Professional Documents

Culture Documents

Moment Connection Design (Ver-6)

Moment Connection Design (Ver-6)

Uploaded by

Saurabh GuptaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Moment Connection Design (Ver-6)

Moment Connection Design (Ver-6)

Uploaded by

Saurabh GuptaCopyright:

Available Formats

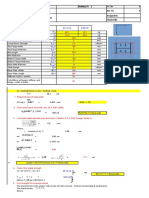

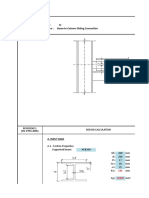

Extended End Plate Moment Connection

Job No : SA2-1763 Bldg. No : 1 Drawing No : E01 Connection No : SP-1 Ver. No. : ARUN 6.0

Controlling Forces

Major Axis Moment (Mw) = 90 kNm

Axial (Pw) = 25 kN Tension

Shear (Vw) = 80 kN

Connection Configuration Material Grade

Is it a Knee Connection = Yes End Plate Grade = A572 200000 N/mm2

Member needs connection Width Thk. Web thk. @ Haunch Another member Width

Flange = 200 6 mm 6 mm Flange Width = 175 mm

Web = 500 6 mm Web Depth = 400 mm

Design Method LRFD Bolt Grade = Gr. 8.8 Bolt Dia. (db) = 20 mm

End Plate Data

Connection Code = CON_E01

No. of Bolts in Comp. Side (nbc) = 6 Stiffener Input

Total No. of Bolts (nb) = 10 Stiff thick, tst= 10 mm

Stiffener = Yes Weld Stiff. to Flg. = 0.8 mm

End Plate Width (bp) = 200 mm Weld Stiff. to End Pl. = 1.3 mm

End Plate Thickness (tp) = 20 mm Weld Flange to End Pl. = 1.8 mm

Area of One Bolt (Ab) = 314.16 mm2 Weld Web to End Pl. = 1.6 mm

Shear / Bolt (Vb) = 8.00 kN Vu / nb

Shear Stress / Bolt (fv) = 25.46 N/mm2 Vb / Ab --- AISC 05

Allowable Tensile Stress (F t) = 600.00 N/mm2 1.3 Fnt - ( Fnt / Φ Fnv ) fv <= Fnt' --- J3-3a Design Summary

Description Stress Ratio

Beam Side Design Bolt Shear 0.08

1) Connection Design Moment Bolt Shear + Tension 0.59

Connection Design Moment Plate Bending 0.71

Moment due to Axial Force Ma = 6.33 kNm 0.5 P ( d - tf1 / 2 - tf2 / 2 ) Gusset Plate 0.19

Muc = 96.33 kNm Muc = 1.5 ( Mw1 + / - Ma ) for ASD Knee Web Shear 0.37

2) Connection Configuration 4) Calculate the No Prying Bolt Moment

pext = 122 mm Distance from top of flange to edge of connection plate

pfo = 62 mm Distance from center of Bolt to top flange top

pfi = 62 mm Distance from center of Bolt to top flange bottom

pb = 130 mm Pitch of Bolts

g= 100 mm Gage of Bolts

ho = 574 mm ( dB + Pfo ) OR ( dB + Pfo + Pb ) For CON-E04

h1 = 444 mm ( dB - tf1 - pfi ) OR ( dB + pfo ) For CON-E04

h2 = 0 mm ( h1 - pb ) OR ( dB - tf1 - pf1 ) For CON-E04

h3 = 0 mm h2 - pb

do = 571 mm ho - tf2 / 2 Bolt Diameter (db) = 20 mm

d1 = 441 mm h1 - tf2 / 2 Pt = 188.50 kN π db2 Ft / 4

d2 = 0 mm h2 - tf2 / 2 Ф Mnp = 286.14 kNm Ф [ 2 ( Pt ) Σ dn ]

d3 = 0 mm h3 - tf2 / 2

de = 50 mm Top Edge Distance 5) Determine the Required End Plate Thickness

s= 71 mm [ 0.5 sqrt ( bp g ) ]

3) Determine the required Bolt Diameter pfi = 62 mm If Pfi > S, then Pfi = S

db, reqd = 11.60 mm sqrt ( 2 Muc / π Ф Ft Σ dn ) Yp = 5139.96 Design Guide 16 page 32-38

tp, reqd = 14.11 mm

sqrt [ 1.11 gr ( Ф Mnp ) / Φb Fyp Yp ]

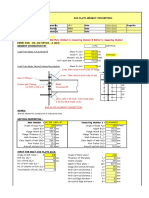

Stiffener Design Weld Details

Tension due to Moment, T1 = 180 kN Moment / Depth Stiff. to Flg. = 0.8 mm tst > 3/8 in.

Axial Tension, T1 = 13 kN Axial Force / 2 Stiff. to End Pl. = 1.3 mm tst > 3/8 in.

Net Tension per flange = 193 kN Flange to End Pl. = 1.8 mm

Actual Tension per bolt, T = 48 kN Tension / No. of bolts Web to End Pl. = 1.6 mm

Height of Stiffener, hst = 125 mm

Length of Stiffener, lst = 200 mm All weld thickness shown above are on both sides

Stiffener Stress f = 39 N/mm2 < 0.6Fy

Knee Web Shear

Total Shear, V = 193 kN Net Tension / flange h / tw = 83.3333333333 d / tw

Actual Shear stress, fv = 64 N/mm2 V / (d x tw) a/h= 1.25

Allow. Shear stress, Fv = 171 N/mm2 0.6 Fy Cv Kv = 8.2

Revised on 22nd Nov 2015

Cv = 0.92 AISC-05 (Chap-G)

Revised on 22nd Nov 2015

Please note the following points:

1) This sheet is for Extended end plate moment connections only.

2) This sheet is for column to rafter, column to column and rafter to rafter connections only.

3) This sheet should not be used to check the truss vertical & diagonal connections with either top / bottom chord.

4) The bolt capacities are considered for fully threaded bolts only.

5) It is to be noted that bolt capacity of A325 grade are bit higher than Gr. 8.8

6) It is often said that two threads must be exposed above a nut. The reason for this is that the first two threads

of a bolt are often poorly formed, and may not engage the nut properly. If they're not doing their share, the other

threads in the nut will be overloaded, and the nut may strip.

7) The thickness of the stiffener plate should not be less than the thickness of the web.

8) CJP denotes complete joint penetration weld.

9) The size of the stiffener is 125x200 for upto 36mm dia bolts and 150x250 for more than 36mm dia bolts.

ns with either top / bottom chord.

his is that the first two threads

re not doing their share, the other

more than 36mm dia bolts.

You might also like

- CBSE Happy Classrooms Workshop-FinalDocument54 pagesCBSE Happy Classrooms Workshop-FinalAman ambani100% (7)

- Padeye DesignDocument2 pagesPadeye DesignChiedu Okondu100% (2)

- Analysis and Design of Base Plate and Anchor Bolt For Pinned BaseDocument4 pagesAnalysis and Design of Base Plate and Anchor Bolt For Pinned BaseSunil PulikkalNo ratings yet

- Splice Plate - F13.5extDocument6 pagesSplice Plate - F13.5extManish DuggadNo ratings yet

- IA-PB-15141-CP-1Document37 pagesIA-PB-15141-CP-1Aamir SuhailNo ratings yet

- Design Calculation For Splice & Bottom Plate of Vertical Column MembersDocument4 pagesDesign Calculation For Splice & Bottom Plate of Vertical Column Membersinnovativekarthi100% (1)

- Cleat Angle ConnectionDocument3 pagesCleat Angle ConnectionSrishti Project ConsultantsNo ratings yet

- AISC2005 Anchor Bolt5 Pin Connection NewDocument6 pagesAISC2005 Anchor Bolt5 Pin Connection NewThuyTranNo ratings yet

- AISC2005 Anchor Bolt5 Pin Connection NewDocument6 pagesAISC2005 Anchor Bolt5 Pin Connection NewThuyTranNo ratings yet

- Design of Column SpliceDocument2 pagesDesign of Column SpliceAndro Rebuyas100% (1)

- Beam To Col. Pin Connection DesignDocument2 pagesBeam To Col. Pin Connection DesignmaheshbandhamNo ratings yet

- Fin Plate G3Document3 pagesFin Plate G3jiun yee chinNo ratings yet

- End-Plate-Design BS CodeDocument15 pagesEnd-Plate-Design BS CodeRaymond SabadoNo ratings yet

- 4.2.5.RS ConnectionDocument14 pages4.2.5.RS ConnectionAnh KyNo ratings yet

- PLATE Beam To BeamDocument73 pagesPLATE Beam To BeamKutty Mansoor100% (1)

- Design of Beam To Column SpliceDocument1 pageDesign of Beam To Column SpliceAndro RebuyasNo ratings yet

- Column Splice Detail (UC 203x203x86)Document2 pagesColumn Splice Detail (UC 203x203x86)Sudhakar KrishnamurthyNo ratings yet

- Design of Anchor Bolt Rev ADocument8 pagesDesign of Anchor Bolt Rev ACalvin TehNo ratings yet

- Design of Ss Connection v.2Document68 pagesDesign of Ss Connection v.2markespinoNo ratings yet

- ST ST ND ND RD 1 1 2 2 3 2Document3 pagesST ST ND ND RD 1 1 2 2 3 2jatin kalraNo ratings yet

- Idn - 2Document7 pagesIdn - 2Anh KyNo ratings yet

- Column Base Plate Design CalculationDocument3 pagesColumn Base Plate Design CalculationPilippenge Asanka Iraj LaknathaNo ratings yet

- U NT U NV U B: Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023 REV: 2Document14 pagesU NT U NV U B: Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023 REV: 2Anh KyNo ratings yet

- Beam To Beam-Fin PlateDocument105 pagesBeam To Beam-Fin PlateGasthuri Devi100% (1)

- End Plate Moment ConnectionDocument3 pagesEnd Plate Moment ConnectionIndustry Standard Structural DesignNo ratings yet

- 4.3.5.tap BS ConnectionDocument30 pages4.3.5.tap BS ConnectionAnh KyNo ratings yet

- UB406X178X85Document5 pagesUB406X178X85Uday UdmaleNo ratings yet

- HBDocument81 pagesHBFajar Alam HudiNo ratings yet

- Vertical Bracing With End Plate ConnectionDocument85 pagesVertical Bracing With End Plate ConnectionFajar Alam HudiNo ratings yet

- Header Plate ConnectionDocument7 pagesHeader Plate Connectioncretz2No ratings yet

- Connection - Foundation To PileDocument5 pagesConnection - Foundation To PileSandesh Kumar100% (1)

- Moment Connection With Haunch Flush EndDocument78 pagesMoment Connection With Haunch Flush EndFilip Risteski0% (1)

- Design of Shear Connection Between Beam To Beam:: As Per AISC 13 Edition (ASD)Document13 pagesDesign of Shear Connection Between Beam To Beam:: As Per AISC 13 Edition (ASD)rohitnrg0% (1)

- Beam Splice Connection With End Plate CalculationDocument76 pagesBeam Splice Connection With End Plate CalculationFajar Alam HudiNo ratings yet

- Stiffener Check For Pipe SupportDocument5 pagesStiffener Check For Pipe SupportSai Sushank100% (1)

- MB4 (Rafter To Corner Column)Document63 pagesMB4 (Rafter To Corner Column)Crystal JaneNo ratings yet

- BCF Type Local WF 400 (Full Weld)Document4 pagesBCF Type Local WF 400 (Full Weld)Puji KurniawanNo ratings yet

- 4.T&Angle-Brace Connection (M Project) - 0618Document49 pages4.T&Angle-Brace Connection (M Project) - 0618Omprakash KhodkeNo ratings yet

- Anchor Bolt-Pinned ConnectionDocument7 pagesAnchor Bolt-Pinned ConnectionThắngg TrịnhhNo ratings yet

- Idn - 3Document6 pagesIdn - 3Anh KyNo ratings yet

- Project: Sg038 (101) Description: Detail 19: Splice Joint For SB1Document8 pagesProject: Sg038 (101) Description: Detail 19: Splice Joint For SB1y2chongNo ratings yet

- Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023 REV: 2Document30 pagesProject Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023 REV: 2Anh KyNo ratings yet

- Type FRB1. 333 Ton Free Sliding Bearing DesignDocument8 pagesType FRB1. 333 Ton Free Sliding Bearing DesignAnkush SharmaNo ratings yet

- Moment Connection DesignDocument2 pagesMoment Connection DesignmaheshbandhamNo ratings yet

- Base PlateDocument6 pagesBase Platemonika sahuNo ratings yet

- AISC Connection 2nd Edition (4+2) Bolts Knee No UseDocument6 pagesAISC Connection 2nd Edition (4+2) Bolts Knee No UseTuấnThanhNo ratings yet

- Base Plate (ML Gambhir)Document6 pagesBase Plate (ML Gambhir)Prakash SinghNo ratings yet

- Aisc - LRFD Punch Plate Connection For HSSDocument14 pagesAisc - LRFD Punch Plate Connection For HSSJeff cadava0% (1)

- Fixed Base Plate Design-ECPLUS Design-ExampleDocument4 pagesFixed Base Plate Design-ECPLUS Design-ExampleNivarNo ratings yet

- Cover Plate Details: P, Row, F Row, P, FDocument19 pagesCover Plate Details: P, Row, F Row, P, Fy2chong100% (1)

- Anchor Bolt & Base Plate - H SectionDocument9 pagesAnchor Bolt & Base Plate - H SectionBalamuruganNo ratings yet

- Splice ConnectionDocument18 pagesSplice ConnectionAhmad Pooladi0% (1)

- Base Plate DesignDocument20 pagesBase Plate DesignMohammad KasimNo ratings yet

- End Plate Beam To Column Moment ConnectionDocument84 pagesEnd Plate Beam To Column Moment ConnectionNguyen Duc CuongNo ratings yet

- One Side Beam-Beam ConnectionDocument1 pageOne Side Beam-Beam Connectionsamon.itc2019No ratings yet

- Anchor Bolt - AISC ASDDocument7 pagesAnchor Bolt - AISC ASDameyyammaiNo ratings yet

- Design of Base Plate 1Document2 pagesDesign of Base Plate 1Andro RebuyasNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Analog Dialogue, Volume 48, Number 1: Analog Dialogue, #13From EverandAnalog Dialogue, Volume 48, Number 1: Analog Dialogue, #13Rating: 4 out of 5 stars4/5 (1)

- Ab Design-Grid PDDocument16 pagesAb Design-Grid PDSaurabh GuptaNo ratings yet

- 2012-M.TECH.-ME-METAL FARMING ANALYSIS-1st SEM.Document3 pages2012-M.TECH.-ME-METAL FARMING ANALYSIS-1st SEM.Saurabh GuptaNo ratings yet

- TaxCalc 2025Document21 pagesTaxCalc 2025Saurabh GuptaNo ratings yet

- 2012-M.TECH.-CSE-RESOURCE MANAGEMENT IN COMPUTER SYSTEMS-2nd SEM.Document2 pages2012-M.TECH.-CSE-RESOURCE MANAGEMENT IN COMPUTER SYSTEMS-2nd SEM.Saurabh GuptaNo ratings yet

- 2012-M.TECH.-CSE-MOBILE AND WIRELESS COMMUNICATION-2nd SEM.Document2 pages2012-M.TECH.-CSE-MOBILE AND WIRELESS COMMUNICATION-2nd SEM.Saurabh GuptaNo ratings yet

- USA Comparison6Document30 pagesUSA Comparison6api-27259648No ratings yet

- Text-Mindset Grit Learning and SRLDocument14 pagesText-Mindset Grit Learning and SRLapi-262774252No ratings yet

- MCQ ObgDocument3 pagesMCQ ObgSahil sharma100% (1)

- Factors Affecting The Tardiness of Selected Senior High Students of Queen Anne School Santa Rosa S.Y. 2010-2020Document11 pagesFactors Affecting The Tardiness of Selected Senior High Students of Queen Anne School Santa Rosa S.Y. 2010-2020Shai Anne Cortez100% (2)

- Improved WoodDocument17 pagesImproved WoodPavo33% (3)

- Aquatic ActivitiesDocument21 pagesAquatic ActivitiesJames Baryl GarceloNo ratings yet

- 11.9 - Anh Đ C - Task 1 - Writing 16 - EDITEDDocument3 pages11.9 - Anh Đ C - Task 1 - Writing 16 - EDITEDNickNo ratings yet

- Lesson Plan Using The Expression "Hope-Can" and "Wish-Could"by Jonavelle DG. PascualDocument4 pagesLesson Plan Using The Expression "Hope-Can" and "Wish-Could"by Jonavelle DG. Pascualjonavelle_25pascual100% (8)

- Final Module in Principles and Theories in Language AcquisitionDocument14 pagesFinal Module in Principles and Theories in Language AcquisitionChristel VirtucioNo ratings yet

- Bushman and Smith 2001Document97 pagesBushman and Smith 2001Rajesh VijayaraghavanNo ratings yet

- How Does Photodynamic Therapy WorkDocument13 pagesHow Does Photodynamic Therapy WorkLoredana VoiculescuNo ratings yet

- Seligram, IncDocument5 pagesSeligram, IncAto SumartoNo ratings yet

- Challenges Q&AsDocument12 pagesChallenges Q&AsRaneesha MadurawalaNo ratings yet

- English A Status ReportDocument3 pagesEnglish A Status ReportNataliasol07No ratings yet

- Gradsaleh PDFDocument257 pagesGradsaleh PDFميرفت بكرى نمرNo ratings yet

- Research Paper On Trade FacilitationDocument5 pagesResearch Paper On Trade Facilitationsgfdsvbnd100% (1)

- Market Structure - Single TableDocument24 pagesMarket Structure - Single TablegaurigopinathNo ratings yet

- B23 PDFDocument3 pagesB23 PDFHector SilvaNo ratings yet

- Hubungan Penerapan Metode Tim Dengan Rencana Asuhan Keperawatan Pasien Diruang Rawat Inap Sari Madonni 1Document9 pagesHubungan Penerapan Metode Tim Dengan Rencana Asuhan Keperawatan Pasien Diruang Rawat Inap Sari Madonni 1rogerNo ratings yet

- Intellectual CharismaDocument16 pagesIntellectual CharismaAlejandraNo ratings yet

- Me 321: Fluid Mechanics-I: Dr. A.B.M. Toufique HasanDocument12 pagesMe 321: Fluid Mechanics-I: Dr. A.B.M. Toufique HasanankitaNo ratings yet

- Ce511 Tabinas HW01Document18 pagesCe511 Tabinas HW01Kathlyn Kit TabinasNo ratings yet

- Teradata Interview QuestionsDocument11 pagesTeradata Interview QuestionsnarendrareddybanthiNo ratings yet

- Introduction About LinuxDocument81 pagesIntroduction About LinuxManwinder Singh GillNo ratings yet

- Nlsiu RepugnancyDocument25 pagesNlsiu Repugnancysimran yadavNo ratings yet

- Monica Ward ThesisDocument7 pagesMonica Ward Thesiscandacedaiglelafayette100% (2)

- R304 0307 Env HHDocument221 pagesR304 0307 Env HHsyamsundariitmiitmNo ratings yet

- Grade 6 - Crit A and D On Eye Spy Observational Drawing RubricDocument2 pagesGrade 6 - Crit A and D On Eye Spy Observational Drawing Rubricapi-185034533100% (1)

- DSF BoltsDocument2 pagesDSF BoltsSai SushankNo ratings yet