Professional Documents

Culture Documents

Ground Sensor Ga Class 0940 Testing

Ground Sensor Ga Class 0940 Testing

Uploaded by

Humberto CruzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ground Sensor Ga Class 0940 Testing

Ground Sensor Ga Class 0940 Testing

Uploaded by

Humberto CruzCopyright:

Available Formats

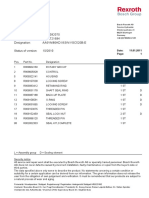

0940DB0101

September 2001

Data Bulletin Cedar Rapids, IA, USA

Ground-Censor® Ground-Fault

Protection System Field Test

Procedure

Type GA

Class 940

09403009

GA Sensor

Motor Control Circuit

or Shunt Trip of

Circuit Interrupter

N

Ø

Ø

Ø

Window Area

for Conductors

GA Relay GA Test Panel

Ground-Censor® Ground-Fault Protection System Field Test Procedure Bulletin No. 0940DB0101

Data Bulletin September 2001

DESCRIPTION Paragraph 230-95(c) of the National Electrical Code requires that all ground-

fault protection systems shall be performance tested when first installed.

Paragraph 230-95(a) requires that the maximum setting of equipment ground-

fault protection shall be 1200 amperes and the maximum time delay shall be

one second for ground-fault current equal to or greater than 3000 amperes.

The Square D Type GA equipment ground-fault protection system is field

adjustable and available with trip settings from 4 to 1200 amperes. Both

instantaneous and field adjustable time delay relays are available. Below is a

diagram showing the general layout and interrelation of the various ground-

fault system components.

09403007

Test Relay

Panel

A

B

Load

C

N

Neutral Circuit

Bonding Interrupting

Jumper Sensor Device

Figure 1: Equipment Grounding Conductor

The Type GA equipment ground-fault protection system utilizes a type GA

sensor. Except for two sensors (Type GA-250 and GA-375), a testing winding

is superimposed over the main winding. When this test winding is energized,

a current is induced in the main windings. The test winding current induces a

current in the main winding which results in circuit interrupter operation in less

than one second.

09403010

Figure 2: GA Sensor

Field testing is basically limited to only those tests which determine that the

installation is correct, the components of the ground-fault system are

operational, and the system operates as required by the National Electrical

Code.

Because of the many variables involved, field testing, as described in the

succeeding paragraphs, cannot be considered as an accurate check of the

calibration of the relay. If calibration tests are required, refer to the instruction

manual supplied with the ground-fault protection equipment.

2 © 1984–2001 Schneider Electric All Rights Reserved

Bulletin No. 0940DB0101 Ground-Censor® Ground-Fault Protection System Field Test Procedure

September 2001 Data Bulletin

PREPARATION FOR TEST Disconnect all power supplying the equipment and switch all main service

entrance disconnects off. Isolate the neutral from both supply and ground.

Measure insulation resistance of the neutral to ground to verify that no ground

connections exist downstream (load side) of the sensor.

Visually inspect the wiring system to confirm grounding connection at the

service equipment is upstream (line side) of the sensor and that the system

supply is grounded. Failure to do so will result in an inoperative ground-fault

protection system which will not be detected by the following tests. Also, be

certain that all load conductors pass through the sensor.

Reconnect all neutral and ground conductors.

FIELD TEST Before electrically testing this equipment, review the Instruction Manual

included with ground-fault protection equipment for more detailed information.

Testing should be accomplished with the power turned off ahead of the service

disconnect.

This field test requires a 120 Vac, 60 Hz power source capable of supplying a

minimum of 1 A. Additional power is required for the service disconnect electric

trip or shunt trip coil.

Depending upon whether the circuit is energized or de-energized, conduct the

electrical test as follows:

A. De-energized System—With Test Panel GA–12TPM*

GA Relay

1. This de-energized test will normally be conducted only at the time of

installation. Be certain that interconnections are in accordance with

appropriate wiring diagram (Figure 3 for electric or shunt trip coil

applications or Figure 4 for motor starter applications).

2. To test WITH TRIPPING, press the Test button. After relay times out,

GA handle will move to the tripped position and transfer of the output

contacts will be accomplished causing the circuit interrupting device

to trip, indicating proper operation of the ground-fault system.

NOTE: Do not hold the PUSH-TO-TEST button in for longer than two

seconds as damage to the ground-fault circuit may result.

3. (a) To reset, move the GA handle to the reset position.

(b) Reset the circuit interrupting device.

DANGER B. Energized System—With Test Panel GA–12TPM*

NOTE: Extreme caution must be taken if working on an energized system

HAZARD OF ELECTRIC SHOCK, BURN,

as contact with an energized component can result in electric shock and

OR EXPLOSION

burn.

When testing energized system, extreme

1. Follow the instructions shown on the GA–12TPM.

caution must be taken as contact with an

energized component can result in electric 2. If additional testing is necessary, allow 30 seconds before repeating

shock and burn. above procedures.

Failure to follow these instructions will *This system is designed specifically for testing only the GA–12TPM test

result in death or serious injury. panel.

Record the results and the test date on both the log at the bottom of the label

entitled “Installation Testing and Maintenance Instructions for Ground-fault

Systems” and the log appearing on the 3 x 5 card provided with this test

procedure. This 3 x 5 card is to be retained by those in charge of the building’s

electrical maintenance.

© 1984–2001 Schneider Electric All Rights Reserved 3

Ground-Censor® Ground-Fault Protection System Field Test Procedure Bulletin No. 0940DB0101

Data Bulletin August 2001

WIRING DIAGRAM

GA Sensor

09403006

+10% ØA

120 Vac/60 Hz

Momentary ØB

Test Switch –15%

(Shown in ØC

Normal Position)

N

Test Panel GA–12TPM

1 Sensor Pickup

3 T X1 Connections per Page 3

Test

Signal 5

Generator 7 Test Signal Out GA or GAT Relay

2 Control

4 Circuits

6

Shunt

8 Trip Coil

Normal By-pass Switch }To Control Power

Contacts Shown in

Normal (Reset) Position

Figure 3: Typical Shunt Trip Disconnect

GA Sensor

09403005

+10% ØA

120 Vac/60 Hz ØB

Momentary –15% ØC

Test Switch

(Shown in

N

Normal Position)

Test Panel GA–12TPM

Sensor Pickup

1 T X1 Connections per Page 3

Test 3

Signal 5 GAT Relay

Generator 7 Test Signal Out Control

2 Circuits

4

6

8

Contactor Coil

Normal By-pass Switch }To Control Power

Contacts Shown in

Normal (Reset) Position

Figure 4: Typical Contactor Disconnect

Square D Company

PO Box 3069

3700 Sixth St SW

Cedar Rapids IA 52406-3069 USA Electrical equipment should be serviced only by qualified personnel. No responsibility is assumed

1-888-SquareD (1-888-778-2733) by Schneider Electric for any consequences arising out of the use of this material.

www.SquareD.com Bulletin No. 0940DB0101 August 2001 Replaces 63020-272-01 dated 07/84.

4 © 1984–2001 Schneider Electric All Rights Reserved

You might also like

- Method Statement For Protection TestingDocument4 pagesMethod Statement For Protection TestingAfanda Rodgers100% (4)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Wind Power Plant Testing and CommissioningDocument4 pagesWind Power Plant Testing and CommissioningaNo ratings yet

- FAT Procedure of LV SwitchboardsDocument17 pagesFAT Procedure of LV SwitchboardsWilliam Wong100% (2)

- High Voltage On - Site Test GIS - InstructionDocument8 pagesHigh Voltage On - Site Test GIS - InstructionJairo MoralesNo ratings yet

- Lighting DesignDocument34 pagesLighting DesignMitiMehta2290% (29)

- Suzuki Shugun PDFDocument69 pagesSuzuki Shugun PDFPrashanthKumar33% (3)

- Manual A6VM80Document14 pagesManual A6VM80SergioCarlosQuispeJurado100% (1)

- The Complete Guide To Renovating and Improving Your PropertyDocument241 pagesThe Complete Guide To Renovating and Improving Your PropertyBozidar VasiljevicNo ratings yet

- Adwea/addc/aadc Standard: Sat-Aaa-Mv La (Rev.0-2015)Document3 pagesAdwea/addc/aadc Standard: Sat-Aaa-Mv La (Rev.0-2015)robert.blazevicNo ratings yet

- Lexx0604 01Document6 pagesLexx0604 01marinesparkyNo ratings yet

- Littelfuse SE-134C SE 135 DatasheetDocument1 pageLittelfuse SE-134C SE 135 DatasheetMarcialNo ratings yet

- Ideal Air Circuit Breaker (Jan - Mar 02)Document4 pagesIdeal Air Circuit Breaker (Jan - Mar 02)santhoshNo ratings yet

- Ground-Fault Detection, Charging Current and Neutral-Grounding Resistor SelectionDocument4 pagesGround-Fault Detection, Charging Current and Neutral-Grounding Resistor SelectionbbenartoNo ratings yet

- Grounding Equipment: Catalog 3000 March 2020Document32 pagesGrounding Equipment: Catalog 3000 March 2020destro57No ratings yet

- Adwea/addc/aadc Standard: Sat-Aaa-Swg-Mv-Accessories (Rev.0-2015)Document7 pagesAdwea/addc/aadc Standard: Sat-Aaa-Swg-Mv-Accessories (Rev.0-2015)robert.blazevicNo ratings yet

- RM 23Document36 pagesRM 23Jabita Aguilera CabreraNo ratings yet

- CT Testing LTDocument25 pagesCT Testing LTVijaya Kumar100% (2)

- Over Current and Earth Fault Protection Relay CommissioningDocument7 pagesOver Current and Earth Fault Protection Relay Commissioningkemu sindiNo ratings yet

- Engineering Encyclopedia: Ground System TestingDocument31 pagesEngineering Encyclopedia: Ground System TestingAhmed OusamaNo ratings yet

- Ground System TestingDocument31 pagesGround System TestingJellyn BaseNo ratings yet

- SG2008 0Document3 pagesSG2008 0Rigoberto UrrutiaNo ratings yet

- 182 03 - SGR&MDGFDocument32 pages182 03 - SGR&MDGFArturo Isidro Conde PérezNo ratings yet

- Clamp-On Ground Resistance Testing: Fall 2008 NETA WORLDDocument4 pagesClamp-On Ground Resistance Testing: Fall 2008 NETA WORLDAnonymous utxGVB5VyNo ratings yet

- Commissioning of Agl SystemsDocument26 pagesCommissioning of Agl SystemsTendayi K Chiureki100% (1)

- SP0510ver4-Earth System Site Injection TestDocument14 pagesSP0510ver4-Earth System Site Injection TestvipinrajNo ratings yet

- Wcica 2006 1714078Document4 pagesWcica 2006 1714078denny yusufNo ratings yet

- Restricted Earth Fault Protection Stability & Sensitivity Test Rev01Document9 pagesRestricted Earth Fault Protection Stability & Sensitivity Test Rev01Mohamed EldinNo ratings yet

- Instructions For Type KT Thermal-Magnetic Trip Unit Installation and Operation With K-Frame Series C Circuit BreakersDocument4 pagesInstructions For Type KT Thermal-Magnetic Trip Unit Installation and Operation With K-Frame Series C Circuit BreakersJussel Villafuerte AnamariaNo ratings yet

- Note To Spec. Writer: This System Must Be Only Installed On Bushings That HaveDocument6 pagesNote To Spec. Writer: This System Must Be Only Installed On Bushings That HaveRisdian Tetap OutsiderNo ratings yet

- Battery SpecificationDocument7 pagesBattery Specificationanirban pahariNo ratings yet

- Electronics Overview: Multiplex Drilling Control SystemsDocument12 pagesElectronics Overview: Multiplex Drilling Control SystemsMohammed DiabNo ratings yet

- 373-ELR Earth Leakage Protection Relay: DescriptionDocument3 pages373-ELR Earth Leakage Protection Relay: DescriptionWilmer SayasNo ratings yet

- The Importance of The NGRDocument58 pagesThe Importance of The NGRmelekimNo ratings yet

- MEGGER BGL Battery Ground Fault LocatorDocument2 pagesMEGGER BGL Battery Ground Fault Locatormeltemax1No ratings yet

- Short Circuit Current Rating CalculationsDocument21 pagesShort Circuit Current Rating Calculationsrettore84No ratings yet

- Testing SANS 10142 1 Edition 3Document7 pagesTesting SANS 10142 1 Edition 3lootNo ratings yet

- Section Cover Page: Section 26 08 30 Electrical Starting and Testing 2010-11-01 by Contractor's Testing AgentDocument31 pagesSection Cover Page: Section 26 08 30 Electrical Starting and Testing 2010-11-01 by Contractor's Testing Agentአረጋዊ ሐይለማርያምNo ratings yet

- Electrical Safety in Mines Brochure MiningDocument12 pagesElectrical Safety in Mines Brochure Mininghugodennis88No ratings yet

- Pre Commissioning Check List For Addressable Fire Alarm Voice Evacuation System Testing CommissioningDocument2 pagesPre Commissioning Check List For Addressable Fire Alarm Voice Evacuation System Testing CommissioningNaing Win TunNo ratings yet

- Digital Multiple: Loop / PSC / Earth TesterDocument16 pagesDigital Multiple: Loop / PSC / Earth TestermlutfimaNo ratings yet

- Installation Instructions: Analogue Instruments - Sealed and Ruggedised Meters 08X SeriesDocument2 pagesInstallation Instructions: Analogue Instruments - Sealed and Ruggedised Meters 08X SeriesMauricio GuanellaNo ratings yet

- 700 Series AC Dielectric Test SetsDocument7 pages700 Series AC Dielectric Test SetsKhoilnNo ratings yet

- Installation Instructions: Compact ANSI Switchboard Analogue MetersDocument4 pagesInstallation Instructions: Compact ANSI Switchboard Analogue MetersAllen BradleyNo ratings yet

- Installation Instructions: Compact ANSI Switchboard Analogue MetersDocument2 pagesInstallation Instructions: Compact ANSI Switchboard Analogue MetersMauricio GuanellaNo ratings yet

- NWFall08 GingrasDocument2 pagesNWFall08 GingrasumairbvsNo ratings yet

- 2instruction Manuals SG25-1150Document11 pages2instruction Manuals SG25-1150Claudio VazquezNo ratings yet

- Generic EICDocument6 pagesGeneric EICKuljinder VirdiNo ratings yet

- Power System Protection Earthing System: Substation Automation ProductsDocument17 pagesPower System Protection Earthing System: Substation Automation ProductsRobert MihayoNo ratings yet

- CL-NG-6460-002-057 Checklist For Protection Relays General Electrical Tests Rev01Document2 pagesCL-NG-6460-002-057 Checklist For Protection Relays General Electrical Tests Rev01Ahmed SabryNo ratings yet

- 6la+r - P546Document8 pages6la+r - P546Mohamed AwadNo ratings yet

- Dkg-207 Automatic Mains Failure and Remote Start UnitDocument27 pagesDkg-207 Automatic Mains Failure and Remote Start Unitemad alsarhanNo ratings yet

- 5 15kv SMG TD Bolted Cable Type Instuction Booklet 3778a74h01Document12 pages5 15kv SMG TD Bolted Cable Type Instuction Booklet 3778a74h01neranjansNo ratings yet

- 17th Edition Testing GuideDocument13 pages17th Edition Testing GuideOdoch Herbert0% (1)

- Ei GSM Ericsson) Bts atDocument5 pagesEi GSM Ericsson) Bts atGayan IndikaNo ratings yet

- Megger SVERKER-900 - Relay and Substation Test System - DatasheetDocument7 pagesMegger SVERKER-900 - Relay and Substation Test System - DatasheetISGENo ratings yet

- Why Neutral Grounding Resistors Need Continuous Monitoring.: CMK B.E (EEE)Document18 pagesWhy Neutral Grounding Resistors Need Continuous Monitoring.: CMK B.E (EEE)minjutNo ratings yet

- Electrical Safety in MinesDocument12 pagesElectrical Safety in Mineshugodennis88No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- DTC P0335 Crankshaft Position Sensor "A" CircuitDocument3 pagesDTC P0335 Crankshaft Position Sensor "A" CircuitErln LimaNo ratings yet

- Antenna Near Field Power EstimationDocument5 pagesAntenna Near Field Power EstimationJohn McDowallNo ratings yet

- Heat Loss From Oil Filled Tanks and Pipe LinesDocument2 pagesHeat Loss From Oil Filled Tanks and Pipe LinesAs'adNo ratings yet

- Ils ExamDocument36 pagesIls ExamzsifyounusNo ratings yet

- Linear Circuit Analysis Lab 2Document6 pagesLinear Circuit Analysis Lab 2M.HUSSAIN KHANNo ratings yet

- MCT 311 Lesson 3Document14 pagesMCT 311 Lesson 3Moussa SaidNo ratings yet

- Distilasi Kondisi 2 REV FIXDocument36 pagesDistilasi Kondisi 2 REV FIXM Ragil ZandisyahNo ratings yet

- Waste To Energy: Outlook For The PhilippinesDocument17 pagesWaste To Energy: Outlook For The PhilippinesSun TzuNo ratings yet

- Heterogeneous Catalysis Materials and Applications Moises Romolos Cesario Full ChapterDocument67 pagesHeterogeneous Catalysis Materials and Applications Moises Romolos Cesario Full Chaptertracy.zimmer564100% (16)

- Nashat Osman Abu Alhassan: Contact DetailsDocument3 pagesNashat Osman Abu Alhassan: Contact DetailsNashat OsmanNo ratings yet

- 9701 w08 QP 1Document16 pages9701 w08 QP 1Hubbak KhanNo ratings yet

- Constant Volume CycleDocument10 pagesConstant Volume CycleAditya Shiva AppallaNo ratings yet

- A Review On Floating Photovoltaic (FPV) Power Generation UnitsDocument16 pagesA Review On Floating Photovoltaic (FPV) Power Generation UnitsJefferson Viana MoralesNo ratings yet

- RE 10 030/04.99 External Gear Pumps Type G: 2, Series 4XDocument12 pagesRE 10 030/04.99 External Gear Pumps Type G: 2, Series 4XEnayat IzadiNo ratings yet

- Service Manual - : Issued in May 2008Document13 pagesService Manual - : Issued in May 2008tuttesoluzioniNo ratings yet

- Stepwise Simulation of Vacuum Transfer Line HydraulicsDocument6 pagesStepwise Simulation of Vacuum Transfer Line HydraulicsJose CantorNo ratings yet

- Chapter 1 Introduction - Fundamental Petroleum Engineering, UTMDocument90 pagesChapter 1 Introduction - Fundamental Petroleum Engineering, UTMNurzanM.Jefry100% (11)

- BC 2000 ManualDocument8 pagesBC 2000 ManualRoxana IoanaNo ratings yet

- Zamil Process Equipment Company Ltd.Document17 pagesZamil Process Equipment Company Ltd.Skorpio KonstelacioNo ratings yet

- Apho2018 Theory Q3 Thermoelectricity Solution & Marking SchemeDocument6 pagesApho2018 Theory Q3 Thermoelectricity Solution & Marking SchemempecthNo ratings yet

- MSC Dissertation Week LseDocument4 pagesMSC Dissertation Week LsePayToWriteAPaperMilwaukee100% (1)

- Mines SaftyDocument47 pagesMines SaftyMuwafaq2002No ratings yet

- Method Statement Template - Rev01Document18 pagesMethod Statement Template - Rev01Senthilkumaran VenkatasamyNo ratings yet

- Edexcel GCSE (9-1) Physics SP5 Light and The Electromagnetic Spectrum Test With Mark Scheme 16 - 17Document11 pagesEdexcel GCSE (9-1) Physics SP5 Light and The Electromagnetic Spectrum Test With Mark Scheme 16 - 17Paul Burgess100% (3)

- Daily - Fire Pump InspectionDocument4 pagesDaily - Fire Pump InspectionEmilezola L. ToruanNo ratings yet

- Lewmar Hardware Technical Reference PDFDocument9 pagesLewmar Hardware Technical Reference PDFjohnnydfred100% (1)