Professional Documents

Culture Documents

Audit Report Personal Locks

Audit Report Personal Locks

Uploaded by

Muhammad Rehan0 ratings0% found this document useful (0 votes)

3 views3 pagesaudit

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentaudit

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

3 views3 pagesAudit Report Personal Locks

Audit Report Personal Locks

Uploaded by

Muhammad Rehanaudit

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 3

Audit Report of Employee’s Personal LOTOTO locks FCCL (JB) Plant.

Audit Conducted By:

1. Sardar Shujja AM HSE

2. Muhammad REHAN SAM E&I

Report

Audit was conducted to check Personal LOTOTO locks randomly from the following employees of

different departments.

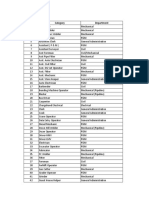

S.No Name Designation Area Department Lock Status

1 Muhshtaq Hussain TO Raw Mill II Mechanical Available

2 Aurengzeb Fitter Raw Mill II Mechanical Available but Faulty

3 Arshad Ali TO Raw Mill I Mechanical Available

4 Zafar Iqbal Assitant Fitter Raw Mill II Mechanical Available

5 Nasir Amin Attendent Mechanical workshop Mechanical Available

6 Fazal Ur Rehman Welder Mechanical workshop Mechanical Available

7 Abid Hussain Welder Mechanical workshop Mechanical Available

8 Abid Hussain TO Cooler/Coal Mill II Mechanical Available

9 Salman Salim SAM Cooler/Coal Mill II Mechanical Available

10 Bashir Ahmed TO Packing Plant I Mechanical Available

11 Arshad Ali Sr.Fitter Packing Plant I Mechanical Available

12 Saeed Ahmed Sr. Fitter Cement Mill II Mechanical Available

13 Saeed ur Rehman Helper Packing Plant II Mechanical Available

14 Shahid Khan Sr. Fitter Packing Plant II Mechanical Available

15 Muhammad Haris SAM Raw Mill Electrical Available

16 Shakeel Ahmed Sr.Electrician Raw Mill Electrical Available

17 Muhammad Waqas Sr.Electrician Kiln II Electrical Available

18 Qasim Ali Khan Electrician Cooler II Electrical Available

19 Saqlain Shah TO Electrical Workshop Electrical Available

20 Munir Yaqub Winder Electrical Workshop Electrical Available

21 Shafaqat Hussain AC Technician AC Workshop Electrical Available

22 Abrar Hussain TO Cement Mill II Electrical Available

23 Muhammad Arslan Helper Cement Mill II Electrical Available

24 Iftikhar Ahmed Sr.Electrician Packing Plant II Electrical Available

25 Abdul Latif Sr.Electrician Ball Mill Electrical Available

26 Shuja Ud Din Electrician Electrical Shift Electrical Available

27 Abdul Basit Shah TO Kiln II Production Available

28 Khurram Shahzad Attendent Kiln II Production Available

29 Raja Naveed TO Kiln II Production Available

30 Yasir TO Raw Mill Production Available

31 Khalid Attendent Raw Mill Production Available

32 Sikandar Attendent Raw Mill Production Available

33 Awais Paracha SAM Packing Plant Production Available

34 Hameed Awan TO Packing Plant Production Available

35 Shahid Mehmood Attendent Packing Plant I Production Not Available

36 Kaleem Arif LCR Operatpr Packing Plant I Production Not Available

37 Rashid Khan LCR Operatpr Packing Plant II Production Not Available

38 Alamgir TO Kiln II Instrument Available

39 Aftab TO Raw Mill Instrument Available

40 Siddique TO Raw Mill Instrument Available

41 Waseem Nawaz Technician Kiln II Instrument Available

42 Tahir Technician Kiln II Instrument Available

43 Saqib TO Shift Instrument Available

44 Irfan Shah TO Packing Plant Instrument Available

45 Manan Helper Packing Plant Instrument Available

46 Danish Helper Packing Plant Instrument Available

Red Highlighted employees in the list and all apprentices don not have personal LOTOTO locks.

1. Shifting of transformer form FCCL-JB plant to Workshop.

2. Testing of transformer before job start. Provide tests report.

3. Removal of transformer active part from main tank.

4. Replacement of tap changer.

5. Transformer winding coil work

6. Replacement of transformer top plate gas kit and MV/LV bushings oil seals.

7. Coil assembly ovening.

8. Degasification and dehydration of transformer oil.

9. Final test reports after job completion.

10. Shifting of transformer from Workshop to FCCL-JB plant.

11. Commissioning of transformer at FCCL-JB plant site.

12. Party will give 1 year transformer operation warranty certificate of maintenance work done.

13. Unloading/loading at workshop responsibility

14. Receiving tests report

15. Dismantling of motor parts at workshop

16. Removal of rotor and bearing

17. Rebuild with metal filled compound/cold welding of NDE bearing Housing of motor end shield.

18. Resizing of rebuilt end-shield as per bearing-housing fit tolerance of motor end-shield.

19. Installation of rotor and bearing .

20. Rotor balancing along with report of balancing

21. Motor Complete overhauling including washing, drying and repainting of motor winding as

well as other parts.

22. Mechanical and electrical tests report submission.

23.

You might also like

- KPK IndustriesDocument78 pagesKPK IndustriesArsalan Rehman100% (1)

- RSP Panorama PDFDocument328 pagesRSP Panorama PDFNayak Swaraj Pankaj50% (2)

- Hvac - Supplier List UpdatedDocument218 pagesHvac - Supplier List UpdatedMohammad Altaf Hussain100% (1)

- Employees Names: Employee Full Name Nationality NoDocument7 pagesEmployees Names: Employee Full Name Nationality NoChris ChrisNo ratings yet

- 5S Circles - 1S & 2S Audit ScheduleDocument8 pages5S Circles - 1S & 2S Audit ScheduleUsman KhalidNo ratings yet

- Img 20240328 0006Document1 pageImg 20240328 0006Adil AnwarNo ratings yet

- SR - No Name Position Signature: Manpower ListDocument2 pagesSR - No Name Position Signature: Manpower ListMuhammad Umar GondalNo ratings yet

- Khetri Nagar: Aravali Institute of Technical Studies UdaipurDocument21 pagesKhetri Nagar: Aravali Institute of Technical Studies UdaipurbhoopsharmaNo ratings yet

- List of Sme'S Availing Common Facilities Services (CFS) From Midc SialkotDocument4 pagesList of Sme'S Availing Common Facilities Services (CFS) From Midc SialkotAmbreen ZainebNo ratings yet

- Rekrutmen Tenaga Kerja - Kab. KolakaDocument7 pagesRekrutmen Tenaga Kerja - Kab. KolakaTRI MUHAMMAD NANDANG BADIUNNo ratings yet

- Nuovoter Asset Schedule.1Document5 pagesNuovoter Asset Schedule.1Hadedapo Shearer HadebiyiNo ratings yet

- SL# Category DepartmentDocument6 pagesSL# Category Departmentphone2hireNo ratings yet

- Vatva Data CheckDocument283 pagesVatva Data CheckchiragmNo ratings yet

- Daily Toolbox Talk Attendance: Conducted By: Name: Muhammad Umar-HSE Lead SignatureDocument1 pageDaily Toolbox Talk Attendance: Conducted By: Name: Muhammad Umar-HSE Lead SignatureMuhammad Umar GondalNo ratings yet

- Prioritize Clients Reference ListDocument2 pagesPrioritize Clients Reference ListSunny SyedNo ratings yet

- Panorama Final 11-07-2012 PDFDocument292 pagesPanorama Final 11-07-2012 PDFSomdeep DuttaNo ratings yet

- Hasil PTS PKK Dan Pkknon Kelas Xi-1Document6 pagesHasil PTS PKK Dan Pkknon Kelas Xi-1Ricky Cahyasari PutraNo ratings yet

- Motorpool Manpower SummaryDocument8 pagesMotorpool Manpower SummaryRamsNo ratings yet

- Training TK Baru O&M Pltu Malinau: No Nama Proyeksi Posisi Jadwal TrainingDocument1 pageTraining TK Baru O&M Pltu Malinau: No Nama Proyeksi Posisi Jadwal TrainingferryNo ratings yet

- Rajendra Jhariya Sector 25, Krishna NagarDocument12 pagesRajendra Jhariya Sector 25, Krishna NagarrajendrajhaNo ratings yet

- Index:: Revised Minimum Wages: SRO-460. Notification 26 Oct, 2017Document24 pagesIndex:: Revised Minimum Wages: SRO-460. Notification 26 Oct, 2017Suresh CNo ratings yet

- Electrical Safety Training ParticipantsDocument4 pagesElectrical Safety Training ParticipantsNoe AranelNo ratings yet

- Electrical 2Document4 pagesElectrical 2fakhar zulfiqarNo ratings yet

- Somil SewagramDocument53 pagesSomil SewagramSomil GuptaNo ratings yet

- S.No. Student Name Supervisor Industry For Mini Project II: Aleem Ahmad ManufacturingDocument2 pagesS.No. Student Name Supervisor Industry For Mini Project II: Aleem Ahmad Manufacturingmohd ameerNo ratings yet

- Rapit Swab Antigen Dan Crew Change 13 July-2022Document3 pagesRapit Swab Antigen Dan Crew Change 13 July-2022Engkus KuswaraNo ratings yet

- Curing Press Status in PCR As at 24.02.2023Document8 pagesCuring Press Status in PCR As at 24.02.2023IsuruNo ratings yet

- Exhibitors ListDocument7 pagesExhibitors ListNiraj PandeyNo ratings yet

- Infrastructure N DeficiencyDocument8 pagesInfrastructure N DeficiencyRamesh BammankattiNo ratings yet

- (Internship Program Report) Pakistan Steel No. of Weeks:-4 Weeks Intership Program Date: 14-06-2010 To 09-07-2010 Submitted To: Submitted byDocument59 pages(Internship Program Report) Pakistan Steel No. of Weeks:-4 Weeks Intership Program Date: 14-06-2010 To 09-07-2010 Submitted To: Submitted byAdnan ArainNo ratings yet

- CSR Internee 2023Document3 pagesCSR Internee 2023Mahmood Ul HasnainNo ratings yet

- Infrastructure N DeficiencyDocument8 pagesInfrastructure N Deficiency55511223344No ratings yet

- Infrastructure N DeficiencyDocument8 pagesInfrastructure N DeficiencyRamesh BammankattiNo ratings yet

- Service RequestDocument6 pagesService RequestnabeelNo ratings yet

- Internship ReportDocument18 pagesInternship ReportMuhammad QasimNo ratings yet

- Lndian Standard: Specification. FOR High Heat Duty Fireclay Refractorie$Document8 pagesLndian Standard: Specification. FOR High Heat Duty Fireclay Refractorie$nishanth132No ratings yet

- Eid Ul Adha-2024 Name ListDocument1 pageEid Ul Adha-2024 Name Listarmanh865No ratings yet

- List of FiguresDocument22 pagesList of FiguresvishalNo ratings yet

- Exhibitor List - IfEX 2017 & Cast India 2017Document1 pageExhibitor List - IfEX 2017 & Cast India 2017sentamil vigneshwaranNo ratings yet

- Copper ProductionDocument4 pagesCopper ProductionkamalNo ratings yet

- PRPO Aug 2025 SD - XLSX BBBDocument18 pagesPRPO Aug 2025 SD - XLSX BBBirfan.ali0463No ratings yet

- 5 Lack of Rest Area and Temporary Shade TBT AL HDCCDocument5 pages5 Lack of Rest Area and Temporary Shade TBT AL HDCCrizvidawar221No ratings yet

- 1.0 PURPOSE:: Machine Movement From Crp1 To Crp2Document4 pages1.0 PURPOSE:: Machine Movement From Crp1 To Crp2zul isymaNo ratings yet

- Orientation ReportDocument147 pagesOrientation ReportKhalid SaifullahNo ratings yet

- The Outdoor Substation The Outdoor Substation: Scholars' Mine Scholars' MineDocument289 pagesThe Outdoor Substation The Outdoor Substation: Scholars' Mine Scholars' MineFLORENS CAROLINENo ratings yet

- Sulfuric Acid:: Hiistory and Production ProcessDocument33 pagesSulfuric Acid:: Hiistory and Production ProcesswaqaskhanNo ratings yet

- Presentation - Method Statement For Fire Fighting System 20.04.22Document21 pagesPresentation - Method Statement For Fire Fighting System 20.04.22TranDungNo ratings yet

- 3996Document2 pages3996Karthik MethukuNo ratings yet

- Coker Crane Ref ListDocument1 pageCoker Crane Ref ListAakash JainNo ratings yet

- Report On Sitara ChemicalsDocument28 pagesReport On Sitara Chemicalsnoraiziqbal2100% (3)

- Classroom and Laboratory: Mechanical Engineering DepartmentDocument8 pagesClassroom and Laboratory: Mechanical Engineering Department55511223344No ratings yet

- Classroom and Laboratory: Mechanical Engineering DepartmentDocument8 pagesClassroom and Laboratory: Mechanical Engineering Department55511223344No ratings yet

- HZL Chanderiya Pyro Training ReportDocument48 pagesHZL Chanderiya Pyro Training Reportkunalmech100% (5)

- Infrastructure N DeficiencyDocument8 pagesInfrastructure N Deficiency55511223344No ratings yet

- Traning ReportDocument27 pagesTraning ReportvivekNo ratings yet

- Classroom and Laboratory: Mechanical Engineering DepartmentDocument8 pagesClassroom and Laboratory: Mechanical Engineering Department55511223344No ratings yet

- Neyveli Lignite Corporation 12 Mar 12Document5 pagesNeyveli Lignite Corporation 12 Mar 12Chandrakumar87No ratings yet

- Flotation Theory Reagents and Ore TestingDocument368 pagesFlotation Theory Reagents and Ore TestingDeker Wales Albornoz MinalayaNo ratings yet

- Electrical Ist ShiftDocument4 pagesElectrical Ist Shiftfakhar zulfiqarNo ratings yet

- Small Signal Transistors (PNP) : New Product New Product New ProductDocument4 pagesSmall Signal Transistors (PNP) : New Product New Product New ProductIven GaneshaNo ratings yet

- GIS CB Time TestingDocument26 pagesGIS CB Time TestingVISHAL TELANGNo ratings yet

- Logic Gates QuestionsDocument14 pagesLogic Gates QuestionsDinMat33% (3)

- AB 14 para Tranzystorow DarlingtonaDocument23 pagesAB 14 para Tranzystorow DarlingtonavengalamahenderNo ratings yet

- Altronix - PD8Document1 pageAltronix - PD8Tv Chacon ChaconNo ratings yet

- Assignment3 EMIDocument6 pagesAssignment3 EMISaurav SomeshNo ratings yet

- 2 Wattmeter MethodDocument8 pages2 Wattmeter Methodahg#0% (1)

- JDSW51A Electric Wiring DiagramDocument2 pagesJDSW51A Electric Wiring Diagramabelmil1230% (1)

- Low Voltage Universal Cable Joint Kits: (Excludes Connectors)Document2 pagesLow Voltage Universal Cable Joint Kits: (Excludes Connectors)sridharanNo ratings yet

- Lecture 3: Electrochemical Energy Storage: I. Equivalent Circuit ModelsDocument8 pagesLecture 3: Electrochemical Energy Storage: I. Equivalent Circuit Modelsanup chauhanNo ratings yet

- EHVAC Unit 5 Practice - Assignment Quiz - Attempt ReviewDocument4 pagesEHVAC Unit 5 Practice - Assignment Quiz - Attempt ReviewRitNo ratings yet

- AEM6000 Based 50W Amp Construction NotesDocument22 pagesAEM6000 Based 50W Amp Construction NotesMortenGundersenNo ratings yet

- Cis Eo Dte Power Factor 138474 7Document28 pagesCis Eo Dte Power Factor 138474 7czds6594No ratings yet

- Digital Clock Timer: Owner's ManualDocument11 pagesDigital Clock Timer: Owner's ManualIBJSC.comNo ratings yet

- Replacing2 The Diode Pack On A Denso AlternatorDocument7 pagesReplacing2 The Diode Pack On A Denso AlternatorKirkNo ratings yet

- DynamoDocument4 pagesDynamoReyvy AlcardeNo ratings yet

- g5v2 pdf5b57092925997Document5 pagesg5v2 pdf5b57092925997NesaNo ratings yet

- Section 93 - 30 2011-11 GSCR I&O Manual Three PhaseDocument68 pagesSection 93 - 30 2011-11 GSCR I&O Manual Three PhaseEriflonaNo ratings yet

- Polytechnic of Namibia School of Engineering Electrical Engineering DepartmentDocument17 pagesPolytechnic of Namibia School of Engineering Electrical Engineering DepartmentDarshan Rai KanungoNo ratings yet

- Questions On Synchronous GeneratorsDocument30 pagesQuestions On Synchronous Generatorskibrom atsbhaNo ratings yet

- 1la2 113-4na80Document3 pages1la2 113-4na80rajivsinghal90No ratings yet

- Chapter 7 Electronic Analysis of CMOS Logic GatesDocument42 pagesChapter 7 Electronic Analysis of CMOS Logic GatesmanjulavkNo ratings yet

- A7 Amps Manual - Compressed PDFDocument12 pagesA7 Amps Manual - Compressed PDFKeidesh RamnanansinghNo ratings yet

- Olympian 4001 OmniMetrix Installation Guide PDFDocument2 pagesOlympian 4001 OmniMetrix Installation Guide PDFAndresan507No ratings yet

- Electrical Machines - IDocument2 pagesElectrical Machines - Idhirajbharat20No ratings yet

- AIM StradaDocument6 pagesAIM StradaProSales CasNo ratings yet

- Notes:: Colombo Port City Development ProjectDocument1 pageNotes:: Colombo Port City Development Projectnadim7862No ratings yet

- Volume 2 PDFDocument34 pagesVolume 2 PDFChanna SamarasingheNo ratings yet

- "Intelligent Energy Saving System": Project Report ONDocument64 pages"Intelligent Energy Saving System": Project Report ONPankajDhobleNo ratings yet

- En JKM320P 72 (4BB)Document2 pagesEn JKM320P 72 (4BB)Sreevathsa GururajNo ratings yet