Professional Documents

Culture Documents

Loudspeaker-Repair-Procedure - Foam Surround-Replacement-Guide

Loudspeaker-Repair-Procedure - Foam Surround-Replacement-Guide

Uploaded by

404object524Copyright:

Available Formats

You might also like

- Practice Sheet Tammy TaylorDocument1 pagePractice Sheet Tammy TaylorStefanie Provoost75% (12)

- Pikler Triangle Plans WriteupDocument11 pagesPikler Triangle Plans WriteupMirna AL AmirNo ratings yet

- AG AFLX 1500 01 Splice REV5 0108Document2 pagesAG AFLX 1500 01 Splice REV5 0108kisan singh100% (1)

- Tips & Installation InstructionsDocument2 pagesTips & Installation InstructionsAthul T.NNo ratings yet

- Urban Birds Quail CallDocument1 pageUrban Birds Quail CallAnonymous zzPvaL89fGNo ratings yet

- Wrapped Rainbow Wall Art O'goDocument2 pagesWrapped Rainbow Wall Art O'goxandrakevNo ratings yet

- Bor Land 1968Document3 pagesBor Land 1968Aldrin DíazNo ratings yet

- Read Me First!: Resophonic and National Biscuit Installation GuideDocument3 pagesRead Me First!: Resophonic and National Biscuit Installation GuideJohn BrombaNo ratings yet

- Mini-Guide For Adjusting Oboe ReedsDocument2 pagesMini-Guide For Adjusting Oboe ReedsYick THNo ratings yet

- TentsDocument2 pagesTentsapi-320935985No ratings yet

- Invention Spotting For Defeathering FinalDocument6 pagesInvention Spotting For Defeathering FinalJohairah GumampongNo ratings yet

- Project 3 - Fabricated Mokume Band - Steven JacobDocument1 pageProject 3 - Fabricated Mokume Band - Steven Jacobmajope1966No ratings yet

- TentsDocument2 pagesTentsapi-321376162No ratings yet

- 110A2FB Packfilm Conversion - Reset Infinity Instant OptionsDocument2 pages110A2FB Packfilm Conversion - Reset Infinity Instant OptionsGustavo MejíaNo ratings yet

- Cavigelli 2007Document45 pagesCavigelli 2007Elemmire8No ratings yet

- Hose AssemblyDocument1 pageHose AssemblyScott SepperNo ratings yet

- TentsDocument2 pagesTentsapi-476870848No ratings yet

- How To Finish Your Plane With Aluminum Foil: Story and Photos by Bucky SheftallDocument6 pagesHow To Finish Your Plane With Aluminum Foil: Story and Photos by Bucky SheftallHeretic HarmoniesNo ratings yet

- Installing Tuning Pin Bushings - Revised PDFDocument11 pagesInstalling Tuning Pin Bushings - Revised PDFDénes SimonyiNo ratings yet

- Scrim MeshDocument2 pagesScrim MeshFreddom foreverNo ratings yet

- White : Smartcare Crack SealDocument2 pagesWhite : Smartcare Crack Sealpramodyad5810No ratings yet

- Before You Begin, Get Your Tools ReadyDocument16 pagesBefore You Begin, Get Your Tools ReadykdopsonNo ratings yet

- Read Me First!: Matrix Infinity VT Matrix Infinity Mic Blend Installation GuideDocument7 pagesRead Me First!: Matrix Infinity VT Matrix Infinity Mic Blend Installation GuideRofers Produções MusicaisNo ratings yet

- RepairsDocument7 pagesRepairsMauricio FemeniaNo ratings yet

- Metal Working For ElectronicsDocument1 pageMetal Working For ElectronicsJonathan ReaNo ratings yet

- No Picture Instruction: Packing Instruction Rollers Works Standard KH 8070 Page 03 Oct 2008Document2 pagesNo Picture Instruction: Packing Instruction Rollers Works Standard KH 8070 Page 03 Oct 2008jrc029No ratings yet

- EC TDS Resin Infusion Setup DiagramsDocument7 pagesEC TDS Resin Infusion Setup DiagramsDiego JimenezNo ratings yet

- Operating Instructions Cleaver A8Document2 pagesOperating Instructions Cleaver A8عبدالله الشهاريNo ratings yet

- Routing: Hinge MortisesDocument1 pageRouting: Hinge MortisesNormann StoehrNo ratings yet

- Tool Maintenance Demo Sandblaster - LexDocument4 pagesTool Maintenance Demo Sandblaster - Lexapi-639942719No ratings yet

- Kit 70160-903 - 02 Design Shimming Process: Medium Duty Series Eaton PumpsDocument1 pageKit 70160-903 - 02 Design Shimming Process: Medium Duty Series Eaton PumpsEng-Mohammed SalemNo ratings yet

- Project Pattern Leather Tissue Holder: Printing InstructionDocument5 pagesProject Pattern Leather Tissue Holder: Printing Instructionamirjoudeh22No ratings yet

- CMSFull PDFDocument1 pageCMSFull PDFAlexsandro Pereira Dos ReisNo ratings yet

- Trouble-Shooting Five Common Belt Conveyor Buildup ProblemsDocument2 pagesTrouble-Shooting Five Common Belt Conveyor Buildup ProblemsTamal Tanu RoyNo ratings yet

- Making A Desert Bag The Materials: When Buying FabricDocument3 pagesMaking A Desert Bag The Materials: When Buying FabricMarta Ma Calvo TrianaNo ratings yet

- How To Make A Loopy BowDocument7 pagesHow To Make A Loopy BowLina_22100% (6)

- Tape & Glue Process 2Document6 pagesTape & Glue Process 2ocolibriNo ratings yet

- Refelting The Keybed: Basic Step-by-Step ProceduresDocument11 pagesRefelting The Keybed: Basic Step-by-Step Proceduresaeroseb1No ratings yet

- AWKDocument14 pagesAWKMcMgNo ratings yet

- Editdocument15025560101098 PDFDocument6 pagesEditdocument15025560101098 PDFmimiscriNo ratings yet

- AQ Mistral Guide RoundDocument1 pageAQ Mistral Guide RoundgeorgelorinczNo ratings yet

- Vacumm PadDocument8 pagesVacumm PadRafael Mena FredesNo ratings yet

- Eris Morn Eris Morn: Papercraft MasksDocument9 pagesEris Morn Eris Morn: Papercraft MasksSam Charette100% (1)

- Section & U Value Calculation SheetDocument1 pageSection & U Value Calculation Sheetmain.engineerNo ratings yet

- InstructionsDocument4 pagesInstructionsGiocondo FracaroNo ratings yet

- Foredom: Buffing and Polishing GuideDocument3 pagesForedom: Buffing and Polishing Guidemaito2270No ratings yet

- Seymour Duncan Installing Humbucker CoversDocument3 pagesSeymour Duncan Installing Humbucker Coversshu2uNo ratings yet

- "Slimline" Pen & Pencil Kit Assembly Instructions: Item #Pkpen and PK-PCLDocument2 pages"Slimline" Pen & Pencil Kit Assembly Instructions: Item #Pkpen and PK-PCLTamara MarreroNo ratings yet

- Crosby Manual 6Document10 pagesCrosby Manual 6Salih KaderNo ratings yet

- The-Sportplane-Builder 5b70af45097c477a1b8b457aDocument4 pagesThe-Sportplane-Builder 5b70af45097c477a1b8b457ajacob ellyNo ratings yet

- Deep Margin ElevationDocument1 pageDeep Margin ElevationJazNo ratings yet

- Clipper Duet Manual 19 PDFDocument16 pagesClipper Duet Manual 19 PDFcarylangleyNo ratings yet

- SEPCO 14 Procedimiento para La InstalaciónDocument1 pageSEPCO 14 Procedimiento para La InstalaciónVictor Flores ResendizNo ratings yet

- Season: © 2016 Cruz Bay Publishing, IncDocument8 pagesSeason: © 2016 Cruz Bay Publishing, IncGeoNo ratings yet

- Ap Ta In: DIY Gopro Helmet Chin Mount. Custom MoldDocument9 pagesAp Ta In: DIY Gopro Helmet Chin Mount. Custom MoldMikeNo ratings yet

- Airmar Transducer In-Hull MountingDocument4 pagesAirmar Transducer In-Hull MountingvedranNo ratings yet

- Removing and Miking Treble Strings For Replacement: Basic Step-by-Step ProceduresDocument10 pagesRemoving and Miking Treble Strings For Replacement: Basic Step-by-Step Proceduresaeroseb1No ratings yet

- RG No. 2 Cavity Trays (DPCS) - SuperstructureDocument2 pagesRG No. 2 Cavity Trays (DPCS) - SuperstructureSofiaNo ratings yet

- Main - NPG MENS CONSTRUCTION MANUAL 5.29.19Document1 pageMain - NPG MENS CONSTRUCTION MANUAL 5.29.19Marriagr - MAF KnitsNo ratings yet

- Export Service Bulletin: Clunking Noise From The Trunk AreaDocument1 pageExport Service Bulletin: Clunking Noise From The Trunk AreaJavier DíazNo ratings yet

- DR Horton Homeowners ManualDocument80 pagesDR Horton Homeowners ManualLynn RaisesNo ratings yet

- ALC Lightweight PanelDocument10 pagesALC Lightweight PanelpenghzNo ratings yet

- Isoldesign Inn Acoustic DatasheetDocument6 pagesIsoldesign Inn Acoustic DatasheetSrushti ChawareNo ratings yet

- 7 Sisters of India - Sakshi JadhavDocument5 pages7 Sisters of India - Sakshi JadhavSakshi JadhavNo ratings yet

- Part B 1000 Bedded HostelDocument128 pagesPart B 1000 Bedded Hosteldhirajagarwal1989No ratings yet

- ES SMP Weekly Report WE 2012 08 16Document6 pagesES SMP Weekly Report WE 2012 08 16Yudi HamdaniNo ratings yet

- Module 1 - Costeffective Construction TechniquesDocument42 pagesModule 1 - Costeffective Construction TechniquesmUSINo ratings yet

- Final PortfolioDocument63 pagesFinal PortfolioSydney SeinaNo ratings yet

- Guide - Foam Glass InsulationDocument25 pagesGuide - Foam Glass InsulationChristian DoriaNo ratings yet

- Timber: Building Constrction and MaterailsDocument70 pagesTimber: Building Constrction and MaterailsWilliam Arpit SinghNo ratings yet

- ARCHITECTURAL DETAILS 2.1-ModelDocument1 pageARCHITECTURAL DETAILS 2.1-ModelRitesh LoharNo ratings yet

- Timberland Pro 6 in Hyperion XL Alloy Safety Toe Waterproof: FeaturesDocument1 pageTimberland Pro 6 in Hyperion XL Alloy Safety Toe Waterproof: FeaturesRenán SuárezNo ratings yet

- Design SheetDocument10 pagesDesign SheetPadma Shahi100% (1)

- Expanded Metal Wire MeshDocument2 pagesExpanded Metal Wire MeshMohammad TaherNo ratings yet

- IEA Solar Heating and CoolingDocument33 pagesIEA Solar Heating and CoolingJoana LuariNo ratings yet

- QS001 P03 QBC SH FS 4003Document1 pageQS001 P03 QBC SH FS 4003Athambawa RameesNo ratings yet

- Lower DoubleDocument4 pagesLower DoubleotNo ratings yet

- Shear Load ConnectorsDocument20 pagesShear Load ConnectorsPanagiotis StamatisNo ratings yet

- UGWT 1lack PDFDocument7 pagesUGWT 1lack PDFwali mustafaNo ratings yet

- How To Make Wall Moulding Design For Rooms Accent Wall Video TutorialsDocument15 pagesHow To Make Wall Moulding Design For Rooms Accent Wall Video Tutorialsdonaldwhale1151No ratings yet

- SBW-RFAMS-008-Submission of Method Statement For Plastering WorkDocument24 pagesSBW-RFAMS-008-Submission of Method Statement For Plastering WorkChamux skalNo ratings yet

- ReportDocument86 pagesReportJyothi KsNo ratings yet

- Fosroc Proofex Engage BrochureDocument9 pagesFosroc Proofex Engage BrochurecsaNo ratings yet

- Saudi Arabian Oil Company: Mechanical - Plumbing (Non-Electrical Utilities)Document5 pagesSaudi Arabian Oil Company: Mechanical - Plumbing (Non-Electrical Utilities)zarrar malikNo ratings yet

- Aavarna 2Document13 pagesAavarna 2SNEHA DEVARAJU100% (1)

- Single Storey Extension SMMDocument13 pagesSingle Storey Extension SMMFlokrida SherifiNo ratings yet

- 700 BMC QuestionDocument72 pages700 BMC QuestionrpsirNo ratings yet

- 3q CarpentryDocument3 pages3q CarpentryUnamono BenaventeNo ratings yet

- 101 Traps Puzles ND Challenges For D&DDocument14 pages101 Traps Puzles ND Challenges For D&DMatt KaiserNo ratings yet

Loudspeaker-Repair-Procedure - Foam Surround-Replacement-Guide

Loudspeaker-Repair-Procedure - Foam Surround-Replacement-Guide

Uploaded by

404object524Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Loudspeaker-Repair-Procedure - Foam Surround-Replacement-Guide

Loudspeaker-Repair-Procedure - Foam Surround-Replacement-Guide

Uploaded by

404object524Copyright:

Available Formats

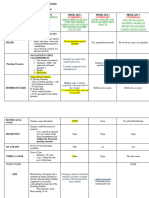

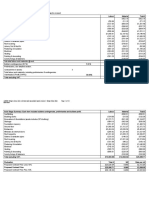

LOUDSPEAKER REPAIR PROCEDURE – SURROUND REPLACEMENT GUIDE

CONTENTS OF REPAIR KIT: scissors - VISIT “REPAIR CORNER” STEP 6 - FITTING SURROUND TO coil is central and there is no side to ensure you have found

- Glue Pen (Bostic EVA - MSDS PAGE @ qsr.net.au for a ‘’how BASKET - There are two methods scratchy sound ‘’sweet spot’’ where there is no

available at to’’ movie of doing this scaping or rubbing sound

http://www.qsr.net.au/msd.html)

STEP 5 - GLUEING SURROUND TO A) SHIM METHOD - if you do not

- Instruction Procedure

CONE wish to use the “shim” method

- Speaker Surrounds

STEP 3 - Very carefully scrape off

please skip this step.

- Note: Dust caps, Shims & Trims

old glue from cone. In some Prepare glue pen by removing

are an optional Purchase

instances you may need to peel cap and twisting body in a Remove dust cap by a single cut

Glue new dust cap into place

old glue off or gently rub old glue clockwise direction until glue is with a very sharp knife or scalpel

ITEMS TO BE SUPPLIED BY THE

Push surround onto basket until

with an Acetone/alcohol soaked visible at tip. NOTE - turning glue

REPAIRER

surround stops lifting Allow glue 4-

cotton buds. pen anti-clock wise will damage

- Rubbing Alcohol (Acetone or

8 hours to set. Remove tissue

glue pen.

similar) or sandpaper

from under cone if used

- Cotton Buds

Smear a bead of glue around top

-Tissues (for lifting cone) STEP 6 - Reglue trims to basket

of cone and inner edge of

- Stanley Knife or similar B) FEEL METHOD

surround. Replace cap Ensure there is absolutely no

- Soldering Iron & solder (Terminal contamination in voice coil gap

This method is slightly more

of Speaker) STEP 4 - FITTING SURROUND

difficult but does not involve

- Screw Driver or Drill (fixing Shim voice coil gap with shims –

removal of the dust cap

speaker) Check surround for correct fitting note cut shims to 4mm wide and

size. NOTE: The surround must fit must cover 75% of voice coil gap.

Apply glue to surround and

STEP 1 - Remove speaker from box Allow 4-8 hours for trims to dry.

neatly onto the cone. This is done Shims must be a gentle push fit

basket

by removing screw with screw by lifting up the cone and into voice coil gap

driver: Note wire polarity +/- with packing up with tissues. This is also

marker pen. Unsolder or pull a good time to check to see if

termination lugs off. Place the outer edge of the surround is

speaker on clean work bench. over lapping the screw holes.

Mark and cut screw holes with Place surround on cone in a

STEP 7 - REFIT SPEAKERS TO BOX

scissors. central position. Gently push Push centre if dust cap gently

Apply glue to basket and

surround onto the cone. down to centralise cone Make sure polarity is correct.

surround and push together

NOTE Polarity (+/-) must be fitted

Remove excess glue with a

the same for both speakers.

cotton bud

STEP 2 - Carefully remove Check impedance with

gasket/cardboard trims. These If the surround lifts slightly off the

multimeter, if all is satisfactory

parts can be reused (If damaged cone wait a few minutes until

To match surround angel with perform a sound check.

we do sell replacements).Scrape glue is tacky and push surround Push surround into basket

cone bend angle of surround to

off old glue from speaker frame back onto the cone. Repeat until If surround lifts off the basket push Congratulations you have

by pinching surround - Visit

with knife, finish off with surround is fully glued to the cone down gently every 3 (three) completed your repair!

“REPAIR CORNER” page @

sandpaper. Gently rub old glue minutes until glue holds

qsr.net.au for a ‘’how to’’ movie

Allow glue to set 4-8 hours

off with an Acetone/alcohol

Remove shims and push down

soaked cotton bud If outer diameter of surround is

gently on cone to ensure voice

too big trim to correct size with Gently push cone from side to

You might also like

- Practice Sheet Tammy TaylorDocument1 pagePractice Sheet Tammy TaylorStefanie Provoost75% (12)

- Pikler Triangle Plans WriteupDocument11 pagesPikler Triangle Plans WriteupMirna AL AmirNo ratings yet

- AG AFLX 1500 01 Splice REV5 0108Document2 pagesAG AFLX 1500 01 Splice REV5 0108kisan singh100% (1)

- Tips & Installation InstructionsDocument2 pagesTips & Installation InstructionsAthul T.NNo ratings yet

- Urban Birds Quail CallDocument1 pageUrban Birds Quail CallAnonymous zzPvaL89fGNo ratings yet

- Wrapped Rainbow Wall Art O'goDocument2 pagesWrapped Rainbow Wall Art O'goxandrakevNo ratings yet

- Bor Land 1968Document3 pagesBor Land 1968Aldrin DíazNo ratings yet

- Read Me First!: Resophonic and National Biscuit Installation GuideDocument3 pagesRead Me First!: Resophonic and National Biscuit Installation GuideJohn BrombaNo ratings yet

- Mini-Guide For Adjusting Oboe ReedsDocument2 pagesMini-Guide For Adjusting Oboe ReedsYick THNo ratings yet

- TentsDocument2 pagesTentsapi-320935985No ratings yet

- Invention Spotting For Defeathering FinalDocument6 pagesInvention Spotting For Defeathering FinalJohairah GumampongNo ratings yet

- Project 3 - Fabricated Mokume Band - Steven JacobDocument1 pageProject 3 - Fabricated Mokume Band - Steven Jacobmajope1966No ratings yet

- TentsDocument2 pagesTentsapi-321376162No ratings yet

- 110A2FB Packfilm Conversion - Reset Infinity Instant OptionsDocument2 pages110A2FB Packfilm Conversion - Reset Infinity Instant OptionsGustavo MejíaNo ratings yet

- Cavigelli 2007Document45 pagesCavigelli 2007Elemmire8No ratings yet

- Hose AssemblyDocument1 pageHose AssemblyScott SepperNo ratings yet

- TentsDocument2 pagesTentsapi-476870848No ratings yet

- How To Finish Your Plane With Aluminum Foil: Story and Photos by Bucky SheftallDocument6 pagesHow To Finish Your Plane With Aluminum Foil: Story and Photos by Bucky SheftallHeretic HarmoniesNo ratings yet

- Installing Tuning Pin Bushings - Revised PDFDocument11 pagesInstalling Tuning Pin Bushings - Revised PDFDénes SimonyiNo ratings yet

- Scrim MeshDocument2 pagesScrim MeshFreddom foreverNo ratings yet

- White : Smartcare Crack SealDocument2 pagesWhite : Smartcare Crack Sealpramodyad5810No ratings yet

- Before You Begin, Get Your Tools ReadyDocument16 pagesBefore You Begin, Get Your Tools ReadykdopsonNo ratings yet

- Read Me First!: Matrix Infinity VT Matrix Infinity Mic Blend Installation GuideDocument7 pagesRead Me First!: Matrix Infinity VT Matrix Infinity Mic Blend Installation GuideRofers Produções MusicaisNo ratings yet

- RepairsDocument7 pagesRepairsMauricio FemeniaNo ratings yet

- Metal Working For ElectronicsDocument1 pageMetal Working For ElectronicsJonathan ReaNo ratings yet

- No Picture Instruction: Packing Instruction Rollers Works Standard KH 8070 Page 03 Oct 2008Document2 pagesNo Picture Instruction: Packing Instruction Rollers Works Standard KH 8070 Page 03 Oct 2008jrc029No ratings yet

- EC TDS Resin Infusion Setup DiagramsDocument7 pagesEC TDS Resin Infusion Setup DiagramsDiego JimenezNo ratings yet

- Operating Instructions Cleaver A8Document2 pagesOperating Instructions Cleaver A8عبدالله الشهاريNo ratings yet

- Routing: Hinge MortisesDocument1 pageRouting: Hinge MortisesNormann StoehrNo ratings yet

- Tool Maintenance Demo Sandblaster - LexDocument4 pagesTool Maintenance Demo Sandblaster - Lexapi-639942719No ratings yet

- Kit 70160-903 - 02 Design Shimming Process: Medium Duty Series Eaton PumpsDocument1 pageKit 70160-903 - 02 Design Shimming Process: Medium Duty Series Eaton PumpsEng-Mohammed SalemNo ratings yet

- Project Pattern Leather Tissue Holder: Printing InstructionDocument5 pagesProject Pattern Leather Tissue Holder: Printing Instructionamirjoudeh22No ratings yet

- CMSFull PDFDocument1 pageCMSFull PDFAlexsandro Pereira Dos ReisNo ratings yet

- Trouble-Shooting Five Common Belt Conveyor Buildup ProblemsDocument2 pagesTrouble-Shooting Five Common Belt Conveyor Buildup ProblemsTamal Tanu RoyNo ratings yet

- Making A Desert Bag The Materials: When Buying FabricDocument3 pagesMaking A Desert Bag The Materials: When Buying FabricMarta Ma Calvo TrianaNo ratings yet

- How To Make A Loopy BowDocument7 pagesHow To Make A Loopy BowLina_22100% (6)

- Tape & Glue Process 2Document6 pagesTape & Glue Process 2ocolibriNo ratings yet

- Refelting The Keybed: Basic Step-by-Step ProceduresDocument11 pagesRefelting The Keybed: Basic Step-by-Step Proceduresaeroseb1No ratings yet

- AWKDocument14 pagesAWKMcMgNo ratings yet

- Editdocument15025560101098 PDFDocument6 pagesEditdocument15025560101098 PDFmimiscriNo ratings yet

- AQ Mistral Guide RoundDocument1 pageAQ Mistral Guide RoundgeorgelorinczNo ratings yet

- Vacumm PadDocument8 pagesVacumm PadRafael Mena FredesNo ratings yet

- Eris Morn Eris Morn: Papercraft MasksDocument9 pagesEris Morn Eris Morn: Papercraft MasksSam Charette100% (1)

- Section & U Value Calculation SheetDocument1 pageSection & U Value Calculation Sheetmain.engineerNo ratings yet

- InstructionsDocument4 pagesInstructionsGiocondo FracaroNo ratings yet

- Foredom: Buffing and Polishing GuideDocument3 pagesForedom: Buffing and Polishing Guidemaito2270No ratings yet

- Seymour Duncan Installing Humbucker CoversDocument3 pagesSeymour Duncan Installing Humbucker Coversshu2uNo ratings yet

- "Slimline" Pen & Pencil Kit Assembly Instructions: Item #Pkpen and PK-PCLDocument2 pages"Slimline" Pen & Pencil Kit Assembly Instructions: Item #Pkpen and PK-PCLTamara MarreroNo ratings yet

- Crosby Manual 6Document10 pagesCrosby Manual 6Salih KaderNo ratings yet

- The-Sportplane-Builder 5b70af45097c477a1b8b457aDocument4 pagesThe-Sportplane-Builder 5b70af45097c477a1b8b457ajacob ellyNo ratings yet

- Deep Margin ElevationDocument1 pageDeep Margin ElevationJazNo ratings yet

- Clipper Duet Manual 19 PDFDocument16 pagesClipper Duet Manual 19 PDFcarylangleyNo ratings yet

- SEPCO 14 Procedimiento para La InstalaciónDocument1 pageSEPCO 14 Procedimiento para La InstalaciónVictor Flores ResendizNo ratings yet

- Season: © 2016 Cruz Bay Publishing, IncDocument8 pagesSeason: © 2016 Cruz Bay Publishing, IncGeoNo ratings yet

- Ap Ta In: DIY Gopro Helmet Chin Mount. Custom MoldDocument9 pagesAp Ta In: DIY Gopro Helmet Chin Mount. Custom MoldMikeNo ratings yet

- Airmar Transducer In-Hull MountingDocument4 pagesAirmar Transducer In-Hull MountingvedranNo ratings yet

- Removing and Miking Treble Strings For Replacement: Basic Step-by-Step ProceduresDocument10 pagesRemoving and Miking Treble Strings For Replacement: Basic Step-by-Step Proceduresaeroseb1No ratings yet

- RG No. 2 Cavity Trays (DPCS) - SuperstructureDocument2 pagesRG No. 2 Cavity Trays (DPCS) - SuperstructureSofiaNo ratings yet

- Main - NPG MENS CONSTRUCTION MANUAL 5.29.19Document1 pageMain - NPG MENS CONSTRUCTION MANUAL 5.29.19Marriagr - MAF KnitsNo ratings yet

- Export Service Bulletin: Clunking Noise From The Trunk AreaDocument1 pageExport Service Bulletin: Clunking Noise From The Trunk AreaJavier DíazNo ratings yet

- DR Horton Homeowners ManualDocument80 pagesDR Horton Homeowners ManualLynn RaisesNo ratings yet

- ALC Lightweight PanelDocument10 pagesALC Lightweight PanelpenghzNo ratings yet

- Isoldesign Inn Acoustic DatasheetDocument6 pagesIsoldesign Inn Acoustic DatasheetSrushti ChawareNo ratings yet

- 7 Sisters of India - Sakshi JadhavDocument5 pages7 Sisters of India - Sakshi JadhavSakshi JadhavNo ratings yet

- Part B 1000 Bedded HostelDocument128 pagesPart B 1000 Bedded Hosteldhirajagarwal1989No ratings yet

- ES SMP Weekly Report WE 2012 08 16Document6 pagesES SMP Weekly Report WE 2012 08 16Yudi HamdaniNo ratings yet

- Module 1 - Costeffective Construction TechniquesDocument42 pagesModule 1 - Costeffective Construction TechniquesmUSINo ratings yet

- Final PortfolioDocument63 pagesFinal PortfolioSydney SeinaNo ratings yet

- Guide - Foam Glass InsulationDocument25 pagesGuide - Foam Glass InsulationChristian DoriaNo ratings yet

- Timber: Building Constrction and MaterailsDocument70 pagesTimber: Building Constrction and MaterailsWilliam Arpit SinghNo ratings yet

- ARCHITECTURAL DETAILS 2.1-ModelDocument1 pageARCHITECTURAL DETAILS 2.1-ModelRitesh LoharNo ratings yet

- Timberland Pro 6 in Hyperion XL Alloy Safety Toe Waterproof: FeaturesDocument1 pageTimberland Pro 6 in Hyperion XL Alloy Safety Toe Waterproof: FeaturesRenán SuárezNo ratings yet

- Design SheetDocument10 pagesDesign SheetPadma Shahi100% (1)

- Expanded Metal Wire MeshDocument2 pagesExpanded Metal Wire MeshMohammad TaherNo ratings yet

- IEA Solar Heating and CoolingDocument33 pagesIEA Solar Heating and CoolingJoana LuariNo ratings yet

- QS001 P03 QBC SH FS 4003Document1 pageQS001 P03 QBC SH FS 4003Athambawa RameesNo ratings yet

- Lower DoubleDocument4 pagesLower DoubleotNo ratings yet

- Shear Load ConnectorsDocument20 pagesShear Load ConnectorsPanagiotis StamatisNo ratings yet

- UGWT 1lack PDFDocument7 pagesUGWT 1lack PDFwali mustafaNo ratings yet

- How To Make Wall Moulding Design For Rooms Accent Wall Video TutorialsDocument15 pagesHow To Make Wall Moulding Design For Rooms Accent Wall Video Tutorialsdonaldwhale1151No ratings yet

- SBW-RFAMS-008-Submission of Method Statement For Plastering WorkDocument24 pagesSBW-RFAMS-008-Submission of Method Statement For Plastering WorkChamux skalNo ratings yet

- ReportDocument86 pagesReportJyothi KsNo ratings yet

- Fosroc Proofex Engage BrochureDocument9 pagesFosroc Proofex Engage BrochurecsaNo ratings yet

- Saudi Arabian Oil Company: Mechanical - Plumbing (Non-Electrical Utilities)Document5 pagesSaudi Arabian Oil Company: Mechanical - Plumbing (Non-Electrical Utilities)zarrar malikNo ratings yet

- Aavarna 2Document13 pagesAavarna 2SNEHA DEVARAJU100% (1)

- Single Storey Extension SMMDocument13 pagesSingle Storey Extension SMMFlokrida SherifiNo ratings yet

- 700 BMC QuestionDocument72 pages700 BMC QuestionrpsirNo ratings yet

- 3q CarpentryDocument3 pages3q CarpentryUnamono BenaventeNo ratings yet

- 101 Traps Puzles ND Challenges For D&DDocument14 pages101 Traps Puzles ND Challenges For D&DMatt KaiserNo ratings yet