Professional Documents

Culture Documents

Form No. HBK-PT-001 - Pressure Lines

Form No. HBK-PT-001 - Pressure Lines

Uploaded by

soorajCopyright:

Available Formats

You might also like

- Dosing Pumps ChecklistDocument2 pagesDosing Pumps ChecklistDeshan Sing100% (2)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- S.O.P For Hydro-Test: Ipcl-Gandhar Complex WI/GC-C&I/6.3/001 GC Maintenance Manual Hydro Test OF5Document7 pagesS.O.P For Hydro-Test: Ipcl-Gandhar Complex WI/GC-C&I/6.3/001 GC Maintenance Manual Hydro Test OF5கோகுல் இராNo ratings yet

- Hydro test-Method-StatementDocument20 pagesHydro test-Method-StatementGodwin A.udo-akanNo ratings yet

- LPG Metal CylinderDocument20 pagesLPG Metal Cylinderorode franklynNo ratings yet

- CHE572 Chapter 3 Fluidization PDFDocument31 pagesCHE572 Chapter 3 Fluidization PDFMuhd FahmiNo ratings yet

- 32-Ve-711 (Hydrostatic Test Procedure Piping - FT Gas) A11 PDFDocument5 pages32-Ve-711 (Hydrostatic Test Procedure Piping - FT Gas) A11 PDFMarlon Turner100% (1)

- Hydro Testing: Mode of MeasurementDocument6 pagesHydro Testing: Mode of Measurementruhuna013100% (1)

- Job Procedure of Post HydroDocument21 pagesJob Procedure of Post Hydroshahroz alamNo ratings yet

- Hydrotesting of PipelineDocument14 pagesHydrotesting of PipelineJWC Sales & Services :100% (1)

- Ies-Industrial Engineering Services: Hydraulic Test ReportDocument7 pagesIes-Industrial Engineering Services: Hydraulic Test ReportMD Shadikul Huq ShezanNo ratings yet

- P43-R00 - Hydrotesting of PipelineDocument14 pagesP43-R00 - Hydrotesting of PipelinesojeckNo ratings yet

- Upg Stream Pe100 HydrotestDocument4 pagesUpg Stream Pe100 Hydrotestqa/qcNo ratings yet

- Upg Stream Pe100 HydrotestDocument4 pagesUpg Stream Pe100 HydrotestMoezNo ratings yet

- Hydrostatic Test ChartDocument10 pagesHydrostatic Test ChartAnanda ShofwanNo ratings yet

- Determination of Friction Factor of Pipe Lines: Al Habeeb College of Engineering & TechnologyDocument3 pagesDetermination of Friction Factor of Pipe Lines: Al Habeeb College of Engineering & TechnologyAsrar UddinNo ratings yet

- Hydrotest Method Statement 12th Mar 2012-1Document21 pagesHydrotest Method Statement 12th Mar 2012-1sethu1091100% (21)

- Hydrotest Procedure - UTCL Hirmi AQC & PHDocument12 pagesHydrotest Procedure - UTCL Hirmi AQC & PHJOHnNo ratings yet

- Accumulator Draw Down TestDocument8 pagesAccumulator Draw Down Testadeelsn100% (4)

- Welltest Interpretation Report Analysis Name: Leaky Fault Company: Hydrocarbon Theater Company Field:Moliere Test Type: Standard Test Name / #: DST 3Document14 pagesWelltest Interpretation Report Analysis Name: Leaky Fault Company: Hydrocarbon Theater Company Field:Moliere Test Type: Standard Test Name / #: DST 3xsmartieNo ratings yet

- HydroDocument4 pagesHydroSamir ChaudharyNo ratings yet

- NITON - HYDRO TEST PROCEDURE - Rev.0Document6 pagesNITON - HYDRO TEST PROCEDURE - Rev.0PRASHANT100% (2)

- Hydrotest Procedure (Final) 16.11.21 VR CommentDocument6 pagesHydrotest Procedure (Final) 16.11.21 VR CommentZamri AhmadNo ratings yet

- SOP of PrehydrotestDocument7 pagesSOP of PrehydrotestVenkateswarlu BoduguNo ratings yet

- 30 Mainline Hydrotesting 111Document25 pages30 Mainline Hydrotesting 111rexNo ratings yet

- Hydrostatic Testing of Pipelines: The City of GalvestonDocument4 pagesHydrostatic Testing of Pipelines: The City of GalvestonMoezNo ratings yet

- Kind Attn: - MR - Vijaybhai Sub: - Yourrequirement of 12.5 M3/Hrsoftening Plant (Obr 200 M3) (CAPACITY - 12.5 M3/HR)Document6 pagesKind Attn: - MR - Vijaybhai Sub: - Yourrequirement of 12.5 M3/Hrsoftening Plant (Obr 200 M3) (CAPACITY - 12.5 M3/HR)Raol VarshabenNo ratings yet

- Procedure For Vacuum Test Procedure For Tube To Tubesheet Joint - Rev.0 - 07.09.2020Document6 pagesProcedure For Vacuum Test Procedure For Tube To Tubesheet Joint - Rev.0 - 07.09.2020Aravind AravindNo ratings yet

- Hydro TestDocument12 pagesHydro TestEndika Alfan100% (2)

- Item Inspected: CBLT-TPI-00F-186-12623Document16 pagesItem Inspected: CBLT-TPI-00F-186-12623Zulfadli RaniNo ratings yet

- Kind Attn: - MR - Vijaybhai Sub: - Yourrequirement of 12.5 M3/Hr Softening Plant (Obr 200 M3) (CAPACITY - 12.5 M3/HR)Document6 pagesKind Attn: - MR - Vijaybhai Sub: - Yourrequirement of 12.5 M3/Hr Softening Plant (Obr 200 M3) (CAPACITY - 12.5 M3/HR)Raol VarshabenNo ratings yet

- Hydrotest Method Statement 12th Mar 2012 1Document21 pagesHydrotest Method Statement 12th Mar 2012 1Saut Maruli Tua Samosir100% (1)

- STS Qac Sop 003 - 1 Hydrotest & Pnuematic Test ProcedureDocument11 pagesSTS Qac Sop 003 - 1 Hydrotest & Pnuematic Test Proceduremohd as shahiddin jafriNo ratings yet

- Hydro-Test FormatDocument1 pageHydro-Test Formatjasbir.iitdNo ratings yet

- Condenser Flood TestDocument14 pagesCondenser Flood Testsrigirisetty208100% (2)

- Test Report 2Document14 pagesTest Report 2Rogelio PabuayaNo ratings yet

- Ebs1 Aaaa00 Saqa Prqa 0006Document10 pagesEbs1 Aaaa00 Saqa Prqa 0006SERT-QA/QC- BUZNo ratings yet

- Data HydrotestDocument4 pagesData HydrotestRichard AdolfNo ratings yet

- HRSG HydrotestDocument7 pagesHRSG Hydrotestshubham raj bhawsarNo ratings yet

- Avalon New PlantDocument4 pagesAvalon New PlantAhmed S ElalaftyNo ratings yet

- Hydrotest Report LOADING DOCKDocument3 pagesHydrotest Report LOADING DOCKmhafidz.projectNo ratings yet

- Hydrotesting Procedure Rev 4Document6 pagesHydrotesting Procedure Rev 4Rajesh K PillaiNo ratings yet

- Procedure For Condenser Flood Test and Vacuum Tightness TestDocument13 pagesProcedure For Condenser Flood Test and Vacuum Tightness TestJackSparrow86No ratings yet

- 4008-Pi-Pro-001 - 0 - Piping Hydrotest Procedure-1Document8 pages4008-Pi-Pro-001 - 0 - Piping Hydrotest Procedure-1Randu WatangNo ratings yet

- Hidrostatic Test Procedure: Hafizul - HasrolDocument7 pagesHidrostatic Test Procedure: Hafizul - HasrolRafique MunirNo ratings yet

- Hydrostatic Test Procedure R0Document10 pagesHydrostatic Test Procedure R0mhajaraswadi2023No ratings yet

- Hydrostatic Test Procedure Site RevDDocument23 pagesHydrostatic Test Procedure Site RevDBhavani Prasad100% (8)

- RWT Ro188. (500 LPH)Document5 pagesRWT Ro188. (500 LPH)Rinse Water TechnologyNo ratings yet

- Hydro Test Procedure: ItemDocument6 pagesHydro Test Procedure: Itemtulasirao.nammiNo ratings yet

- Hydrostatic Testing ProceduresDocument2 pagesHydrostatic Testing Proceduresomar sadiqNo ratings yet

- Generic Well Test ProgramDocument9 pagesGeneric Well Test Programinyene ekereNo ratings yet

- Mabel Engineers Private Limited Hydro Test ProcedureDocument5 pagesMabel Engineers Private Limited Hydro Test ProcedureQuality TeamNo ratings yet

- 16.4. Mmf-Ax-bx-Vdr-0014 Hydrotest Procedure Rev. 0Document28 pages16.4. Mmf-Ax-bx-Vdr-0014 Hydrotest Procedure Rev. 0Fauzan Rusmayadi Reharder100% (1)

- Heder Boiler Room Hydrolic TestDocument5 pagesHeder Boiler Room Hydrolic TestMD Shadikul Huq ShezanNo ratings yet

- Procedure For The Pressure Mechanical Integrity Test For The Casing of An Underground Hydrocarbon Storage WellDocument3 pagesProcedure For The Pressure Mechanical Integrity Test For The Casing of An Underground Hydrocarbon Storage Wellvirnando nainggolanNo ratings yet

- Hydrostatic Test Report: Form No.: JFC-F-QC-06, Form Rev. No.: 0, Form Released Date: 01-Jan-17 Page 1 of 1Document1 pageHydrostatic Test Report: Form No.: JFC-F-QC-06, Form Rev. No.: 0, Form Released Date: 01-Jan-17 Page 1 of 1Dhaval ChitreNo ratings yet

- Emrsn HTP 001 A1Document7 pagesEmrsn HTP 001 A1Karthik BanariNo ratings yet

- Leak Test Proc DemoDocument7 pagesLeak Test Proc DemoroeslanteaNo ratings yet

- MS For Pressure Test-ReDocument9 pagesMS For Pressure Test-Reanishdev6No ratings yet

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AFrom EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANo ratings yet

- BBS Compound WallDocument4 pagesBBS Compound WallsoorajNo ratings yet

- BCS StairDocument3 pagesBCS StairsoorajNo ratings yet

- BCS FootingDocument10 pagesBCS FootingsoorajNo ratings yet

- SAADIYAT ITP (THERMAL Block Works) NEWDocument5 pagesSAADIYAT ITP (THERMAL Block Works) NEWsoorajNo ratings yet

- 01-SAADIYAT ITP (Concreting For Super Structure)Document12 pages01-SAADIYAT ITP (Concreting For Super Structure)soorajNo ratings yet

- Itsupport@apbava - Com 20100208 142544Document63 pagesItsupport@apbava - Com 20100208 142544soorajNo ratings yet

- 05-Saadiyat Itp (Backfilling) VillaDocument4 pages05-Saadiyat Itp (Backfilling) VillasoorajNo ratings yet

- 4 - Cable TraysDocument1 page4 - Cable TrayssoorajNo ratings yet

- Itsupport@apbava - Com 20100208 143105Document42 pagesItsupport@apbava - Com 20100208 143105soorajNo ratings yet

- Itsupport@apbava - Com 20100208 142443Document5 pagesItsupport@apbava - Com 20100208 142443soorajNo ratings yet

- Itsupport@apbava - Com 20100208 143400Document1 pageItsupport@apbava - Com 20100208 143400soorajNo ratings yet

- Itsupport@apbava - Com 20100208 143325Document1 pageItsupport@apbava - Com 20100208 143325soorajNo ratings yet

- Aluminium FramesDocument4 pagesAluminium FramessoorajNo ratings yet

- Break Down ScheduleDocument4 pagesBreak Down SchedulesoorajNo ratings yet

- Form # 1 - ICS 1 Electric Motor (HV LV)Document3 pagesForm # 1 - ICS 1 Electric Motor (HV LV)soorajNo ratings yet

- Form # 4 - ICS 4 Cable Installation Below GroundDocument1 pageForm # 4 - ICS 4 Cable Installation Below GroundsoorajNo ratings yet

- System Safety Rule-OETCDocument107 pagesSystem Safety Rule-OETCsoorajNo ratings yet

- 12 Battery & Battery ChargerDocument1 page12 Battery & Battery ChargersoorajNo ratings yet

- 1 - Cable Installation Above GroundDocument2 pages1 - Cable Installation Above GroundsoorajNo ratings yet

- 8 Cube Test ReportDocument1 page8 Cube Test ReportsoorajNo ratings yet

- 6 - Neutral Earth ResistorDocument1 page6 - Neutral Earth ResistorsoorajNo ratings yet

- 16 Checklist For PaintingDocument2 pages16 Checklist For PaintingsoorajNo ratings yet

- 18 Check List For Wall & Flooring TileDocument1 page18 Check List For Wall & Flooring Tilesooraj100% (1)

- 15 Checklist For PlasteringDocument1 page15 Checklist For PlasteringsoorajNo ratings yet

- 17 Checklist For Roof WaterproofingDocument2 pages17 Checklist For Roof WaterproofingsoorajNo ratings yet

- 2 - Cable JointDocument1 page2 - Cable JointsoorajNo ratings yet

- 7 Bar Bending ScheduleDocument1 page7 Bar Bending SchedulesoorajNo ratings yet

- 9 Post Pour Inspection ReportDocument1 page9 Post Pour Inspection ReportsoorajNo ratings yet

- 1 RfiDocument1 page1 RfisoorajNo ratings yet

- 0015-BS 142 - Section 4.1 - 1984Document12 pages0015-BS 142 - Section 4.1 - 1984soorajNo ratings yet

- DynamicDocument34 pagesDynamicCentral HydraulicsNo ratings yet

- FMRC 1311 Centrifugal Fire Pumps (Horizontal Split-Case Type) PDFDocument28 pagesFMRC 1311 Centrifugal Fire Pumps (Horizontal Split-Case Type) PDFdyıldırım_4100% (1)

- Sensor ProblemsDocument20 pagesSensor ProblemsSalih AbbasNo ratings yet

- PavlosPoutachidis CMGDocument24 pagesPavlosPoutachidis CMGPaulos PoutachidisNo ratings yet

- IPR - Leslie ThompsonDocument57 pagesIPR - Leslie ThompsonGabriel Cevallos100% (1)

- AE 11 Chapter 5 Group 1Document69 pagesAE 11 Chapter 5 Group 1Daphne Ba-ang GamoNo ratings yet

- Unit 1. Fluid and Fluid PropertiesDocument9 pagesUnit 1. Fluid and Fluid PropertiesNirmal PatelNo ratings yet

- Series 58 Modular Version ISO 4401-03 P Max: Bar Max (See Table of Performances)Document4 pagesSeries 58 Modular Version ISO 4401-03 P Max: Bar Max (See Table of Performances)francis_15inNo ratings yet

- APL Math FunctionsDocument4 pagesAPL Math FunctionsAshish KotwalNo ratings yet

- Safety ValvesDocument65 pagesSafety Valvesserturkbudak_3448365No ratings yet

- Perforating Innovations (SafeJet)Document18 pagesPerforating Innovations (SafeJet)Saulo Caceres LaricoNo ratings yet

- Paradeep Refinery Project: A Sunrise Project For A Sunshine FutureDocument79 pagesParadeep Refinery Project: A Sunrise Project For A Sunshine Futuremujeebtalib50% (2)

- CCI - Casing - Gas CompressorDocument30 pagesCCI - Casing - Gas CompressorManuel ChNo ratings yet

- 11th Physics YearlyDocument2 pages11th Physics Yearlydadhich.archit15No ratings yet

- Compact, Continuous, Effective: BOLL Automatic FiltersDocument7 pagesCompact, Continuous, Effective: BOLL Automatic FiltersFer SevanNo ratings yet

- Course Plan KNJ1053-Sem2!10!11Document2 pagesCourse Plan KNJ1053-Sem2!10!11Ash MochiNo ratings yet

- l4 The Clausius-UpadiDocument8 pagesl4 The Clausius-UpadiMarcos Sánchez MartínezNo ratings yet

- IS 5422-Turbine Type Generator-Gen Spec PDFDocument15 pagesIS 5422-Turbine Type Generator-Gen Spec PDFmailbkraoNo ratings yet

- Rotating Control Device 18in PsDocument2 pagesRotating Control Device 18in PsnagarajakumarNo ratings yet

- Chapter 5Document25 pagesChapter 5roxy8marie8chanNo ratings yet

- Smartlay™ Pipeline Flooding Prevention System: Service Data SheetDocument2 pagesSmartlay™ Pipeline Flooding Prevention System: Service Data Sheetnagid_428463849No ratings yet

- Pgs-13-49-13-64 Detector de TemperaturaDocument16 pagesPgs-13-49-13-64 Detector de TemperaturaBrunophb2012No ratings yet

- Plate Heat ExchangerDocument1 pagePlate Heat ExchangerBvitalize100% (1)

- Litreature Review 1. History of Water Pumping Technolgy: Water Pumps How Potable Water Is To The Top of The BuildingDocument6 pagesLitreature Review 1. History of Water Pumping Technolgy: Water Pumps How Potable Water Is To The Top of The BuildingAwanyo thomasNo ratings yet

- YS 11 Laboratory Activity # 1Document3 pagesYS 11 Laboratory Activity # 1HECTOR ARANTE TANNo ratings yet

- 5 Presentation Corac Downhole Pressure BoostingDocument19 pages5 Presentation Corac Downhole Pressure BoostingEdwin VargadNo ratings yet

- Ge F-Class Gek111895Document2 pagesGe F-Class Gek111895gopinathsampath0% (2)

- Physics Terms & DefinitionDocument11 pagesPhysics Terms & DefinitionSniper Grenade100% (1)

- Particle Model of Matter MUSA GCSEDocument16 pagesParticle Model of Matter MUSA GCSEMethyl OrangeNo ratings yet

Form No. HBK-PT-001 - Pressure Lines

Form No. HBK-PT-001 - Pressure Lines

Uploaded by

soorajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Form No. HBK-PT-001 - Pressure Lines

Form No. HBK-PT-001 - Pressure Lines

Uploaded by

soorajCopyright:

Available Formats

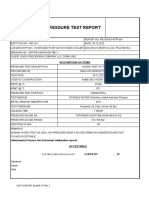

Form No.

HBK-PT-001 CLIENT: CONSULTANT: CONTRACTOR:

HYDROTEST REPORT

PWA

Pressure Line

Project Name: DN001- Bani Hajer North Project

Test No. : A65385 Date: 23/11/2019 Time: 9:00 am

C/C=

Face to Face (F/F) =

Chamber/MH No: N/A

Chainage:

Pipe Diameter (mm): 1200mm GRP

Pipe Type: HDPE & DI

Total Length: = meters

CHECK LIST PRIOR TO TESTING:

Back Filling Between Joints OK Trench Free from Water OK

Pressure Gauges Installation OK End’s Plugging Condition OK

Gauges Calibrated OK

*Monitoring of Pressure Gauges Test Start: 10:00 AM (23/11/2019) Test End: 10: 00 AM (24/11/2019)

Other Pipes- Required Actual Reading- Required Actual Reading- Required Actual Reading-

Observation Interval 1st (After 24 Hour) 2nd (After 24 Hour) 3rd (After 24 Hours)

Upper End

Gauge Reading (bar) 6 6

HDPE Pipe-

Required Actual Reading Required Actual Reading Required Actual Reading

Observation Interval

(Phase 1) (after 2-hours) (Phase 2) (after 2-hours) (Phase 3) ( (after 1-hour)

(QCS 2014)

Upper End

Gauge Reding (bar)

1. Pressure line shall be subjected to an internal pressure of to a constant test pressure of 1.5 times the

working pressure or 800 kPa, whichever is the greatest. The loss shall not exceed 0.02 litres per mm

diameter per kilometer per 24 hours for each 0.1 MPa of head applied.

2. For HDPE pressure lines, Testing shall be performed in accordance with QCS 2014 Section-8 Part 4,

clause 4.6.5. The Maximum Volume of Water added, Q≤ Di/ 50 – 1 (litres / km/ hour).

Observations & Remarks:

For 24 hours Period of Testing the applicable formula is,

For 1200mm dia., Q = .02 x 1200 x 1.2 x 6 / 1 = Liters

Max. allowable water to be added = Liters

Test Attended by: Date:

For Contractor: For Consultant: Certified by:

You might also like

- Dosing Pumps ChecklistDocument2 pagesDosing Pumps ChecklistDeshan Sing100% (2)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- S.O.P For Hydro-Test: Ipcl-Gandhar Complex WI/GC-C&I/6.3/001 GC Maintenance Manual Hydro Test OF5Document7 pagesS.O.P For Hydro-Test: Ipcl-Gandhar Complex WI/GC-C&I/6.3/001 GC Maintenance Manual Hydro Test OF5கோகுல் இராNo ratings yet

- Hydro test-Method-StatementDocument20 pagesHydro test-Method-StatementGodwin A.udo-akanNo ratings yet

- LPG Metal CylinderDocument20 pagesLPG Metal Cylinderorode franklynNo ratings yet

- CHE572 Chapter 3 Fluidization PDFDocument31 pagesCHE572 Chapter 3 Fluidization PDFMuhd FahmiNo ratings yet

- 32-Ve-711 (Hydrostatic Test Procedure Piping - FT Gas) A11 PDFDocument5 pages32-Ve-711 (Hydrostatic Test Procedure Piping - FT Gas) A11 PDFMarlon Turner100% (1)

- Hydro Testing: Mode of MeasurementDocument6 pagesHydro Testing: Mode of Measurementruhuna013100% (1)

- Job Procedure of Post HydroDocument21 pagesJob Procedure of Post Hydroshahroz alamNo ratings yet

- Hydrotesting of PipelineDocument14 pagesHydrotesting of PipelineJWC Sales & Services :100% (1)

- Ies-Industrial Engineering Services: Hydraulic Test ReportDocument7 pagesIes-Industrial Engineering Services: Hydraulic Test ReportMD Shadikul Huq ShezanNo ratings yet

- P43-R00 - Hydrotesting of PipelineDocument14 pagesP43-R00 - Hydrotesting of PipelinesojeckNo ratings yet

- Upg Stream Pe100 HydrotestDocument4 pagesUpg Stream Pe100 Hydrotestqa/qcNo ratings yet

- Upg Stream Pe100 HydrotestDocument4 pagesUpg Stream Pe100 HydrotestMoezNo ratings yet

- Hydrostatic Test ChartDocument10 pagesHydrostatic Test ChartAnanda ShofwanNo ratings yet

- Determination of Friction Factor of Pipe Lines: Al Habeeb College of Engineering & TechnologyDocument3 pagesDetermination of Friction Factor of Pipe Lines: Al Habeeb College of Engineering & TechnologyAsrar UddinNo ratings yet

- Hydrotest Method Statement 12th Mar 2012-1Document21 pagesHydrotest Method Statement 12th Mar 2012-1sethu1091100% (21)

- Hydrotest Procedure - UTCL Hirmi AQC & PHDocument12 pagesHydrotest Procedure - UTCL Hirmi AQC & PHJOHnNo ratings yet

- Accumulator Draw Down TestDocument8 pagesAccumulator Draw Down Testadeelsn100% (4)

- Welltest Interpretation Report Analysis Name: Leaky Fault Company: Hydrocarbon Theater Company Field:Moliere Test Type: Standard Test Name / #: DST 3Document14 pagesWelltest Interpretation Report Analysis Name: Leaky Fault Company: Hydrocarbon Theater Company Field:Moliere Test Type: Standard Test Name / #: DST 3xsmartieNo ratings yet

- HydroDocument4 pagesHydroSamir ChaudharyNo ratings yet

- NITON - HYDRO TEST PROCEDURE - Rev.0Document6 pagesNITON - HYDRO TEST PROCEDURE - Rev.0PRASHANT100% (2)

- Hydrotest Procedure (Final) 16.11.21 VR CommentDocument6 pagesHydrotest Procedure (Final) 16.11.21 VR CommentZamri AhmadNo ratings yet

- SOP of PrehydrotestDocument7 pagesSOP of PrehydrotestVenkateswarlu BoduguNo ratings yet

- 30 Mainline Hydrotesting 111Document25 pages30 Mainline Hydrotesting 111rexNo ratings yet

- Hydrostatic Testing of Pipelines: The City of GalvestonDocument4 pagesHydrostatic Testing of Pipelines: The City of GalvestonMoezNo ratings yet

- Kind Attn: - MR - Vijaybhai Sub: - Yourrequirement of 12.5 M3/Hrsoftening Plant (Obr 200 M3) (CAPACITY - 12.5 M3/HR)Document6 pagesKind Attn: - MR - Vijaybhai Sub: - Yourrequirement of 12.5 M3/Hrsoftening Plant (Obr 200 M3) (CAPACITY - 12.5 M3/HR)Raol VarshabenNo ratings yet

- Procedure For Vacuum Test Procedure For Tube To Tubesheet Joint - Rev.0 - 07.09.2020Document6 pagesProcedure For Vacuum Test Procedure For Tube To Tubesheet Joint - Rev.0 - 07.09.2020Aravind AravindNo ratings yet

- Hydro TestDocument12 pagesHydro TestEndika Alfan100% (2)

- Item Inspected: CBLT-TPI-00F-186-12623Document16 pagesItem Inspected: CBLT-TPI-00F-186-12623Zulfadli RaniNo ratings yet

- Kind Attn: - MR - Vijaybhai Sub: - Yourrequirement of 12.5 M3/Hr Softening Plant (Obr 200 M3) (CAPACITY - 12.5 M3/HR)Document6 pagesKind Attn: - MR - Vijaybhai Sub: - Yourrequirement of 12.5 M3/Hr Softening Plant (Obr 200 M3) (CAPACITY - 12.5 M3/HR)Raol VarshabenNo ratings yet

- Hydrotest Method Statement 12th Mar 2012 1Document21 pagesHydrotest Method Statement 12th Mar 2012 1Saut Maruli Tua Samosir100% (1)

- STS Qac Sop 003 - 1 Hydrotest & Pnuematic Test ProcedureDocument11 pagesSTS Qac Sop 003 - 1 Hydrotest & Pnuematic Test Proceduremohd as shahiddin jafriNo ratings yet

- Hydro-Test FormatDocument1 pageHydro-Test Formatjasbir.iitdNo ratings yet

- Condenser Flood TestDocument14 pagesCondenser Flood Testsrigirisetty208100% (2)

- Test Report 2Document14 pagesTest Report 2Rogelio PabuayaNo ratings yet

- Ebs1 Aaaa00 Saqa Prqa 0006Document10 pagesEbs1 Aaaa00 Saqa Prqa 0006SERT-QA/QC- BUZNo ratings yet

- Data HydrotestDocument4 pagesData HydrotestRichard AdolfNo ratings yet

- HRSG HydrotestDocument7 pagesHRSG Hydrotestshubham raj bhawsarNo ratings yet

- Avalon New PlantDocument4 pagesAvalon New PlantAhmed S ElalaftyNo ratings yet

- Hydrotest Report LOADING DOCKDocument3 pagesHydrotest Report LOADING DOCKmhafidz.projectNo ratings yet

- Hydrotesting Procedure Rev 4Document6 pagesHydrotesting Procedure Rev 4Rajesh K PillaiNo ratings yet

- Procedure For Condenser Flood Test and Vacuum Tightness TestDocument13 pagesProcedure For Condenser Flood Test and Vacuum Tightness TestJackSparrow86No ratings yet

- 4008-Pi-Pro-001 - 0 - Piping Hydrotest Procedure-1Document8 pages4008-Pi-Pro-001 - 0 - Piping Hydrotest Procedure-1Randu WatangNo ratings yet

- Hidrostatic Test Procedure: Hafizul - HasrolDocument7 pagesHidrostatic Test Procedure: Hafizul - HasrolRafique MunirNo ratings yet

- Hydrostatic Test Procedure R0Document10 pagesHydrostatic Test Procedure R0mhajaraswadi2023No ratings yet

- Hydrostatic Test Procedure Site RevDDocument23 pagesHydrostatic Test Procedure Site RevDBhavani Prasad100% (8)

- RWT Ro188. (500 LPH)Document5 pagesRWT Ro188. (500 LPH)Rinse Water TechnologyNo ratings yet

- Hydro Test Procedure: ItemDocument6 pagesHydro Test Procedure: Itemtulasirao.nammiNo ratings yet

- Hydrostatic Testing ProceduresDocument2 pagesHydrostatic Testing Proceduresomar sadiqNo ratings yet

- Generic Well Test ProgramDocument9 pagesGeneric Well Test Programinyene ekereNo ratings yet

- Mabel Engineers Private Limited Hydro Test ProcedureDocument5 pagesMabel Engineers Private Limited Hydro Test ProcedureQuality TeamNo ratings yet

- 16.4. Mmf-Ax-bx-Vdr-0014 Hydrotest Procedure Rev. 0Document28 pages16.4. Mmf-Ax-bx-Vdr-0014 Hydrotest Procedure Rev. 0Fauzan Rusmayadi Reharder100% (1)

- Heder Boiler Room Hydrolic TestDocument5 pagesHeder Boiler Room Hydrolic TestMD Shadikul Huq ShezanNo ratings yet

- Procedure For The Pressure Mechanical Integrity Test For The Casing of An Underground Hydrocarbon Storage WellDocument3 pagesProcedure For The Pressure Mechanical Integrity Test For The Casing of An Underground Hydrocarbon Storage Wellvirnando nainggolanNo ratings yet

- Hydrostatic Test Report: Form No.: JFC-F-QC-06, Form Rev. No.: 0, Form Released Date: 01-Jan-17 Page 1 of 1Document1 pageHydrostatic Test Report: Form No.: JFC-F-QC-06, Form Rev. No.: 0, Form Released Date: 01-Jan-17 Page 1 of 1Dhaval ChitreNo ratings yet

- Emrsn HTP 001 A1Document7 pagesEmrsn HTP 001 A1Karthik BanariNo ratings yet

- Leak Test Proc DemoDocument7 pagesLeak Test Proc DemoroeslanteaNo ratings yet

- MS For Pressure Test-ReDocument9 pagesMS For Pressure Test-Reanishdev6No ratings yet

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AFrom EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANo ratings yet

- BBS Compound WallDocument4 pagesBBS Compound WallsoorajNo ratings yet

- BCS StairDocument3 pagesBCS StairsoorajNo ratings yet

- BCS FootingDocument10 pagesBCS FootingsoorajNo ratings yet

- SAADIYAT ITP (THERMAL Block Works) NEWDocument5 pagesSAADIYAT ITP (THERMAL Block Works) NEWsoorajNo ratings yet

- 01-SAADIYAT ITP (Concreting For Super Structure)Document12 pages01-SAADIYAT ITP (Concreting For Super Structure)soorajNo ratings yet

- Itsupport@apbava - Com 20100208 142544Document63 pagesItsupport@apbava - Com 20100208 142544soorajNo ratings yet

- 05-Saadiyat Itp (Backfilling) VillaDocument4 pages05-Saadiyat Itp (Backfilling) VillasoorajNo ratings yet

- 4 - Cable TraysDocument1 page4 - Cable TrayssoorajNo ratings yet

- Itsupport@apbava - Com 20100208 143105Document42 pagesItsupport@apbava - Com 20100208 143105soorajNo ratings yet

- Itsupport@apbava - Com 20100208 142443Document5 pagesItsupport@apbava - Com 20100208 142443soorajNo ratings yet

- Itsupport@apbava - Com 20100208 143400Document1 pageItsupport@apbava - Com 20100208 143400soorajNo ratings yet

- Itsupport@apbava - Com 20100208 143325Document1 pageItsupport@apbava - Com 20100208 143325soorajNo ratings yet

- Aluminium FramesDocument4 pagesAluminium FramessoorajNo ratings yet

- Break Down ScheduleDocument4 pagesBreak Down SchedulesoorajNo ratings yet

- Form # 1 - ICS 1 Electric Motor (HV LV)Document3 pagesForm # 1 - ICS 1 Electric Motor (HV LV)soorajNo ratings yet

- Form # 4 - ICS 4 Cable Installation Below GroundDocument1 pageForm # 4 - ICS 4 Cable Installation Below GroundsoorajNo ratings yet

- System Safety Rule-OETCDocument107 pagesSystem Safety Rule-OETCsoorajNo ratings yet

- 12 Battery & Battery ChargerDocument1 page12 Battery & Battery ChargersoorajNo ratings yet

- 1 - Cable Installation Above GroundDocument2 pages1 - Cable Installation Above GroundsoorajNo ratings yet

- 8 Cube Test ReportDocument1 page8 Cube Test ReportsoorajNo ratings yet

- 6 - Neutral Earth ResistorDocument1 page6 - Neutral Earth ResistorsoorajNo ratings yet

- 16 Checklist For PaintingDocument2 pages16 Checklist For PaintingsoorajNo ratings yet

- 18 Check List For Wall & Flooring TileDocument1 page18 Check List For Wall & Flooring Tilesooraj100% (1)

- 15 Checklist For PlasteringDocument1 page15 Checklist For PlasteringsoorajNo ratings yet

- 17 Checklist For Roof WaterproofingDocument2 pages17 Checklist For Roof WaterproofingsoorajNo ratings yet

- 2 - Cable JointDocument1 page2 - Cable JointsoorajNo ratings yet

- 7 Bar Bending ScheduleDocument1 page7 Bar Bending SchedulesoorajNo ratings yet

- 9 Post Pour Inspection ReportDocument1 page9 Post Pour Inspection ReportsoorajNo ratings yet

- 1 RfiDocument1 page1 RfisoorajNo ratings yet

- 0015-BS 142 - Section 4.1 - 1984Document12 pages0015-BS 142 - Section 4.1 - 1984soorajNo ratings yet

- DynamicDocument34 pagesDynamicCentral HydraulicsNo ratings yet

- FMRC 1311 Centrifugal Fire Pumps (Horizontal Split-Case Type) PDFDocument28 pagesFMRC 1311 Centrifugal Fire Pumps (Horizontal Split-Case Type) PDFdyıldırım_4100% (1)

- Sensor ProblemsDocument20 pagesSensor ProblemsSalih AbbasNo ratings yet

- PavlosPoutachidis CMGDocument24 pagesPavlosPoutachidis CMGPaulos PoutachidisNo ratings yet

- IPR - Leslie ThompsonDocument57 pagesIPR - Leslie ThompsonGabriel Cevallos100% (1)

- AE 11 Chapter 5 Group 1Document69 pagesAE 11 Chapter 5 Group 1Daphne Ba-ang GamoNo ratings yet

- Unit 1. Fluid and Fluid PropertiesDocument9 pagesUnit 1. Fluid and Fluid PropertiesNirmal PatelNo ratings yet

- Series 58 Modular Version ISO 4401-03 P Max: Bar Max (See Table of Performances)Document4 pagesSeries 58 Modular Version ISO 4401-03 P Max: Bar Max (See Table of Performances)francis_15inNo ratings yet

- APL Math FunctionsDocument4 pagesAPL Math FunctionsAshish KotwalNo ratings yet

- Safety ValvesDocument65 pagesSafety Valvesserturkbudak_3448365No ratings yet

- Perforating Innovations (SafeJet)Document18 pagesPerforating Innovations (SafeJet)Saulo Caceres LaricoNo ratings yet

- Paradeep Refinery Project: A Sunrise Project For A Sunshine FutureDocument79 pagesParadeep Refinery Project: A Sunrise Project For A Sunshine Futuremujeebtalib50% (2)

- CCI - Casing - Gas CompressorDocument30 pagesCCI - Casing - Gas CompressorManuel ChNo ratings yet

- 11th Physics YearlyDocument2 pages11th Physics Yearlydadhich.archit15No ratings yet

- Compact, Continuous, Effective: BOLL Automatic FiltersDocument7 pagesCompact, Continuous, Effective: BOLL Automatic FiltersFer SevanNo ratings yet

- Course Plan KNJ1053-Sem2!10!11Document2 pagesCourse Plan KNJ1053-Sem2!10!11Ash MochiNo ratings yet

- l4 The Clausius-UpadiDocument8 pagesl4 The Clausius-UpadiMarcos Sánchez MartínezNo ratings yet

- IS 5422-Turbine Type Generator-Gen Spec PDFDocument15 pagesIS 5422-Turbine Type Generator-Gen Spec PDFmailbkraoNo ratings yet

- Rotating Control Device 18in PsDocument2 pagesRotating Control Device 18in PsnagarajakumarNo ratings yet

- Chapter 5Document25 pagesChapter 5roxy8marie8chanNo ratings yet

- Smartlay™ Pipeline Flooding Prevention System: Service Data SheetDocument2 pagesSmartlay™ Pipeline Flooding Prevention System: Service Data Sheetnagid_428463849No ratings yet

- Pgs-13-49-13-64 Detector de TemperaturaDocument16 pagesPgs-13-49-13-64 Detector de TemperaturaBrunophb2012No ratings yet

- Plate Heat ExchangerDocument1 pagePlate Heat ExchangerBvitalize100% (1)

- Litreature Review 1. History of Water Pumping Technolgy: Water Pumps How Potable Water Is To The Top of The BuildingDocument6 pagesLitreature Review 1. History of Water Pumping Technolgy: Water Pumps How Potable Water Is To The Top of The BuildingAwanyo thomasNo ratings yet

- YS 11 Laboratory Activity # 1Document3 pagesYS 11 Laboratory Activity # 1HECTOR ARANTE TANNo ratings yet

- 5 Presentation Corac Downhole Pressure BoostingDocument19 pages5 Presentation Corac Downhole Pressure BoostingEdwin VargadNo ratings yet

- Ge F-Class Gek111895Document2 pagesGe F-Class Gek111895gopinathsampath0% (2)

- Physics Terms & DefinitionDocument11 pagesPhysics Terms & DefinitionSniper Grenade100% (1)

- Particle Model of Matter MUSA GCSEDocument16 pagesParticle Model of Matter MUSA GCSEMethyl OrangeNo ratings yet