mortising Jig PDFDocument8 pagesSN11240 - Router Mortising Jig PDFMariano100% (3)

- Awusato Abaya Nursery Vermicompost House Takeoff & BoQ-3Document7 pagesAwusato Abaya Nursery Vermicompost House Takeoff & BoQ-3Tesfalem NekereNo ratings yet

- Samsung HMX-F90 Lens Replacement - Guia de Reparo IfixitDocument7 pagesSamsung HMX-F90 Lens Replacement - Guia de Reparo IfixitPedro RobertoNo ratings yet

- Eldorado Stone Finishing DetailsDocument16 pagesEldorado Stone Finishing DetailsGeorges HageNo ratings yet

- Wood Bending: by Trey Howard, Cal Fore, Bobby Connor, Ling QiuDocument78 pagesWood Bending: by Trey Howard, Cal Fore, Bobby Connor, Ling QiuPuneeth Raj100% (1)

Start Spindle Turning

Start Spindle Turning

Uploaded by

elyas0 ratings0% found this document useful (0 votes)

4 views2 pagesOriginal Title

start-spindle-turning

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

4 views2 pagesStart Spindle Turning

Start Spindle Turning

Uploaded by

elyasCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

at the lathe by Jon Siegel 1

I meet many woodworkers who

have been making furniture for

a while and have reached the

point where they need more than

just square or tapered legs. Often

cost is about $40. – see Enco in

Sources)

There are five chisels you need for

spindle turning of furniture parts.

to sharpen,

but I recom-

mend a belt and buff system. This

provides convenience, accuracy (re-

peatability), speed, and a flat grind

they ask me what tools and equip- • 3/4˝ roughing gouge which is best for woodturning. To

ment they will need to begin mak- • 1/2˝ spindle gouge learn more about various sharpening

ing woodturnings for their furniture • 3/8˝ spindle gouge systems, view the tape in the Guild

projects. In this article, I will de- • 1/2˝ rolled edge skew chisel library which we made November

scribe what you need to get started. • Diamond pattern parting tool 2004 at the GSWT meeting.

First, find a lathe Furniture work is

that suits your needs. often long and thin.

If you want to make Whenever the length

table legs, you will exceeds ten times

need a lathe with at the diameter, vibra-

least 30 or 36 inch tion of the workpiece

length capacity. If is a problem. You

you also want to can dampen the vi-

make bed posts you brations by holding

will need a much the work with your

longer lathe; about left hand while you

six or seven feet. If hold the chisel in

you are handy at your right hand, and

fixing things, you in fact this is a good

should consider get- thing for you to learn

ting an old lathe, to do. But for seri-

because you will get ous furniture turn-

more mass for your ing, you will need

money. Mass is good, a steady rest. There

and you should get the heaviest lathe Don’t buy a beginners set. You are several kinds on the market. For

you can afford. You can put a vari- would probably end up with some a brief discussion of steady rests, see

able speed motor on any old lathe chisels you can’t use, such as scrap- the article in this issue reviewing the

for not much money. New or used, ers which are almost never used on January meeting of GSWT.

make sure the lathe has a heavy bed – spindle turning.

this is the foundation of the machine

and is very important. Before you Next, you need some way

buy a lathe, read my article in Fine to keep your chisels sharp.

Woodworking, issue #149, June 2001 – Turning chisels need sharp-

Basic Buying Guide to Lathes. ening much more frequently

than other types of wood-

Get a good spur center with sharp working tools because of the

teeth, and a 60 degree ball bear- demanding nature of the work

ing tailstock center. I recommend a they do. There is a huge diver-

Skoda for the tailstock center. The sity of opinion on the best ways

Photos by Jon Siegel, Dean Powell 2

other small decorative turnings. Nutting’s 1928 classic book,

A drill chuck mounted on a taper Some screw centers fit into the taper, Furniture Treasury (Volumes 1 & 2

shank is a very useful accessory some screw onto the spindle nose combined, Macmillan, ISBN 0-02-

for your lathe. You may use it for like the one in the photo. 590980-0). This book has thousands

rechucking cabinet knobs as well as of photographs which will give you

for drilling. A screw center can be You may already have some tools – a a look at the rich history of how the

used to make knobs, rosettes, and marking gage (sometimes called a art of woodturning has been applied

mortise gage) for finding to furniture.

the center on the end of a

square, an awl to punch Good luck in your endeavor to add

Ball Bearing a little hole in the cen- turnings to your furniture. I hope

Tailstock Centers ter, and a try square for that this will be the beginning of an

Screw marking out the work enchanting adventure. While the

Skoda Center

before turning. An as- lathe is one of the oldest and most

sortment of calipers and basic of the machines in the wood-

Morse Taper dividers are also useful. shop, I think it is the most fascinat-

Spur Centers

Drill ing.

#1 Center Now that you’re

equipped with all the

#2 hardware you need,

there is one more thing

– a copy of Wallace

Set of five required chisels Marking gauge at right is easier to use Assortment of calipers and dividers

Looking for more information?

Books are good, videos are better, but lessons are best. The book which influenced me the Sources Classes

most is Frank Pain, The Practical Woodturner. It has been updated by Sterling Press.

Packard Woodworks Homestead

There are many good videos, although few that cover spindle turning. Mike Darlow is Tools & Equipment Woodworking School

packardwoodworks.com woodschoolnh.com

good. But the Guild has a great number of tapes on turning (dozens), and some are on

800-683-8876 888-659-2345

spindle turning. Members can borrow them free.

Craft Supplies McLaughlin Woods

Classes on turning are available at the Homestead Woodworking School in Newmarket, Tools & Equipment mclaughlinwoods.com

NH, the Worcester Center for Crafts in Worcester, MA, or the School for Furniture woodturnerscatalog.com 603-783-9700

800-551-8876

Craftsmanship in Rockport, ME. Starting in the summer (‘05) there will be woodturning Worcester

classes at Tom McLaughlin’s new shop in Canterbury, NH. Enco Center for Crafts

Lathe Centers & Chucks worcestercraftcenter.org

Classes typically have 8 to 12 students, and you can expect to pay about $15 to $20 use-enco.com 508-753-8183

per hour for classes. Private lessons are best for some people, because you can set the 800-873-3626

Center for Furniture

agenda and work on whatever you want. But private lessons cost at least twice as much Craftsmanship

per hour as classes. The reason I recommend getting professional instruction right away woodschool.org

207-594-5611

is so that you start out right, and avoid bad habits (such as scraping) which are difficult

and frustrating to unlearn later.

You might also like

- Scythe Peening ManualDocument16 pagesScythe Peening ManualBotan Anderson100% (1)

- Carpentry Tools and EquipmentDocument6 pagesCarpentry Tools and EquipmentErikson Morales79% (19)

- Wood Shells - A New Art Form: Steve GarrisonDocument43 pagesWood Shells - A New Art Form: Steve GarrisonRileyNo ratings yet

- The Beginners Guide To Sculpting Miniature FiguresDocument22 pagesThe Beginners Guide To Sculpting Miniature Figureskykendra82% (17)

- Morsa Vertical CaseraDocument4 pagesMorsa Vertical CaseraCarlos Fco Secco100% (1)

- Knife Making 101 TextDocument19 pagesKnife Making 101 Textrace egrNo ratings yet

- Improvebargainlute PDFDocument9 pagesImprovebargainlute PDFGrillo ParlerinoNo ratings yet

- Grizzly Ukulele Kit H3125 ManualDocument24 pagesGrizzly Ukulele Kit H3125 ManualChoo Seng QuahNo ratings yet

- A Circular Saw in The Furniture Shop-FinewoodworkingDocument4 pagesA Circular Saw in The Furniture Shop-Finewoodworkingkurt100% (1)

- WorkbenchesDocument162 pagesWorkbenchesHugoMuacho90% (10)

- How To Build A DoorDocument12 pagesHow To Build A DoorOkidok OkickiNo ratings yet

- 45 PenTurning 3Document6 pages45 PenTurning 3Chris HollidayNo ratings yet

- 5 Router PlaneDocument4 pages5 Router PlaneAngel R Rodriguez100% (1)

- Bench Hooks For WorkbenchDocument2 pagesBench Hooks For WorkbenchZahid AsifNo ratings yet

- 79 FT Latheless-Spindles FINALDocument4 pages79 FT Latheless-Spindles FINALAndrew LeeNo ratings yet

- SIEGEL Steady RestDocument6 pagesSIEGEL Steady RestHenry LopesNo ratings yet

- Queen Anne FootstoolDocument17 pagesQueen Anne FootstoolMonte William NorthNo ratings yet

- Kitless Pens Part 2Document3 pagesKitless Pens Part 2Inform7105No ratings yet

- Bolt Action 2Document10 pagesBolt Action 2spartywrxNo ratings yet

- Woodworking - Basics-Shopjigs PDFDocument4 pagesWoodworking - Basics-Shopjigs PDFv00d00blues100% (1)

- Woodworking: Complete Woodworking Guide for Beginner's With Step-by-Step Instructions (BONUS - 16,000 Woodworking Plans and Projects)From EverandWoodworking: Complete Woodworking Guide for Beginner's With Step-by-Step Instructions (BONUS - 16,000 Woodworking Plans and Projects)Rating: 3 out of 5 stars3/5 (12)

- New Inventions - Old ToolsDocument3 pagesNew Inventions - Old Toolswoodbee2No ratings yet

- Antique Tools: A Buyer's Guide To Many You Can UseDocument3 pagesAntique Tools: A Buyer's Guide To Many You Can UseAnonymous QJ5j94luLmNo ratings yet

- Pocket Hole JoineryDocument2 pagesPocket Hole JoineryFrancois Vaaltyn100% (1)

- Karpentiro PrintDocument22 pagesKarpentiro PrintErick MonteNo ratings yet

- Woodsmith - 063Document24 pagesWoodsmith - 063rsotoqp100% (2)

- The Basics Conga DrumDocument10 pagesThe Basics Conga DrumAidil Amin100% (1)

- Tambour Cabinet PlanDocument8 pagesTambour Cabinet Planvidawo1012No ratings yet

- Spoon Carving - by Peter FollansbeeDocument4 pagesSpoon Carving - by Peter FollansbeeAlan SouzaNo ratings yet

- Melting Display Shelves PlansDocument14 pagesMelting Display Shelves Plansmihai.stanNo ratings yet

- Mini La The Users GuideDocument9 pagesMini La The Users GuidepedjaNo ratings yet

- Bolt Action 10Document11 pagesBolt Action 10spartywrx100% (1)

- Beds - Four Poster Bed PlansDocument8 pagesBeds - Four Poster Bed Planspoimandres100% (1)

- Joinery BasicsDocument36 pagesJoinery Basicsjohnnyd1234100% (11)

- How To Make Fishing Lures Vlad EvanoffDocument103 pagesHow To Make Fishing Lures Vlad Evanoffdescarao100% (3)

- Traditional Wooden Handplanes: How to Restore, Modify & Use Antique PlanesFrom EverandTraditional Wooden Handplanes: How to Restore, Modify & Use Antique PlanesRating: 5 out of 5 stars5/5 (1)

- Building A Kentucky RifleDocument27 pagesBuilding A Kentucky RifleTrinity Parore100% (2)

- An Everyday CabinetDocument8 pagesAn Everyday CabinetJonathan Hopkins100% (2)

- DIY Outdoors - The AtlatlDocument4 pagesDIY Outdoors - The AtlatlKasiaNo ratings yet

- Dart MakingDocument13 pagesDart MakingJNo ratings yet

- (Click Here For Home Page: Www.3rguitars - Co.uk) : 1960s Style SC or TC Neck BuildDocument38 pages(Click Here For Home Page: Www.3rguitars - Co.uk) : 1960s Style SC or TC Neck BuildAbraham TedyNo ratings yet

- Making Moldings With Hollows and Rounds (And A Few Other Planes)Document4 pagesMaking Moldings With Hollows and Rounds (And A Few Other Planes)hansolosnahNo ratings yet

- Literature Review Lathe MachineDocument5 pagesLiterature Review Lathe Machinecmppcmwgf100% (1)

- Box Joints On The Table SawsDocument4 pagesBox Joints On The Table SawsAnonymous QJ5j94luLmNo ratings yet

- 16 Metalworking Workshop Projects for Home Machinists: Practical & Useful Ideas for the Small ShopFrom Everand16 Metalworking Workshop Projects for Home Machinists: Practical & Useful Ideas for the Small ShopRating: 5 out of 5 stars5/5 (1)

- Basic Armouring - A Practical Introduction To Armour Making - Paul BlackwellDocument116 pagesBasic Armouring - A Practical Introduction To Armour Making - Paul Blackwellcliftoncage100% (6)

- A Benchtop BenchDocument2 pagesA Benchtop Benchcorneliu.modilca67% (3)

- The Return of Roubo: An 18th-Century French Workbench Is Quite Possibly The Most Perfect Design Ever Put To PaperDocument10 pagesThe Return of Roubo: An 18th-Century French Workbench Is Quite Possibly The Most Perfect Design Ever Put To PaperRodrigo Alonso Garrido StuardoNo ratings yet

- A Long-Term Survival Guide - Make A Survival StaffDocument9 pagesA Long-Term Survival Guide - Make A Survival Staffbuckonbeach100% (8)

- Making Guitar: The - ComponentsDocument9 pagesMaking Guitar: The - ComponentsIwan TejasukmanaNo ratings yet

- Tip #47 Resawing: There's A Fine Art To Making Thin Boards Out of Thick OnesDocument4 pagesTip #47 Resawing: There's A Fine Art To Making Thin Boards Out of Thick OnesAntonio Alberto Fonseca FilhoNo ratings yet

- The Home Craftsman (1906)Document10 pagesThe Home Craftsman (1906)Robert Elliott PH.dNo ratings yet

- Woodworking - Home Made Table Saw Box Joint JigDocument5 pagesWoodworking - Home Made Table Saw Box Joint Jigleehoin100% (2)

- OceanofPDF - Com The Basics of Beginning Leatherwork Begin - William SmithDocument63 pagesOceanofPDF - Com The Basics of Beginning Leatherwork Begin - William SmithOmar DionisiNo ratings yet

- Metal Guilhotine - Metal Working Shop From Scrap - Upload by Dave The RaveDocument5 pagesMetal Guilhotine - Metal Working Shop From Scrap - Upload by Dave The RaveAndy LNo ratings yet

- Fine - Woodworking.-.A Workbench That WorksDocument2 pagesFine - Woodworking.-.A Workbench That WorksSarasaNo ratings yet

- Woodrat: Genius or Just Another Jig? We Have The Answer Right HereDocument2 pagesWoodrat: Genius or Just Another Jig? We Have The Answer Right HereEric UzueliNo ratings yet

- Add A Router Table To A Table Saw: Step 1: Tools and MaterialsDocument8 pagesAdd A Router Table To A Table Saw: Step 1: Tools and Materialsafrica schoolNo ratings yet

- Felted Fiber Menagerie: Needle Felted Table ToppersFrom EverandFelted Fiber Menagerie: Needle Felted Table ToppersRating: 4 out of 5 stars4/5 (1)

- OMNI 6090 CNC Router QuotationDocument4 pagesOMNI 6090 CNC Router QuotationJosé PeNo ratings yet

- 001 2020 4 BDocument113 pages001 2020 4 BMyran PillayNo ratings yet

- Is53 Iso - 5836 - 1988Document8 pagesIs53 Iso - 5836 - 1988elvisonderNo ratings yet

- CBLM 5 Use Hand ToolsDocument127 pagesCBLM 5 Use Hand ToolsDonabel NoveroNo ratings yet

- Product Technical Data Sheet: 14-10 Bugle Head Part Threaded Type 17Document2 pagesProduct Technical Data Sheet: 14-10 Bugle Head Part Threaded Type 17jnudsaNo ratings yet

- Workshop Practice II LAB Manual by Bilal ZamanDocument24 pagesWorkshop Practice II LAB Manual by Bilal ZamanJawad NadeemNo ratings yet

- Trimmer: Instruction ManualDocument20 pagesTrimmer: Instruction ManualOnagro XNo ratings yet

- Wood Design Manual 2015 ErrataDocument1 pageWood Design Manual 2015 ErratanoobfNo ratings yet

- Shellac Flake: Restoration, Repair, & Finishing SuppliesDocument1 pageShellac Flake: Restoration, Repair, & Finishing SuppliesvajdazitaNo ratings yet

- Product: Metrotile UK Limited Metrobond 450 and Metrobond 900Document4 pagesProduct: Metrotile UK Limited Metrobond 450 and Metrobond 900Niroj MaharjanNo ratings yet

- Straight Razor How To Do PDFDocument10 pagesStraight Razor How To Do PDFRaziel MugsueNo ratings yet

- Vertical Shaft Impactor - : Design NotesDocument2 pagesVertical Shaft Impactor - : Design Notesilyas mursalNo ratings yet

- Partes y PiezasDocument2 pagesPartes y Piezasst.hpexNo ratings yet

- CherryMax Catalog CA-1016Document2 pagesCherryMax Catalog CA-1016Manuel Antonio Oñate CarvajalNo ratings yet

- QUEST® - Maintenance Manual PDFDocument196 pagesQUEST® - Maintenance Manual PDFMontserrat GuNo ratings yet

- Official Quotation: Picture Goods Description Accessories FOB Qingdao Port Price (USD)Document7 pagesOfficial Quotation: Picture Goods Description Accessories FOB Qingdao Port Price (USD)Hugh O'Brien GwazeNo ratings yet

- TDS Formula Gr12Document4 pagesTDS Formula Gr12Cvaldivia001No ratings yet

- Product Instructions - Barrel Press Kit InstructionsDocument7 pagesProduct Instructions - Barrel Press Kit InstructionsDale WadeNo ratings yet

- Installation of Stucco Exterior Finish Over WoodDocument6 pagesInstallation of Stucco Exterior Finish Over WoodFernando LlacayNo ratings yet

- The Pencil Post BedDocument6 pagesThe Pencil Post BedAnonymous QJ5j94luLmNo ratings yet

- Chapter 2Document32 pagesChapter 2Huzairee IsmailNo ratings yet

- Schedule - M - FORMULADocument148 pagesSchedule - M - FORMULAZainabu waziriNo ratings yet

- ATK LASERS-Company ProfileDocument9 pagesATK LASERS-Company ProfileATK LASERSNo ratings yet

- Assignment No.1 - Types and Costs of Materials in The Civil Engineering IndustryDocument17 pagesAssignment No.1 - Types and Costs of Materials in The Civil Engineering Industryvarun100% (1)

- SN11240 - Router Mortising Jig PDFDocument8 pagesSN11240 - Router Mortising Jig PDFMariano100% (3)

- Awusato Abaya Nursery Vermicompost House Takeoff & BoQ-3Document7 pagesAwusato Abaya Nursery Vermicompost House Takeoff & BoQ-3Tesfalem NekereNo ratings yet

- Samsung HMX-F90 Lens Replacement - Guia de Reparo IfixitDocument7 pagesSamsung HMX-F90 Lens Replacement - Guia de Reparo IfixitPedro RobertoNo ratings yet

- Eldorado Stone Finishing DetailsDocument16 pagesEldorado Stone Finishing DetailsGeorges HageNo ratings yet

- Wood Bending: by Trey Howard, Cal Fore, Bobby Connor, Ling QiuDocument78 pagesWood Bending: by Trey Howard, Cal Fore, Bobby Connor, Ling QiuPuneeth Raj100% (1)