Professional Documents

Culture Documents

Sample Hazard Analysis Checklist

Sample Hazard Analysis Checklist

Uploaded by

hassankhalid.work10 ratings0% found this document useful (0 votes)

4 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

4 views1 pageSample Hazard Analysis Checklist

Sample Hazard Analysis Checklist

Uploaded by

hassankhalid.work1Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Introduction to Hazard & Risk Management eLearning

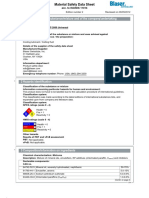

Sample Hazard Analysis Checklist Location_________________________________________________

1. Task Analysis Hazard and Risk Review 3. Training Y NA 5. Hazard Control

Date: ________________________________ Fall protection Eyes: Eye wash

Company: ____________________________ WHMIS Glasses/goggle Face shield

Employee: ____________________________ First Aid Ears: Plugs/muffs

Foreman: _____________________________ Powerline awareness Body:

Job Location: __________________________ Fire extinguisher Boots Hard hat

2. Pre-Job Evaluation Y NA Elevated work platform Fire retardant Gloves

Job scope understood Traffic control Traffic vest Chaps

Orientation completed TDG Welding helmet Knee pads

Safety equipment available Forklift Elevation: Guardrails

Proper tools available for task Explosive Actuated tools Fall protection Scaffolding

All isolation points identified Other training: Overhead prot. Signage

MSDSs available ___________________ Environment:

Job procedures reviewed ___________________ Job rotation Lighting

Environmental impact review ___________________ Ventilation Water

Permits required 4. Potential Hazards Housekeeping:

Safe work Eyes: Particle Clear work area Clean up

Hot work Ears: Loud noise Fire:

Confined spaces Respiratory: Inhalation Extinguisher Grounding

Energized electrical Body: UV protection Fire watch

Underground Cuts, sharp edges Additional Controls:

Waste disposal Repetitive motion Proper equipment for task

Critical lifting Pinch point Guards on moving parts

Other Overexertion Tag and lockout required

Housekeeping reviewed Pressure test and isolation

Awkward posture

Weather conditions considered Engineered trench box

Vibration

PPE requirements reviewed Utility locates

Elevation

Inspection checklists complete Hazard signage

Overhead hazards identified Falling material

Overhead work Communication devices

Excavation hazards reviewed Material handling equipment

Traffic control plan reviewed Elevated work

Shoring or cutbacks

Open holes secured Environment

Proper cranes

Slips, trips, falls assessed Cold stress

Proper rigging and tag lines

Proper equipment reviewed Heat stress Potable water

Lockout reviewed Poor access/egress Other:

Fire plan reviewed Inadequate lighting _________________________

Flammable storage reviewed Inadequate ventilation _________________________

Emergency plan reviewed Weather conditions _________________________

Other: Housekeeping _________________________

________________________ Debris, material, tools _________________________

________________________ Equipment _________________________

________________________ Reversing equipment _________________________

Moving equipment _________________________

Cranes

IF A MORE SPECIFIC JOB/TASK RISK ANALYSIS IS REQUIRED FILL IN BELOW

JOB HAZARDS CONTROL HAZARD CONTROLLED?

Worker Name Signature Worker Name Signature

Supervisor Name ________________________ Signature: ________________________________ Date : _______________

You might also like

- Apple Case StudyDocument2 pagesApple Case StudyJohn Pickle100% (2)

- Working Heights Risk Assessment TemplateDocument8 pagesWorking Heights Risk Assessment TemplatemahmoudmakladNo ratings yet

- W@H PermitDocument2 pagesW@H PermitJixtha SaintNo ratings yet

- Question 8 in A Chemical Process, Workers Use A Mixture Composed of Several LiquidDocument9 pagesQuestion 8 in A Chemical Process, Workers Use A Mixture Composed of Several LiquidManu K Joy0% (1)

- JSA For Concrete WorkDocument6 pagesJSA For Concrete Worklê ngọc tùng0% (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Occupational HazardsDocument24 pagesOccupational HazardsMahesh Boopathy100% (1)

- Hairdressing DLLDocument5 pagesHairdressing DLLeureca83% (12)

- Appendix A SPA FormDocument2 pagesAppendix A SPA FormMohamed HadjkacemNo ratings yet

- Toolbox TalkDocument3 pagesToolbox Talkshane.ramirez1980No ratings yet

- Pre-Job HES CheclkistDocument2 pagesPre-Job HES Checlkistshane.ramirez1980No ratings yet

- WP-HSE-010 (Bored Pile)Document1 pageWP-HSE-010 (Bored Pile)Armando AballeNo ratings yet

- Jsa Servicing of Rudder RoomDocument2 pagesJsa Servicing of Rudder RoomIlya BordonosovNo ratings yet

- Confined Space Entry PermitDocument2 pagesConfined Space Entry PermitEdwardNo ratings yet

- JsaDocument3 pagesJsaChinmoy MallickNo ratings yet

- Work Permit - HotworkDocument2 pagesWork Permit - Hotworkakhilsmenon.metroNo ratings yet

- Engineering Principles - PEO 19 2023Document54 pagesEngineering Principles - PEO 19 2023Christopher RedfernNo ratings yet

- Ti - PWHTDocument1 pageTi - PWHTchettikulangara8075817096No ratings yet

- Safety Officer - S Daily Hazard Inspection ReportDocument2 pagesSafety Officer - S Daily Hazard Inspection ReportyasirNo ratings yet

- Repair CableDocument2 pagesRepair CableMohammed AdnanNo ratings yet

- Dma - Task InstructionDocument2 pagesDma - Task InstructionOpuni EbenezerNo ratings yet

- Hot PermitDocument2 pagesHot Permitmohamed esmailNo ratings yet

- MSU Confined Space Entry Permit Fillable FormDocument1 pageMSU Confined Space Entry Permit Fillable FormArif FebriantoNo ratings yet

- Solar Hot Water System - Repair and ServiceDocument4 pagesSolar Hot Water System - Repair and Servicehari karanNo ratings yet

- Attachment 6 Job Observation / Task AnalysisDocument6 pagesAttachment 6 Job Observation / Task AnalysissaraNo ratings yet

- Hot Works PermitDocument1 pageHot Works PermitghodekartttNo ratings yet

- General Work PermitDocument2 pagesGeneral Work PermitGreg GenoveNo ratings yet

- Cold & Lifting Work PermitsDocument2 pagesCold & Lifting Work Permitsumar KhitabNo ratings yet

- BAWTP1A Project: (Sign Name & Position (Sign Name & PositionDocument8 pagesBAWTP1A Project: (Sign Name & Position (Sign Name & PositionAsad PrinceNo ratings yet

- JSA WorksheetspdDocument2 pagesJSA WorksheetspdNina SeimeniNo ratings yet

- JSA Loading & UnloadingDocument2 pagesJSA Loading & UnloadingSodikinNo ratings yet

- Permit To Work Application: Vistamarine Shipbuilding and Shiprepair IncDocument2 pagesPermit To Work Application: Vistamarine Shipbuilding and Shiprepair IncJezreel TolentinoNo ratings yet

- General Work PermitDocument2 pagesGeneral Work PermitJareem PeesNo ratings yet

- AMPTPL MHS Conv Belt ReplacementDocument2 pagesAMPTPL MHS Conv Belt ReplacementsamNo ratings yet

- Supervisor: Job/Location: Date: Work To Be Done: Task LocationDocument1 pageSupervisor: Job/Location: Date: Work To Be Done: Task LocationBala SingamNo ratings yet

- JSA Welding & GrindingDocument2 pagesJSA Welding & GrindingtaufikNo ratings yet

- Pre-Job Safety Assessment: Site InformationDocument2 pagesPre-Job Safety Assessment: Site Informationgueettaf faresNo ratings yet

- Hazard AnalysisDocument4 pagesHazard AnalysisFrancis Mayowa Ezekiel100% (1)

- Procédure Des Permis de TravailDocument48 pagesProcédure Des Permis de TravailMed Hillel Elarouci67% (3)

- LOTO Permit ACC JamulDocument1 pageLOTO Permit ACC JamulathulpcucekNo ratings yet

- 2 ConectionDocument2 pages2 ConectionMohammed AdnanNo ratings yet

- Work PermitDocument2 pagesWork PermitDoita Dutta ChoudhuryNo ratings yet

- Clearing RADocument24 pagesClearing RAStansilous Tatenda NyagomoNo ratings yet

- CV3038 Stair Tower Bracing JSEA REV.ADocument13 pagesCV3038 Stair Tower Bracing JSEA REV.ADavid ThomasNo ratings yet

- 001 - Safe Work Permit Form - R2Document2 pages001 - Safe Work Permit Form - R2John Renz Caling RetiroNo ratings yet

- ASA Form-Lifting Immersion 2Document2 pagesASA Form-Lifting Immersion 2Mostafa KhalifaNo ratings yet

- Job Hazard Environment Analysis - BenchmarkDocument8 pagesJob Hazard Environment Analysis - BenchmarkStansilous Tatenda Nyagomo100% (1)

- Wap2 Cp05a MS 0008 01 - Installation of PanelDocument6 pagesWap2 Cp05a MS 0008 01 - Installation of PanelElisco Pher SalmasanNo ratings yet

- FLHA'sDocument2 pagesFLHA'salthaherashNo ratings yet

- BAWTP1A Project: (Sign Name & Position (Sign Name & PositionDocument6 pagesBAWTP1A Project: (Sign Name & Position (Sign Name & PositionazerNo ratings yet

- 001 ABGJHA001 Installation of T-WallsDocument5 pages001 ABGJHA001 Installation of T-WallsALBILAL HSENo ratings yet

- Working Heights Risk Assessment TemplateDocument8 pagesWorking Heights Risk Assessment TemplateJUAN NICANOR ALIAGA GIRONNo ratings yet

- JSA-01 WeldingDocument7 pagesJSA-01 WeldingAlfian Novialdi LaksonoNo ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisAndhy DhannyNo ratings yet

- Work Permit - ExcavationDocument2 pagesWork Permit - Excavationakhilsmenon.metroNo ratings yet

- SA-924-2 Red PrintDocument2 pagesSA-924-2 Red PrintAbdus SamadNo ratings yet

- Job Safety Analysis WorksheetDocument5 pagesJob Safety Analysis WorksheetDean Delon NanlohyNo ratings yet

- 007ABGJHA007 Rebar WorkDocument4 pages007ABGJHA007 Rebar WorkALBILAL HSENo ratings yet

- FRM-2571-3016 Railroad Maintenance Safe Work PermitDocument4 pagesFRM-2571-3016 Railroad Maintenance Safe Work PermitdrakoniiNo ratings yet

- Work Permit - Ionizing Radiation: Work Should Not Commence Until Stages 1 To 5 Are CompletedDocument2 pagesWork Permit - Ionizing Radiation: Work Should Not Commence Until Stages 1 To 5 Are CompletedIonian TribeNo ratings yet

- JSA FormDocument4 pagesJSA Formandrew rachmanNo ratings yet

- Confined Space Entry Permit Rev 01Document3 pagesConfined Space Entry Permit Rev 01Neel Vadera100% (1)

- Pigment (1922)Document6 pagesPigment (1922)Waqar YounasNo ratings yet

- Safety Leadership As A Means For Safe and Sustainable ShippingDocument12 pagesSafety Leadership As A Means For Safe and Sustainable ShippingWallet BurnNo ratings yet

- Environment Health Safety Director in Huntsville AL Resume Ainsworth ThomasDocument2 pagesEnvironment Health Safety Director in Huntsville AL Resume Ainsworth ThomasAinsworthThomasNo ratings yet

- Bromocresol GreenDocument9 pagesBromocresol GreenNur ShahirahNo ratings yet

- Occupational Health and Safety in The Kitchen: Report With Chloe and SethDocument27 pagesOccupational Health and Safety in The Kitchen: Report With Chloe and SethJay Lord Santos SalvadorNo ratings yet

- SDS - Delo Gear TDL SAE 80W-90Document10 pagesSDS - Delo Gear TDL SAE 80W-90Georgina SuleNo ratings yet

- Officer - Sr. Officer - Compliance - Palmal Group of Industries - BdjobsDocument3 pagesOfficer - Sr. Officer - Compliance - Palmal Group of Industries - BdjobsTitas KhanNo ratings yet

- HSG38 Lighting at WorkDocument71 pagesHSG38 Lighting at WorkthelaceNo ratings yet

- BZ-09 Brand Management Coca Cola v1Document26 pagesBZ-09 Brand Management Coca Cola v1NobiaWahabNo ratings yet

- Laporan Pemakaian Farmasi EditDocument29 pagesLaporan Pemakaian Farmasi EditIebeth UtanNo ratings yet

- ISO 45001 2018 Audit ChecklistDocument16 pagesISO 45001 2018 Audit ChecklistSiv KumarNo ratings yet

- Training Program and ProcedureDocument126 pagesTraining Program and ProcedureAnousack KittilathNo ratings yet

- Assessment I - WHSRMDocument40 pagesAssessment I - WHSRMCindy Huang0% (4)

- Internship Report JackDocument85 pagesInternship Report JackdamarismagererNo ratings yet

- HSG 136Document53 pagesHSG 136MUHAMMAD KASHIF SiddiqiNo ratings yet

- SITXGLC001 Student TemplateDocument68 pagesSITXGLC001 Student TemplateMary Flor Agbayani KyosangshinNo ratings yet

- A3. Alka-M-Photometer Tablet - MSDSDocument7 pagesA3. Alka-M-Photometer Tablet - MSDSLailaNo ratings yet

- Ehs Fact SheetDocument2 pagesEhs Fact SheetBhavany SindhuNo ratings yet

- 1 Identification of The Substance/mixture and of The Company/undertakingDocument6 pages1 Identification of The Substance/mixture and of The Company/undertakingzaqNo ratings yet

- Company Profile UltrapureDocument37 pagesCompany Profile Ultrapurekhenette.ultrapureNo ratings yet

- Health and Safety ManualDocument118 pagesHealth and Safety ManualSergio González SilvaNo ratings yet

- Muhammad Nauman (CV) ...Document3 pagesMuhammad Nauman (CV) ...SajidNo ratings yet

- Fiji TCF MIIF Audit DocumentDocument14 pagesFiji TCF MIIF Audit Documentkrishan_cyprusNo ratings yet

- Workplace Emergency PreparednessDocument37 pagesWorkplace Emergency PreparednessEviok Anfone Zosa100% (2)

- Safety Data Sheet: Sodium CyanideDocument10 pagesSafety Data Sheet: Sodium CyanideGerson Castro RodriguezNo ratings yet

- GermX New MSDS PDFDocument6 pagesGermX New MSDS PDFJune AguinaldoNo ratings yet