Professional Documents

Culture Documents

System No. C-AJ-2898

System No. C-AJ-2898

Uploaded by

darwish.hiltiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

System No. C-AJ-2898

System No. C-AJ-2898

Uploaded by

darwish.hiltiCopyright:

Available Formats

S IFI

CAJ 2898

AS

CL

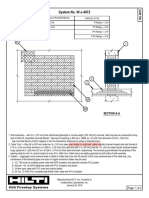

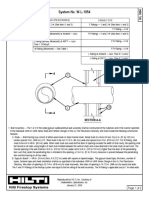

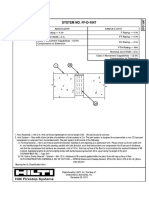

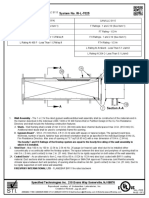

System No. C-AJ-2898

ED

F Rating - 3 Hr

Classified by

Underwriters Laboratories, Inc.

T Rating - 3 Hr

to UL 1479 L-RATING AT AMBIENT = Less Than 1 CFM/ft²

L-RATING AT 400°F = Less Than 1 CFM/ft²

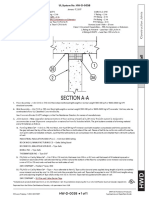

3C 1 2 3A

3B

2 3D 3D 3C

SECTION A-A

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

May 11, 2020

Hilti Firestop Systems Page: 1 of 2

CAJ 2898

System No. C-AJ-2898

1. Floor or Wall Assembly — Min 4-1/2 in. (114 mm) thick reinforced lightweight or normal weight (100-150 pcf or 1600-2400 kg/m3) concrete.

Wall may also be constructed of any UL Classified Concrete Blocks*. Max diameter of opening is 10 in. (254 mm).

See Concrete Blocks (CAZT) in the Fire Resistance Directory for names of manufacturers.

2. Through Penetrants — One nonmetallic pipe to be installed concentrically or eccentrically within the firestop system. Annular space between

pipe and periphery of opening to be min 0 in. (point contact) to max 1-1/4 in. (32 mm). For L Rating, a minimum annular space of 1/4 in. (6

mm) is required. The following types and sizes of nonmetallic pipes may be used:

A. Polybutylene (PB) Pipe — Nom 8 in. (203 mm) diam (or smaller) SDR11 PB pipe for use in closed (process or supply) piping systems.

3. Firestop System — The firestop system shall consist of the following:

A. Packing or Forming Materials — Min 2 in. (51 mm) thickness of min 4 pcf (64 kg/m3) mineral wool batt insulation tightly packed into the

opening as a permanent form. Packing material to be recessed from the bottom surface of floor or both surfaces of wall to accommodate

the required thickness of sealant (Item 3B).

B. Fill, Void or Cavity Material* — Min 1 in. (25 mm) thickness of sealant applied within the annulus, flush with bottom surface of floor or with

both surfaces of wall.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC — FS-ONE MAX Intumescent Sealant

C. Fill, Void or Cavity Material* — Wrap Strip - Two stacks of four layers of intumescent wrap strip are continuously wrapped around the

pipe with ends held in place with masking or aluminum tape. When multiple wrap strips are used to achieve the required total length, the

ends are butted end to end and held in place with tape. Butted ends in successive layers shall be offset. Wrap strip butted tightly against

bottom surface of floor or both surfaces of wall.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC — CP48-E W45/1-3/4" Firestop Wrap Strip

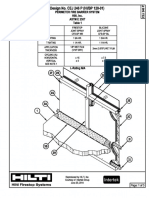

D. Steel Collars — Steel collar fabricated from coils of precut min 0.016 in. (1.6 mm) thick (No. 28 gauge) galv steel available from fill

material manufacturer. Collar shall be nom 1-3/4 in. (44 mm) deep with 1 in. (25 mm) wide by 2 in. (52 mm) long anchor tabs on 1-3/4 in.

(44 mm) centers for securement to the underside of floor or both surfaces of wall. The opposite side incorporates retainer tabs, 1/2 in. (13

mm) wide by 3/16 in. (4.8 mm) long, prebent toward the pipe surface. Collar shall be tightly wrapped over the wrap strip, overlapping min.

1 in (25 mm) at seam. Collar secured with two sheet metal screws though the overlapping portion of the collar. The length of the sheet

metal screws shall not exceed the thickness of the wrap strip. A second collar to be wrapped around the second stack of wrap strip with a

min 1 in. (25 mm) overlap at the seam. Second collar secured with four sheet metal screws though the overlapping portion of the collar.

Anchor tabs of second collar left unbent and every other tab is secured to the first retaining collar with one no. 8 sheet metal screw per

tab. Optional securement of the anchor tabs of second collar may be accomplished with one nom 1/2 in. (13mm) wide stainless steel hose

clamp secured at the mid height of collar. Every other anchor tab of first collar secured to bottom surface of floor or both surfaces of wall

with 1/4 in. (6 mm) diam by 1-1/4 in. (32 mm) long steel expansion bolts in conjunction with steel nuts and 1/4 in. (6 mm) by 1-1/4 in. (32

mm) diam washers, 1/4 in.(6 mm) diam by 1-1/2 in. (44 mm) long steel concrete screws or 0.145 in. (3.8 mm) diam by 1-1/4 in. (32 mm)

long powder actuated fasteners and min 1-1/4 (32 mm) diam by 1/16 in. (1.6 mm) thick steel washer. As alternates to the anchors

specified above, Hilti 1/4 in. (6 mm) diam by 1-1/4 in.(32 mm) long KWIK-CON II+ concrete screw anchor, Hilti 1/4 in.(6 mm) diam by 1-3/4

in. (44 mm) long KWIK-BOLT 3 steel expansion anchor or Hilti X-DNI 27 P8 S15 powder actuated floor pin with integral nom 9/16 in. diam

washer may be used. Collars to be used at the bottom surface of floor or both surfaces of wall.

* Indicates such products shall bear the UL or cUL Certification Mark for jurisdictions employing the UL or cUL Certification (such as Canada),

respectively.

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

May 11, 2020

Hilti Firestop Systems Page: 2 of 2

You might also like

- U412 - 2 HourDocument4 pagesU412 - 2 Hourmaher58No ratings yet

- HWD0194Document2 pagesHWD0194Ever Nina LauraNo ratings yet

- Press BrakesDocument19 pagesPress Brakeszivkovic brankoNo ratings yet

- Approval Document ASSET DOC LOC 145Document2 pagesApproval Document ASSET DOC LOC 145Amir IqbalNo ratings yet

- Ul Fs On Max Rectangular Duct Block WallDocument2 pagesUl Fs On Max Rectangular Duct Block WallhossamNo ratings yet

- Approval Document ASSET DOC LOC 716Document2 pagesApproval Document ASSET DOC LOC 716fazil yoosufNo ratings yet

- HWD0134Document2 pagesHWD0134Edwin Jalanoca LlaulliNo ratings yet

- Firstop DesignDocument2 pagesFirstop DesignAmir IqbalNo ratings yet

- Sistema UL HWD0079 Junta 2 Hrs DrywallDocument2 pagesSistema UL HWD0079 Junta 2 Hrs DrywallRaul Fernando Villarreal VargasNo ratings yet

- Firestop Application Handbook (Macau) - Part-9 PDFDocument40 pagesFirestop Application Handbook (Macau) - Part-9 PDFSharoon S raoNo ratings yet

- UntitledDocument2 pagesUntitledandy_ramblaNo ratings yet

- System PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFEmanuel PastlNo ratings yet

- System PDF Files - 1. UL and cUL Systems - cwd1033Document3 pagesSystem PDF Files - 1. UL and cUL Systems - cwd1033Emanuel Almeida PastlNo ratings yet

- Ul HWD 0209Document2 pagesUl HWD 0209jlledwinestebanNo ratings yet

- FS - Muro Cortina - ASSET-DOC-LOC-7765712Document3 pagesFS - Muro Cortina - ASSET-DOC-LOC-7765712S. Priscila Castillo V.No ratings yet

- Approval Document ASSET DOC LOC 340Document2 pagesApproval Document ASSET DOC LOC 340aNo ratings yet

- XHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQDocument4 pagesXHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQMd. Atiqul IslamNo ratings yet

- Approval Document ASSET DOC LOC 709Document2 pagesApproval Document ASSET DOC LOC 709fazil yoosufNo ratings yet

- W-L-1054 Pipe Through Gyp Board AssemblyDocument2 pagesW-L-1054 Pipe Through Gyp Board AssemblyJason StelleNo ratings yet

- C-AJ-2834 - Through-Penetration Firestop Systems - UL Product IqDocument3 pagesC-AJ-2834 - Through-Penetration Firestop Systems - UL Product Iqchatgpt MohitNo ratings yet

- Ì86WWDÇ!#ÈANÇ 4/pî: System No. WW-D-0103Document2 pagesÌ86WWDÇ!#ÈANÇ 4/pî: System No. WW-D-0103AnaMorenoNo ratings yet

- Fire Stop InstallationDocument3 pagesFire Stop InstallationAristo OnanNo ratings yet

- CAJ1427Document1 pageCAJ1427mr. mydNo ratings yet

- Caj 4107Document2 pagesCaj 4107Jorge OropezaNo ratings yet

- Design Number 3MU/BPF 180-01: Perimeter Fire BarriersDocument2 pagesDesign Number 3MU/BPF 180-01: Perimeter Fire BarriersAbram SelimNo ratings yet

- System PDF Files - 1. UL and cUL Systems - cws0002Document2 pagesSystem PDF Files - 1. UL and cUL Systems - cws0002Emanuel Almeida PastlNo ratings yet

- Hilti Firestop Submittal - Balamand UniversityDocument32 pagesHilti Firestop Submittal - Balamand UniversitybasbousrNo ratings yet

- Firestop CEJ 421 PDocument4 pagesFirestop CEJ 421 PErlanggaRizkiFauziNo ratings yet

- Fabrication Standard of Duct-AcDocument5 pagesFabrication Standard of Duct-AcVicky KumarNo ratings yet

- CWD1004 - Curtain Wall Design - Firestopping - STIDocument2 pagesCWD1004 - Curtain Wall Design - Firestopping - STIMDNo ratings yet

- ICC-ES Report Firestone TPO Roofing MaterialDocument16 pagesICC-ES Report Firestone TPO Roofing MaterialKoushik ThunuguntlaNo ratings yet

- Firestop Application Handbook (Macau) - Part-8 PDFDocument30 pagesFirestop Application Handbook (Macau) - Part-8 PDFSharoon S raoNo ratings yet

- HW-D-0038 - 1 of 1: 3M Fire Protection ProductsDocument1 pageHW-D-0038 - 1 of 1: 3M Fire Protection Productskirollos HabibNo ratings yet

- HILTI - Approval-document-ASSET-DOC-LOC-722Document1 pageHILTI - Approval-document-ASSET-DOC-LOC-722david messierNo ratings yet

- Approval Document ASSET DOC LOC 939Document2 pagesApproval Document ASSET DOC LOC 939andy_ramblaNo ratings yet

- Basic Info TK-U.B.I Sleeves3Document17 pagesBasic Info TK-U.B.I Sleeves3Saradhi MedapureddyNo ratings yet

- System PDF Files - 1. UL and cUL Systems - wl7025 - DLDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - wl7025 - DLEmanuel PastlNo ratings yet

- Flame StopDocument31 pagesFlame StopaNo ratings yet

- Fendolite Thickness IndustrialDocument4 pagesFendolite Thickness IndustrialMohamed Zain100% (1)

- Approval Document ASSET DOC LOC 299Document3 pagesApproval Document ASSET DOC LOC 299Anonymous a3K3WgNo ratings yet

- F A 1017Document3 pagesF A 1017shama093No ratings yet

- Max 24 Inch Dia Insulated Pipe UL System With LCI Sealant OnlyDocument2 pagesMax 24 Inch Dia Insulated Pipe UL System With LCI Sealant OnlyvikaspisalNo ratings yet

- HDPE Pipe SpecificationsDocument2 pagesHDPE Pipe SpecificationsTonoy BanikNo ratings yet

- CAJ1317Document1 pageCAJ1317Luis AlbertoNo ratings yet

- Installation ManualDocument40 pagesInstallation ManualHenryMenacho100% (1)

- Installation Instructions: Supplied As A Complete Fire-Rated Enclosure To Ensure ComplianceDocument1 pageInstallation Instructions: Supplied As A Complete Fire-Rated Enclosure To Ensure ComplianceAnonymous 59kfV93pf4No ratings yet

- C Aj 2586 PDFDocument1 pageC Aj 2586 PDFEmanuel PastlNo ratings yet

- LP Solid Start I-Joists Fire Endurance GuideDocument25 pagesLP Solid Start I-Joists Fire Endurance Guidemonkey47dmbNo ratings yet

- Rociador Cobertura Extendida k8.0Document6 pagesRociador Cobertura Extendida k8.0Anthony OneillNo ratings yet

- Approval Document ASSET DOC LOC 257Document3 pagesApproval Document ASSET DOC LOC 257Omar DDCNo ratings yet

- OHE Fittings & PG Clamps-PPS InternationalDocument8 pagesOHE Fittings & PG Clamps-PPS InternationalSindhuja SharavanNo ratings yet

- System No. C-AJ-2342: F Rating - 3 HR T Rating - 0 HR W Rating - Class 1 (See Item 3B)Document2 pagesSystem No. C-AJ-2342: F Rating - 3 HR T Rating - 0 HR W Rating - Class 1 (See Item 3B)darwish.hiltiNo ratings yet

- Er-5414 (2001)Document7 pagesEr-5414 (2001)m0172No ratings yet

- Marine Firestop SealantDocument4 pagesMarine Firestop SealantGilberto ZamudioNo ratings yet

- Fire Stop Design 673Document4 pagesFire Stop Design 673raviNo ratings yet

- Super Firetemp: Fire Protection SystemsDocument6 pagesSuper Firetemp: Fire Protection SystemstimetemasekNo ratings yet

- FM Design 628 (FB-4003)Document2 pagesFM Design 628 (FB-4003)raviNo ratings yet

- System WJ 2256Document1 pageSystem WJ 2256Manoj SamNo ratings yet

- C Aj 1609Document2 pagesC Aj 1609vhin84No ratings yet

- Product Technical Guide For Kwik Bolt-TZ Expansion Anchor Technical Information ASSET DOC LOC 1543424Document21 pagesProduct Technical Guide For Kwik Bolt-TZ Expansion Anchor Technical Information ASSET DOC LOC 1543424corrokokoNo ratings yet

- En 485-1+a1 - 2009 (NF)Document22 pagesEn 485-1+a1 - 2009 (NF)Shrikant BhirudNo ratings yet

- Genesis Shaftway DP Planning GuideDocument32 pagesGenesis Shaftway DP Planning GuideNicolas GonzalezNo ratings yet

- Katalog ANGLICKYDocument64 pagesKatalog ANGLICKYPiyush SutariyaNo ratings yet

- 2013-Design and Development of Solar Dryer FoDocument47 pages2013-Design and Development of Solar Dryer FosanjuNo ratings yet

- Blueprint Senior 2Document26 pagesBlueprint Senior 2Nur Amira JasminNo ratings yet

- 5 - 1 - Sealed - Radiation - Sources - Product InformationDocument40 pages5 - 1 - Sealed - Radiation - Sources - Product InformationasdtwrNo ratings yet

- Aluminium 1100Document2 pagesAluminium 1100Anup DalalNo ratings yet

- Combined Hardening Behavior PDFDocument31 pagesCombined Hardening Behavior PDFDiegoHenaoLeonNo ratings yet

- Armaflex Application INTMODocument36 pagesArmaflex Application INTMODavid O. AlmeidaNo ratings yet

- Alloy Cross Reference Table PDFDocument4 pagesAlloy Cross Reference Table PDFChad MitchellNo ratings yet

- MetalDocument11 pagesMetalMacedo S OliveiraNo ratings yet

- Sheet Met Dev DrawDocument3 pagesSheet Met Dev DrawSumeet SainiNo ratings yet

- M Pi 170Document10 pagesM Pi 170reza329329No ratings yet

- Elements Machine Shop PDFDocument493 pagesElements Machine Shop PDFJaypes ManzanoNo ratings yet

- PL-SPE-1-13-00 Spec Riser Coat RevA2Document16 pagesPL-SPE-1-13-00 Spec Riser Coat RevA2RamNo ratings yet

- SS 304Document4 pagesSS 304Imtinan Mohsin100% (1)

- Production Process IIIDocument10 pagesProduction Process IIIYash JadhavNo ratings yet

- 1416-MC-DBS-101 - Mechanical Design Basis - R1Document19 pages1416-MC-DBS-101 - Mechanical Design Basis - R1KrunalNo ratings yet

- -Document64 pages-David GastelbondoNo ratings yet

- Aerospace Aluminum PDFDocument6 pagesAerospace Aluminum PDFsmani170No ratings yet

- Renusol CB 062014 GBDocument28 pagesRenusol CB 062014 GBIsmael BassoNo ratings yet

- Mini Project TopicsDocument15 pagesMini Project TopicsKalai SelvanNo ratings yet

- Types of Rebar-WPS OfficeDocument2 pagesTypes of Rebar-WPS OfficePablo Suyu NaragNo ratings yet

- Nes 329 Heat ExchangerDocument32 pagesNes 329 Heat ExchangerSharad Kokate100% (1)

- Civiconcepts: Subscribe To Blog Via EmailDocument16 pagesCiviconcepts: Subscribe To Blog Via EmailRobert MadhlopaNo ratings yet

- Assosa University: Prepared byDocument74 pagesAssosa University: Prepared bySiraj MohammedNo ratings yet

- Astm A570 A570m 98Document1 pageAstm A570 A570m 98Didi Sulaiman AbduhNo ratings yet

- Delboel Catalogue Edit-Đã Nén PDFDocument48 pagesDelboel Catalogue Edit-Đã Nén PDFVi Tiểu BảoNo ratings yet

- City and Guilds Level 1 Certificate in EngineeringDocument82 pagesCity and Guilds Level 1 Certificate in Engineeringmmcneill9043No ratings yet