Professional Documents

Culture Documents

Conceptual Design of Bicycle Frame

Conceptual Design of Bicycle Frame

Uploaded by

Muhammad AzmiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Conceptual Design of Bicycle Frame

Conceptual Design of Bicycle Frame

Uploaded by

Muhammad AzmiCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/309300723

Conceptual Design of Bicycle Frame

Article in International Journal of Engineering Trends and Technology · August 2016

DOI: 10.14445/22315381/IJETT-V38P213

CITATION READS

1 4,755

2 authors:

Munukurthi naga venkata Krishna Veni Amareswari Reddy

Anil Neerukonda Institute of Technology and Sciences Andhra University

2 PUBLICATIONS 1 CITATION 3 PUBLICATIONS 13 CITATIONS

SEE PROFILE SEE PROFILE

All content following this page was uploaded by Amareswari Reddy on 01 October 2020.

The user has requested enhancement of the downloaded file.

International Journal of Engineering Trends and Technology (IJETT) – Volume 38 Number 2- August 2016

Conceptual Design of Bicycle Frame

M. N. V .Krishna Veni1, M.Amareswari Reddy2

Assistant Professors, Department of Mechanical Engineering

ANITS College of Engineering, Sangivalasa, Bheemili Mandal, Visakhapatnam, Andhra Pradesh

Abstract Design is important stage in with pedals on an enlarged front wheel

manufacturing. It is because any product produced (the velocipede). Several inventions followed using

must be through design stage where in design stage rear-wheel drive, the best known being the rod-

consists of conceptual design, concept selection; driven velocipede by Scotsman Thomas McCall in

identify customer need, concept selection, analysis 1869.These bicycles were difficult to ride due to

and others. In design, it should be consider many their high seat and poor weight distribution.

factors such as product design must be satisfied by Staley’s 1885 Rover, manufactured in

customer, material used the ability product to work Coventry, England, is usually described as the

and others. All part in design is to fulfil customer first recognizably modern bicycle. Soon, the seat

need. Beside that design will have an effect to tube was added, creating the double-

Company such as profit, loss and reputation of the triangle diamond frame of the modern bike.

company. In this paper We have modelled a

diamond frame of bicycle by using SOLID WORKS

and performed finite element analysis on it by using

ANSYS 14.5.

A conceptual design of bicycle is proposed for

reducing the effort kept by cycler while he rides on

an inclined plane. The project idea is Fig 1 Tandem and Sociable bicycle

implementation of four bar mechanism in bicycle.

Keywords— Bicycle, Solidworks, ANSYS14.5

I. INTRODUCTION

A bicycle, often called a bike is a human-

powered, pedal-driven, single-track vehicle, having

two wheels attached to a frame, one behind the other.

Bicycles were introduced in the 19th .

century in Europe and now number more than a Fig 2 Terminology of bicycle frame

billion worldwide, twice as many as automobiles.

They are the principal means of transportation in

many regions. They also provide a popular form of II. PROJECT IDEA

recreation, and have been adapted for such uses as

children's toys, general fitness, military and police

applications, courier services and bicycle racing.

The basic shape and configuration of a

typical upright, or safety bicycle, has changed little

since the first chain-driven model was developed

around 1885. However, many details have been

improved, especially since the advent of modern

materials and computer-aided design. These have There may exist many types of bicycle frames based

allowed for a proliferation of specialized designs for on its usage and also based on the kind of people use

diverse types of cycling. like men or women. The geometry of the bicycle

The dandy horse, also called Draisienne or frame, its shape and size varying continuously

laufmaschine, was the first human means of according to the satisfaction of the user. Many

transport to use only two wheels in tandem and was design modifications have been made on the bicycle

invented by the German Baron Karl von Drays. Its frame by the designers to optimize its design

rider sat astride a wooden frame supported by two parameters.

in-line wheels and pushed the vehicle along with Our study on the bicycle frame is to reduce the

his/her feet while steering the front wheel. effort of the person while he will be riding on an

In the early 1860s, Frenchmen Pierre inclined road. While he is riding on a straight

Michaud and Pierre Aliment took bicycle design in a horizontal road, the inertia of the person and the

new direction by adding a mechanical crank drive cycle will affect the driving force of the person. The

ISSN: 2231-5381 http://www.ijettjournal.org Page 64

International Journal of Engineering Trends and Technology (IJETT) – Volume 38 Number 2- August 2016

more the inertia of the person and the cycle, the

more the effort or driving force applied by the cycler.

Hence the driving force of the cycler depends on the

inertia and is proportional to it when he is riding on

a straight horizontal road.

A situation arises when the cycle is driven on the

inclined plane or road. What all forces will resist the

cause of motion?

The answer is along with the friction resistance,

inertia of the person and cycle, there exists a weight

component which acts parallel to plane of inclination

and in the direction opposite to that of movement of

the cycle. The weight component along the plane of Fig 3 Sectional Views of Bicycle Frame

inclination is taken at the combined Centre of mass

of the cycler and the bicycle.

The weight component along the plane of

inclination actually creates a moment about the axis

of the two wheels. The moment caused due to

weight component is in the direction opposite to the

direction of the driving moment caused by driving

force. Therefore the moment is a resistance moment.

The resistance moment will cause an additional Fig 4 Model of diamond type of bicycle frame

effort or driving force to maintain the constant speed 2. ANALYSIS OF MODELLED

while driving on the inclined plane. DIAMOND BICYCLE FRAME

Our concentration is on the reduction of this extra

effort by the cycler while driving on the inclined 2.1 MATERIALPROPERTIESAPPLIED

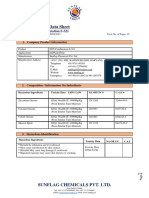

plane. Table 1 Aluminium alloy properties

For that to happen the resistance moment caused

by the weight component should be reduced. Aluminum Alloy > Isotropic Elasticity

Moment is the product of force and perpendicular Young's

distance of the force from the point of rotation. As Temperature Poisson's Bulk Shear

Modulus

the weight of the cycler and the weight of the bicycle C Ratio Modulus Pa Modulus Pa

Pa

remain constant, there is only one criterion to reduce

7.1e+010 0.33 6.9608e+010 2.6692e+010

the moment. It is the perpendicular distance of the

force from the point of rotation.

Young's

The cycle wheel axis cannot be changed because Temperature Poisson's Bulk Shear

Modulus

the radius of the wheel remains constant. The point C Ratio Modulus Pa Modulus Pa

Pa

from which the weight component arises should be

varied. The point from which the weight component 7.1e+010 0.33 6.9608e+010 2.6692e+010

arises is the combined Centre of mass of the cycler Aluminum Alloy > Constants

and the bicycle. Density 2770 kg m^-3

Displacement of the Centre of mass is Aluminum Alloy > Compressive Ultimate

compulsory. Strength

To displace the Centre of mass of a frame, a Compressive Ultimate Strength Pa

mechanism is required to displace the parts of the 0

frame so that the frame reaches to a minimum Aluminum Alloy > Compressive Yield Strength

Centre of mass from the ground reference. We have

Compressive Yield Strength Pa

chosen a four bar mechanism to fulfil this objective.

One of the inversions of four bar mechanism is 2.8e+008

double rocker mechanism. Implementing this Aluminum Alloy > Tensile Yield Strength

mechanism in the bicycle frame, our objective can Tensile Yield Strength Pa

be reached. 2.8e+008

Aluminum Alloy > Tensile Ultimate Strength

III. DIAMOND TYPE BICYCLE FRAME Tensile Ultimate Strength Pa

MODELING AND ANALYSIS 3.1e+008

1. MODELING OF DIAMOND TYPE

OF BICYCLE FRAME 2.2 LOADING CONDITIONS

2.2.1 PEDALLING

Sitting ,push on right pedal

ISSN: 2231-5381 http://www.ijettjournal.org Page 65

International Journal of Engineering Trends and Technology (IJETT) – Volume 38 Number 2- August 2016

Sitting, push on left pedal

Standing, push on right pedal

Standing, push on left pedal

2.2.2 ADDITIONAL CONDITIONS

Surface irregularity

Braking

2.3 ANALYSIS OF FRAME IN SITTING Fig 9 Total deformation

POSITION

Table2 Sitting position analysis

Directional Equivalent

Equivalent Total

Type Deformation Elastic

Stress Deformation

Strain

-1.4111e-

Minimum 0. Pa 0. m 0. m/m

005 m

6.6843e+006 3.6678e-005 9.9004e-006 9.4469e-

Maximum

Pa m m 005 m/m

Fig 5 Analysis of frame in sitting position

SITTING POSITION 2.4 ANALYSIS OF FRAME IN

STANDING POSITION

Fig 10 Analysis of frame in standing position

Fig 6 Directional Deformation

STANDING

Fig11 Directional deformation

Fig 7 Equivalent strain

Fig12 Equivalent strain

Fig 8 Equivalent stress

ISSN: 2231-5381 http://www.ijettjournal.org Page 66

International Journal of Engineering Trends and Technology (IJETT) – Volume 38 Number 2- August 2016

BRAKING

Fig16 Directional deformation

Fig13 Equivalent stress

Fig17 Equivalent strain

Fig14 Total deformation

Table 3 Standing position analysis

Directional Equivalent

Equivalent Total

Type Deformation Elastic

Stress Deformation

Strain

-1.2873e-

Minimum 0. Pa 0. m 0. m/m

005 m

1.6168e+007 3.5249e-005 3.319e-005 2.9461e-

Maximum

Pa m m 004 m/m

Fig18 Equivalent stress

2.5 ANALYSIS OF FRAME IN BRAKING

POSITION

Fig19 Total deformation

Fig15 Braking position

Table 4 Braking analysis

Directional Equivalent

Equivalent Total

Type Deformation Elastic

Stress Deformation

Strain

-7.7252e-

Minimum 0. Pa 0. m 0. m/m

006 m

3.7669e+006 2.1042e-005 3.1037e-006 5.4695e-

Maximum

Pa m m 005 m/m

ISSN: 2231-5381 http://www.ijettjournal.org Page 67

International Journal of Engineering Trends and Technology (IJETT) – Volume 38 Number 2- August 2016

2.6 ANALYSIS OF FRAME WITH SURFACE

IRREGULARITIES

Fig24 Equivalent stress

Fig20 Surface irregularities

Table 5 Surface irregularity

SURFACEIRREGULARITIES

Directional Equivalent

Equivalent Total

Type Deformation Elastic

Stress Deformation

Strain

-8.0995e-

Minimum 0. Pa 0. m 0. m/m

005 m

3.3168e+007 1.8612e-004 1.9878e-005 4.8407e-

Maximum

Pa m m 004 m/m

Fig21 Directional deformation

IV. CONCEPTUAL DESIGN OF BICYCLE

FRAME

Reducing the effort by reducing the combined

Centre of mass of the cycler and bicycle can be

achieved by implementing a four bar mechanism

in the bicycle. Proposing the idea of

implementation of four bar mechanism in the

bicycle in order to reduce the effort is our main

intention.

The modelling of each part was carried out in

Solid works then assembled and analysis of this

was done using ANSYS as shown in below

Fig22 Equivalent strain figure.

Fig23 total deformation

Fig25 Conceptual design of bicycle frame

ISSN: 2231-5381 http://www.ijettjournal.org Page 68

International Journal of Engineering Trends and Technology (IJETT) – Volume 38 Number 2- August 2016

V. RESULTS

1. MASS PROPERTIES OF CYCLE

FRAME IN FIRST POSITION

Fig26 Mass properties of bicycle frame in first

position

3. RESULTS OF DISPLACED CENTER

OF MASS FROM FIRST POSITION TO

SECOND POSITION

vertical displacement of seat post= 1.36 cm

(downwards)

vertical displacement of center of mass of

the frame=1.41 cm (upwards)

Our objective is to displace the Centre of mass

of the frame vertically downwards, but the results

are showing that the displacement of Centre of mass

of the frame of 1.41 cm in vertically upward

direction. The upward movement of Centre of mass

of the frame is due to angular movement of front

handle bar in upward direction.

The displacement of seat post in vertically

downward direction by the value of 1.36 cm is

assumed as the displacement of Centre of mass of

2. MASS PROPERTIES OF CYCLE the person in vertically downward direction by the

FRAME IN SECOND POSITION value of 1.36 cm.

Centre of mass of a two mass system distributed

at known distances can be given by formula:

X = (M1 X1 + M2 X2)

(M1 + M2)

Y = (M1 Y1 + M2 Y2)

(M1 + M2)

The above formula indicates that Centre of mass

depends on the magnitude of mass of each body and

the distribution of mass from the reference

Fig27 Mass properties of bicycle frame coordinates

in second position Taking the above sentence into consideration,

the above results can be explained as: The main

objective is to lower the combined Centre of mass of

bicycle and the cycler. The fact is that the mass of

cycler is more than that of the mass of the bicycle.

Though there is uplift in the value of Centre of

mass of the bicycle frame, the multiplication factor

ISSN: 2231-5381 http://www.ijettjournal.org Page 69

International Journal of Engineering Trends and Technology (IJETT) – Volume 38 Number 2- August 2016

of Centre of mass of the bicycle frame in the formula

of Centre of mass i.e. the mass of bicycle frame is

small.

Though the value of increase in the Centre of

mass of bicycle (1.41 cm) is more than decrease in

the Centre of mass of cycler (1.36 cm), the

multiplication factor of Centre of mass of cycler i.e.

the mass of the cycler is very large.

Sum of larger the mass magnitude of the cycler

multiplied with small decrease in the Centre of mass

of the cycler and smaller the mass magnitude of the

bicycle multiplied with small increase in the Centre

of mass of the bicycle results in decrease in the

combined Centre of mass of the cycler and the

bicycle.

VI. CONCLUSIONS

Design is the very important stage in

manufacturing. It is because any product produced

must be through design stage where in design stage

consists of conceptual design, concept selection;

identify customer need, concept selection, analysis

and others.

Modelling of the existing diamond frame,

assuming load conditions, performing analysis on

the modelled diamond frame and presentation of

results have been done. The results show a proper

and safe design of diamond frame.

Reducing the effort by reducing the combined

Centre of mass of the cycler and bicycle can be

achieved by implementing a four bar mechanism in

the bicycle. Proposing the idea of implementation of

four bar mechanism in the bicycle in order to reduce

the effort is our main intention.

The results that we have got are not up to the

reach. The increased Centre of mass of the bicycle is

restricting the objective of the project. Redesigning

of the present idea with appropriate link lengths may

give an optimise result.

VII. REFERENCES

[1] Mr.M.V.Pazare, Prof.S.D.Khamankar “Stress Analysis of

Bicycle Frame”, International Journal of Engineering Science and

Technology (IJEST).

[2] Derek Covill, Steven Begg, Eddy Elton, Mark Milne, Richard

Morris, Tim Katz “Parametric finite element analysis of bicycle

frame geometries”, The 2014 conference of the International

Sports Engineering Association, Procedia Engineering 72 ( 2014 )

441 – 446.

[3] Forrest Dwyer, Adrian Shaw, Richard Tombarelli presented

the thesis on “Material and Design Optimization for an

Aluminium Bike Frame”.

[4] D. S. De Lorenzo, M. L. Hull “Quantification of Structural

Loading During Off-Road Cycling”, Thomas Jin-Chee Liu,

Huang-Chieh Wu,” Fiber direction and stacking sequence design

for bicycle frame made of Carbon epoxy composite laminate”,

Materials and Design 31 (2010) 1971–1980

[5] Fabian Fuerle , Johann Sienz “Decomposed surrogate based

optimization of carbon-fibre bicycle frames using Optimum Latin

Hyper cubes for constrained design spaces”.

ISSN: 2231-5381 http://www.ijettjournal.org Page 70

View publication stats

You might also like

- Grease Making PDFDocument56 pagesGrease Making PDFElmar Asgerzade100% (2)

- JIS ChlorideDocument2 pagesJIS ChlorideAndhikaAgraWisesaNo ratings yet

- Conceptual Designof Bicycle FrameDocument8 pagesConceptual Designof Bicycle FrameCedricNo ratings yet

- RVD Ijates DesignanalysisfabricationofshaftdrivenbicycleDocument11 pagesRVD Ijates DesignanalysisfabricationofshaftdrivenbicycleTertsegha IpilakyaaNo ratings yet

- Bicycle Crank AnalysisDocument7 pagesBicycle Crank AnalysisrisirarocksNo ratings yet

- Vibrational Analysis of Bicycle ChassisDocument13 pagesVibrational Analysis of Bicycle ChassisIJIRSTNo ratings yet

- 128301-Design and Fabrication of Elipticle BicycleDocument8 pages128301-Design and Fabrication of Elipticle BicycleSACHIN DESHPANDENo ratings yet

- Irjet V11i4327Document5 pagesIrjet V11i4327Vineet MudliarNo ratings yet

- Presentation On Car Design With SpoilerDocument25 pagesPresentation On Car Design With SpoilerPrashant KumarNo ratings yet

- Design and Analysis of Elliptical Bicycle Frame: Ajith Arul Daniel S, Manikandan AR, Vijay Ananth. S, Parthiban ADocument6 pagesDesign and Analysis of Elliptical Bicycle Frame: Ajith Arul Daniel S, Manikandan AR, Vijay Ananth. S, Parthiban ANaveen KumarNo ratings yet

- Passion Performers - DR1Document14 pagesPassion Performers - DR1Lavanya PNo ratings yet

- Design & Fabrication of Shaft Drive Bicycle: Project Members: Abishek PDocument18 pagesDesign & Fabrication of Shaft Drive Bicycle: Project Members: Abishek Pameer kannanNo ratings yet

- Design and Fabrication of Off-Road Electric Bike For Single OccupantDocument14 pagesDesign and Fabrication of Off-Road Electric Bike For Single Occupantshivam kumarNo ratings yet

- CPP 2Document21 pagesCPP 2Sumit deoreNo ratings yet

- Chainless CycleDocument53 pagesChainless CycleKritisundar Garnayak89% (9)

- Fabrication of Shaft Driven BicycleDocument6 pagesFabrication of Shaft Driven BicycleMANTECH PublicationsNo ratings yet

- Design and Optimization of Bicycle Frame For The Cyclist's ComfortDocument5 pagesDesign and Optimization of Bicycle Frame For The Cyclist's ComfortEditor IJRITCCNo ratings yet

- Treadmill Bicycle Using Solar and Manual PoweredDocument41 pagesTreadmill Bicycle Using Solar and Manual PoweredKushal MalikNo ratings yet

- Static and Fatigue Simulation of Telescopic Fork Suspension System Used For MotorcycleDocument5 pagesStatic and Fatigue Simulation of Telescopic Fork Suspension System Used For MotorcycleRasbin SharmaNo ratings yet

- Mee 512Document31 pagesMee 512Gabriel UdokangNo ratings yet

- Fabrication of A Bicycle Without A ChainDocument6 pagesFabrication of A Bicycle Without A ChainFranklin Delano JuniorNo ratings yet

- Fin Irjmets1669908514Document8 pagesFin Irjmets1669908514nicusor1995No ratings yet

- Static Analysis of Wheel Rim Using Catia and Ansys16.0: August 2016Document7 pagesStatic Analysis of Wheel Rim Using Catia and Ansys16.0: August 2016Immanuel ANo ratings yet

- Design, Analysis & Fabrication of Shaft Driven Bicycle: Dandage R.V. Patil A.A., Kamble P.NDocument10 pagesDesign, Analysis & Fabrication of Shaft Driven Bicycle: Dandage R.V. Patil A.A., Kamble P.Nsrihariharan dhandapaniNo ratings yet

- Topology Optimization of Motorcycle SwinDocument5 pagesTopology Optimization of Motorcycle SwinBhawesh SthaNo ratings yet

- 1 5024108Document7 pages1 5024108GamerNo ratings yet

- Design and Fabrication of Shaft Driven Electric BicycleDocument5 pagesDesign and Fabrication of Shaft Driven Electric BicycleInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Chainless BicycleDocument66 pagesChainless BicycleRaghu Ram100% (1)

- International Journal of Advance Engineering and Research DevelopmentDocument3 pagesInternational Journal of Advance Engineering and Research DevelopmentSam Khaushal100% (1)

- Jawaharlal Nehru Technological University: Material, Design & Analysis of A Bicycle FrameDocument28 pagesJawaharlal Nehru Technological University: Material, Design & Analysis of A Bicycle FrameRisira Erantha KannangaraNo ratings yet

- Modified Suspension of Motorcycle - A ReviewDocument4 pagesModified Suspension of Motorcycle - A ReviewMULYADINo ratings yet

- Design of Walking Bike: Suhasinee Ravindra Deshmukh, Namita Vishnu Sanap, Rahul Eknath DhobleDocument9 pagesDesign of Walking Bike: Suhasinee Ravindra Deshmukh, Namita Vishnu Sanap, Rahul Eknath Dhoblechinmay bhattNo ratings yet

- JETIR2009041Document7 pagesJETIR2009041Glorius CarmenNo ratings yet

- Design of Racing Motorcycle Swingarm With Shape OptimisationDocument6 pagesDesign of Racing Motorcycle Swingarm With Shape OptimisationChi ZhangNo ratings yet

- Design and Analysis of Electric Bike With Seat Expansion Capability-A Design ReportDocument7 pagesDesign and Analysis of Electric Bike With Seat Expansion Capability-A Design ReportrakeshjhaNo ratings yet

- B0801010816Document9 pagesB0801010816Deepak SNo ratings yet

- Design of Head Light Moving Mechanism With SteeringDocument7 pagesDesign of Head Light Moving Mechanism With SteeringPraveen MathiasNo ratings yet

- Static Analysis of Wheel Rim Using Catia and Ansys16.0: August 2016Document7 pagesStatic Analysis of Wheel Rim Using Catia and Ansys16.0: August 2016Anonymous 9xvU1FNo ratings yet

- Design and Fabrication of Shaft Driven BicycleDocument46 pagesDesign and Fabrication of Shaft Driven BicycleNishanth Krishnan80% (10)

- Future ChainlessDocument13 pagesFuture ChainlessKendujhar fun KFNo ratings yet

- Dynamic Chainless BicycleDocument6 pagesDynamic Chainless BicycleVenkata RamuduNo ratings yet

- Vibration AnalysisDocument4 pagesVibration AnalysisJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Dynamic Analysis of The Crank Shaft UsinDocument14 pagesDynamic Analysis of The Crank Shaft UsinAVINASHNo ratings yet

- Design and Analysis of Two Wheeler Shock Absorber Coil SpringDocument8 pagesDesign and Analysis of Two Wheeler Shock Absorber Coil SpringVivek VikuNo ratings yet

- Modeling and Static Analysis of Shock Absorber Using Different MaterialsDocument8 pagesModeling and Static Analysis of Shock Absorber Using Different MaterialsManjunath ReddyNo ratings yet

- A Review On Various Self Balanacing MethodsDocument4 pagesA Review On Various Self Balanacing MethodsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Simulator & Emulations of Solar Bike: Resented by Waris Ali Khan Asfand Yar KhanDocument13 pagesSimulator & Emulations of Solar Bike: Resented by Waris Ali Khan Asfand Yar KhanWARIS KHANNo ratings yet

- Design and Fabrication of Solar Powered Treadmill Bi-CylceDocument6 pagesDesign and Fabrication of Solar Powered Treadmill Bi-CylceBunnyNo ratings yet

- Design Optimization of Bicycle Crank Using (FEA)Document6 pagesDesign Optimization of Bicycle Crank Using (FEA)abhishek dmaleNo ratings yet

- Treadmill ProjectDocument12 pagesTreadmill Projectsivaenotes75% (4)

- (Remf-45) Design and Fabrication of Shaft Driven Bicycle (Abstract)Document3 pages(Remf-45) Design and Fabrication of Shaft Driven Bicycle (Abstract)retechNo ratings yet

- Irjet V5i968Document5 pagesIrjet V5i968April RojoNo ratings yet

- Study On Design and Analysis of In-Wheel Suspension SystemDocument9 pagesStudy On Design and Analysis of In-Wheel Suspension SystemIJRASETPublicationsNo ratings yet

- Design and Analysis of Push Rod Rocker Arm Suspension Using Mono SpringDocument12 pagesDesign and Analysis of Push Rod Rocker Arm Suspension Using Mono SpringAmanNo ratings yet

- MD1 18Document6 pagesMD1 18Rushikesh KopnarNo ratings yet

- Fabrication of Cross Trainer With BicycleDocument7 pagesFabrication of Cross Trainer With BicycleIJRASETPublicationsNo ratings yet

- A Review On Modeling and Analysis of Car Wheel Rim Using CATIA & ANSYS PDFDocument5 pagesA Review On Modeling and Analysis of Car Wheel Rim Using CATIA & ANSYS PDFHafiz M TahirNo ratings yet

- Solar Tredmil BicycleDocument19 pagesSolar Tredmil BicycleIshwarjit SinghNo ratings yet

- Design and Fabrication of Portable Electric Bike: Rahul.H 3GN16ME075Document30 pagesDesign and Fabrication of Portable Electric Bike: Rahul.H 3GN16ME075Rahul KullkarniNo ratings yet

- Whelhub DesignDocument10 pagesWhelhub DesignamoyaNo ratings yet

- 2 - Cement Raw MaterialsDocument32 pages2 - Cement Raw MaterialsDubistWhiteNo ratings yet

- Cross Reference of Steel StandardsDocument4 pagesCross Reference of Steel StandardsNugroho Adhi SaputroNo ratings yet

- Electrode E70TGDocument1 pageElectrode E70TGkapsarcNo ratings yet

- 8008 1 PDFDocument6 pages8008 1 PDFraji357No ratings yet

- RT Interpretation ReferenceDocument25 pagesRT Interpretation ReferenceRichard MitchellNo ratings yet

- Design Deliverable Documents ListDocument2 pagesDesign Deliverable Documents ListLai HuynhNo ratings yet

- The Use of Silica-Breccia As A Supplementary Cementing MaterialDocument8 pagesThe Use of Silica-Breccia As A Supplementary Cementing MaterialTarek ChikerNo ratings yet

- Boiler ManualDocument22 pagesBoiler Manualengrasadullah000No ratings yet

- Chemplasa Ebs L-205F-TdsDocument1 pageChemplasa Ebs L-205F-TdsÁnh Nguyễn100% (1)

- VW 54045 enDocument17 pagesVW 54045 enmarco.hang00No ratings yet

- Design, Manufacture and Test A Hydraulic Ram: ThesisDocument42 pagesDesign, Manufacture and Test A Hydraulic Ram: ThesisIrfan ShaikhNo ratings yet

- Physics Past PaperDocument22 pagesPhysics Past PaperkenisyaNo ratings yet

- Microstructure and Mechanical Characteristics of CDA-B C Hybrid Metal Matrix CompositesDocument15 pagesMicrostructure and Mechanical Characteristics of CDA-B C Hybrid Metal Matrix Compositestamil selvanNo ratings yet

- Shear Box TestDocument7 pagesShear Box Testcedric iradukundaNo ratings yet

- MSDS SUN Combi. S-321Document5 pagesMSDS SUN Combi. S-321kunalNo ratings yet

- MUL ACS880 01 R1 R3 QIG H ScreenDocument104 pagesMUL ACS880 01 R1 R3 QIG H ScreenMarcoNo ratings yet

- A Report On Technical Seminar Presented On: Pre-Stressed ConcreteDocument24 pagesA Report On Technical Seminar Presented On: Pre-Stressed ConcreteSMART AVINo ratings yet

- Coal Chapter 3Document24 pagesCoal Chapter 3Ihwan Limanto100% (1)

- Smith6e Chapter28 TB AnswerKeyDocument24 pagesSmith6e Chapter28 TB AnswerKeyandrew.gregory978No ratings yet

- ESET0911Joshua and Lawal PDFDocument6 pagesESET0911Joshua and Lawal PDFVictor OmotoriogunNo ratings yet

- Characterization of Textile Wastewater A Reviewd - AsdDocument15 pagesCharacterization of Textile Wastewater A Reviewd - Asdlidik23489No ratings yet

- Tai Lieu SV AV2Document54 pagesTai Lieu SV AV2nguyenthanhtruc01060209No ratings yet

- Earths Water ResourcesDocument21 pagesEarths Water ResourcesAvrylle MacatangayNo ratings yet

- DAF Introduction 20231106Document26 pagesDAF Introduction 20231106Sunny OoiNo ratings yet

- What Is Rogers Tmm6 PCBDocument13 pagesWhat Is Rogers Tmm6 PCBjackNo ratings yet

- RTR Bearing PDFDocument52 pagesRTR Bearing PDFkamelNo ratings yet

- Fundamentals of Ultrasonic Imaging and Flaw Detection - NI-Tutorial-3368-EnDocument5 pagesFundamentals of Ultrasonic Imaging and Flaw Detection - NI-Tutorial-3368-Enafsajghfd1No ratings yet

- Mabini Colleges, Inc. High School Department Daet, Camarines NorteDocument39 pagesMabini Colleges, Inc. High School Department Daet, Camarines NorteNancy QuiozonNo ratings yet