Professional Documents

Culture Documents

58-TMSS-02-R0 Air Core Series Reactor 13.8kV To 380kV

58-TMSS-02-R0 Air Core Series Reactor 13.8kV To 380kV

Uploaded by

srifaceCopyright:

Available Formats

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- 12-TMSS-01-R1 Line HardwareDocument25 pages12-TMSS-01-R1 Line HardwareNauman Habib KhanNo ratings yet

- 43 TMSS 01 R0Document0 pages43 TMSS 01 R0renjithas2005No ratings yet

- 50 TMSS 02 R0Document0 pages50 TMSS 02 R0renjithas20050% (1)

- 50 TMSS 01 R0Document0 pages50 TMSS 01 R0renjithas2005No ratings yet

- P-192-94 WAPDA SPECIFICATION For 132kV CAPACITOR BANKSDocument12 pagesP-192-94 WAPDA SPECIFICATION For 132kV CAPACITOR BANKSHasnain AwanNo ratings yet

- PGCIL GIS Specification - Rev 4 (June-14)Document74 pagesPGCIL GIS Specification - Rev 4 (June-14)Travis Wood100% (1)

- 0048 Vivem175enDocument110 pages0048 Vivem175enArmando MaloneNo ratings yet

- 58-TMSS-01-R0 - Oil Immersed Reactor, 33kV To 380kVDocument32 pages58-TMSS-01-R0 - Oil Immersed Reactor, 33kV To 380kVsrifaceNo ratings yet

- 43TMSS01R1 Shunt Capacitor Bank, 13.8kV Through 380kVDocument16 pages43TMSS01R1 Shunt Capacitor Bank, 13.8kV Through 380kVMohamed NasrNo ratings yet

- 1-) 52-TMSS-01-Rev.00Document29 pages1-) 52-TMSS-01-Rev.00Orcun CalayNo ratings yet

- 52TMSS01R0Document29 pages52TMSS01R0Orcun CalayNo ratings yet

- 37-TMSS-02-R0 (LiveTankCB)Document28 pages37-TMSS-02-R0 (LiveTankCB)Jyoti SinghNo ratings yet

- Air Core Series Reactor Design ConsiderationsDocument4 pagesAir Core Series Reactor Design Considerationswaqas_a_shaikh4348No ratings yet

- 15TMSS01R1 Insulators, Station Post Type, Porcelain, IndoorOutdoor 69kv Through 380KvDocument15 pages15TMSS01R1 Insulators, Station Post Type, Porcelain, IndoorOutdoor 69kv Through 380KvDominic Mukesh KumarNo ratings yet

- 31 TMSS 06 R0Document30 pages31 TMSS 06 R0Nauman Habib KhanNo ratings yet

- 50-TMSS-01 (Rev 01)Document17 pages50-TMSS-01 (Rev 01)GardellNo ratings yet

- Nigam 11 KV Shunt CapacitorDocument13 pagesNigam 11 KV Shunt CapacitorSandeep SharmaNo ratings yet

- 33kV - Cap - Bank-SIKAP - Spec - FY 12-13 - 30.11.11-Cesc - 20 MVARDocument9 pages33kV - Cap - Bank-SIKAP - Spec - FY 12-13 - 30.11.11-Cesc - 20 MVARSatyajit RaiNo ratings yet

- Eaton PFC Guide Spec 16280BDocument7 pagesEaton PFC Guide Spec 16280Btareknakhle_16311323No ratings yet

- AVR SpecificationDocument18 pagesAVR Specificationmanu892007No ratings yet

- Technical Specification For Gas Insulated Metalclad 36kV Switchgear For Indoor ApplicationDocument30 pagesTechnical Specification For Gas Insulated Metalclad 36kV Switchgear For Indoor ApplicationS.M.Touhidur RahmanNo ratings yet

- Reactors - Specification: Indian StandardDocument9 pagesReactors - Specification: Indian StandardAustindaniel JoelsimeonNo ratings yet

- 35 TMSS 01 R0Document13 pages35 TMSS 01 R0AWNo ratings yet

- 57-TMSS-01-R0 Neutral Grounding Resister - 11kV To 34.5kVDocument11 pages57-TMSS-01-R0 Neutral Grounding Resister - 11kV To 34.5kVsrifaceNo ratings yet

- June 30, 2010Document56 pagesJune 30, 2010mohamedNo ratings yet

- Earthing Transformer: Engineering DepartmentDocument12 pagesEarthing Transformer: Engineering DepartmentVíctor CasadoNo ratings yet

- Spec Automatic Reactive Power CompensationDocument7 pagesSpec Automatic Reactive Power CompensationDolyNo ratings yet

- Cidco of Maharashtra Limited. SL - Pg.NoDocument7 pagesCidco of Maharashtra Limited. SL - Pg.Nordeepak99No ratings yet

- Ac Operated Automatic TR Unit WithDocument15 pagesAc Operated Automatic TR Unit WithTech1No ratings yet

- D) Mechanical Forces On Bushing TerminalsDocument1 pageD) Mechanical Forces On Bushing Terminalsimcoolmailme2No ratings yet

- Capacitor BankDocument28 pagesCapacitor BankPrakash Rout100% (1)

- 12 TMSS 10Document19 pages12 TMSS 10Fouad AliNo ratings yet

- GIS SubstationDocument232 pagesGIS Substationcrazy devil100% (1)

- 245 KV SF6 BreakerDocument33 pages245 KV SF6 Breakerpalash_monNo ratings yet

- Annexure 12 - Technical Specification 216kV LA R0 - 20190903173116Document16 pagesAnnexure 12 - Technical Specification 216kV LA R0 - 20190903173116Solar PowerNo ratings yet

- 12 TMSS 11Document29 pages12 TMSS 11Fouad AliNo ratings yet

- 15-TMSS-05 R.1Document20 pages15-TMSS-05 R.1wastazoheb_700349353No ratings yet

- 53 TMSS 01 R0 UnlockedDocument57 pages53 TMSS 01 R0 UnlockedGanesh DuraisamyNo ratings yet

- Va 26 22 00Document7 pagesVa 26 22 00adrian karl bonaNo ratings yet

- Technical Specification: Section-Series Reactor (400 KV CLASS)Document15 pagesTechnical Specification: Section-Series Reactor (400 KV CLASS)byjuvcNo ratings yet

- Earthing Transformer PDFDocument13 pagesEarthing Transformer PDFNelson SarriasNo ratings yet

- 10-Sdms-02 (Bare Copper Conductors)Document17 pages10-Sdms-02 (Bare Copper Conductors)Haytham BafoNo ratings yet

- 50 TMSS 03 R0Document0 pages50 TMSS 03 R0renjithas2005No ratings yet

- Materials System Specification: Saudi Aramco Desktop StandardsDocument13 pagesMaterials System Specification: Saudi Aramco Desktop StandardsEagle Spirit100% (1)

- Technical Specification OF 36 KV Gas Insulated Metal Clad Indoor Switchgear 1.1 ScopeDocument17 pagesTechnical Specification OF 36 KV Gas Insulated Metal Clad Indoor Switchgear 1.1 ScopeManohar PotnuruNo ratings yet

- 38smss4 Specification For Coupling Capacitor Voltage Transformer and or Carrier Coupler CapacitorDocument20 pages38smss4 Specification For Coupling Capacitor Voltage Transformer and or Carrier Coupler CapacitorengrandyNo ratings yet

- Transformer - Technical Specification 10 To 1600KVADocument48 pagesTransformer - Technical Specification 10 To 1600KVAsepta ibnuNo ratings yet

- Specification For 33KV VCB PDFDocument20 pagesSpecification For 33KV VCB PDFUma KantNo ratings yet

- 12 TMSS 10 R0Document0 pages12 TMSS 10 R0renjithas2005No ratings yet

- Volume-2 P2 - RRA & Breaker ChangeDocument381 pagesVolume-2 P2 - RRA & Breaker ChangeKaneNo ratings yet

- 2667 SpecDocument27 pages2667 SpecanuragpugaliaNo ratings yet

- June 30, 2010Document41 pagesJune 30, 2010TTPL ProjectsNo ratings yet

- Capacitor Bank DesignDocument31 pagesCapacitor Bank DesignRamani Ranjan Chiku100% (1)

- 15 TMSS 01 R0Document12 pages15 TMSS 01 R0Khaja MoinNo ratings yet

- Gems l-2d9 Cathodic Protection SystemsDocument15 pagesGems l-2d9 Cathodic Protection SystemsMochamad TaufikNo ratings yet

- Technical Specification of 12 KV Indoor Type Vacuum Circuit Breakers Against Tn-2593 1.0 ScopeDocument26 pagesTechnical Specification of 12 KV Indoor Type Vacuum Circuit Breakers Against Tn-2593 1.0 ScopePrintmeNo ratings yet

- Tss A 3 Transmission Lightning ArrestersDocument5 pagesTss A 3 Transmission Lightning ArrestersRegata Restu RespatiNo ratings yet

- Wave Trap Tech SpecsDocument13 pagesWave Trap Tech SpecsPrashant gaur100% (1)

- Balance of Plant Specifications For 12MW Archean PlantDocument47 pagesBalance of Plant Specifications For 12MW Archean Plantnagraj204No ratings yet

- Punch List - Juaymah Diversion - Rev53 - Week03 - 2024Document22 pagesPunch List - Juaymah Diversion - Rev53 - Week03 - 2024srifaceNo ratings yet

- Hvac 1675220171Document36 pagesHvac 1675220171srifaceNo ratings yet

- Adaptive Distance RelayingDocument25 pagesAdaptive Distance RelayingsrifaceNo ratings yet

- Classification Generator TrippingDocument6 pagesClassification Generator TrippingsrifaceNo ratings yet

- Bus Bar Differential Protection or Circulating Current ProtectionDocument2 pagesBus Bar Differential Protection or Circulating Current ProtectionsrifaceNo ratings yet

- Busbar Protection & Frame Leakage Protection Working PrincipleDocument3 pagesBusbar Protection & Frame Leakage Protection Working PrinciplesrifaceNo ratings yet

- Droop CTDocument2 pagesDroop CTsrifaceNo ratings yet

- Advantage of Neutral Grounding TransformerDocument2 pagesAdvantage of Neutral Grounding TransformersrifaceNo ratings yet

- Anti-Pumping Relay Diagram and Working Function ExplanationDocument2 pagesAnti-Pumping Relay Diagram and Working Function ExplanationsrifaceNo ratings yet

- Different Types of Current TransformersDocument3 pagesDifferent Types of Current TransformerssrifaceNo ratings yet

- CVT in Electrical Capacitive Voltage TransformerDocument5 pagesCVT in Electrical Capacitive Voltage TransformersrifaceNo ratings yet

- Pick Up Current Current Setting Plug Setting Multiplier and Time Setting Multiplier of RelayDocument6 pagesPick Up Current Current Setting Plug Setting Multiplier and Time Setting Multiplier of RelaysrifaceNo ratings yet

- Armature: Definition, Function and Parts (Electric Motor & Generator)Document6 pagesArmature: Definition, Function and Parts (Electric Motor & Generator)srifaceNo ratings yet

- Rating of AlternatorDocument3 pagesRating of AlternatorsrifaceNo ratings yet

- Course Outline of Applied Physics by Tahseen SanaDocument2 pagesCourse Outline of Applied Physics by Tahseen SanaTahseen SanaNo ratings yet

- Industrial Autoation and MechatronicsDocument17 pagesIndustrial Autoation and Mechatronicsambresh mirajkarNo ratings yet

- 1 Linear Eddy Current Brake For Railway Vehicles Using Dynamic BrakingDocument6 pages1 Linear Eddy Current Brake For Railway Vehicles Using Dynamic BrakingRohith MohanNo ratings yet

- PhysicsrealDocument11 pagesPhysicsreallodhishivansh2567No ratings yet

- Extraefi - Co.Uk Reset Problems: Ms1-Extra and Ms2-ExtraDocument8 pagesExtraefi - Co.Uk Reset Problems: Ms1-Extra and Ms2-Extraasser_salehNo ratings yet

- Experiment No. 01: Single Phase Half Wave Rectification With Inductive Load Psychomotor Skill Level: P4 Name: Roll NoDocument8 pagesExperiment No. 01: Single Phase Half Wave Rectification With Inductive Load Psychomotor Skill Level: P4 Name: Roll NoRana EhsanNo ratings yet

- Self Inductance of A CoilDocument13 pagesSelf Inductance of A Coilselena lee100% (2)

- SR Physics - Ipe - Important Questions: Very Short Answer QuestionsDocument8 pagesSR Physics - Ipe - Important Questions: Very Short Answer QuestionsRithik Reddy100% (1)

- Journal Jpe 18-3 249301697Document8 pagesJournal Jpe 18-3 249301697Carlos DPNo ratings yet

- Elect 3 PDFDocument22 pagesElect 3 PDFmudasirNo ratings yet

- Ch1 Current Volt Relationship Trasmission LineDocument84 pagesCh1 Current Volt Relationship Trasmission Linerathorsumit2006No ratings yet

- Transformer-Induced Low-Frequency Oscillations in The Series-Resonant Converter Ieee - Klesser - 1991Document12 pagesTransformer-Induced Low-Frequency Oscillations in The Series-Resonant Converter Ieee - Klesser - 1991cristian1961No ratings yet

- Become A Master ElectricianDocument7 pagesBecome A Master ElectricianShazmaniaNo ratings yet

- ISJR - Impulse TRDocument5 pagesISJR - Impulse TRmanjeetNo ratings yet

- Unit - Ii Switching TransientsDocument42 pagesUnit - Ii Switching Transientsshree100% (5)

- Resistor Capacitor Inductor: Presented by - Manish KumarDocument61 pagesResistor Capacitor Inductor: Presented by - Manish KumarDr-Eng Amir ElsafraweyNo ratings yet

- Top 258 PNDocument42 pagesTop 258 PNDavi Tavares100% (1)

- NUD3124-D (1) Transistor jw6Document10 pagesNUD3124-D (1) Transistor jw6Producciones3NNo ratings yet

- Ferrite Core Transformer Design Engineering and Technology 6Document10 pagesFerrite Core Transformer Design Engineering and Technology 6nedian_2006100% (2)

- An Enhanced High Order Sliding ModeDocument32 pagesAn Enhanced High Order Sliding ModeBadre BellaliNo ratings yet

- BKM Classes - EMIDocument25 pagesBKM Classes - EMIdny001No ratings yet

- Circuits and Systems For Efficient Portable-to-Portable Wireless ChargingDocument125 pagesCircuits and Systems For Efficient Portable-to-Portable Wireless ChargingBilisuma ZewduNo ratings yet

- Sensitivity Studies On Power Transformer Ferroresonance of 400kVDocument8 pagesSensitivity Studies On Power Transformer Ferroresonance of 400kV_FlyMan_No ratings yet

- Ept Lab ManualDocument100 pagesEpt Lab ManualSiddhuNo ratings yet

- Application of Duality For Derivation of Current Converter TopologiesDocument29 pagesApplication of Duality For Derivation of Current Converter Topologiestinhmaixatoi2006No ratings yet

- Novel ForwardFlyback Hybrid Bidirectional DCDC ConverterDocument7 pagesNovel ForwardFlyback Hybrid Bidirectional DCDC ConverterHsekum RamukNo ratings yet

- eCARS2x 2018 T3-1 Introduction Charging Methods EVs-1-4Document4 pageseCARS2x 2018 T3-1 Introduction Charging Methods EVs-1-4EulerNo ratings yet

- A Smart Monitoring of Faults in Power Transformers and Maintenance Based On Wi-FiDocument6 pagesA Smart Monitoring of Faults in Power Transformers and Maintenance Based On Wi-FiInnovative Research PublicationsNo ratings yet

58-TMSS-02-R0 Air Core Series Reactor 13.8kV To 380kV

58-TMSS-02-R0 Air Core Series Reactor 13.8kV To 380kV

Uploaded by

srifaceOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

58-TMSS-02-R0 Air Core Series Reactor 13.8kV To 380kV

58-TMSS-02-R0 Air Core Series Reactor 13.8kV To 380kV

Uploaded by

srifaceCopyright:

Available Formats

August 6, 2006 G

58TMSS02R0/KSB PAGE NO. 1 OF 12

TRANSMISSION MATERIALS STANDARD SPECIFICATION 58-TMSS-02, Rev. 0

TABLE OF CONTENTS

1.0 SCOPE

2.0 CROSS REFERENCES

3.0 APPLICABLE CODES AND STANDARDS

4.0 DESIGN AND CONSTRUCTION REQUIREMENTS

4.1 Type

4.2 Design and Construction

4.3 Rating

4.4 Terminals

4.5 Grounding

4.6 Nameplate

5.0 TESTS

6.0 DATA SCHEDULE

58TMSS02R0/KSB Date of Approval: August 6, 2006 G PAGE NO. 2 OF 12

TRANSMISSION MATERIALS STANDARD SPECIFICATION 58-TMSS-02, Rev. 0

1.0 SCOPE

This SEC Transmission Material Standard Specification (TMSS) specifies the minimum

technical requirements for design, engineering, manufacture, inspection, testing and performance

of air-core reactors intended to be used for current limiting (damping) in series with shunt

connected capacitor banks, 13.8kV thru’ 230kV and tuning (filter) reactors for filtering

harmonics up to 380kV, in the electrical system of the Saudi Electricity Company, Saudi Arabia.

2.0 CROSS REFERENCES

This Material Standard Specification shall always be read in conjunction with SEC General

Specification No. 01-TMSS-01, titled "General Requirements for All Equipment/Materials",

which shall be considered as an integral part of this TMSS.

This TMSS shall also be read in conjunction with SEC Purchase Order or Contract Schedules for

project, as applicable.

3.0 APPLICABLE CODES AND STANDARDS

The latest revision/amendments of the following Codes and Standards shall be applicable for the

equipment/material covered in this TMSS. In case of conflict, the vendor/manufacturer may

propose equipment/material conforming to one group of Industry Codes and Standards quoted

hereunder without jeopardizing the requirements of this TMSS.

3.1 IEC 60273 Characteristics of Indoor and Outdoor Post Insulators for

Systems with Nominal Voltage greater than 1000V

3.2 IEC 60289 Reactors

3.3 ANSI C29.9 Wet Process Porcelain Insulators (Apparatus, Post Type)

3.4 ANSI C57.16 Standard Requirements, Terminology, and Test Code for

Dry-Type Air-Core Series-Connected Reactors

3.5 ANSI C29.1 Test Methods for Electrical Power Insulators

3.6 IEC 60168 Test on Indoor and Outdoor Post Insulators of Ceramic

Materials or Glass for Systems with Nominal Voltages

Greater than 1000V

58TMSS02R0/KSB Date of Approval: August 6, 2006 G PAGE NO. 3 OF 12

TRANSMISSION MATERIALS STANDARD SPECIFICATION 58-TMSS-02, Rev. 0

4.0 DESIGN AND CONSTRUCTION REQUIREMENTS

4.1 Type

The dry type air-core reactor shall be either single phase or three phase as specified in

data schedule. Reactor from 69kV up to 380kV shall be self (AN) cooled outdoor type.

Reactors rated from 13.8kV up to 34.5kV shall be either installed outdoor or inside self

cooled outdoor type enclosure as specified in data schedule.

4.2 Design and Construction

4.2.1 General

a. The application of air-core reactor shall be either for damping or harmonic

filtering as specified in data schedule.

b. Reactor shall be designed per IEC 60289 or ANSI C57.16.

c. Reactor shall be made of concentric cylindrical coil, having vertical axis.

The coil shall be made of insulated aluminum or copper conductor as

specified in data schedule. Outdoor reactor shall be UV resistant.

d. Manufacturer shall furnish minimum magnetic clearances to other reactors

and metallic parts not forming closed loops along with magnetic flux

versus distance (mean radius) curve per Annexure D of ANSI C57.16.

Magnetic field from the reactor shall not cause eddy-current heating in

adjacent metallic objects such as fence, ground mat, etc., and equipment.

e. Reactors shall be pedestal mounted on support insulators and associated

support brackets and shall include all necessary accessories to complete

the installation. Reactor shall be installed side by side or vertically stacked

as specified in data schedule. Minimum pedestal height for outdoor

reactors shall be 2440mm.

f. Support insulator caps, supporting brackets, nut, bolts etc. shall be non-

magnetic material.

g. Supporting insulators shall be made of electrical grade wet processed

porcelain per 15-TMSS-01. Calculations shall be furnished to justify the

mechanical characteristics of the insulators.

58TMSS02R0/KSB Date of Approval: August 6, 2006 G PAGE NO. 4 OF 12

TRANSMISSION MATERIALS STANDARD SPECIFICATION 58-TMSS-02, Rev. 0

h. Suitable lifting arrangements for balanced lifting of the completely

assembled reactor shall be provided.

i. The mechanical and thermal withstand capabilities of the reactor to

withstand short circuit current shall be demonstrated with calculation.

j. Current carrying joints shall be brazed and not soldered.

k. Reactor insulation shall be minimum class B and shall be selected per

temperature rise. Temperature rise shall be within the limits for the

ambient conditions per 01-TMSS-01.

4.2.2 Damping Reactors

In addition to the criteria stated under Section 4.2.1 damping reactors shall meet

the following requirements:

a. Shall limit the magnitude and frequency of in-rush currents due to

capacitor switching and the out-rush currents caused by close in fault

within the withstand capability of associated switching element.

b. Unless otherwise specified in data schedule inductance tolerance shall be

per relevant IEC and ANSI standards.

c. Q-factor (X/R ratio) at the in-rush frequency shall be furnished.

d. Unless otherwise specified in data schedule reactor shall be rated for a

continuous voltage across the reactor that is five times (harmonic voltage

distortion factor) the fundamental voltage drop.

4.2.3 Tuning (Filter) Reactors

In addition to the criteria stated under Section 4.2.1 tuning (filter) reactor shall

meet the following requirements:

a. If inductance adjustment for fine tuning is required then the tap range for

the same shall be as specified in data schedule.

b. For filter applications which require a Q factor at tuning frequency lower

than natural Q factor of the reactor, the same shall be achieved without any

additional damping resistor.

c. Shall be designed so as to avoid mechanical or acoustic resonances at

major audible sound frequencies.

58TMSS02R0/KSB Date of Approval: August 6, 2006 G PAGE NO. 5 OF 12

TRANSMISSION MATERIALS STANDARD SPECIFICATION 58-TMSS-02, Rev. 0

d. Shall withstand short-time current, which is related to system overcurrent

faults for series-connected reactors and in-rush phenomena for parallel

connected reactor, with duration as specified in data schedule.

e. Unless otherwise specified in data schedule, maximum tolerance for

inductance at the principal and other taps (if applicable) shall be 5% at the

tuning frequency.

4.3 Rating

Inductance value shall be as specified in data schedule.

4.4 Terminals

The terminal of outdoor reactor shall be welded with the coil and the connectors shall be

per NEMA CC1, tin plated and suitable for copper or aluminum conductors. Connectors

shall be sized to accommodate conductor sizes as specified in data schedule.

4.5 Grounding

Two solder-less ground connectors with one (1) each on two diagonally opposite legs of

the pedestal shall be provided which will accommodate conductor sizes of 1x 240 mm²

for station fault level up to 40 kA and 2x240 mm² for station fault level above 40 kA.

4.6 Nameplate

Each reactor shall bear a nameplate, which shall be written in English and Arabic and

contain the information listed in IEC 60289 or ANSI C57.16, plus additional information

as follows:

The words “ kV Reactor”.

Place and Year of Manufacture

SEC Purchase Order No. or Contract No. or J.O. No

Design Ambient Temperature

58-TMSS-02

The nameplate shall be readable from the ground. The nameplate material shall be

stainless steel and fastened to the equipment by stainless steel screws.

5.0 TESTS

All test results shall be provided for review and approval by SEC.

5.1 Design (Type) Tests

58TMSS02R0/KSB Date of Approval: August 6, 2006 G PAGE NO. 6 OF 12

TRANSMISSION MATERIALS STANDARD SPECIFICATION 58-TMSS-02, Rev. 0

All design (Type) tests prescribed in IEC 60289 or ANSI C57.16 standards shall be

performed on a complete functional assembly of one representative unit having same

design, arrangement and ratings as of those to be supplied or on the first unit of every new

design, rating or size to be supplied to SEC. For air-core reactor manufactured per ANSI

C57.16 standard, dielectric tests shall be carried out as type tests in addition to all other

type tests prescribed in ANSI.

In lieu of the actual design (type) tests, certified test reports of design (type) tests

performed on an identical unit may be submitted to SEC for review and approval during

bidding stage.

5.2 Production (Routine Tests)

5.2.1 General

All production (routine) tests prescribed in IEC 60289 or ANSI C57.16 shall

be performed on all units prior to delivery to SEC.

5.2.2 Damping Reactor

For damping reactors manufactured per IEC standard, measurement of loss and Q

factor shall be carried out as additional routine tests in addition to all other routine

tests per IEC standard.

5.2.3 Supporting Insulator

All routine and type test per 15-TMSS-01 shall be carried out.

5.2.4 Special Test

Special tests, when specified in data schedule, shall be carried out.

58TMSS02R0/KSB Date of Approval: August 6, 2006 G PAGE NO. 7 OF 12

TRANSMISSION MATERIALS STANDARD SPECIFICATION 58-TMSS-02, Rev. 0

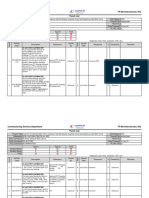

6.0 DATA SCHEDULE

AIR CORE SERIES REACTOR 13.8 KV THROUGH 380kV

SEC Enquiry No. Date:

SEC Purchase Order No. Date:

or Contract No.

SEC PTS No./Project Title with J.O. No.

REFERENCE

SECTION NO. DESCRIPTION 'A' 'B' 'C'

3.0 APPLICABLE CODES AND STANDARDS

Applicable Industry Standards *

4.0 DESIGN AND CONSTRUCTION REQUIREMENTS

Model Designation *

4.1 No. of phases 3/1

Outdoor/Inside

Type of mounting Weather proof

enclosure

Reactor Arrangement

(side by side or vertically stacked)

A'- SEC SPECIFIED DATA/PARAMETER.

'B'- BIDDER/SUPPLIER/VENDOR/CONTRACTOR PROPOSED DATA/PARAMETERS.

'C'- REMARKS SUPPORTING THE PROPOSED DEVIATION IN COLUMN 'B'.

(*)- DATA/PARAMETER TO BE PROVIDED/PROPOSED BY THE BIDDER/SUPPLIER/

VENDOR/CONTRACTOR IN COLUMN 'B'.

58TMSS02R0/KSB Date of Approval: August 6, 2006 G PAGE NO. 8 OF 12

TRANSMISSION MATERIALS STANDARD SPECIFICATION 58-TMSS-02, Rev. 0

6.0 DATA SCHEDULE

AIR CORE SERIES REACTOR 13.8 KV THROUGH 380kV

REFERENCE

SECTION NO. DESCRIPTION 'A' 'B' 'C'

4.2.1 Design and Construction

Damping/

Application

Tuning

Copper/

Coil conductor

Aluminum

Magnetic clearance (Minimum)

Reactor coil

Center to center (mm) *

Edge to edge (mm) *

Edge of reactor to metallic parts

*

not forming closed loops (mm)

Noise Level (dB) *

Maximum RIV at maximum line to

ground value of system voltage 250μV

(applicable for 230kV and 380kV only)

Complete dimension with drawing

* Yes/No

details provided

Reactor weight (kg) *

Design Ambient Temperature *

Class of Insulation *

Maximum temperature rise (ºC) *

Hot spot temperature (ºC) *

Supporting Insulator

(Manufacturer shall fill up column ‘B’ *

of 15-TMSS-01 data schedule)

4.2.2 Damping Reactors

Nominal System Voltage UN (kVrms)

Inductance per phase (mH)

Inductance tolerance *

Rated continuous current IN (A)

Overload current rating (A)

(suitable for capacitor bank *

overloading)

High frequency in-rush current

*

IIN (kApeak)

In-rush current frequency fib (Hz) *

58TMSS02R0/KSB Date of Approval: August 6, 2006 G PAGE NO. 9 OF 12

TRANSMISSION MATERIALS STANDARD SPECIFICATION 58-TMSS-02, Rev. 0

6.0 DATA SCHEDULE

AIR CORE SERIES REACTOR 13.8 KV THROUGH 380kV

REFERENCE

SECTION NO. DESCRIPTION 'A' 'B' 'C'

4.2.2 (continued)

High frequency out-rush current

*

IOUT (kApeak)

Out-rush current frequency fob (Hz) *

Rated short circuit withstand current

(kA) for 1 second

Thermal short-time overcurrent (kApeak)

Harmonic voltage distortion factor FhU *

BIL (kVpeak) *

Power frequency withstand voltage

*

(kVrms)

Switching Impulse Withstand Voltage

*

(BSL) if applicable (kVpeak)

Total Losses at 75°C and 110% rated

*

voltage (kW) at in-rush frequency

Q-factor at in-rush frequency *

Impedance at rated frequency (ohm) *

Thermal class of insulation *

Temperature rise °C *

Voltage drop (V) *

4.2.3 Tuning (Filter) Reactors

Nominal System Voltage UN (kVrms)

Rated inductance LA (mH) at tuning

frequency

Inductance tolerance for principal tap Max 5%

Tapping Range (%) (if applicable)

Inductance Step (%)

Number of steps

Inductance tolerance at other taps

Fundamental current rating IN (A)

Rated tuning frequency current IA

(A)

Rated tuning frequency fA (Hz)

58TMSS02R0/KSB Date of Approval: August 6, 2006 G PAGE NO. 10 OF 12

TRANSMISSION MATERIALS STANDARD SPECIFICATION 58-TMSS-02, Rev. 0

6.0 DATA SCHEDULE

AIR CORE SERIES REACTOR 13.8 KV THROUGH 380kV

REFERENCE

SECTION NO. DESCRIPTION 'A' 'B' 'C'

Rated short time current IKN (kA) and

*/* /

duration

Mechanical peak current (kApeak) *

Type of filter (band-pass/high pass)

BIL (kVpeak)

Power frequency withstand voltage

(kVrms)

Switching Impulse Withstand Voltage

(BSL) if applicable (kVpeak)

Total Losses at 75°C and 110% rated

*

voltage (kW) at tuning frequency

Q-factor at tuning frequency *

Impedance at rated frequency (ohm) *

Thermal class of insulation *

Temperature rise °C *

Voltage drop (V)

*

(for each tap and principal tap)

Power Network Single line Diagram

Yes/No

enclosed

4.4 Terminals (applicable for outdoor reactors)

Type *

Copper/

Material

Aluminum

No. of holes *

For Conductor Size (mm2)

For Conductor Material (Al or Cu)

Incoming conductor take-off

(vertical, horizontal, angle to horizontal)

ADDITIONAL INFORMATION

Approximate shipping Dimensions

*

(mm)

Approximate shipping weight (kg) *

58TMSS02R0/KSB Date of Approval: August 6, 2006 G PAGE NO. 11 OF 12

TRANSMISSION MATERIALS STANDARD SPECIFICATION 58-TMSS-02, Rev. 0

6.0 DATA SCHEDULE

AIR CORE SERIES REACTOR 13.8 KV THROUGH 380kV

A. ADDITIONAL TECHNICAL INFORMATION OR FEATURES TO BE FURNISHED BY

SEC:

B. ADDITIONAL SUPPLEMENTARY DATA OR FEATURES PROPOSED BY

BIDDER/VENDOR/SUPPLIER/CONTRACTOR:

C. OTHER PARTICULARS TO BE FILLED UP BY BIDDER/VENDOR/SUPPLIER/

CONTRACTOR:

Actual Manufacturer Vendor/Supplier/

of Equipment/Material Contractor

Name of the Company

Location and address

Name and Signature of

authorized

representative

and date

Official Seal/Stamp

of the Company & Date

58TMSS02R0/KSB Date of Approval: August 6, 2006 G PAGE NO. 12 OF 12

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- 12-TMSS-01-R1 Line HardwareDocument25 pages12-TMSS-01-R1 Line HardwareNauman Habib KhanNo ratings yet

- 43 TMSS 01 R0Document0 pages43 TMSS 01 R0renjithas2005No ratings yet

- 50 TMSS 02 R0Document0 pages50 TMSS 02 R0renjithas20050% (1)

- 50 TMSS 01 R0Document0 pages50 TMSS 01 R0renjithas2005No ratings yet

- P-192-94 WAPDA SPECIFICATION For 132kV CAPACITOR BANKSDocument12 pagesP-192-94 WAPDA SPECIFICATION For 132kV CAPACITOR BANKSHasnain AwanNo ratings yet

- PGCIL GIS Specification - Rev 4 (June-14)Document74 pagesPGCIL GIS Specification - Rev 4 (June-14)Travis Wood100% (1)

- 0048 Vivem175enDocument110 pages0048 Vivem175enArmando MaloneNo ratings yet

- 58-TMSS-01-R0 - Oil Immersed Reactor, 33kV To 380kVDocument32 pages58-TMSS-01-R0 - Oil Immersed Reactor, 33kV To 380kVsrifaceNo ratings yet

- 43TMSS01R1 Shunt Capacitor Bank, 13.8kV Through 380kVDocument16 pages43TMSS01R1 Shunt Capacitor Bank, 13.8kV Through 380kVMohamed NasrNo ratings yet

- 1-) 52-TMSS-01-Rev.00Document29 pages1-) 52-TMSS-01-Rev.00Orcun CalayNo ratings yet

- 52TMSS01R0Document29 pages52TMSS01R0Orcun CalayNo ratings yet

- 37-TMSS-02-R0 (LiveTankCB)Document28 pages37-TMSS-02-R0 (LiveTankCB)Jyoti SinghNo ratings yet

- Air Core Series Reactor Design ConsiderationsDocument4 pagesAir Core Series Reactor Design Considerationswaqas_a_shaikh4348No ratings yet

- 15TMSS01R1 Insulators, Station Post Type, Porcelain, IndoorOutdoor 69kv Through 380KvDocument15 pages15TMSS01R1 Insulators, Station Post Type, Porcelain, IndoorOutdoor 69kv Through 380KvDominic Mukesh KumarNo ratings yet

- 31 TMSS 06 R0Document30 pages31 TMSS 06 R0Nauman Habib KhanNo ratings yet

- 50-TMSS-01 (Rev 01)Document17 pages50-TMSS-01 (Rev 01)GardellNo ratings yet

- Nigam 11 KV Shunt CapacitorDocument13 pagesNigam 11 KV Shunt CapacitorSandeep SharmaNo ratings yet

- 33kV - Cap - Bank-SIKAP - Spec - FY 12-13 - 30.11.11-Cesc - 20 MVARDocument9 pages33kV - Cap - Bank-SIKAP - Spec - FY 12-13 - 30.11.11-Cesc - 20 MVARSatyajit RaiNo ratings yet

- Eaton PFC Guide Spec 16280BDocument7 pagesEaton PFC Guide Spec 16280Btareknakhle_16311323No ratings yet

- AVR SpecificationDocument18 pagesAVR Specificationmanu892007No ratings yet

- Technical Specification For Gas Insulated Metalclad 36kV Switchgear For Indoor ApplicationDocument30 pagesTechnical Specification For Gas Insulated Metalclad 36kV Switchgear For Indoor ApplicationS.M.Touhidur RahmanNo ratings yet

- Reactors - Specification: Indian StandardDocument9 pagesReactors - Specification: Indian StandardAustindaniel JoelsimeonNo ratings yet

- 35 TMSS 01 R0Document13 pages35 TMSS 01 R0AWNo ratings yet

- 57-TMSS-01-R0 Neutral Grounding Resister - 11kV To 34.5kVDocument11 pages57-TMSS-01-R0 Neutral Grounding Resister - 11kV To 34.5kVsrifaceNo ratings yet

- June 30, 2010Document56 pagesJune 30, 2010mohamedNo ratings yet

- Earthing Transformer: Engineering DepartmentDocument12 pagesEarthing Transformer: Engineering DepartmentVíctor CasadoNo ratings yet

- Spec Automatic Reactive Power CompensationDocument7 pagesSpec Automatic Reactive Power CompensationDolyNo ratings yet

- Cidco of Maharashtra Limited. SL - Pg.NoDocument7 pagesCidco of Maharashtra Limited. SL - Pg.Nordeepak99No ratings yet

- Ac Operated Automatic TR Unit WithDocument15 pagesAc Operated Automatic TR Unit WithTech1No ratings yet

- D) Mechanical Forces On Bushing TerminalsDocument1 pageD) Mechanical Forces On Bushing Terminalsimcoolmailme2No ratings yet

- Capacitor BankDocument28 pagesCapacitor BankPrakash Rout100% (1)

- 12 TMSS 10Document19 pages12 TMSS 10Fouad AliNo ratings yet

- GIS SubstationDocument232 pagesGIS Substationcrazy devil100% (1)

- 245 KV SF6 BreakerDocument33 pages245 KV SF6 Breakerpalash_monNo ratings yet

- Annexure 12 - Technical Specification 216kV LA R0 - 20190903173116Document16 pagesAnnexure 12 - Technical Specification 216kV LA R0 - 20190903173116Solar PowerNo ratings yet

- 12 TMSS 11Document29 pages12 TMSS 11Fouad AliNo ratings yet

- 15-TMSS-05 R.1Document20 pages15-TMSS-05 R.1wastazoheb_700349353No ratings yet

- 53 TMSS 01 R0 UnlockedDocument57 pages53 TMSS 01 R0 UnlockedGanesh DuraisamyNo ratings yet

- Va 26 22 00Document7 pagesVa 26 22 00adrian karl bonaNo ratings yet

- Technical Specification: Section-Series Reactor (400 KV CLASS)Document15 pagesTechnical Specification: Section-Series Reactor (400 KV CLASS)byjuvcNo ratings yet

- Earthing Transformer PDFDocument13 pagesEarthing Transformer PDFNelson SarriasNo ratings yet

- 10-Sdms-02 (Bare Copper Conductors)Document17 pages10-Sdms-02 (Bare Copper Conductors)Haytham BafoNo ratings yet

- 50 TMSS 03 R0Document0 pages50 TMSS 03 R0renjithas2005No ratings yet

- Materials System Specification: Saudi Aramco Desktop StandardsDocument13 pagesMaterials System Specification: Saudi Aramco Desktop StandardsEagle Spirit100% (1)

- Technical Specification OF 36 KV Gas Insulated Metal Clad Indoor Switchgear 1.1 ScopeDocument17 pagesTechnical Specification OF 36 KV Gas Insulated Metal Clad Indoor Switchgear 1.1 ScopeManohar PotnuruNo ratings yet

- 38smss4 Specification For Coupling Capacitor Voltage Transformer and or Carrier Coupler CapacitorDocument20 pages38smss4 Specification For Coupling Capacitor Voltage Transformer and or Carrier Coupler CapacitorengrandyNo ratings yet

- Transformer - Technical Specification 10 To 1600KVADocument48 pagesTransformer - Technical Specification 10 To 1600KVAsepta ibnuNo ratings yet

- Specification For 33KV VCB PDFDocument20 pagesSpecification For 33KV VCB PDFUma KantNo ratings yet

- 12 TMSS 10 R0Document0 pages12 TMSS 10 R0renjithas2005No ratings yet

- Volume-2 P2 - RRA & Breaker ChangeDocument381 pagesVolume-2 P2 - RRA & Breaker ChangeKaneNo ratings yet

- 2667 SpecDocument27 pages2667 SpecanuragpugaliaNo ratings yet

- June 30, 2010Document41 pagesJune 30, 2010TTPL ProjectsNo ratings yet

- Capacitor Bank DesignDocument31 pagesCapacitor Bank DesignRamani Ranjan Chiku100% (1)

- 15 TMSS 01 R0Document12 pages15 TMSS 01 R0Khaja MoinNo ratings yet

- Gems l-2d9 Cathodic Protection SystemsDocument15 pagesGems l-2d9 Cathodic Protection SystemsMochamad TaufikNo ratings yet

- Technical Specification of 12 KV Indoor Type Vacuum Circuit Breakers Against Tn-2593 1.0 ScopeDocument26 pagesTechnical Specification of 12 KV Indoor Type Vacuum Circuit Breakers Against Tn-2593 1.0 ScopePrintmeNo ratings yet

- Tss A 3 Transmission Lightning ArrestersDocument5 pagesTss A 3 Transmission Lightning ArrestersRegata Restu RespatiNo ratings yet

- Wave Trap Tech SpecsDocument13 pagesWave Trap Tech SpecsPrashant gaur100% (1)

- Balance of Plant Specifications For 12MW Archean PlantDocument47 pagesBalance of Plant Specifications For 12MW Archean Plantnagraj204No ratings yet

- Punch List - Juaymah Diversion - Rev53 - Week03 - 2024Document22 pagesPunch List - Juaymah Diversion - Rev53 - Week03 - 2024srifaceNo ratings yet

- Hvac 1675220171Document36 pagesHvac 1675220171srifaceNo ratings yet

- Adaptive Distance RelayingDocument25 pagesAdaptive Distance RelayingsrifaceNo ratings yet

- Classification Generator TrippingDocument6 pagesClassification Generator TrippingsrifaceNo ratings yet

- Bus Bar Differential Protection or Circulating Current ProtectionDocument2 pagesBus Bar Differential Protection or Circulating Current ProtectionsrifaceNo ratings yet

- Busbar Protection & Frame Leakage Protection Working PrincipleDocument3 pagesBusbar Protection & Frame Leakage Protection Working PrinciplesrifaceNo ratings yet

- Droop CTDocument2 pagesDroop CTsrifaceNo ratings yet

- Advantage of Neutral Grounding TransformerDocument2 pagesAdvantage of Neutral Grounding TransformersrifaceNo ratings yet

- Anti-Pumping Relay Diagram and Working Function ExplanationDocument2 pagesAnti-Pumping Relay Diagram and Working Function ExplanationsrifaceNo ratings yet

- Different Types of Current TransformersDocument3 pagesDifferent Types of Current TransformerssrifaceNo ratings yet

- CVT in Electrical Capacitive Voltage TransformerDocument5 pagesCVT in Electrical Capacitive Voltage TransformersrifaceNo ratings yet

- Pick Up Current Current Setting Plug Setting Multiplier and Time Setting Multiplier of RelayDocument6 pagesPick Up Current Current Setting Plug Setting Multiplier and Time Setting Multiplier of RelaysrifaceNo ratings yet

- Armature: Definition, Function and Parts (Electric Motor & Generator)Document6 pagesArmature: Definition, Function and Parts (Electric Motor & Generator)srifaceNo ratings yet

- Rating of AlternatorDocument3 pagesRating of AlternatorsrifaceNo ratings yet

- Course Outline of Applied Physics by Tahseen SanaDocument2 pagesCourse Outline of Applied Physics by Tahseen SanaTahseen SanaNo ratings yet

- Industrial Autoation and MechatronicsDocument17 pagesIndustrial Autoation and Mechatronicsambresh mirajkarNo ratings yet

- 1 Linear Eddy Current Brake For Railway Vehicles Using Dynamic BrakingDocument6 pages1 Linear Eddy Current Brake For Railway Vehicles Using Dynamic BrakingRohith MohanNo ratings yet

- PhysicsrealDocument11 pagesPhysicsreallodhishivansh2567No ratings yet

- Extraefi - Co.Uk Reset Problems: Ms1-Extra and Ms2-ExtraDocument8 pagesExtraefi - Co.Uk Reset Problems: Ms1-Extra and Ms2-Extraasser_salehNo ratings yet

- Experiment No. 01: Single Phase Half Wave Rectification With Inductive Load Psychomotor Skill Level: P4 Name: Roll NoDocument8 pagesExperiment No. 01: Single Phase Half Wave Rectification With Inductive Load Psychomotor Skill Level: P4 Name: Roll NoRana EhsanNo ratings yet

- Self Inductance of A CoilDocument13 pagesSelf Inductance of A Coilselena lee100% (2)

- SR Physics - Ipe - Important Questions: Very Short Answer QuestionsDocument8 pagesSR Physics - Ipe - Important Questions: Very Short Answer QuestionsRithik Reddy100% (1)

- Journal Jpe 18-3 249301697Document8 pagesJournal Jpe 18-3 249301697Carlos DPNo ratings yet

- Elect 3 PDFDocument22 pagesElect 3 PDFmudasirNo ratings yet

- Ch1 Current Volt Relationship Trasmission LineDocument84 pagesCh1 Current Volt Relationship Trasmission Linerathorsumit2006No ratings yet

- Transformer-Induced Low-Frequency Oscillations in The Series-Resonant Converter Ieee - Klesser - 1991Document12 pagesTransformer-Induced Low-Frequency Oscillations in The Series-Resonant Converter Ieee - Klesser - 1991cristian1961No ratings yet

- Become A Master ElectricianDocument7 pagesBecome A Master ElectricianShazmaniaNo ratings yet

- ISJR - Impulse TRDocument5 pagesISJR - Impulse TRmanjeetNo ratings yet

- Unit - Ii Switching TransientsDocument42 pagesUnit - Ii Switching Transientsshree100% (5)

- Resistor Capacitor Inductor: Presented by - Manish KumarDocument61 pagesResistor Capacitor Inductor: Presented by - Manish KumarDr-Eng Amir ElsafraweyNo ratings yet

- Top 258 PNDocument42 pagesTop 258 PNDavi Tavares100% (1)

- NUD3124-D (1) Transistor jw6Document10 pagesNUD3124-D (1) Transistor jw6Producciones3NNo ratings yet

- Ferrite Core Transformer Design Engineering and Technology 6Document10 pagesFerrite Core Transformer Design Engineering and Technology 6nedian_2006100% (2)

- An Enhanced High Order Sliding ModeDocument32 pagesAn Enhanced High Order Sliding ModeBadre BellaliNo ratings yet

- BKM Classes - EMIDocument25 pagesBKM Classes - EMIdny001No ratings yet

- Circuits and Systems For Efficient Portable-to-Portable Wireless ChargingDocument125 pagesCircuits and Systems For Efficient Portable-to-Portable Wireless ChargingBilisuma ZewduNo ratings yet

- Sensitivity Studies On Power Transformer Ferroresonance of 400kVDocument8 pagesSensitivity Studies On Power Transformer Ferroresonance of 400kV_FlyMan_No ratings yet

- Ept Lab ManualDocument100 pagesEpt Lab ManualSiddhuNo ratings yet

- Application of Duality For Derivation of Current Converter TopologiesDocument29 pagesApplication of Duality For Derivation of Current Converter Topologiestinhmaixatoi2006No ratings yet

- Novel ForwardFlyback Hybrid Bidirectional DCDC ConverterDocument7 pagesNovel ForwardFlyback Hybrid Bidirectional DCDC ConverterHsekum RamukNo ratings yet

- eCARS2x 2018 T3-1 Introduction Charging Methods EVs-1-4Document4 pageseCARS2x 2018 T3-1 Introduction Charging Methods EVs-1-4EulerNo ratings yet

- A Smart Monitoring of Faults in Power Transformers and Maintenance Based On Wi-FiDocument6 pagesA Smart Monitoring of Faults in Power Transformers and Maintenance Based On Wi-FiInnovative Research PublicationsNo ratings yet