Professional Documents

Culture Documents

HR-FR-01 Training Skills Matrix Maintenance Team

HR-FR-01 Training Skills Matrix Maintenance Team

Uploaded by

Majd DraidiCopyright:

Available Formats

You might also like

- Workshop Manual: Sisudiesel 645Document80 pagesWorkshop Manual: Sisudiesel 645Victor Pinedo100% (1)

- Fuller-Kinyon (FK) PumpDocument9 pagesFuller-Kinyon (FK) PumpAli Hüthüt100% (2)

- Unit 3-Fluid MechanicsDocument38 pagesUnit 3-Fluid MechanicsApechRanger92% (66)

- 27-11-2022-DPR KPGFCCI ProjectDocument2 pages27-11-2022-DPR KPGFCCI ProjectBilalNo ratings yet

- Progress Report ProjectDocument2 pagesProgress Report ProjectBilalNo ratings yet

- Project ReportDocument2 pagesProject ReportBilalNo ratings yet

- SCCI. MOB (ADMIN) - March 13,2023-EditedDocument13 pagesSCCI. MOB (ADMIN) - March 13,2023-Editedsimeon james villacrusisNo ratings yet

- 310C22011 RA Refurbishment of Tank T-201 ForDocument9 pages310C22011 RA Refurbishment of Tank T-201 ForVinay Mishra100% (1)

- SCCI. MOB (ADMIN) - March 06,2023Document13 pagesSCCI. MOB (ADMIN) - March 06,2023simeon james villacrusisNo ratings yet

- BDocument215 pagesBapi-26144115100% (1)

- 28-11-2022-DPR KPGFCCI ProjectDocument2 pages28-11-2022-DPR KPGFCCI ProjectBilalNo ratings yet

- 26-11-2022-DPR KPGFCCI ProjectDocument2 pages26-11-2022-DPR KPGFCCI ProjectBilalNo ratings yet

- Framework Diagram - Safety Case Assessment: Inc. Material Changes & Dismantlement SubmissionsDocument3 pagesFramework Diagram - Safety Case Assessment: Inc. Material Changes & Dismantlement SubmissionsasdasdNo ratings yet

- 29-11-2022-DPR KPGFCCI ProjectDocument2 pages29-11-2022-DPR KPGFCCI ProjectBilalNo ratings yet

- 2,016 Units: Shagufta MasoodDocument2 pages2,016 Units: Shagufta MasoodAliNo ratings yet

- SCCI. MOB (ADMIN) - Feb.20,2023Document13 pagesSCCI. MOB (ADMIN) - Feb.20,2023simeon james villacrusisNo ratings yet

- 01-12-2022-DPR KPGFCCI ProjectDocument2 pages01-12-2022-DPR KPGFCCI ProjectBilalNo ratings yet

- 30-11-2022-DPR KPGFCCI ProjectDocument2 pages30-11-2022-DPR KPGFCCI ProjectBilalNo ratings yet

- SCCI. MOB (ADMIN) - Feb.13,2023-EditedDocument13 pagesSCCI. MOB (ADMIN) - Feb.13,2023-Editedsimeon james villacrusisNo ratings yet

- HCIS-SECSAF Status - Updated 04dec23Document3 pagesHCIS-SECSAF Status - Updated 04dec23Siva GuruNo ratings yet

- PM by REDocument5 pagesPM by REAshebirNo ratings yet

- 16 12 2023 DPR KPGF Cci Project.Document2 pages16 12 2023 DPR KPGF Cci Project.rashid khattakNo ratings yet

- Jun-22Document2 pagesJun-22Syed Umar AhmedNo ratings yet

- 112 Units Rs. 849.12: MR - Intizar KhanDocument3 pages112 Units Rs. 849.12: MR - Intizar KhanMuahammad DanishNo ratings yet

- Contractor by Emp. ReprDocument14 pagesContractor by Emp. ReprAshebirNo ratings yet

- 361 Units Rs. 8,162.62: Abdul Majeed - Naseem AkhtarDocument3 pages361 Units Rs. 8,162.62: Abdul Majeed - Naseem Akhtarabdul qadirNo ratings yet

- TMP 07Document6 pagesTMP 07Lê HoànNo ratings yet

- Siddaganga Institute of Technology, Tumakuru - 572 103Document1 pageSiddaganga Institute of Technology, Tumakuru - 572 103Chutiya ChutiyaNo ratings yet

- 15 12 2023 DPR KPGF Cci Project.Document2 pages15 12 2023 DPR KPGF Cci Project.rashid khattakNo ratings yet

- 14 12 2023 DPR KPGF Cci Project.Document2 pages14 12 2023 DPR KPGF Cci Project.rashid khattakNo ratings yet

- LC and Long Load Status (23-03-2023)Document71 pagesLC and Long Load Status (23-03-2023)M. Aamir SaeedNo ratings yet

- 438 Units Rs. 10,240.24: MR Noor Muhammad RehmaniDocument3 pages438 Units Rs. 10,240.24: MR Noor Muhammad RehmaniAliNo ratings yet

- Ref 4 - CRS Taif SDDocument4 pagesRef 4 - CRS Taif SDRahul KumarNo ratings yet

- Aug 21Document2 pagesAug 21AttaNo ratings yet

- For Audit Point 2&8. Organization Chart (Southern Area-VCPIII) Updated May-01-2023Document1 pageFor Audit Point 2&8. Organization Chart (Southern Area-VCPIII) Updated May-01-2023yaseenahmedbaigNo ratings yet

- 310C22011 RA Refurbishment of Tank T-201 For Mechanical Repair Works Rev.00Document9 pages310C22011 RA Refurbishment of Tank T-201 For Mechanical Repair Works Rev.00Vinay MishraNo ratings yet

- Gammon India Ltd. C/o Bhavnagar Energy Company Limited 2X250 MW Lignite Based TPP at Padva, Bhavnagar Daily Progress ReportDocument1 pageGammon India Ltd. C/o Bhavnagar Energy Company Limited 2X250 MW Lignite Based TPP at Padva, Bhavnagar Daily Progress Reportsaravan1891No ratings yet

- Duplicate Bill - Jan-2023 - 0400026720123Document2 pagesDuplicate Bill - Jan-2023 - 0400026720123Farasat SaeedNo ratings yet

- Units: Muhammad ArifDocument2 pagesUnits: Muhammad Arifrizzkhan1978No ratings yet

- 18-12-2023-DPR KPGF CCI Project.Document2 pages18-12-2023-DPR KPGF CCI Project.rashid khattakNo ratings yet

- NCR Status SGRE 31-01-2023 - QCDocument2 pagesNCR Status SGRE 31-01-2023 - QCIndraNo ratings yet

- Cambridge PaperDocument2 pagesCambridge Paperrutherfordatomic365No ratings yet

- Apr-23Document2 pagesApr-23Fahad Bin ImranNo ratings yet

- Empl - Rep by ContractorDocument20 pagesEmpl - Rep by ContractorAshebirNo ratings yet

- 05 Weekly Progress 22-28septDocument8 pages05 Weekly Progress 22-28septpranjal.dhakaNo ratings yet

- Far 1a - Summary of Appropriations, Allotment, Obligations, Disbursments and Balances As of December 31, 2022Document4 pagesFar 1a - Summary of Appropriations, Allotment, Obligations, Disbursments and Balances As of December 31, 2022Whenng LopezNo ratings yet

- 6-14-9 Control ValvesDocument14 pages6-14-9 Control ValvessudokuNo ratings yet

- Yeshwantrao Chavan College of EngineeringDocument6 pagesYeshwantrao Chavan College of EngineeringSheetal BhoyarNo ratings yet

- Eng CD 2374900 A4-3077475Document4 pagesEng CD 2374900 A4-3077475Roger SuzanoNo ratings yet

- FLORES ES eNAT School Report KS1Document15 pagesFLORES ES eNAT School Report KS1noel r. moralNo ratings yet

- 359 Units: MR Mohammad Abdul GhaniDocument2 pages359 Units: MR Mohammad Abdul GhaniTwT DarkerNo ratings yet

- Divn.2, Budget Amount Required For Works & LA-14!01!2022Document4 pagesDivn.2, Budget Amount Required For Works & LA-14!01!2022cekpknr filesNo ratings yet

- Gujarat Housing BoardDocument32 pagesGujarat Housing Board16SA156.RohanShahNo ratings yet

- ICPprivilegesDocument5 pagesICPprivilegesBUREAU VERITASNo ratings yet

- How To Read Utility BillsDocument2 pagesHow To Read Utility BillsSikander QaziNo ratings yet

- 162 Units: Muhammad FarooqDocument2 pages162 Units: Muhammad FarooqMuhammad FarooqNo ratings yet

- 9th CAD Minutes PDFDocument34 pages9th CAD Minutes PDFsnehaNo ratings yet

- Units: Pakistan RangersDocument2 pagesUnits: Pakistan RangersrasheedNo ratings yet

- HIRA-03 Erection and Dismantaling of Temporary StructureDocument8 pagesHIRA-03 Erection and Dismantaling of Temporary StructureMD AbdullahNo ratings yet

- Presentasi RMM 2019 Q2 SIP1 NEW - PPTX (Autosaved)Document150 pagesPresentasi RMM 2019 Q2 SIP1 NEW - PPTX (Autosaved)FERNANDONo ratings yet

- 1,067 Units: Moin UlhaqDocument2 pages1,067 Units: Moin UlhaqAliNo ratings yet

- 379 Units: Habib-Ur-Rehman Siddiqui & OthersDocument2 pages379 Units: Habib-Ur-Rehman Siddiqui & OthersdfNo ratings yet

- National Violations PlatformDocument1 pageNational Violations PlatformMajd DraidiNo ratings yet

- ISO Correlation MatrixDocument7 pagesISO Correlation MatrixMajd Draidi100% (1)

- Safety Data Sheet Permatreat® Pc-191T: Section: 1. Product and Company IdentificationDocument9 pagesSafety Data Sheet Permatreat® Pc-191T: Section: 1. Product and Company IdentificationMajd DraidiNo ratings yet

- 9001 2015 Awarness Training CourseDocument2 pages9001 2015 Awarness Training CourseMajd DraidiNo ratings yet

- Project Close Out Final NoticeDocument1 pageProject Close Out Final NoticeMajd DraidiNo ratings yet

- Transmitted LoadDocument17 pagesTransmitted LoadDipak100% (2)

- Suggested Numerical Problems For First ExamDocument3 pagesSuggested Numerical Problems For First Examahmad adnanNo ratings yet

- Ventilador CSPDocument2 pagesVentilador CSPJuan Jose RobalinoNo ratings yet

- PT Samsung Telecommunication IndonesiaDocument2 pagesPT Samsung Telecommunication Indonesiaaldo no1No ratings yet

- Construction Specification 402. Steel Pipe Conduits 1. ScopeDocument5 pagesConstruction Specification 402. Steel Pipe Conduits 1. ScopeHendrys AguileraNo ratings yet

- DF150 175 SetupDocument16 pagesDF150 175 SetupElvin HernándezNo ratings yet

- Lecture 1 - Introduction Steel FamiliarizationDocument15 pagesLecture 1 - Introduction Steel FamiliarizationDubu DubuNo ratings yet

- Iv2906 Iveco Ad380t42h 6x4Document2 pagesIv2906 Iveco Ad380t42h 6x4أبو خالد الأثرىNo ratings yet

- P P B B A: Design of Machinery Robert L. NortonDocument1 pageP P B B A: Design of Machinery Robert L. NortonCARLOS FABIAN MELGAREJO AGUDELONo ratings yet

- Technical Data: 1. DescriptionDocument10 pagesTechnical Data: 1. Descriptionpandi achmadan100% (1)

- Heat Exchange Modeling of A Grate Clinker Cooler and Entropy Production AnalysisDocument9 pagesHeat Exchange Modeling of A Grate Clinker Cooler and Entropy Production AnalysisNhacaNo ratings yet

- Name: - Section: - Schedule: - Class Number: - DateDocument11 pagesName: - Section: - Schedule: - Class Number: - DateSir COCNo ratings yet

- Tarea 8 Bombas Damian A61610 Minor B06661Document7 pagesTarea 8 Bombas Damian A61610 Minor B06661Orlando Porras MoraNo ratings yet

- Finite Element Analysis of Aircraft Wing Using Composite StructureDocument22 pagesFinite Element Analysis of Aircraft Wing Using Composite StructureAumair MalikNo ratings yet

- Dalton's Law Amagat's Law For The Mixture of Real Gases: Whan Woo and Sang Ihn YeoDocument8 pagesDalton's Law Amagat's Law For The Mixture of Real Gases: Whan Woo and Sang Ihn YeoTri SulyonoNo ratings yet

- 5204 Series API Valve OriginalDocument16 pages5204 Series API Valve OriginalPatricio G. ArrienNo ratings yet

- Operation and Maintenance Manual: Diesel EngineDocument10 pagesOperation and Maintenance Manual: Diesel EngineООО "СК "СМП-708"No ratings yet

- Y290 WML 201Document14 pagesY290 WML 201alex generalNo ratings yet

- Multiple Stiffened Cold-Formed Steel Profiles For Cylindrical Vault Roofing SystemsDocument24 pagesMultiple Stiffened Cold-Formed Steel Profiles For Cylindrical Vault Roofing SystemsTiago LopesNo ratings yet

- Your Partner in Materials Handling.: Cat Lift TrucksDocument3 pagesYour Partner in Materials Handling.: Cat Lift Trucksslawny77No ratings yet

- Presentation 1Document73 pagesPresentation 1Rajib DebnathNo ratings yet

- Soil Dynamics Assignment (Bit) : Set by Dr. Tensay Gebremedhin Page 1/2Document2 pagesSoil Dynamics Assignment (Bit) : Set by Dr. Tensay Gebremedhin Page 1/2Bogale SenayNo ratings yet

- TMM070 - MotorDocument2 pagesTMM070 - MotorEvandroNo ratings yet

- S e N I H C A M G N I T S e T L A S R e V I N U C I N o R T C L eDocument4 pagesS e N I H C A M G N I T S e T L A S R e V I N U C I N o R T C L eahana expotech lab abeerNo ratings yet

- Kent Cams Fitting and Timing InstructionsDocument2 pagesKent Cams Fitting and Timing InstructionsPeter QuinnNo ratings yet

- Saes L 100Document13 pagesSaes L 100Honesto Bautista100% (3)

- Tga CatalogueDocument172 pagesTga Cataloguea_salehiNo ratings yet

HR-FR-01 Training Skills Matrix Maintenance Team

HR-FR-01 Training Skills Matrix Maintenance Team

Uploaded by

Majd DraidiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HR-FR-01 Training Skills Matrix Maintenance Team

HR-FR-01 Training Skills Matrix Maintenance Team

Uploaded by

Majd DraidiCopyright:

Available Formats

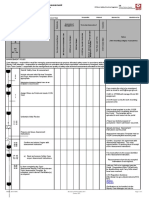

Training Skills Matrix HR-FR-01 Revision 1

Departmant: Maintenance 31-01-22 09-02-21 01-11-22 07-05-22 02-09-22 06-04-22 07-03-23 18-09-21 17-02-2022

Updates By: Electrical Engineer Mechanical Engineer Mechanical Engineer Mechanical Technician Utilities Technician Electrical Technician Electrical Technician Maintenance Storekeeper Maint. Manager

Shabir Ahmad

Training Plan for the Year of 2023 Matthew Reyes Leandro Abu Abu Khurram Riaz Joey Ogavar Jamandron Ferdinand Metrillo Cherlin Jovial Chellathural Melvin Sayson Muhammed Tayyab Shabir Ahmad

Updated

Date: 1809 152 2266 1992 2160 1961 2365 1261 1869

21-12-2023

Legend

1 Not Trained

Current Evaluation

Current Evaluation

Current Evaluation

Current Evaluation

Current Evaluation

Current Evaluation

Current Evaluation

Current Evaluation

Current Evaluation

September

November

December

February

October

January

August

March

2 Trained

April

June

May

July

Description GAP by Topic

3 Can practice with help

Target

Target

Target

Target

Target

Target

Target

Target

Target

4 Can practice Alone

GAP

GAP

GAP

GAP

GAP

GAP

GAP

GAP

GAP

5 Can Train Others

Establishing, implementing, maintaining

ISO 50001:2018 and improving an energy management x 3 5 2 1 5 4 1 5 4 1 3 2 1 3 2 1 4 3 2 4 2 1 2 1 3 5 2 20

system (EnMS)

Identification of energy sources. Lockout

LOTO and tag out procedure for safe work x 1 4 3 1 4 3 1 4 3 1 4 3 1 4 3 1 4 3 1 4 3 1 4 3 1 4 3 24

conditions

To inspect and analyze machine vital signs

Predictive Maintenance Program for machine health and failure prevention x 1 5 4 1 5 4 1 5 4 1 4 3 1 4 3 1 4 3 1 4 3 1 4 3 1 5 4 27

using condition monitoring tools

To understand logic and work with

PLC training x 1 4 3 1 2 1 1 2 1 1 2 1 1 2 1 1 4 3 1 4 3 1 1 0 1 4 3 13

Siemens PLC S7300, S71200 and S7 1500

Skills Matrix

AF compressor 4000Hrs and 8000Hrs

HP Compressor maintenance x 3 4 1 4 4 0 3 4 1 3 4 1 2 4 2 2 4 2 1 4 3 1 4 3 3 4 1 13

Maintenance

Analyze electrical and mechanical part

drawing to find a Krones part number and

Krones E-catalogue x 4 5 1 4 5 1 4 5 1 2 4 2 2 4 2 2 4 2 2 4 2 2 4 2 4 5 1 13

its description for parts searching and

ordering

Labeler Gripper Drum calibration Calibration of Gripper drum of labeler x 4 5 1 4 5 1 5 5 0 4 5 1 4 5 1 4 5 1 4 5 1 1 1 0 4 5 1 6

Filling valve wear parts

Filling valve repair and maintenance x 3 5 2 3 5 2 4 5 1 2 4 2 2 4 2 2 4 2 2 4 2 1 1 0 3 5 2 13

replacement

idnetify the mold having air leak and Stem

Blowmolding blowing nozzle

seal replacement for blow moding nozzle, x 4 5 1 4 5 1 4 5 1 4 5 1 4 5 1 4 5 1 4 5 1 1 1 0 4 5 1 7

stem seal replacement

nozzle distance adjustment

Water treatment double seat Overhauling of double seat valve for water

x 1 5 4 2 5 3 1 5 4 1 5 4 1 5 4 1 5 4 1 5 4 1 1 0 1 5 4 27

valve maintenance treatment

Periodic maintenance of filler ozone sensor

Ozone sensor overhauling x 4 5 1 4 5 1 4 5 1 1 5 4 1 5 4 1 5 4 1 5 4 1 1 0 4 5 1 19

with OEM spare parts kit

Total Gap 29 47 22 25 47 20 25 45 20 20 40 20 19 45 21 19 48 24 19 116 24 11 24 12 25 52 22

You might also like

- Workshop Manual: Sisudiesel 645Document80 pagesWorkshop Manual: Sisudiesel 645Victor Pinedo100% (1)

- Fuller-Kinyon (FK) PumpDocument9 pagesFuller-Kinyon (FK) PumpAli Hüthüt100% (2)

- Unit 3-Fluid MechanicsDocument38 pagesUnit 3-Fluid MechanicsApechRanger92% (66)

- 27-11-2022-DPR KPGFCCI ProjectDocument2 pages27-11-2022-DPR KPGFCCI ProjectBilalNo ratings yet

- Progress Report ProjectDocument2 pagesProgress Report ProjectBilalNo ratings yet

- Project ReportDocument2 pagesProject ReportBilalNo ratings yet

- SCCI. MOB (ADMIN) - March 13,2023-EditedDocument13 pagesSCCI. MOB (ADMIN) - March 13,2023-Editedsimeon james villacrusisNo ratings yet

- 310C22011 RA Refurbishment of Tank T-201 ForDocument9 pages310C22011 RA Refurbishment of Tank T-201 ForVinay Mishra100% (1)

- SCCI. MOB (ADMIN) - March 06,2023Document13 pagesSCCI. MOB (ADMIN) - March 06,2023simeon james villacrusisNo ratings yet

- BDocument215 pagesBapi-26144115100% (1)

- 28-11-2022-DPR KPGFCCI ProjectDocument2 pages28-11-2022-DPR KPGFCCI ProjectBilalNo ratings yet

- 26-11-2022-DPR KPGFCCI ProjectDocument2 pages26-11-2022-DPR KPGFCCI ProjectBilalNo ratings yet

- Framework Diagram - Safety Case Assessment: Inc. Material Changes & Dismantlement SubmissionsDocument3 pagesFramework Diagram - Safety Case Assessment: Inc. Material Changes & Dismantlement SubmissionsasdasdNo ratings yet

- 29-11-2022-DPR KPGFCCI ProjectDocument2 pages29-11-2022-DPR KPGFCCI ProjectBilalNo ratings yet

- 2,016 Units: Shagufta MasoodDocument2 pages2,016 Units: Shagufta MasoodAliNo ratings yet

- SCCI. MOB (ADMIN) - Feb.20,2023Document13 pagesSCCI. MOB (ADMIN) - Feb.20,2023simeon james villacrusisNo ratings yet

- 01-12-2022-DPR KPGFCCI ProjectDocument2 pages01-12-2022-DPR KPGFCCI ProjectBilalNo ratings yet

- 30-11-2022-DPR KPGFCCI ProjectDocument2 pages30-11-2022-DPR KPGFCCI ProjectBilalNo ratings yet

- SCCI. MOB (ADMIN) - Feb.13,2023-EditedDocument13 pagesSCCI. MOB (ADMIN) - Feb.13,2023-Editedsimeon james villacrusisNo ratings yet

- HCIS-SECSAF Status - Updated 04dec23Document3 pagesHCIS-SECSAF Status - Updated 04dec23Siva GuruNo ratings yet

- PM by REDocument5 pagesPM by REAshebirNo ratings yet

- 16 12 2023 DPR KPGF Cci Project.Document2 pages16 12 2023 DPR KPGF Cci Project.rashid khattakNo ratings yet

- Jun-22Document2 pagesJun-22Syed Umar AhmedNo ratings yet

- 112 Units Rs. 849.12: MR - Intizar KhanDocument3 pages112 Units Rs. 849.12: MR - Intizar KhanMuahammad DanishNo ratings yet

- Contractor by Emp. ReprDocument14 pagesContractor by Emp. ReprAshebirNo ratings yet

- 361 Units Rs. 8,162.62: Abdul Majeed - Naseem AkhtarDocument3 pages361 Units Rs. 8,162.62: Abdul Majeed - Naseem Akhtarabdul qadirNo ratings yet

- TMP 07Document6 pagesTMP 07Lê HoànNo ratings yet

- Siddaganga Institute of Technology, Tumakuru - 572 103Document1 pageSiddaganga Institute of Technology, Tumakuru - 572 103Chutiya ChutiyaNo ratings yet

- 15 12 2023 DPR KPGF Cci Project.Document2 pages15 12 2023 DPR KPGF Cci Project.rashid khattakNo ratings yet

- 14 12 2023 DPR KPGF Cci Project.Document2 pages14 12 2023 DPR KPGF Cci Project.rashid khattakNo ratings yet

- LC and Long Load Status (23-03-2023)Document71 pagesLC and Long Load Status (23-03-2023)M. Aamir SaeedNo ratings yet

- 438 Units Rs. 10,240.24: MR Noor Muhammad RehmaniDocument3 pages438 Units Rs. 10,240.24: MR Noor Muhammad RehmaniAliNo ratings yet

- Ref 4 - CRS Taif SDDocument4 pagesRef 4 - CRS Taif SDRahul KumarNo ratings yet

- Aug 21Document2 pagesAug 21AttaNo ratings yet

- For Audit Point 2&8. Organization Chart (Southern Area-VCPIII) Updated May-01-2023Document1 pageFor Audit Point 2&8. Organization Chart (Southern Area-VCPIII) Updated May-01-2023yaseenahmedbaigNo ratings yet

- 310C22011 RA Refurbishment of Tank T-201 For Mechanical Repair Works Rev.00Document9 pages310C22011 RA Refurbishment of Tank T-201 For Mechanical Repair Works Rev.00Vinay MishraNo ratings yet

- Gammon India Ltd. C/o Bhavnagar Energy Company Limited 2X250 MW Lignite Based TPP at Padva, Bhavnagar Daily Progress ReportDocument1 pageGammon India Ltd. C/o Bhavnagar Energy Company Limited 2X250 MW Lignite Based TPP at Padva, Bhavnagar Daily Progress Reportsaravan1891No ratings yet

- Duplicate Bill - Jan-2023 - 0400026720123Document2 pagesDuplicate Bill - Jan-2023 - 0400026720123Farasat SaeedNo ratings yet

- Units: Muhammad ArifDocument2 pagesUnits: Muhammad Arifrizzkhan1978No ratings yet

- 18-12-2023-DPR KPGF CCI Project.Document2 pages18-12-2023-DPR KPGF CCI Project.rashid khattakNo ratings yet

- NCR Status SGRE 31-01-2023 - QCDocument2 pagesNCR Status SGRE 31-01-2023 - QCIndraNo ratings yet

- Cambridge PaperDocument2 pagesCambridge Paperrutherfordatomic365No ratings yet

- Apr-23Document2 pagesApr-23Fahad Bin ImranNo ratings yet

- Empl - Rep by ContractorDocument20 pagesEmpl - Rep by ContractorAshebirNo ratings yet

- 05 Weekly Progress 22-28septDocument8 pages05 Weekly Progress 22-28septpranjal.dhakaNo ratings yet

- Far 1a - Summary of Appropriations, Allotment, Obligations, Disbursments and Balances As of December 31, 2022Document4 pagesFar 1a - Summary of Appropriations, Allotment, Obligations, Disbursments and Balances As of December 31, 2022Whenng LopezNo ratings yet

- 6-14-9 Control ValvesDocument14 pages6-14-9 Control ValvessudokuNo ratings yet

- Yeshwantrao Chavan College of EngineeringDocument6 pagesYeshwantrao Chavan College of EngineeringSheetal BhoyarNo ratings yet

- Eng CD 2374900 A4-3077475Document4 pagesEng CD 2374900 A4-3077475Roger SuzanoNo ratings yet

- FLORES ES eNAT School Report KS1Document15 pagesFLORES ES eNAT School Report KS1noel r. moralNo ratings yet

- 359 Units: MR Mohammad Abdul GhaniDocument2 pages359 Units: MR Mohammad Abdul GhaniTwT DarkerNo ratings yet

- Divn.2, Budget Amount Required For Works & LA-14!01!2022Document4 pagesDivn.2, Budget Amount Required For Works & LA-14!01!2022cekpknr filesNo ratings yet

- Gujarat Housing BoardDocument32 pagesGujarat Housing Board16SA156.RohanShahNo ratings yet

- ICPprivilegesDocument5 pagesICPprivilegesBUREAU VERITASNo ratings yet

- How To Read Utility BillsDocument2 pagesHow To Read Utility BillsSikander QaziNo ratings yet

- 162 Units: Muhammad FarooqDocument2 pages162 Units: Muhammad FarooqMuhammad FarooqNo ratings yet

- 9th CAD Minutes PDFDocument34 pages9th CAD Minutes PDFsnehaNo ratings yet

- Units: Pakistan RangersDocument2 pagesUnits: Pakistan RangersrasheedNo ratings yet

- HIRA-03 Erection and Dismantaling of Temporary StructureDocument8 pagesHIRA-03 Erection and Dismantaling of Temporary StructureMD AbdullahNo ratings yet

- Presentasi RMM 2019 Q2 SIP1 NEW - PPTX (Autosaved)Document150 pagesPresentasi RMM 2019 Q2 SIP1 NEW - PPTX (Autosaved)FERNANDONo ratings yet

- 1,067 Units: Moin UlhaqDocument2 pages1,067 Units: Moin UlhaqAliNo ratings yet

- 379 Units: Habib-Ur-Rehman Siddiqui & OthersDocument2 pages379 Units: Habib-Ur-Rehman Siddiqui & OthersdfNo ratings yet

- National Violations PlatformDocument1 pageNational Violations PlatformMajd DraidiNo ratings yet

- ISO Correlation MatrixDocument7 pagesISO Correlation MatrixMajd Draidi100% (1)

- Safety Data Sheet Permatreat® Pc-191T: Section: 1. Product and Company IdentificationDocument9 pagesSafety Data Sheet Permatreat® Pc-191T: Section: 1. Product and Company IdentificationMajd DraidiNo ratings yet

- 9001 2015 Awarness Training CourseDocument2 pages9001 2015 Awarness Training CourseMajd DraidiNo ratings yet

- Project Close Out Final NoticeDocument1 pageProject Close Out Final NoticeMajd DraidiNo ratings yet

- Transmitted LoadDocument17 pagesTransmitted LoadDipak100% (2)

- Suggested Numerical Problems For First ExamDocument3 pagesSuggested Numerical Problems For First Examahmad adnanNo ratings yet

- Ventilador CSPDocument2 pagesVentilador CSPJuan Jose RobalinoNo ratings yet

- PT Samsung Telecommunication IndonesiaDocument2 pagesPT Samsung Telecommunication Indonesiaaldo no1No ratings yet

- Construction Specification 402. Steel Pipe Conduits 1. ScopeDocument5 pagesConstruction Specification 402. Steel Pipe Conduits 1. ScopeHendrys AguileraNo ratings yet

- DF150 175 SetupDocument16 pagesDF150 175 SetupElvin HernándezNo ratings yet

- Lecture 1 - Introduction Steel FamiliarizationDocument15 pagesLecture 1 - Introduction Steel FamiliarizationDubu DubuNo ratings yet

- Iv2906 Iveco Ad380t42h 6x4Document2 pagesIv2906 Iveco Ad380t42h 6x4أبو خالد الأثرىNo ratings yet

- P P B B A: Design of Machinery Robert L. NortonDocument1 pageP P B B A: Design of Machinery Robert L. NortonCARLOS FABIAN MELGAREJO AGUDELONo ratings yet

- Technical Data: 1. DescriptionDocument10 pagesTechnical Data: 1. Descriptionpandi achmadan100% (1)

- Heat Exchange Modeling of A Grate Clinker Cooler and Entropy Production AnalysisDocument9 pagesHeat Exchange Modeling of A Grate Clinker Cooler and Entropy Production AnalysisNhacaNo ratings yet

- Name: - Section: - Schedule: - Class Number: - DateDocument11 pagesName: - Section: - Schedule: - Class Number: - DateSir COCNo ratings yet

- Tarea 8 Bombas Damian A61610 Minor B06661Document7 pagesTarea 8 Bombas Damian A61610 Minor B06661Orlando Porras MoraNo ratings yet

- Finite Element Analysis of Aircraft Wing Using Composite StructureDocument22 pagesFinite Element Analysis of Aircraft Wing Using Composite StructureAumair MalikNo ratings yet

- Dalton's Law Amagat's Law For The Mixture of Real Gases: Whan Woo and Sang Ihn YeoDocument8 pagesDalton's Law Amagat's Law For The Mixture of Real Gases: Whan Woo and Sang Ihn YeoTri SulyonoNo ratings yet

- 5204 Series API Valve OriginalDocument16 pages5204 Series API Valve OriginalPatricio G. ArrienNo ratings yet

- Operation and Maintenance Manual: Diesel EngineDocument10 pagesOperation and Maintenance Manual: Diesel EngineООО "СК "СМП-708"No ratings yet

- Y290 WML 201Document14 pagesY290 WML 201alex generalNo ratings yet

- Multiple Stiffened Cold-Formed Steel Profiles For Cylindrical Vault Roofing SystemsDocument24 pagesMultiple Stiffened Cold-Formed Steel Profiles For Cylindrical Vault Roofing SystemsTiago LopesNo ratings yet

- Your Partner in Materials Handling.: Cat Lift TrucksDocument3 pagesYour Partner in Materials Handling.: Cat Lift Trucksslawny77No ratings yet

- Presentation 1Document73 pagesPresentation 1Rajib DebnathNo ratings yet

- Soil Dynamics Assignment (Bit) : Set by Dr. Tensay Gebremedhin Page 1/2Document2 pagesSoil Dynamics Assignment (Bit) : Set by Dr. Tensay Gebremedhin Page 1/2Bogale SenayNo ratings yet

- TMM070 - MotorDocument2 pagesTMM070 - MotorEvandroNo ratings yet

- S e N I H C A M G N I T S e T L A S R e V I N U C I N o R T C L eDocument4 pagesS e N I H C A M G N I T S e T L A S R e V I N U C I N o R T C L eahana expotech lab abeerNo ratings yet

- Kent Cams Fitting and Timing InstructionsDocument2 pagesKent Cams Fitting and Timing InstructionsPeter QuinnNo ratings yet

- Saes L 100Document13 pagesSaes L 100Honesto Bautista100% (3)

- Tga CatalogueDocument172 pagesTga Cataloguea_salehiNo ratings yet