Professional Documents

Culture Documents

Rigid Pavementfailures

Rigid Pavementfailures

Uploaded by

gowthamgr1202Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rigid Pavementfailures

Rigid Pavementfailures

Uploaded by

gowthamgr1202Copyright:

Available Formats

ROHINI COLLEGE OF ENGINEERING & TECHNOLOGY

5.1 Pavement Distress in Flexible and Rigid Pavements

Causes of Failures in Flexible Pavements

This may be due to settlement of any one of the components of the pavement.

Causes of Failure in subgrade soil:

• Excessive settlement of the subgrade of soil in the form of excessive undulations or

waves or corrugations on the pavement surface.

• Inadequate stability is due to excessive moisture, improper compaction and

inherent weakness of the soil

• Excessive stress application causes the deformation of the subgrade to be plastic

and unrecoverable resulting in subsidence of the subgrade

Causes of Failure of sub-base or base course:

• Settlement of layers due to internal readjustment of aggregates and movement of

wheel loads which results in loosening of compacted layer.

• Lack of stability due to inadequate thickness or poor mix of base or sub-base

course.

• Loss of base course materials

Causes of Failure of wearing course:

• Inferior or improper mix design

• Inadequate binder cement and Inferior quality of binder

TYPES OF FLEXIBLE PAVEMENT FAILURES

Alligator cracking or Map cracking (Fatigue)

This is a common type of failure of flexible pavements. This is also known as fatigue

failure. Followings are the primary causes of this type of failure.

• Relative movement of pavement layer material

• Repeated application of heavy wheel loads

• Swelling or shrinkage of subgrade or other layers due to moisture variation

Alligators on Road surface

CE8604 HIGHWAY ENGINEERING

ROHINI COLLEGE OF ENGINEERING & TECHNOLOGY

Figure 5.1.1 Map cracking

[Source: “Highway Engineering” by S.K.Khanna,C.E.G.Justo, Page: 494]

Consolidation of Pavement layers (Rutting)

Formation of ruts falls in this type of failure. A rut is a depression or groove worn

into a road by the travel of wheels.

This type of failure is caused due to following reasons.

• Repeated application of load along the same wheel path resulting longitudinal ruts.

• Wearing of the surface course along the wheel path resulting shallow ruts.

Rutting on Road Surface

Figure 5.1.2 Formation of Ruts

[Source: “Highway Engineering” by S.K.Khanna,C.E.G.Justo, Page: 494]

CE8604 HIGHWAY ENGINEERING

ROHINI COLLEGE OF ENGINEERING & TECHNOLOGY

Shear Failure Cracking

Shear failure causes upheaval of pavement material by forming a fracture or cracking.

Followings are the primary causes of shear failure cracking.

• Excessive wheel loading

• Low shearing resistance of pavement mixture

Shear Fail on Road Surface

Figure 5.1.3 Shear Failure Cracking

[Source: “Highway Engineering” by S.K.Khanna,C.E.G.Justo, Page: 494]

Longitudinal cracking

This types of cracks extents to the full thickness of pavement. The following are the

primary causes of longitudinal cracking.

• Differential volume changes in subgrade soil

• Settlement of fill materials

• Sliding of side slopes

Longitudinal Crack on Road Surface

CE8604 HIGHWAY ENGINEERING

ROHINI COLLEGE OF ENGINEERING & TECHNOLOGY

Frost heaving

Frost heaving causes upheaval of localized portion of a pavement. The extent of frost

heaving depends upon the ground water table and climatic condition.

Frost Crack on Road Surface

Figure 5.1.2 Failure due to Frost heaving

[Source: “Highway Engineering” by S.K.Khanna,C.E.G.Justo, Page: 495]

Lack of binding to the lower course

When there is lack of binding between surface course and underlying layer, some

portion of surface course looses up materials creating patches and potholes. Slippage

cracking is one form of this type of failure. Lack of prime coat or tack coat in

between two layers is the primary reason behind this type of failure.

Road Failure due to Lack of Binding

CE8604 HIGHWAY ENGINEERING

ROHINI COLLEGE OF ENGINEERING & TECHNOLOGY

Reflection cracking

This type of failure occurs, when bituminous surface course is laid over the existing

cement concrete pavement with some cracks. This crack is reflected in the same

pattern on bituminous surface.

Reflection Crack on Road Surface

Formation of waves and corrugation

Transverse undulations appear at regular intervals due to the unstable surface course

caused by stop- and-go traffic.

Wave Failure on Road Surface

Bleeding

Excess bituminous binder occurring on the pavement surface causes bleeding.

Bleeding causes a shiny, glass-like, reflective surface that may be tacky to the touch.

Usually found in the wheel paths.

Bleeding Failure on Road Surface

CE8604 HIGHWAY ENGINEERING

ROHINI COLLEGE OF ENGINEERING & TECHNOLOGY

Pumping

Seeping or ejection of water and fines from beneath the pavement through cracks is

called pumping.

Mud Pumping on Road Surface

CAUSES OF FAILURES OF RIGID PAVEMENTS

• Deficiencies in Pavement materials

• Structural Inadequacy

• Improper Construction and Maintenance

Deficiencies in Pavement materials

Causes are;

• Soft aggregates

• Dirty aggregates with silt and clay

• Low quality joint filler

• Poor sealer material

• Poor quality steel

• Improper use of cement for the specific region

Structural Inadequacy

Causes are;

• Poor subgrade soil and improper assessment of its strength

• Improper mix design approach

• Inadequate pavement thickness

• Incorrect spacing of joints

• Incorrect design of load transfer devices

• Absence of longitudinal hinge joints

• Long length of slab

• Non-existence of temperature steel

CE8604 HIGHWAY ENGINEERING

ROHINI COLLEGE OF ENGINEERING & TECHNOLOGY

• Deep foundation movements

Improper Construction and Maintenance

Causes:

• Poor workmanship in pavement and joint construction

• Poor surface finish

• Improper and insufficient curing

• Use of concrete mixes which are wet

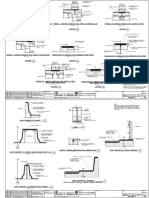

TYPICAL RIGID PAVEMENT FAILURES

• Scaling of Cement Concrete

• Shrinkage Cracks

• Warping Cracks

• Spalling of Joints

Scaling of cement concrete

Scaling of rigid pavement simply means, peeling off or flaking off of the top layer or

skin of the concrete surface. This may be due to the following reasons

• Improper mix design

• Excessive vibration during compaction of concrete

• Performing finishing operation while bleed water is on surface

Shrinkage cracks

Shrinkage Crack on Road Surface (a)

Formation of hairline shallow cracks on concrete slab is the indication of shrinkage

cracks. Shrinkage cracks develop on concrete surface during the setting & curing

operation. These cracks may form in longitudinal as well as in transverse direction.

CE8604 HIGHWAY ENGINEERING

ROHINI COLLEGE OF ENGINEERING & TECHNOLOGY

Shrinkage Crack on Road Surface (b)

Joint spalling

Joint spalling is the breakdown of the slab near edge of the joint. Normally it occurs

within 0.5 m of the joints. The common reasons for this defect are

• Faulty alignment of incompressible material below concrete slab

• Insufficient strength of concrete slab near joints

• Freeze-thaw cycle

• Excessive stress at joint due to wheel load

Joint Spalling Crack on Road Surface

Warping cracks

In hot weather, concrete slab tends to expand. Therefore the joints should be so

designed to accommodate this expansion. When joints are not designed properly, it

prevents expansion of concrete slab and therefore results in development of excessive

stress. This stress cause formation of warping cracks of the concrete slab near the

joint edge. This type of crack can be prevented by providing proper reinforcement at

the longitudinal and transverse joints. Hinge joints are generally used to relieve the

stress due to warping.

CE8604 HIGHWAY ENGINEERING

ROHINI COLLEGE OF ENGINEERING & TECHNOLOGY

Warping Crack on Road Surface

Pumping

When material present below the road slab ejects out through the joints or cracks, it is

called pumping. When soil slurry comes out it is called mud pumping.

The common reasons for this defect are

• Infiltration of water through the joints, cracks or edge of the pavement

forms soil slurry. Movement of heavy vehicles on pavement forces this

soil slurry to come out causing mud pumping.

• When there is void space between slab and the underlying base of sub-

grade layer

• Poor joint sealer allowing infiltration of water

• Repeated wheel loading causing erosion of underlying material

Pumping can also lead to formation of cracks. This is because; ejection of sub-grade

material below the slab causes loss of sub-grade support. When traffic movement

occurs at these locations, it fails to resist the wheel load due to reduction of sub-grade

support and develops cracks.

This type of defect can be identified when there is presence of base or sub-grade

material on the pavement surface close to joints or cracks.

Joint Soil Spillage on Road Surface

CE8604 HIGHWAY ENGINEERING

You might also like

- Pavement Deterioration and Its CausesDocument7 pagesPavement Deterioration and Its Causesخيرالله موسى نوافNo ratings yet

- Types of Portland Cement Concrete Pavement FailuresDocument3 pagesTypes of Portland Cement Concrete Pavement FailureshungrynomadphNo ratings yet

- Vigilance Corner List of RegistersDocument13 pagesVigilance Corner List of RegistersRitunjay JhaNo ratings yet

- Highway Maintenance & Evaluation Unit 5Document40 pagesHighway Maintenance & Evaluation Unit 5Amith SharmaNo ratings yet

- Presentation Pavement Failures 1507355219 83810Document21 pagesPresentation Pavement Failures 1507355219 83810Abhishek PawarNo ratings yet

- Presentation Pavement Failures 1507355219 83810Document26 pagesPresentation Pavement Failures 1507355219 83810suraj shetNo ratings yet

- Pavement FailuresDocument11 pagesPavement FailureskhuramNo ratings yet

- An Assignment On: Mahesh Gyawali Roll No.:017-1212Document9 pagesAn Assignment On: Mahesh Gyawali Roll No.:017-1212Mahesh GyawaliNo ratings yet

- Factors Causing Failures in Cement Concrete PavementsDocument3 pagesFactors Causing Failures in Cement Concrete PavementsAnonymous kB6xcEvLg100% (1)

- Highway Maintence, Repair and RehabilitationDocument32 pagesHighway Maintence, Repair and RehabilitationDIMariaAUnitedNo ratings yet

- Unit - 5Document69 pagesUnit - 5Jothi RamanathanNo ratings yet

- Homework: 2: AnswerDocument34 pagesHomework: 2: AnswerRobel TeweldeNo ratings yet

- Highway Group 2 1Document16 pagesHighway Group 2 1Johnrick LasquetyNo ratings yet

- 8 TR U3 Rigid Pavement Failures and Remidies 211121Document18 pages8 TR U3 Rigid Pavement Failures and Remidies 211121SAVYA SAACHEINNo ratings yet

- Highway Group 2Document17 pagesHighway Group 2Johnrick LasquetyNo ratings yet

- Types of Failures of Flexible PavementDocument9 pagesTypes of Failures of Flexible PavementReshmi RameshanNo ratings yet

- Chapter 2 HGWDocument48 pagesChapter 2 HGWSagni Oo ChambNo ratings yet

- Flexible Pavement: Click To Edit Master Title StyleDocument13 pagesFlexible Pavement: Click To Edit Master Title StyleFaisal SharifNo ratings yet

- Different Types of Failures of Flexible PavementDocument10 pagesDifferent Types of Failures of Flexible PavementRajesh KhadkaNo ratings yet

- Flexible Pavements Failures (Types, Causes & Treatments)Document26 pagesFlexible Pavements Failures (Types, Causes & Treatments)Baseer BaigNo ratings yet

- Concrete Road Repair SolutionDocument9 pagesConcrete Road Repair SolutionAbhishek Pawar100% (1)

- Study of Deformations That Occur On Road Surfaces and Develop Measures To Prevent ThemDocument5 pagesStudy of Deformations That Occur On Road Surfaces and Develop Measures To Prevent ThemResearch ParkNo ratings yet

- Chapter 2 Road Maintenance and RehabilitationDocument79 pagesChapter 2 Road Maintenance and Rehabilitationbini1221100% (1)

- Flexible Pavement: Click To Edit Master Title StyleDocument13 pagesFlexible Pavement: Click To Edit Master Title StyleFaisal SharifNo ratings yet

- Types of Failure: 1. Alligator Cracking of Flexible PavementsDocument12 pagesTypes of Failure: 1. Alligator Cracking of Flexible PavementsStalan JonathanNo ratings yet

- Construction Defects in ConcreteDocument13 pagesConstruction Defects in ConcreteManish KumarNo ratings yet

- Highway Maintainance, Repair and Rehabilitation: Defects in Pavement GROUP: 6 (ROLLNO: 64-75)Document22 pagesHighway Maintainance, Repair and Rehabilitation: Defects in Pavement GROUP: 6 (ROLLNO: 64-75)pasang ghisingNo ratings yet

- l3 - Defects in ConcreteDocument33 pagesl3 - Defects in ConcreteWajira Sanjaya PereraNo ratings yet

- Distress - Cement Concrete PavementDocument35 pagesDistress - Cement Concrete PavementSHIVANSH BAGHELNo ratings yet

- Failure of Flexible PavementsDocument8 pagesFailure of Flexible PavementskommelNo ratings yet

- DSR MicroprojectDocument7 pagesDSR Microprojectsgadekar634No ratings yet

- 1.3 Defects in Building-1Document88 pages1.3 Defects in Building-1zodiackiller1960sNo ratings yet

- Pavement Design, Its Types and Types of Failures in Pavement Their CausesDocument30 pagesPavement Design, Its Types and Types of Failures in Pavement Their CausesHari Shad OwNo ratings yet

- Civil ReportDocument7 pagesCivil Report33-Siddharth NairNo ratings yet

- 3 SurfacesDocument21 pages3 SurfacesKieth LadimoNo ratings yet

- CH-5 Reading MaterialDocument71 pagesCH-5 Reading MaterialNaty GriffinNo ratings yet

- Chapter 2HWIIIDocument89 pagesChapter 2HWIIIAmy MengistuNo ratings yet

- Pavement DistressDocument65 pagesPavement DistressPadma ShahiNo ratings yet

- Building Construction - VDocument40 pagesBuilding Construction - Vvivek krishna chinthakrindiNo ratings yet

- Building Defects Ali 03Document26 pagesBuilding Defects Ali 03Ali Azhar RajputNo ratings yet

- Types of Defects After and While ConsructionDocument10 pagesTypes of Defects After and While Consructionanon_831233388No ratings yet

- CT321 Module 3Document30 pagesCT321 Module 3Anthony NacaytunaNo ratings yet

- Failures in Rigid PavementsDocument7 pagesFailures in Rigid Pavementsshaky1978No ratings yet

- Behaviour and Performance of Concrete Sidewalks: by Balvant RajaniDocument4 pagesBehaviour and Performance of Concrete Sidewalks: by Balvant RajaniTherese AraymondNo ratings yet

- Distresses of Flexible PavementDocument9 pagesDistresses of Flexible PavementAnwar Bilind AbdulhafidhNo ratings yet

- Repairs of Concrete Roads: 1. Failure in Cement Concrete PavementsDocument10 pagesRepairs of Concrete Roads: 1. Failure in Cement Concrete PavementsPradeepLokhande100% (1)

- Flexible Pavement Distress PDFDocument25 pagesFlexible Pavement Distress PDFAravind Vadakapuram100% (1)

- Chapter 2 - Highway Maintenance and RehabilitationDocument77 pagesChapter 2 - Highway Maintenance and RehabilitationNathanNo ratings yet

- Defects in Concrete Monday, 18 November 2019: Title: DateDocument49 pagesDefects in Concrete Monday, 18 November 2019: Title: DateKrishnan SubraNo ratings yet

- Pavement RepairDocument15 pagesPavement RepairtoddlbyrnesNo ratings yet

- Failures in Paver BlockDocument5 pagesFailures in Paver BlockGaneshNo ratings yet

- Pavement DistressesDocument44 pagesPavement DistressesAsad W WaxeerNo ratings yet

- Failures in Rigid PavementsDocument6 pagesFailures in Rigid PavementsRajesh KhadkaNo ratings yet

- Types of Failures in Rigid Pavement: Bract'S Vishwakarma Institute of Information TechnologyDocument39 pagesTypes of Failures in Rigid Pavement: Bract'S Vishwakarma Institute of Information TechnologyNIKHIL DHAKNENo ratings yet

- Defects in BuildingDocument29 pagesDefects in BuildingDevendra KumarNo ratings yet

- Bridge Inspection and Maintenance-4Document21 pagesBridge Inspection and Maintenance-4vpmohammedNo ratings yet

- Pekan Ke 10 - Literatur - Jung Et Al - Fuctional Concrete Pavement RepairDocument13 pagesPekan Ke 10 - Literatur - Jung Et Al - Fuctional Concrete Pavement RepairChavid OktaviliantoNo ratings yet

- The Modern Bricklayer - A Practical Work on Bricklaying in all its Branches - Volume III: With Special Selections on Tiling and Slating, Specifications Estimating, EtcFrom EverandThe Modern Bricklayer - A Practical Work on Bricklaying in all its Branches - Volume III: With Special Selections on Tiling and Slating, Specifications Estimating, EtcRating: 5 out of 5 stars5/5 (1)

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- Asphaltic Plug Joint Details 1Document2 pagesAsphaltic Plug Joint Details 1mNo ratings yet

- EARIST Civil EngineeringDocument76 pagesEARIST Civil EngineeringNathaniel RoblesNo ratings yet

- 02cost Estimate 16+500 To 31+800 Final 7-24 ApplDocument333 pages02cost Estimate 16+500 To 31+800 Final 7-24 Applnitish JhaNo ratings yet

- Concrete ManualDocument122 pagesConcrete Manualashish ku bhatiaNo ratings yet

- NotaDocument38 pagesNotamuhammad zairiNo ratings yet

- HighwayDocument23 pagesHighwayRommel Carlo LargadoNo ratings yet

- PWA-IAN 101 Rev 1 - Amendments To QHDMDocument35 pagesPWA-IAN 101 Rev 1 - Amendments To QHDMMahmoud AlsuradiNo ratings yet

- Dynasty Company ProfileDocument28 pagesDynasty Company Profilejoseph mtalemwaNo ratings yet

- WSDOT Pavement GuideDocument553 pagesWSDOT Pavement GuidehaftamuTekle100% (4)

- Structural Design of Asphalt Pavement On Concrete BridgesDocument8 pagesStructural Design of Asphalt Pavement On Concrete Bridgesforismei5644No ratings yet

- Bernhard Hofko 1Document19 pagesBernhard Hofko 1Dem HasiNo ratings yet

- Compliance Report On DPR S-KDocument9 pagesCompliance Report On DPR S-KGurram Lakshmi NavakanthNo ratings yet

- Topic No.: 675-000-000 Materials Manual Superpave Mix Design Manual March 29, 2005Document56 pagesTopic No.: 675-000-000 Materials Manual Superpave Mix Design Manual March 29, 2005vinay rodeNo ratings yet

- Experimental Study of Bituminous Concrete Mix by Using Waste PlasticDocument6 pagesExperimental Study of Bituminous Concrete Mix by Using Waste PlasticIJSTENo ratings yet

- Typical Layers of A Flexible PavementDocument5 pagesTypical Layers of A Flexible Pavementruel galutanNo ratings yet

- Civil-Vii-pavement Materials and Construction (10cv763) - Question PaperDocument3 pagesCivil-Vii-pavement Materials and Construction (10cv763) - Question PaperNm100% (1)

- Flexible Pavement Design LiteratureDocument8 pagesFlexible Pavement Design Literaturejignesh shahNo ratings yet

- Section 17 Standard Notes: ManualDocument53 pagesSection 17 Standard Notes: Manualabdikarim_omarNo ratings yet

- Visvesvaraya Technological UniversityDocument21 pagesVisvesvaraya Technological Universityshubham shindeNo ratings yet

- Sup Mix PTC.11 PDFDocument69 pagesSup Mix PTC.11 PDFMohamed AbbassyNo ratings yet

- Constructing The Roadbed: 7-1 Soil As StructureDocument4 pagesConstructing The Roadbed: 7-1 Soil As StructureMark Darryl Mansay DeloriaNo ratings yet

- 8 - Flexible Pavement Design-AASHTO MethodDocument44 pages8 - Flexible Pavement Design-AASHTO MethodRobeam SolomonNo ratings yet

- TCVN9340 2012Document13 pagesTCVN9340 2012Hoàng Anh VũNo ratings yet

- Swayam Siddha Dash, Mahabir Panda - 2018 - Influence of Mix Parameters On Design of Cold Bituminous MixDocument10 pagesSwayam Siddha Dash, Mahabir Panda - 2018 - Influence of Mix Parameters On Design of Cold Bituminous MixmuhammadzilzaNo ratings yet

- Standard Specifications For Road and Bridge Works - 2073Document708 pagesStandard Specifications For Road and Bridge Works - 2073Mohit Kohli67% (3)

- IRC TechnicalDocument16 pagesIRC Technicalnadaf2100% (1)

- Meltem Çubuk, Metin Gürü, M. Kürsßat Çubuk: Article InfoDocument5 pagesMeltem Çubuk, Metin Gürü, M. Kürsßat Çubuk: Article InfoMarno03No ratings yet

- Construction and Building Materials: S.E. Paje, J. Luong, V.F Vázquez, M. Bueno, R. MiróDocument10 pagesConstruction and Building Materials: S.E. Paje, J. Luong, V.F Vázquez, M. Bueno, R. MiróAngie SuescúnNo ratings yet

- Specific Gravity of Coarse Aggregate & FINE AGGREGATEDocument39 pagesSpecific Gravity of Coarse Aggregate & FINE AGGREGATESANJAY KUMAR SINGH63% (8)